Most drivers very quickly move from the desire to just drive to the desire to carry out some repair work on their car on their own. In order to improve your car, you need to know how it works and its internal structure. And it is better to start studying from the very beginning, that is, from the starter of the car - something without which the movement of the vehicle is initially impossible.

Starter, his appointment

A starter is a relatively small device that, by virtue of its design, converts an electrical flow of energy into a mechanical one. From the name itself it follows that it serves as a part for starting the engine.

Visually, the starter is a small DC motor that is mechanically driven. It starts the primary movement of the crankshaft at the frequency necessary to start the internal combustion engine and is necessarily a component of the vehicle's electrical equipment.

If you disassemble the structure of the starter in more detail, you can understand that it looks like a four-pole motor. Such a motor feeds a car battery - immediately after turning the ignition key, a current is supplied to the relay terminal. The power of the element is different, but manufacturers provide 3 kW starters for most gasoline internal combustion engines. The voltage from the car battery significantly enhances the operation of the electric motor.

Since, ideally, the starter motor is the only way to start the engine, car manufacturers are inventing a host of additional features and locking mechanisms to improve safety when starting the engine and reduce the risk of theft.

For example, some car models provide for starting the engine only when the clutch is depressed. With automatic transmission, the starter is switched on only if the selector is in the “parking” position.

Types of starters

Among the entire spectrum of automotive parts, only two types of engine starters are distinguished:

- Without gearbox. Without a gearbox, such parts have the ability to directly affect the gear. In addition, after receiving current to the controller, the starter provides faster ignition due to the instantaneous grip of the gear and flywheel. Such devices have the great advantage of simple construction, easy repair and very low probability of breakdown due to the influence of electricity. However, among the shortcomings, motorists sometimes single out intermittent work in low temperature conditions.

- With a gearbox. It would seem that after a long list of advantages of a gearless starter, the choice can be stopped, but no. Most experts insist on using a starter with a gearbox. Due to the latter, efficient work is possible even if the battery charge is running out. The reduced current demand is enhanced by the presence of permanent magnets. This tandem reduces the likelihood of winding problems to virtually zero. On the other hand, prolonged operation of such a device is fraught with breakdowns of the main gear. Although more often this leads to a production defect.

Internal structure and features

The internal combustion engine generates energy for operation using the crankshaft revolutions. Other electrical systems in the vehicle run on this same energy. To start the vehicle from a fixed point, it is necessary to properly interact between the electric motor and an external source - the battery.

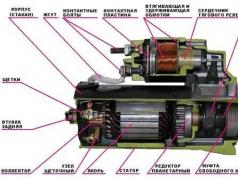

The overall tandem is ensured by several components:

- Anchor. Has a pressed-in core and several collector plates. The base is made of alloy steel.

- Brushes and holders. During the main cycle, the brushes increase the power. First of all, they serve to supply operating voltage to a set of armature plates.

- Relay. The main purpose of the solenoid relay is to supply power from the ignition and push out the freewheel. Manufacturers have provided several power contacts and a specific jumper in the structure.

- Directly an electric motor. Includes multiple cores and field windings; has the shape of a cylinder.

- Bendix and gear. The main operating mechanism of the starter, which redirects the torque to the flywheel crown of the internal combustion engine through a gear using a roller mechanism. After starting, the system breaks the connection between the flywheel ring and the drive gear, keeping the entire device operational.

Most car starters are designed this way, although there may be some differences. In general, if you disassemble the element, you can count about 50 different constituent components.

Most often, the differences between different devices lie in the mechanism for disengaging the gears.

In cars with automatic transmission, the starter motor may have several additional windings to prevent the engine from starting when the selector is in travel position.

How a car starter works

The automobile starter belongs to a number of vehicle electromechanical devices. It is based on the transformation of the nature of one energy into another, and in order to eventually start the engine, the following processes take place:

- The current enters the coil of the traction relay after passing through the starter relay, only after the ignition switch is closed.

- The anchor interacts with the bendix. Through a solenoid relay inside the motor, the bendix forces the flywheel crown and gear to engage.

- When the top point is reached, the contacts interact to transfer voltage to the starter winding.

- The movement of the shaft provokes the start of the internal combustion engine. At the moment when the speeds of the flywheel and the shaft differ in the positive direction, the engagement stops and the bendix returns to the starting position due to the spring.

