It's not a secret for anyone that on the territory of our vast country there are areas where it is absolutely impossible to move normally on the roads due to their poor quality. In this case, comes to the rescue special machine, which is characterized by high traffic. It's about an all-terrain vehicle. But, unfortunately, it is practically unrealistic to acquire such a means of transportation that would be light, economical and inexpensive. Therefore, many craftsmen with engineering and technical skills decide to create a caterpillar all-terrain vehicle with their own hands, taking into account their needs and capabilities.

How can tracked ATVs be used?

Such homemade devices on crawler tracks come in different sizes and are used for a variety of purposes. With their help, heavy loads are moved, which are placed either in a body or in a special trailer. If a self-made caterpillar all-terrain vehicle is used for summer cottages, then in this case, various building materials are most often transported.

In addition, such a vehicle has transport versatility, and if any unforeseen circumstances arise, you can quickly, without any difficulties, get to a certain destination over rough terrain.

What to look for when creating a homemade all-terrain vehicle?

If you decide to make a caterpillar all-terrain vehicle with your own hands, then you must clearly understand for what purpose it will be used. Be sure to consider the following points:

- Weather conditions during operation.

- Dimensions. Width affects the cross-country ability of a caterpillar all-terrain vehicle, made by hand, the length is calculated from the number seats or device availability luggage compartment, and the height should be optimal when creating the amphibious properties of the unit.

- Motor power. How more powerful engine, the easier it is to overcome hard-to-reach sections of the road.

- Target. Depending on the purpose for which the mobile device is intended, its design can be modified.

- Number of wheels. Most often homemade tracked all-terrain vehicle Made by hand, it has wheels from two to eight pairs, which are necessary to support the track.

Drawing creation

The most crucial stage is making a sketch of a tracked all-terrain vehicle. Do-it-yourself drawings with the arrangement of the mechanisms of the unit and its components are drawn after that. They must be very accurate. When creating such a vehicle, they usually use both home-made parts and ready-made elements of factory production. They are drawn separately, with the calculation of the compatibility and performance of parts and assemblies.

Design features

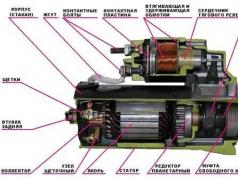

A caterpillar all-terrain vehicle, created by one's own hands, must have an engine. Basically, this element is taken from cars, most often domestic ones. You can also borrow it from a motorcycle. The chassis is presented rubber tracks, tensioning system, suspension, rollers. Car tires are often used to make tracks. The base of the undercarriage consists of a tub, frame or any other metal frame. For the control system, various components are taken or ready-made controls for motorcycles or cars, as well as tractors, are used. A homemade tracked all-terrain vehicle, made by hand, has a power system, which is presented fuel tank, gasoline or diesel. Gas equipment is used much less often.

Manufacturing technology

Do-it-yourself light tracked all-terrain vehicles are made according to a certain technology. Their creation begins with the construction of the body, which must have high strength and complete water resistance. The foundation homemade transport must be rigid, so steel pipes are taken that can withstand any physical stress arising from movement. Then they begin to make caterpillars. To do this, take an ordinary rubber sheet and create a ring rubber. Small aluminum blades are placed on its outer side with rivets, and with inside install the necessary limiters, the step width of which is equal to the width of the rubber of the wheels.

The next stage is that the bridges are removed from the car through the holes that were specially made in the body for this. Rubber couplings are used as protection. Attach the rubber band so that the wheels are right in the center of the stops. In addition, additional wheels are also fixed. They are necessary to keep the track taut. At the end of the work, heavy-duty glass is inserted in the cockpit of the all-terrain vehicle, made by hand.

Output

Thus, this means of transportation is an irreplaceable means of transport in hard-to-reach areas, where there are practically no roads. Possessing engineering and technical qualities, you can easily create tracked all-terrain vehicles with your own hands, the drawings of which will help to correctly design such a unit.

On the basis of a walk-behind tractor, home-made all-terrain vehicles and other high-traffic vehicles are often made. There are several reasons for this:

- there is an energy-rich transport unit with high traction characteristics, assembled on a frame;

- engine and transmission control moved to comfortable grips;

- the mass of motoblocks is low, they can be transported to the desired place in the trunk, body or on a car trailer.

For hunting and fishing, a light mini all-terrain vehicle is quite in demand. But the industry has not yet seen commercial prospects in creating sets of attachments that convert a serial walk-behind tractor into a cross-country vehicle. There are some pretty interesting examples of the creation of such machines. DIYers have created role models with their own hands. There is room for ideas when developing new interesting devices.

Features of all-terrain vehicles from a walk-behind tractor

The main units that should be purchased or made independently for a vehicle based on a walk-behind tractor:

- frame, it serves to organize a mobile vehicle;

- the rear axle is needed to install the rear wheels;

- a seat for the driver, it is desirable to protect it from moisture and dirt from under the wheels;

- a lighting system is needed to move safely at any time of the day.

An all-terrain vehicle based on a walk-behind tractor is created as a single-seat vehicle. Its carrying capacity should be about 200 kg. The width is calculated from the conditions of resistance to overturning, usually it is from 1100 mm or more.

Modern walk-behind tractors Neva, Ugra, MTZ and others are equipped with engines with a capacity of more than 10 hp. This power is enough to move at a speed of over 10 km / h. Off-road, when passing through slurry or swampy places, the speed can drop to 1-2 km / h.

How to make a homemade wheeled all-terrain vehicle

An example of a drawing of an all-terrain vehicle on tires low pressure

It makes sense to equip the base unit. The reason is that the best torque figures are gasoline and diesel engines have at a frequency of rotation crankshaft about 75-85% of the maximum.