- The power supply is cut off when the key is turned.

At first glance, it may seem that the mechanism of the starter is rather confusing, but this feeling haunts the driver until the first self-repair of the element.

Possible starter problems

Naturally, the starter has much less load than many other vehicle components, but even with loyal loads, it is impossible to completely exclude the possibility of breakage.

- The starter "refuses" to start. There may be several reasons for this behavior of the device, and all of them are directly related to the internal design of the element - relay malfunctions, broken contacts or windings.

- Slow motion of the crankshaft. A possible basis for a slower shaft rotation can be an increased oil viscosity, a decrease in the charge of an external power source, or oxidation of the wire contacts.

- Rotation of the armature does not drive the crankshaft. Most likely, such a nuisance arises due to the towing of the drive freewheel or interference in the movement of the element along the screw thread of the shaft.

- Gear grinding. Behind the uncharacteristic behavior of the gears is an incorrectly rebuilt contact closure or seizure marks on the teeth of the ICE flywheel crown. Unlikely, but still the cause may be a weakening of the actuator spring.

- Excessive starter operation. Experts believe that the reason lies in the jamming of the ignition lock or winding in the starter structure, improper operation of the contacts.

- Amplification of noise. Uncharacteristic loud noises occur due to loosening of the fasteners of the starter parts or due to the slow disengagement of the gear.

It is better to avoid problems with the starter. Naturally, almost any damage to it can be compensated for by a competent repair, but it would be more correct to purchase a new serviceable device, without trying to save on the cost of the element.

A starter is a small but very important part of a car. It is with her submission that the car starts up and sets off. The main task of the starter is to mechanically start the engine. But there are situations when nothing happens when you start the car, and this cannot but be frustrating.

There can be a large number of reasons for this, and in order to accurately diagnose the cause of the failure of a part, you need to view all of them. You need to start with the simplest and most common weather conditions. If a part malfunction occurs in severe frost, then the oil may become too viscous. If the air temperature is very high, then problems with the gas pump are likely. But perhaps the matter is completely different, and in order to solve the problem, you will have to turn to experienced craftsmen at the service station.

ATTENTION! Found a completely simple way to reduce fuel consumption! Don't believe me? An auto mechanic with 15 years of experience also did not believe until he tried it. And now he saves 35,000 rubles a year on gasoline!

How the starter works

The principle of operation of the starter is quite simple - when you start the car, energy is supplied from the battery to the starter, then the gear is extended, which immediately creates a clutch with the flywheel. At the same time, the starter motor starts to work, which, with its rotations, gives an impulse to the rotations of the piston engine of the machine. After a few seconds, you will hear a characteristic hum, which indicates that the engine of the car has started to operate independently.

After the ignition process is over, the starter automatically switches to its original position, and is absolutely ready for the next use.

The most common reasons why the starter does not turn

Eliminating the simplest and most banal reasons why the starter does not work, you need to remove it from the car, disassemble it, and try to diagnose it yourself. Here are some of the most common situations:

- Battery performance problems. If there are no problems with the charge, then you need to check the condition of the terminals and contacts.

The most insidious moment is the minus wire connecting the gearbox and the car body. The contact can appear and disappear again. You need to completely disconnect it, clean it and put it in place. If nothing has changed, then we continue to look for the cause of the breakdown further.

- There are situations when the solenoid relay gives the appropriate sounds, but the motor does not start. The reason for this situation is also a discharged battery. In this case, the lights on the dashboard also go out. To solve the problem, just charge the battery, but think about what could lead to a complete discharge.

- Security systems sometimes bring surprises and surprises. It is easy to determine breakdowns of this nature, but getting rid of them is quite difficult. The reason is the discrepancy between the characteristics of security systems and immobilizers of some cars. They do not appear immediately, but after a while. This problem was relevant for the second generation Ford Focus, released in 2008. The car worked exceptionally, but one day the starter stopped working. After a thorough check, it was possible to say for sure that everything was in order with the contacts and electronics of the car, but the part stubbornly did not fulfill its functions. The problem was solved by replacing the standard immobilizer. It turned out to be easy to identify the breakdown - bypassing all systems, power was simply supplied from the battery to the starter from the button, and it worked perfectly. The case looks more like an exception, but still it should not be discounted.