The engine must have a forced cooling system. When driving at low speed, the incoming flow will not be enough to maintain an optimal thermal regime.

ATV frame

An example of a drawing of a fracture frame

A frame is created between the front and rear axles. It is better to use rectangular shaped pipes or square... They provide greater rigidity than rolled corners, channels and I-beams of the same mass.

The joining of the frame elements of a wheeled all-terrain vehicle can be rigid, then it will be formed in a one-volume format. Using heavy motoblocks"Neva" or MTZ, this option will be preferable.

As an option, a breaking frame (fracture) is made, the option is used for areas with a complex profile. Here, the articulation is performed through the king pin. Front and rear axles have independent suspension from each other. Masters create such all-terrain vehicles on the basis of the "Neva" and "Ugra" motoblocks.

For hunting and fishing, it is better to have a wheeled all-terrain vehicle with a breakable frame. Its flotation is higher than with a rigid frame design.

Rear axle and suspension of a homemade all-terrain vehicle

Some DIYers use a ready-made rear axle from a car to simplify the design. For example, from the car "Moskvich-412": its low weight allows installation on a light all-terrain vehicle. Suspension is made on shock absorbers for a smooth ride and reduced vibration.

Other craftsmen make an independent suspension for each rear wheel... This approach is implemented on the "Ant" scooter. When driving, a slight swaying is felt, at the same time, the wheels experience less resistance on bumps, and fuel consumption is noticeably reduced.

Connect the rear axle to the frame with long hardened bolts. For elastic joints, rubber inserts are used, for example, silent blocks. This improves performance characteristics all-terrain vehicle based on a walk-behind tractor.

Rear axle skiing is applied in winter time... Movement resistance is minimal, and the design is greatly simplified.

Wheels (low pressure chambers)

You can use lugs to move on wet and wobbly ground. They provide high grip. Large diameter low pressure chambers behave even better. Pneumatics have minimal ground pressure, and the presence of air trapped in the chambers of the all-terrain vehicle will create a floating all-terrain vehicle.

For installation on the rear axle, self-made or special wheels for all-terrain vehicles, swamp vehicles and snowmobiles are used. They are purchased as an assembly or as separate elements: a tire, a camera, a disk. Assembling the wheel is simple.

It is possible to increase the permeability of conventional wheels on low-pressure chambers by creating an additional protector. For example, you can additionally secure the cameras with chains, conveyor belts, homemade tracks or in another way.

Another option is to cut an overhead lug out of the tire. The depth of the hook of the structure reaches more than 20-25 mm. The rolling resistance is increased, while the slip coefficient is sharply reduced.

Assembling a homemade all-terrain vehicle from a walk-behind tractor

When all the tools, spare parts and accessories are prepared, you can start assembling. This is a rough plan for how to assemble a homemade all-terrain vehicle, it all depends on the chosen design.

- A walk-behind tractor is installed on a welded or finished frame.

- The rear axle and, if necessary, the front axle are mounted.

- The seat is placed on the frame.

- If provided by the drawing and diagram, the steering is installed.

- Protection is attached to the frame; it is made of plastic or metal sheet.

- The prospective driver should test the comfort of landing, if necessary, provide auxiliary devices for adjusting the fit.

- The performance of the brakes is checked.

- Electrical circuits and lighting fixtures are being installed.

As individual elements and assemblies are manufactured, their performance is checked. A five-fold safety factor is provided here.

After the completion of the bench tests, the field tests are started. You need to know how the car behaves in difficult conditions.

Buy a hitch and trailed to a walk-behind tractor in online stores

Homemade tracked all-terrain vehicles with your own hands

The use of tracks will help to reduce the specific ground pressure. The weight is distributed over the entire track area. Such an all-terrain vehicle based on a walk-behind tractor is able to overcome sand, wetlands, steep climbs and other obstacles.

Some do-it-yourselfers make metal track links from plates more than 5 mm thick. Rings from water pipes are welded to the plates. Another version of the track links is made entirely of PVC pipes, cut lengthwise. The tracks are attached to each other on a conveyor belt or other base.

It is easier to make tracks from composite materials. For this, fiberglass and epoxy are used. Glass-polymer reinforcement is used as a frame. Track links are made in special shapes. After making the required amount, they are collected into a caterpillar. In the manufacture of tracks from composite materials, articulation elements made of wear-resistant steels are used.

There are options for using timber tracks. They will need to be impregnated with protective mixtures.

The easiest way to make a track for an all-terrain vehicle based on a walk-behind tractor is to use a conveyor belt. One track requires two lanes. They are connected in a ring, and then a caterpillar is created using pieces of steel pipe.

In the video, you can see the option of making a waterproof case that is kept afloat. In this case, the tracked propeller will allow you to move not only on the ground, but also on the water. The result is an amphibious all-terrain vehicle. For hunting and fishing, it will be irreplaceable.

Ivan Sardaev, a 67-year-old resident of the city of Topki, began inventing and creating various vehicles almost 20 years ago.

In 1993, together with his wife, daughter and son, he returned from Vorkuta to the city of his childhood and built a house in four months. It turned out to be large, spacious, with an area of 150 squares.

Well, about four years after we moved and settled down, I got tired of cleaning the snow after a blizzard in the winter: you work with a shovel, your hands get tired. Like it or not, you involuntarily start to think with your head, - the pensioner laughs.

Snow removal equipment by Ivan Sardaev.