- Problems with the solenoid relay. It is extremely simple to make its diagnostics, it is enough to supply a charge directly from the battery to the relay terminal. If the engine starts to run normally, then the problem comes from the relay itself. You just need to clean the contacts that are most likely burnt. But keep in mind that after such a cleaning, the relay will still not last long, because a special anti-corrosion layer was applied by the manufacturer to the nickels of the terminals, which disappears after cleaning. So get ready to purchase a new part.

- Bendix is a gear that is on the same shaft as the starter rotor. The main task of the bendix is to transfer torque from the electric starter motor to the car engine. To determine that the bendix is not the culprit for the starter's work, you just need to connect the two power terminals on the relay. So we let the current bypass the relay, and we can find out if it works in this position.

Another problem associated with the work of the bendix is the wear of the gear teeth. In this case, the part is loosely connected to the flywheel, making idle turns. In the presence of such a problem, a characteristic noise and crackling sound is heard. To solve this problem, it is enough to replace the gear, disassembling completely the starter.

- Starter bushings. There are special bearings in front and behind the starter, on which the shaft rotates. In this case, the relay emits a clicking sound but does not crank the starter, because the shaft can no longer perform this function, and the primary winding of the part closes with the secondary. In this case, you need to be extremely careful, because such a situation leads to wire melting, due to which a short circuit, a failure in the car's electronics and, in the worst cases, a fire is possible.

If, when starting the car, the relay clicks, and the starter does not turn, then it cannot be kept on for a long time. After several attempts, the shaft will often slide into place and the car will start up normally. But as soon as the first symptoms appear, you need to immediately seek qualified help or replace the bushings on the starter yourself. If you ignore this problem, the consequences can be very dire.

If, when starting the car, the relay clicks, and the starter does not turn, then it cannot be kept on for a long time. After several attempts, the shaft will often slide into place and the car will start up normally. But as soon as the first symptoms appear, you need to immediately seek qualified help or replace the bushings on the starter yourself. If you ignore this problem, the consequences can be very dire.

- Block of brushes. We penetrate deep into the starter, its electric motor works only under the condition of a stable supply of electricity from the battery through the brushes to the primary winding. But brushes have a limited lifespan, as they are made of graphite, and they wear out quickly. This option is easy to calculate by looking at the total mileage of the vehicle. To fix the breakdown, you need to disassemble the starter, get to the brushes and visually objectively assess their condition. If they are worn out, then you just need to replace them with new ones.

- Starter windings. The starter is an electric motor familiar to everyone, which is characterized by all the usual diseases for such devices. One of the most common problems is winding wear. If you smell a pungent smell when starting the engine, this is a clear sign that the winding will need to be replaced in the near future. Having disassembled the starter with a burned out winding, we will see that it has changed color, smells like fumes, the protective varnish has burnt out, and the color has changed to a darker one. This happens if the driver overdid it by trying to start an inoperative starter.

Normally, the starter's work should be limited to a few seconds, but inexperienced warriors can try to start the engine without leaving the starter alone for several minutes, thereby burning the part's winding. After such an incident, you have to change the entire starter, since replacing the winding is a long, expensive and troublesome business. Yes, and in material terms, buying a new starter and replacing the winding are often the same. Therefore, do not try to squeeze all the juice out of the starter, take care of it.

The most common starter breakdowns

Car repair specialists have compiled a list of the most common starter breakdowns they contact. This list includes:

- Oxidized battery leads or loose wire lugs;

- Short-circuits and burns of the starter relay winding;

- Gusts in the food chain;

- Breakdown of the relay to turn on the device;

- Wear of graphite brushes;

- Burning nickels;

- Breakdown in the commutator.

But during the diagnosis of the starter, do not be discouraged if the cause has not been identified. Just try to lubricate the mechanism and put it back. Perhaps this was what he needed.

How to protect the starter from damage?

The car starter is a very important mechanism, without which the car simply will not move. Not every motorist  will be able to independently find the reason why the starter does not turn, but anyone can take preventive measures so that it serves for a long time and efficiently.

will be able to independently find the reason why the starter does not turn, but anyone can take preventive measures so that it serves for a long time and efficiently.