In the beginning there were scooters

Ivan Vasilievich admits: he was fascinated by technology since childhood. Even as a child, he assembled scooters either with bearings or with wheels from a baby carriage. But it was back in 1997 that the tricycle snowblower became his first full-fledged invention. She was unusual - she had two wheels in front, and one - steerable - behind. As the inventor now recalls, the car was weak - it could only rake snow on the paths. He decided to improve it and assembled a model a little more complicated, then another. And then he got so involved in the process that he began to create already snow blowers with buckets and auger machines. And not only them.The very first snow blower of Topkinets was a three-wheeled one.

In 2007, in the magazine "Modelist-Constructor" Ivan Sardaev even published an article about three of his models, and two years later - about security system... He invented it and installed it in his house, if necessary, she sends him a signal to his mobile phone.

Several bucket snow blowers, a pair of auger-rotor machines and a pair of pneumatic snowmobiles - this is an incomplete list of mobile equipment that Ivan Vasilyevich collected until 2013. And all this in his free time from work - despite his age, he still fixes TVs for people. And four years ago, his son gave him a computer, and when the pensioner mastered the Internet, new ideas appeared. One of the last was the idea to make an all-terrain vehicle on a caterpillar track with your own hands.

And the roof is from "Moskvich"

He began to embody the idea in 2015, and it took Ivan Sardaev a year and a half to create an unusual machine. Most of the details in the S-10 all-terrain vehicle, the inventor gave this name to his brainchild - from "Zhiguli" different model... The rear axle, the engine and the gearbox are from the "classics", the rollers in the tracks are from the eleventh VAZ model. Many parts were collected from neighbors who, by the way, admire the master's golden hands, or were picked up at auto-parsing and metal collection points. The roof of the all-terrain vehicle is from "Moskvich", but the caterpillars had to be thought over and assembled completely to the last detail. For them, the inventor even had to buy a conveyor belt from a store.A pneumatic snowmobile is another machine collected by hand TV master from Topki.

In total, Ivan Vasilyevich spent more than 30 thousand rubles on certain purchases for his brainchild.

Most of all I had to tinker with the caterpillars, - the pensioner admits. - It was a very painstaking work that required special care. After all, there is something wrong, you will miss a little and everything, either the teeth will cling, or the tape will slide out, and in both cases the car will not run.

This is how the all-terrain vehicle looked in the summer of 2016.

Currently, the Topkinets are testing their all-terrain vehicle. By flat road it can move at a speed of 35-40 kilometers per hour, and on virgin snow the speed decreases by about half. By the way, instead of a steering wheel, it has two control levers, like a tractor, and the driver and passenger - a two-seater all-terrain vehicle - is always warm, the interior is heated by two stoves.

Until further the yard and the street where his house is located, Ivan Sardaev does not drive his invention. But in the future, after the car passes tests at other times of the year, he hopes to register it, as it should be. But the creator does not want to sell it, even for 350 thousand rubles, which was appreciated by such a technique on one of the sites. You need such an all-terrain vehicle yourself.

C-10 tracked all-terrain vehicle of a Kuzbass pensioner. Ivan Sardaev worked on the all-terrain vehicle for a year and a half. The VAZ-2103 engine, the cabin is the top of the Moskvich-2140 cabin.

What can be done from a UAZ with your own hands. SUV drawings do it yourself

| Section categories | |||||||

|

(from the section Homemade ATVs)

Diagrams and drawings of wheeled, tracked and airmobile homemade products, which will be useful in self-design and construction. Description of various designs of equipment for off-road use, as well as individual nodes and assemblies of a homemade all-terrain vehicle. Layout diagrams and dimensions various all-terrain vehicles (on wheels, low-pressure tires, skis, snowmobiles, airboats and hovercraft "all-terrain vehicles"), built by their own hands.

| Total materials (diagrams / pictures / drawings) in the category Drawings and diagrams of self-made all-terrain vehicles: 14 On this page, only a part of them. To see all the rest, use the "leaflet" at the bottom of the page. To go to the section, click on the photo, to view the material - More. | |

| We also hope that a lot of interesting things for you will be found on the links below: you can choose the category that is most interesting for you in the column on the left, or find the answer to your question in the articles from the menu at the top right >>> Enjoy your viewing! | |

Video drawings of all-terrain vehiclesUnusual display method for diagrams and drawings. Watching the video - online [Add ATV Photo] |

|

vezdehod.poprostomu.com

Do-it-yourself side-turning all-terrain vehicle: drawings, production photos

The craftsman built with his own hands a wheeled all-terrain vehicle for fishing and hunting trips on forest roads and swamps. The design feature of the all-terrain vehicle is the presence of automatic tire inflation and side turning.

We suggest that you familiarize yourself in more detail with the device of an all-terrain vehicle on low-pressure tires.

The frame is made of a 76 mm diameter tube with a wall thickness of 3.5 mm.

For transmission, I purchased such 16V-1 circuits.

We also needed gearboxes from the 5B-C walk-behind tractor.

The figure shows a sketch of the hub.

- from the engine to the gearbox 1-1.45,

- reduced 1 to 24,

- increased 1 to 11,

- back 1 to 17.

On the gearbox, the drive sprocket has 9 teeth and goes to the driven one by 35 teeth.

Dimensions of the gearbox itself.

Drawings of hubs, in addition holes for tire inflation will be made.

Hub axle drawings. Steel 45 was used. The diagrams do not indicate the channel for air perpendicular to the axis, the size was also increased from 28 to 45 mm, there was a decrease between the bearings.

The Lifan engine is installed.

The swap implementation scheme looks like this.

The exhaust system is welded.

The figure shows a diagram of the exhaust direction.

A boat bulb is used to inflate tires, so nipples were made for it.

Fastening the driven stars on the hubs.