- All motorists know that they need to regularly undergo maintenance at a station that you trust. Here they will be able to identify problems at an early stage and fix them immediately. An experienced craftsman can find problems in the starter at the initial stage, and save another working part.

We are talking about those situations when the engine of your car does not start within the first 5 seconds. This indicates a problem with the starter motor. But many novice drivers stubbornly try to solve the problem by pressing the ignition button over and over again. Then the starter simply breaks down and requires replacement.

- Autostart very quickly burns out the starter and discharges the battery, making it impossible for the vehicle to move.

- Experienced drivers are familiar with situations where gasoline suddenly runs out. And in order not to push the car for several kilometers before refueling, they go on the starter. This option is possible, but for a detail it will most likely be the last one. Under such loads, the starter simply cannot withstand and burns out. Think for yourself whether the purchase of a new part is worth several kilometers of the road.

- Do not leave the starter on after starting the engine. This will lead to unreasonably rapid wear of the part.

Remember, in some cases the car will not start the first time, especially on cold winter evenings. But the alarm key fob tells the owner otherwise. In this case, the alarm is to blame for everything, which simply did not understand that the engine did not start, and endlessly drives the starter in an attempt to start the car engine. If you see such a problem in your car, immediately seek help from specialists, otherwise autostart will simply ruin the starter for you by constant attempts to start the engine. In addition, you will have a permanently dead battery.

Sometimes there are situations when the car is started using autostart, but the starter continues to work for a few more seconds. This happens due to the fault of the alarm, which did not turn off the part in time. If this situation repeats itself in the future, then nothing good will come of it.

Broken starter - repair or replace?

Most often, when buying a new car, the starter does not need increased attention for the first 5-7 years. After this, breakdowns and malfunctions are possible, which must be eliminated immediately.

The starter is an expensive component. Before installing a part on a car, it is tested for a long time and checked by experts and during crash tests. That is why in the United States and other developed countries, repair, or rather the restoration of starters, takes place directly at the manufacturer's plant by a conveyor method.

The starter is an expensive component. Before installing a part on a car, it is tested for a long time and checked by experts and during crash tests. That is why in the United States and other developed countries, repair, or rather the restoration of starters, takes place directly at the manufacturer's plant by a conveyor method.

When contacting a service station with complaints about the operation of the starter, it is immediately changed to a new or refurbished one, and the broken part is sent directly to the factory that produced it. In such a situation, the car continues to drive without problems, without prejudice to the owner.

As for our country, in the event of a breakdown, only 1 out of 10 car users change a part for a new one. This situation is directly related to the pricing policy, because repairing a starter is much cheaper than purchasing a new part.

If the breakdown is insignificant, then the repair is more profitable, but if the winding is burned out or the anchor comes out of the standing position, then the repair can cost as much as half of a new starter. In order not to get into a situation in which a miser pays twice, it is better to immediately change the part to a new one.

Due to the fact that new components have a rather high price, and the cost of work is a wound, repairing starters is an excellent opportunity for service station workers to make money. Today, many service centers have a sign with an appeal to contact their company for repair, but in fact there are very few good craftsmen. Most of the responsible craftsmen do not even undertake such work. Those car owners who want to save a little money turn to low-quality craftsmen who do not repair well for help, and after a while you will again find yourself in the captivity of broken parts.

As a conclusion, I would like to say that most of the problems with the starter arise as a result of the inept handling of the car owner himself. After identifying the breakdown and fixing it, think for a minute, what led to this state of the part? Isn't that your way of driving a car?

Friends, let's deal with the starter! What is a starter in a car, consider its principle of operation and device.

How does a car trip start? You need to get behind the wheel, insert the key into the ignition switch, turn it to the extreme position (or press the "Start" button). The engine will start and you can start moving. Stop…!

Here, in this place he said his word and again fell silent! The starter said his main word and modestly switched off!

But he, the starter, did the main job, without which we would not have gone anywhere. In seconds he performed a difficult operation, spun a pile of iron and breathed life into the dead-silent engine.

And so, he is in charge! An irreplaceable element. His name is Starter - he always starts first.

Therefore, it makes sense to consider in detail its operation and structure.