In total, six similar parts were welded to the hub, and the dimensions were changed upward, that is, instead of 8, 10 were made:

The swap was performed in this way:

To combat tire rotation, the width of the disks was cut to 40 cm, teeth were also welded from the electrodes, and then the tires were seated using construction sealant. The author also began work on the tires themselves, eliminating punctures and cuts with the help of an awl and sealant flashing.

During the opening of the hunting season, the all-terrain vehicle was used a lot. There were some breakdowns, in particular, there was an overheating of the engine, opening the chain lock and breaking the nipple of the camera due to the rotation of the tire. But pumping with exhaust helped to get to the place of repair. All wheels were pumped up to 0.1 atmospheres.

As a result, about 10 liters of fuel were consumed for 42 kilometers of the way, which is quite a bit for an all-terrain vehicle.

Tire inflation is used quite often, especially in the off-season, when the temperature drops from +20 to -15 degrees, which greatly affects the pressure in the tires.

A single boat is also transported in the trunk, which is also very convenient to pump up with exhaust.

The video shows a homemade all-terrain vehicle in action.

Popular homemade products from this category

avto-samodelki.ru

2QM.ru: Do-it-yourself dumps for UAZ (drawings)

An SUV on the farm of the owner of a suburban area, taking into account the quality of the roads, is an excellent help, and sometimes even a necessity. Under the hood of such a unit there are almost a hundred, and sometimes even more working "horses", which, together with the impressive mass and running characteristics, becomes a serious argument in the fight against off-road conditions.

Why not use this power to improve traffic situation in local adjoining territory v winter period? Manufacturers have long been concerned with suitable attachments, releasing a snow plow for UAZ and other SUV models popular in our country. Why not save money and make your own blade model, given that artisanal options are no worse, and sometimes even better than factory ones?

Factory option

You should not reinvent the wheel again, it is much easier to see how to make a blade on a UAZ from manufacturers. Most likely, it will not work to completely copy the factory suspension blades, but it is quite possible to take some models as a basis. In addition, a detailed study of proven options will allow you to avoid many mistakes when designing and manufacturing your own snow shovel.

Design

Much depends on the availability of materials and technical skills. It is safer and easier to make a blade without a rotary mechanism, thus saving a little on materials and significantly reducing the production time, however, this will reduce the scope of its application. On the other hand, the swivel mechanism can become the most vulnerable point of the structure; its implementation requires a certain margin of safety on the fixation nodes. The working surface of the blade also requires reinforcement, it is important to monitor the weight of individual parts. It is desirable that the blade can be assembled and disassembled by one person.

To protect the surface to be cleaned, a rubber strip should be used, the fastening of which should be detachable so that the rubber can be replaced as it wears out. At the point where the blade is attached to the vehicle, it is worth considering a possible sharp collision of the blade with an obstacle. The attachment points should not be in front of important parts of the vehicle.

Material selection

At this stage, the choice always remains with the performer, you can only advise or suggest where it is easiest to find suitable parts. Two-hundred-liter barrels have proven themselves well as material for a moldboard shovel, but given the planned dimensions, 2 barrels or additional structural reinforcement will be required. Pipes of square or rectangular cross-section can be used as guiding and reinforcing ribs, it is also possible to use a rolling angle, a thin channel or I-beams.

For adjusting the angle of inclination of the blade of the jumpers, you can use lanyards or pipes of different diameters with holes for fixing pins. When using a winch to control the lift of the blade, additional material will be required to equip the platform for the winch itself and the block system, if necessary.

Homemade dumps on UAZ on the network

On the network, you can find many examples where artisanal craftsmen demonstrate the assembled blade on a UAZ with their own hands. The drawings of talented craftsmen are very diverse, some offer simplified options, others use various modifications, sometimes made more successful than factory products.

The main stages and nodes

Where to start work in order to embody the conceived dump on the UAZ with your own hands? Drawings should be made taking into account the SUV model, and there should always be some margin in size so that possible shortcomings can be leveled on the spot. The first step is to equip the place where the structure is attached to the car. It can be either simple fixed brackets or a whole platform like a "kenguryatnik" to accommodate not only a blade, but also a winch with a block system. The platform can be made both in a permanent design and as a removable structure, which is preferable, since it does not spoil appearance car.

Next, you can start making the most massive part of the blade - a working shovel. It is best to choose the dimensions from the above, 2 x 0.6-0.8 m. A too large blade cleans snow better, but will be inconvenient during installation and transportation. At the next stage, it is better to fix the blade in a working vertical position and so attach the rest of the elements to it. It must be remembered that even simple dumps on a UAZ without a swivel mechanism must be vertically movable, otherwise the car can be severely damaged during operation. The last step is to make control and rotary elements and attach them to the structure.

Lifting mechanisms

You can see options where a manual drum winch is used as a lifting mechanism, and it is operated by a person located on the front platform. It is not very safe, it would be better to raise and lower such dumps on the UAZ after the vehicle has come to a complete stop.

Usage electric winches much more convenient and safer, but not everyone is ready to spend money on such equipment. The most budget option there will be a special stand that is triggered when backward auto, and to constantly hold the blade in the upper position in transport mode, you can use a lanyard.

Conclusion

The case of the master is afraid, they say. A do-it-yourself blade for UAZ, or factory-assembled, will help to use your SUV not only as a means of transportation, but also as a faithful assistant in the household.

2qm.ru

Homemade SUV

Many of us, at least once in our life, have been puzzled by the idea of making a car. Himself. Someone in childhood tried to build a car from cardboard, someone devoted all their free time to this, turning the construction of cars with their own hands not even into a hobby, but into the meaning of life.