And now, before moving on to the design of the starter, we will briefly plunge into the maelstrom of history. At the dawn of the automotive industry, at the beginning of the twentieth century, starting a car was not the easiest thing to do.

It was necessary to desperately twist a special handle, which, if improperly performed, could easily cripple its owner.

It is clear that at a time when the car was synonymous with luxury, car manufacturers did not want to risk the health of their customers, therefore, imaginable and inconceivable ways to automate the engine starting process arose in the minds of engineers.

There were attempts to use compressed air, mechanical springs and much more for this, but all these attempts did not bring visible benefits until one young American engineer managed to create a compact and efficient electric motor, which he proposed to use to spin up motors.

This invention was seized upon at General Motors, and in 1912 an electric starter was first installed on a car. After all, what is a starter at that time - these are the first attempts at automobile comfort.

What's inside and how does it work?

It's time to go back to our days and start studying the starter circuitry that can be found under the hoods of our cars. Among the variety of these devices, two main types can be distinguished:

- with a gearbox;

- without gearbox.

The first type of starter, according to experts, is the most in demand.

The fact is that the presence of a mechanical transmission (gearbox) allows the use of less powerful electric motors, and this is useful for the vehicle's on-board network.

In addition, a starter with a gearbox will start the car engine, even if the battery is slightly discharged, which the second type of these devices cannot do.

Although it should be noted here that the process of starting the engine in any case requires a lot of energy consumption, the starter current at startup can reach 200 or more Amperes, therefore, with a noticeable discharge of the battery, the power unit will not start even with the most efficient gearbox.

The positive aspects of gearless types include the response speed and high maintainability, which is also appreciated.

In general, all starters have a similar design, in which the following key components can be distinguished:

- DC electric motor;

- retractor (traction) relay;

- bendix (freewheel).

So, when you are going to start the car and insert the key into the ignition, everything happens according to the following scenario.

At the moment of turning the key, the current from the battery is supplied to the solenoid relay. The movable part of the relay begins to move and, with the assistance of the lever, moves the bendix with the drive gear so that it is connected to the flywheel crown.

By the way, the bendix in the starter is an interesting detail. Its functions include not only ensuring the engagement with the flywheel crown, but also protecting the entire assembly from the unwound flywheel.

It works like, thanks to its cunning mechanical design, it can rotate at unlimited speed without harm to the starter armature. The truth is not long.

After contact with the flywheel has taken place, the electric motor comes into operation, which spins it up.

When the engine starts up and the flywheel rpm exceeds the starter rpm, the bendix gently disconnects the gear, and the traction relay returns the entire structure to its original position. The engine starting process is complete. It's that simple.

Now, dear readers, what is a starter, you know what work happens between turning the ignition key and starting the power unit. Do not forget to read about, this is also kind of a topic.

Well, we do not say goodbye, but say: "Goodbye and see you again on the pages of our blog!"

Hello dear motorists! Sometimes it is too late to realize the importance of mastering the device of the car. Finding ourselves far from auto service centers and experienced acquaintances, alone with a real car, we begin to regret that we were not attentive enough in the classroom at the driving school.

An ordinary car enthusiast does not need to thoroughly study the device of each of his cars, especially since many manage to change several cars a year. A self-respecting driver, of course, tries to keep abreast of everything that happens with his favorite vehicle.

Solid knowledge helps to quickly understand the breakdown and even if it is not possible to fix it on our own, then in a conversation with the workers of the repair shop we do not look stupid, and we can control the elimination of malfunctions at the service station, at least.

The first thing that a novice car enthusiast should master is a device. First, the movement of any car begins from this node. Secondly, knowing how the starter works, the driver can start the engine correctly and quickly figure out the reasons for a poor start.

Car starter device

In order to be able to independently repair the starter of your car, it is absolutely not necessary to look for special literature on a specific modification.

Starters of all cars have the same device and differ slightly from each other in design features, but not in the principle of operation. If you already know what the starter of one car consists of, then it will not be difficult at all to understand the features of another.

Any of the starters has 40 to 60 individual parts that make up its main parts, namely:

- DC electric motor;

- traction (retraction) relay;

- bendix.

At a minimum, every driver should know what the starter circuit is and what function each of its parts performs. The main unit is an electric motor, the shaft of which, after switching on through the gears, transfers rotation to the crankshaft of the motor.

Bendix is also an auxiliary device. The solenoid relay has a dual function:

- with the longitudinal movement of the armature through the lever along the shaft of the starter electric motor, the bendix with the working gear moves;

- closure of the contacts of the electric motor after the gearing of the gear and the flywheel rim.

The smallest, but no less important element is the bendix. The unusual name of the node is the name of the American inventor Vincent Bendix, who created it. The task of the bendix: to provide a temporary connection of the starter shaft and the flywheel ring for crankshaft rotation.

The principle of the car starter

The starter is an electromechanical device. This suggests that the principle of operation of the starter is to use electrical energy and convert it into mechanical energy.

In order for the car engine to be able to start, the following processes take place in its depths:

- after the contacts in the ignition lock are closed, the current is directed through the starter relay to the retraction winding of the traction relay;

- the anchor of the retractor relay, moving inside the housing, pushes the bendix out of the housing and engages its gear with the flywheel crown;

- when the anchor of the retractor relay reaches the end point, the contacts are closed and the current flows to the holding relay coil and the starter motor winding;

- rotation of the starter shaft will start the engine of the machine. After the speed of rotation of the flywheel exceeds the speed of rotation of the starter shaft, the bendix disengages from the crown and is set to its original position with the help of a return spring;

- when the key in the ignition switch with the engine start returns to the first position, the power supply to the starter is cut off.

The principle of operation of the starter, after a step-by-step analysis, no longer seems so complicated. The first self-repair of the starter is the last step for the driver in mastering his device.

In order to become an advanced connoisseur of the motor starting system, it is useful to study the technical characteristics of your car's starter, the main of which are: rated voltage and power, current and torque consumption, shaft speed.

The starter is the main unit of the engine starting system; in fact, it is a DC electric motor with a mechanical drive. The principle of operation of the starter is based on the movement of the overrunning clutch (bendix) on the shaft when the relay is triggered. The operation of the electromechanical device is short-lived, since after the gear is thrown away, it no longer participates in the movement of the car.

[Hide]

Where is the starter located?

In the car, the starter motor is located at the junction of the engine and transmission mechanism. The place where these parts of the car equipment are connected is closed with a plastic case made in the shape of a bell.

Access to it differs depending on the machine model:

- from below, from under the bottom of the car;

- from the engine compartment, under the hood.

The mechanism is fixed according to the standard with three or two bolts.

The location of the starter in the car: red arrows show the mounting bolts and wiring connections

Why do you need a starter and what are its functions?

A starter is needed to convert electrical energy into mechanical energy to start the power unit.

The purpose of the mechanism is demonstrated in the video. Author - serzh86.

Types of starters

According to its structure, the electromechanism is divided into two types:

- with the presence of a gearbox in the design;

- without gearbox.

With gear

Reduction starters are efficient to operate and save battery power as the permanent magnets in the mechanism extend the life of the stator winding.

Advantages:

- increased service life of the part due to the reinforcement of the gearbox;

- small size and lightness;

- reliable work in winter at subzero temperatures.

Disadvantages of a gear starter:

- repairing an item that is out of order requires the high competence of the repairman;

- difficulty in the selection of spare parts.

Without gear

A starter without a gearbox is designed in such a way that it supplies torque directly to the overrunning clutch without transmission through a gear mechanism.

Its advantages include:

- reliability and ease of use in warm weather;

- availability of repair due to lightweight construction;

- the prevalence of spare parts for restoration to working condition.

The number of disadvantages of starters without a gearbox is not less:

- considerable size and heaviness;

- increased consumption of the battery power reserve;

- unreliable operation in the cold season at subzero temperatures.

Photo gallery

Starter without gear Starter with gear mechanism General diagram of the starter device with a gearbox

Starter device

The part is made in the form of a small cylinder placed in a metal case 13 to 15 centimeters long. Often, a relay is also connected to it through a wire (a similar element, but smaller). The second cable must be connected to the battery.

The device of the engine starting system in the car includes 5 main elements:

- Electric motor. It is presented as a metal cylinder, inside which cores and windings are attached. According to the standard, there are four of them, they are fastened in a screw way, tightly pressing against the inner wall. Special threaded holes in the body provide anchorage for the front end where the overrunning clutch moves.