Here it is necessary to delimit the concepts a little. For some, building a car means welding a couple of channels for half a liter, attaching an engine from a Zaporozhets, wheels from a seeder and a bridge from a scrapped ZIL - a kind of under-tractor that almost any village can boast of. Such "car lashers", as a rule, have a real "animal" appetite and do not live long. For others, building a car takes several months, sometimes years, painstaking work with a scientific approach, calculations and careful manufacture of every detail.

In particular, making an SUV with your own hands requires doubly efforts. Of course, if you want to get not only a bunch of iron that looks like a car from afar, but quite efficient car, overcoming off-road, with moderate fuel consumption and a decent exterior.

The project below is actually implemented, operating and created on the basis of a conventional passenger car. When creating an SUV, you need to understand a few clear rules, the observance of which will be the key to the success of the whole event.

First, remember - the car must be frame. We will not delve into the issues of the types of frames - flat and spatial, just remember - if a car has a frame, then it will be able to withstand serious loads, live a long time and it will be easier for it to overcome off-road conditions.

Frame this car consists of two longitudinal spars, located with some convergence, as well as three cross beams.

The spars have a rather complex section. They are based on two welded water pipes 032 mm, to which a box of two L-shaped bent steel sheets is also welded from above. The spar section height ranges from 120 mm in the central part of the frame to 80 mm at the ends.

The square crossbeams are welded from 2mm thick steel sheet, and the front beam also serves as a reservoir for oil, therefore it has a drain and a filler hole with plugs. In addition to cross members, two diaphragms bent from steel sheet (front 2 mm thick, rear - 1.6 mm) give additional rigidity to the frame.

Not very easy, right? The drawing will facilitate the perception of "the whole picture". The frame of this design is quite reliable.

The engine was taken from a VAZ-2101 car along with a gearbox. Air and oil filters slightly redone. Of course, the "three-point" motor will be somewhat better, and if you want to add power, you can install the motor from the "Niva" too, but that's another story.

Transmission and chassis used from the GAZ-69 with the use of separate parts from the UAZ-469. This car also uses a homemade gimbal - between the gearbox and the transfer case. Cardan half-coupling and crosspiece - from GAZ-69.

Further - the springs. You can, of course, use springs from the UAZ, but in this case, the car will turn out to be too tough. The rear leaf springs of the GAZ-24 "Volga" car are recommended for use, but in this case the course will be somewhat harsh. To improve the softness of the stroke, homemade earrings were used - 20 mm longer than on the Volga - this size is not a panacea, it was obtained experimentally. So it has the right to life and independent selection - so you can achieve the desired softness. Also, shock absorbers from GAZ-24 are installed on the car. The springs are installed parallel to the frame side members, that is, at an angle to the machine axis.

Body. In the manufacture of the body of the SUV, sheet steel of 1.0-1.2 mm was used. It is recommended to assemble the body from small, up to 1 m long, panels and connect them using spot welding. This makes the body parts easier to handle and shape.

The body can be made of fiberglass by gluing. In any case, the authors of the project used material that was easier for them to work with.

Bodywork it was decided to start with the doors. This decision can also be put at the forefront. Those who already have some experience in auto design know that making doors is one of the most difficult operations. Therefore, it is not surprising that many DIYers tend to use ready-made doors from serial cars. But the overall design of the project often suffers from this. With serial doors, it is difficult to achieve individuality in the exterior.

An electromagnetic plate was used for bending work.

For the doors, sheet steel with a thickness of 1.4 mm was used, the rest of the body was assembled from panels with a thickness of 1.2 mm; except for the front fenders, which have gone millimeter steel.

A few words about safety. Since the SUV was being built, safety elements were introduced into the design. windshield a water pipe is welded along the perimeter, which, together with the front frame of the frame, performs the functions of a safety arc (in the event of a rollover of the machine).

Hinges and door locks are homemade, but you can use ready-made - from "Zhiguli". Handles and glass lifting mechanism - from "Moskvich-2140".

The cockpit glass was used from the VAZ-2121 "Niva". To install them around the perimeter of the window, a corner of steel 1.2-2mm thick was welded under the rubber seal.

The hood is assembled from steel panels, surrounded by a frame made of a thin-walled tube with a diameter of 16 mm. The hood tilts forward on homemade horseshoe hinges.

Steering moved from the GAZ-69, but the angle of the steering column had to be slightly reduced. Brake system used from GAZ-24. The headlights are installed from the Chezeta motorcycle (any similar in size will do, you can turn on your imagination here).

The rear lights are from Moskvich-2140, sidelights and direction indicators are homemade. Instrument cluster from GAZ-24, but the top panel of our own production is made of polystyrene, pasted over with fabric.

The gas tank is completely homemade. It consists of an 80-liter capacity welded from sheet steel, mounted on a frame between two rear cross-beams.

The awning frame is welded from water pipes with a diameter of 25 mm. There are four thinner cross members under the roof, three of which are removable. Plexiglass is glued into the awning windows. The method of attaching the plexiglass to the tarpaulin turned out to be very effective, so it can be recommended to all lovers of auto construction. A pocket is sewn to the canvas around the perimeter of the window, glass is inserted into it and the edges are impregnated with dichloroethane (or acetone) as shown in the figure. The tarpaulin is laid on a flat surface (for example, plywood), covered with plastic wrap and loaded - best with sand.

The front seats of the car are from the GAZ-24 car with minor modifications. The back ones are homemade.

Ready-made homemade jeep has a rather belligerent appearance and, as shown by tests - excellent cross-country ability. On tests, the car showed better cross-country ability than the factory "Niva".

In the pickup version, the maximum carrying capacity of the machine is 800 kg. A jeep on A-92 or A-95 gasoline has a consumption of about 10 liters per 100 mm of run. Experimentally, the engine was redesigned for 76 gasoline - fuel consumption increased slightly.

www.4x4info.ru

What can be done from a UAZ with your own hands

(Homemade SUVs)

For those who are interested in home-made, UAZ, all-terrain vehicle, homemade product:

This miracle of homemade technology was built in Dnepropetrovsk. The idea to create a car for outdoor activities was born to Alexander Novoseltsev quite a long time ago. And when an inexpensive UAZ fell into his hands, he served as an excellent donor for manufacturing.

Since, according to the idea, this car was supposed to be a two-seater coupe with increased cross-country ability, it was necessary to completely abandon the use of the huge body of the UAZ. As a result, only the frame and significantly modernized elements of the suspension, brakes and steering system remained from the donor car. Much has been borrowed from the UAZ - PATRIOT. The rather slow-speed native engine was replaced by a more responsive ZMZ-405 (16-valve). Was installed air filter with zero resistance, chip tuning of the control unit was made, the exhaust system was redesigned. As a result of these alterations, 170 hp were obtained. and 7000 revolutions on the shaft.

A snorkel was installed to overcome the fords.

Technical data of UAZ-CRAB:

engine - ZMZ-405 power - 155 (passport) - 170 (after chip tuning) exhaust - homemade direct-flow drive on both sides - full gasoline- AI-95 consumption - 15-17 l / 100 km weight - 1600 kg max speed - 160 km / h max ford depth - 1.2 m tires - 305/75/16 built in 2006

Provided that the gearbox and razdatka remained familiar, with "short" gears (4-speed synchronized) - the acceleration dynamics turned out to be not all-terrain at all ..! The maximum speed is 160 km / h, then it's scary! A gas tank with a volume of 75 liters. shifted to the rear for weight distribution, under the trunk, tudzhe put the spare tire. The first sketches of the body were applied through tracing paper to the pictures of the frame and assemblies, they fought for a long time in Photoshop, but they modeled more with their hands from cardboard and foam. For example, the hood in the throes of creativity was remade 3 times in metal! The roof and doorways were taken from Honda CR-X... All other body parts and plumage were made independently from sheet iron, putty and painted. The whole construction process took place in a regular garage and took 1.5 years. Even in the process of construction, the name CRAB was attached to the car because of the widely spaced front wheels (305/75/16) optics and the bright red color of the body.

The idea paid off. The car, created for outdoor activities, successfully takes part in rally-raids, off-road competitions, auto-exhibitions and just rides. For 3 years of operation, two checkpoints were destroyed, one razdatka, front axle and broke the frame. The good news is that spare parts are available in the corners and villages. And all this is incomparable with the amount of adrenaline that is released upon contact with this growling gland. There are plans to "breed" CRABs, but already on more serious sites, for example, from "PAGERO".

The CRAB was registered as UAZ-469 with a converted body.

***** To see the photos of UAZ - CRAB (there are many photos), click on the pictures:

You may also be interested to see the following materials:

Read more articles in the category: Homemade ATVs and SUVs. All-terrain vehicles built by the skillful hands of DIYersOr go to the section: ATVs and tractors with your own hands

autosam.expert-club.com

manufacturing features, drawings :: SYL.ru

It's not a secret for anyone that on the territory of our vast country there are areas where it is absolutely impossible to move normally on the roads due to their poor quality. In this case, a special vehicle comes to the rescue, which is characterized by high cross-country ability. It's about an all-terrain vehicle. But, unfortunately, it is practically unrealistic to acquire such a means of transportation that would be light, economical and inexpensive. Therefore, many craftsmen with engineering and technical skills decide to create a caterpillar all-terrain vehicle with their own hands, taking into account their needs and capabilities.

How can tracked ATVs be used?

These homemade crawler devices come in a variety of sizes and are used for a variety of purposes. With their help, heavy loads are moved, which are placed either in a body or in a special trailer. If a self-made caterpillar all-terrain vehicle is used for summer cottages, then in this case, various building materials are most often transported.

In addition, such a vehicle has transport versatility, and if any unforeseen circumstances arise, you can quickly, without any difficulties, get to a certain destination over rough terrain.

What to look for when creating a homemade all-terrain vehicle?

If you decide to make a caterpillar all-terrain vehicle with your own hands, then you must clearly understand for what purpose it will be used. Be sure to consider the following points:

- Weather conditions during operation.

- Dimensions. The width affects the cross-country ability of a caterpillar all-terrain vehicle, made by hand, the length is calculated from the number of seats or the presence of a luggage compartment device, and the height should be optimal when creating the amphibious properties of the unit.

- Motor power. The more powerful the engine, the easier it is to navigate hard-to-reach sections of the road.

- Target. Depending on the purpose for which the mobile device is intended, its design can be modified.

- Number of wheels. Most often, a home-made tracked all-terrain vehicle, made by hand, has wheels from two to eight pairs, which are necessary to support the track.

Drawing creation

The most crucial stage is making a sketch of a tracked all-terrain vehicle. Do-it-yourself drawings with the arrangement of the mechanisms of the unit and its components are drawn after that. They must be very accurate. When creating such a vehicle, they usually use both home-made parts and ready-made elements of factory production. They are drawn separately, with the calculation of the compatibility and performance of parts and assemblies.