- Anchor. This starter element is designed as an axle. It is made of alloy steel and serves as the central part of the mechanism, in which the collector plates and the core are placed.

- Solenoid relay. Transmits an impulse from the ignition switch directly to the electric starter motor, pushing out the freewheel.

- Switch-on drive or bendix. Mechanism with a roller attached to one of the armature shafts. This element is movable and performs an important function of transmitting torque. The clutch gear spins the flywheel rim, ensuring the stability of the mechanism during operation. Immediately after starting the combustion engine, the overrunning clutch disengages the gear, keeping the system operational.

- Brush assembly. Stabilizes the voltage across the armature plates. Brushes and special brush holders perform the main work in the current-torque cycle.

In the photo - the components of the starting device

Connection diagram and operating principle

The principle of operation of the starter is carried out according to the given connection diagram:

- When the key is turned in the ignition lock, the traction relay is powered by battery power and forms a contact.

- The overrunning clutch gear engages the flywheel and brings it into motion.

- The closing drive closes the circuit by applying voltage to the armature and plates, thus bringing the electric motor into working condition.

- Then the internal combustion engine is started. At the moment when the internal combustion engine spins faster than the starter, the freewheel disengages the gear and the device turns off.

Standard wiring diagram for starter connections

Possible malfunctions

Possible starter malfunctions occur, as a rule, due to violation of its operating conditions.

Breakdown signs and diagnostics

Symptoms of the most common starter problems:

- suspicious noise or crackling noise when turning the ignition key;

- the motor stalls without triggering the electric motor;

- lack of the ability to start the internal combustion engine;

- "Sneeze" of the starter mechanism without engaging the flywheel.

Most often, the starting device breaks down due to an open electrical circuit, so you should check:

- battery charge level;

- wiring for damage;

- fastening the terminals;

- keyhole ignition.

If there are no problems with the above, then the next step is to check the traction relay. It is possible to diagnose this element without removing the starter, since the operation of the electric motor depends on it. If, when a flat screwdriver closes the contacts on the relay, the electric motor starts up, then the cause of the breakdown lies precisely in this part.

Types of faults

There are two types of malfunctions in the starter - mechanical and electrical.

Electrical problems requiring qualified assistance:

- periodic closure of the armature winding;

- breakage of the solenoid relay and stator;

- breakage of brushes and contact plates;

- core wear and lack of contact in the electric motor.

Mechanical malfunctions of the starter:

- locking of the engagement drive on the flywheel rim;

- deformation of the gear teeth;

- damage to bearings and bendix;

- burnt surface of "nickels".

Causes of malfunctions

The most common causes of malfunctions:

- If the starter starts to “buzz” characteristically and works at “idle”, then the overrunning clutch is not connected, and the mechanism operates without the gear wheel engaging with the shaft. The problem is eliminated by flushing the bendix in a special cleaning solution or gasoline. It is recommended to place the part in a container with liquid, hold for an hour and a half and then set the drive in motion a couple of times to clean the mechanism.

- If the car does not start, then the reason may lie in the lack of power supply. If the circuit is working properly and there is current, it is necessary to check the relay, perhaps the reason lies in it. It is necessary to thoroughly clean the element from dust, carefully examine the contacts again, assemble and put in place the component parts. If the problem persists, most likely the winding is closed, and only replacement of the part will help.

How to protect the starter from damage?

To protect the starter from damage, you need to know that:

- Frequent use is one of the main causes of starter failure.

- It is strictly forbidden to use an electric starter instead of an internal combustion engine if you run out of fuel. Excessive load on the starter unit destroys its individual components. Structurally, the starting device is not intended to function in the mode of the main power plant.

- It is forbidden to hold the starter in the switched on state for more than 10 seconds. Most often, the device is burnt when trying to start the engine. It is necessary to make minute intervals between runs, so that the structural elements have time to cool down and will not be subject to premature wear.

- The contact points and terminals of the battery should be checked regularly. If oxidizing spots are found, they are cleaned for better current conductivity.

- After starting the motor, an immediate shutdown of the starter unit is required. Holding the ignition key in the active position increases the wear of the starting system of the electric motor several times.

Video

The thematic channel Maysternya TV shot a useful video with a visual guide to the maintenance of the starter mechanism.