Design features

A caterpillar all-terrain vehicle, created by one's own hands, must have an engine. Basically, this element is taken from cars, most often domestic ones. You can also borrow it from a motorcycle. The undercarriage is represented by rubber tracks, tensioning system, suspension, rollers. Car tires are often used to make tracks. The base of the undercarriage consists of a tub, frame or any other metal frame. For the control system, various components are taken or ready-made controls for motorcycles or cars, as well as tractors, are used. A homemade tracked all-terrain vehicle, made by hand, has a power system, which is represented by a fuel tank, gasoline or diesel. Gas equipment is used much less often.

Manufacturing technology

Do-it-yourself light tracked all-terrain vehicles are made according to a certain technology. Their creation begins with the construction of the body, which must have high strength and complete water resistance. The basis of homemade transport must be rigid, so steel pipes are taken that can withstand any physical stress arising from movement. Then they begin to make caterpillars. To do this, take an ordinary rubber sheet and create a ring rubber. Small aluminum blades are placed on its outer side with the help of rivets, and the necessary limiters are installed on the inner side, the step width of which is equal to the width of the rubber of the wheels.

The next stage is that the bridges are removed from the car through the holes that were specially made in the body for this. Rubber couplings are used as protection. Attach the rubber band so that the wheels are right in the center of the stops. In addition, additional wheels are also fixed. They are necessary to keep the track taut. At the end of the work, heavy-duty glass is inserted in the cockpit of the all-terrain vehicle, made by hand.

Output

Thus, this means of transportation is an irreplaceable means of transport in hard-to-reach areas, where there are practically no roads. Possessing engineering and technical qualities, you can easily create tracked all-terrain vehicles with your own hands, the drawings of which will help to correctly design such a unit.

www.syl.ru

Jeep all-terrain vehicle with your own hands, homemade all-terrain vehicles - For a car enthusiast - For a master - Let's do it ourselves

Incredibly, you can make a real Jeep all-terrain vehicle out of an ordinary car. Don't believe me? Read the article and see for yourself! The car frame consists of two longitudinal side members, located with some toe, and three cross beams.The spars have a rather complex section. They are based on two welded water pipes 032 mm, to which a box of two L-shaped bent steel sheets is also welded from above. The spar section height ranges from 120 mm in the central part of the frame to 80 mm at the ends. The square crossbeams are welded from 2mm thick steel sheet, and the front beam also serves as a reservoir for oil, therefore it has a drain and a filler hole with plugs. In addition to cross members, two diaphragms bent from steel sheet (front 2 mm thick, rear - 1.6 mm) give additional rigidity to the frame.

The engine was borrowed from the VAZ-2101 car along with the gearbox (although on N. Yakovlev's car, the latter was taken from the VAZ-2103 - perhaps this is the only significant difference in jeeps). The air and oil filters have been slightly redesigned.

The transmission and chassis are used from the GAZ-69 with the use of separate parts from the UAZ-46E. One cardan - between the gearbox and transfer case- homemade. True, the cardan half-coupling and the crosspiece in it are serial, from the GAZ-69.

As springs of both axles, the rear leaf springs of the GAZ-24 Volga were used, however, to improve the softness of the ride, homemade earrings were used - 20 mm longer than on the Volga (the size was obtained experimentally). Shock absorbers are also from GAZ-24. The springs are installed parallel to the frame side members, that is, at an angle to the machine axis. However, this did not in the least worsen their work.

The body is made of steel sheet 1.0-1.2 mm thick. Moreover, the whole of it consists of relatively small (no more than 1 m long) panels, interconnected by a spot welded.

At first we tried to use fiberglass, but nothing worked. Then they opted for metal, - recalls Nikolai Yakovlev. However, this is quite understandable: Nikolai works as a welder, and, of course, he is familiar with this technology. This should be borne in mind by every self-made product: it is very important to find "your" material.

We started to make the body with ... doors! - adds Vladimir Kapusto. Maybe someone will find it unexpected. However, those who already have some experience in auto design know that making doors is one of the most difficult operations. It is not surprising that many do-it-yourselfers tend to use ready-made doors from serial cars. Unfortunately, such solutions sometimes run counter to the requirements of the overall design of the structure.

The most common operation in the construction of a kuzoz is bending. It is not very convenient to perform it in a vice, so Yakovlev and Kapusto equipped their garage with an electromagnetic stove: this significantly increased labor productivity.

For the doors, sheet steel with a thickness of 1.4 mm was used, the rest of the body was assembled from panels with a thickness of 1.2 mm; except for the front fenders, which have gone millimeter steel. The drift was used very limitedly: mainly when adjusting the windshield. The panels were joined using spot welding, for which a simple device, shown in the figure, was made from ordinary pliers.

Behind the windshield, a water pipe is welded along the perimeter, which, together with the front pillar of the frame, performs the functions of a safety arc when the car rolls over.

The hinges and door locks are homemade, although it would be advisable to use ready-made ones - say, from Zhiguli. Wailing handles and lifting mechanism - from "Moskvich-2140".

The cockpit windows were borrowed from the VAZ-2121 "Niva" car. To install them, the designers found a simple and effective solution: a corner of steel 1.2-2mm thick was welded along the perimeter of the window under a rubber seal. It would be much more difficult to knock out the flange.

The bumpers were prepared by rolling from steel sheet 1.6 mm thick, for which it was necessary to specially grind two shaped rollers and build an elementary rolling machine.

The hood is made of steel panels, surrounded by a frame made of a thin-walled tube Ø 16 mm. A thin foam pad is provided in front of the windshield, behind which the windshield wipers are removed. The hood tilts forward on homemade horseshoe hinges. The latter are hinged to the U-shaped frame, which is at the same time a radiator stand.

The tailgate of the car also has a thin tube frame; outside it is covered with steel sheet 1.2 mm thick, and inside - hardboard.

The steering is taken from the GAZ-69, however, due to the peculiarities of the layout, the angle of inclination of the steering column had to be slightly reduced. The brake system is from the GAZ-24. Headlights - motorcycle, from "Chezet". Initially, all four headlights were located strictly horizontally, the car, as they say, did not look good. Then the inner pair was raised by 10 mm - and everything fell into place. The front of the car has taken on a completely finished look.

Rear lights from "Moskvich-2140", sidelights and direction indicators are homemade. The instrument panel is from GAZ-24, but the top panel of our own production is made of polystyrene, pasted over with cloth.

The gas tank of the car is originally made. It consists of an 80-liter capacity welded from sheet steel, mounted on a frame between two rear cross-beams.

The awning frame is welded from water pipes Ø 25 mm. There are four thinner cross members under the roof, three of which are removable. Plexiglass is glued into the awning windows. The method of attaching the plexiglass to the tarpaulin turned out to be very effective, so it can be recommended to all lovers of auto construction. A pocket is sewn to the canvas around the perimeter of the window, glass is inserted into it and the edges are impregnated with dichloroethane (or acetone) as shown in the figure. The tarpaulin is laid on a flat surface (for example, plywood), covered with plastic wrap and loaded - best with sand.

The front seats of the car from the car GAZ-24 "Volga" are slightly altered. The rear ones are self-made, it is planned to modify them so that when the car is converted into a pickup, they turn into the rear wall of the cab.

In conclusion, briefly about the operating data. Perhaps the main advantage of the jeep is its excellent cross-country ability. Last winter, during one of their fishing trips, Nikolai and Vladimir were caught in a heavy snowfall, and whole drifts of snow grew on top of the ice. But homemade cars this obstacle turned out to be overwhelming, while the "Niva" located nearby had to wait for help.

In the pickup version, the maximum carrying capacity (when rear springs become horizontal) of the machine is 800 kg. V. Kapusto's car runs on AI-93 gasoline, and its fuel consumption is about 10 liters per 100 mm of run. In N. Yakovlev's jeep, the engine was redesigned for A-76 gasoline; fuel consumption is somewhat higher.

Try it, dare, and the jeep-all-terrain vehicle will be yours!

Pan-As site, homemade site - the site has everything that you can do with your own hands: handicrafts, homemade products, jewelry, children's handicrafts. Do them yourself, do it yourself and get real pleasure from it.

Related materials:

www.pan-as.ru

Since then, when from the pen of Gogol came out the phrase about the state Russian roads, the problem has not become less urgent. As before, in some of the God-forsaken corners of the country, people generally forgot to dream of asphalt pavement. The only way out is to change to ATVs. Alas, the models offered by car factories are not able to satisfy the needs of motorists from the provinces. The common people need a small-sized, economical, and, of course, cheap vehicle increased cross-country ability. Only in a home workshop from scrap materials can such a dream come true.

Materials and components for the all-terrain vehicle on tracks

It would be fair to warn in advance that power units removed from cars are the reason increased consumption fuel. But in comparison with motorcycle engines, they have a noticeable power reserve. The production of tracks also entails additional costs.

The body of a homemade all-terrain vehicle is best constructed from aluminum or duralumin sheet. It will be necessary to purchase triplex glass, liquid rubber (you can replace silicone grease). The main material for the tracks will be a sheet (or strip) of rubber. One pair of bridges borrowed from Soviet cars - "Zaporozhets" or "Zhiguli".

Can be distinguished important points, which should be considered in the process of creating an all-terrain vehicle on tracks.

For a homemade body, there are requirements such as strength, tightness and streamlining by the oncoming air flow while driving. In terms of geometry, the best solution would be a flat-bottomed boat body.

In view of the fact that you will have to travel (more precisely - "caterpillar") swampy areas or even overcome shallow bodies of water, the body should contain a minimum of seams. In other words, instead of welding, a solid sheet must be bent, giving the desired shape. The metal sheet is used for the manufacture of not only the cab, but also all the compartments, including the one that is intended for the engine. To exclude the harmful effect of water with a moisture-proof material (for example, rubber), they reliably cover the joints and fasteners of the nodes. Particular care should be taken to protect the battery and wiring as much as possible from moisture. It is better if special mines are allocated for them.

The rigidity of the structure of the cross-country vehicle must be provided by a frame made of steel pipes. The axles and engine will be installed and secured on a frame made of copper tubing.

Make holes in the body for leading out the bridges. Seal the joints of the axle shafts and the body (in the holes) thoroughly with rubber couplings.

The highlight of this all-terrain vehicle is the presence caterpillar, without which it is difficult to imagine movement on any off-road and even swimming. The treadmill is cut from rubber sheet and looped back. When calculating the dimensions of the caterpillar, measure the distance between the shafts, which are driving. An important element that provide the ability to easily overcome any dirt, are the lugs attached to the outside of the track by rivets. And if they are made in the form of small blades, then the lugs will play the role of blades when the caterpillar is immersed in the water. This idea is not difficult to implement with a thick aluminum sheet at hand. Next, you need to measure the width of the wheels. You will need this value when calculating the distance between adjacent stop elements that are attached to the inside of the track. The center of each wheel, as here http://modelist-konstruktor.com/, must exactly coincide with the center line of the track and, thus, the wheel will be located between the stops.

The taut state of the tracks can be ensured in the following way: fill the space between the bridge wheels with the driven wheels.

The final stage is to equip the cabin with laminated glass (triplex or duplex) with rubber mountings. All-terrain vehicles - homemade products on tracks, the drawings of which are in this article, are popular with creative people.