Self-propelled full-slewing single-engine diesel crane KS-4361 with a maximum carrying capacity of 16 tons is intended for construction and loading operations with piece and bulk cargo at construction sites, warehouses.

The set of working equipment includes the main lattice hinged-folding a 10 m boom, a 16 ton hook and a 1.5 m 3 grab for 10 and 15 m booms. Replaceable equipment includes extended booms 15, 20 and 25 m long, obtained from the main boom by inserting 5-meter sections, and an uncontrolled jib 6 m long. The boom is equipped with a limiter that prevents it from being thrown back onto the platform when operating at minimum outreach.

The crane has a mixed control system - pneumohydraulic... The shafts of the winches and reverse, as well as drums, are switched on using pneumatic chamber couplings; the direction of movement of the mechanisms of rotation and movement of the crane is changed by a reversing mechanism and bevel gears. The inclusion of the reversing mechanism is also provided by pneumatic chamber couplings. The operating speeds of the crane are regulated within wide limits by means of a torque converter powered by the hydraulic system of the crane.

The crane running gear is equipped with outriggers with screw jacks with small shoes at the ends.

The crane can move around the site under its own power, including with a load on the hook at a speed of up to 3 km / h. Movement with a load on a hook is allowed on the site with a boom of 10 - 15 m directed along the longitudinal axis of the crane.

Over long distances by road, the crane is transported in tow to the tractor using a coupling device. In the process of relocating the crane, the gearbox is set to the neutral position, the wheel turning cylinders are turned off, the propeller shaft of one of the axles is removed. The towing speed should not exceed 20 km / h, and on slopes and turns the speed should be reduced to 3 km / h.

The crane is transported by rail on a four-axle platform. Before loading the crane onto the platform, remove all pneumatic wheels, disconnect the boom sections, placing the upper section on the lower one. The crane is loaded onto the platform using an erection crane with a lifting capacity of 25 tons. If there are replaceable boom sections, they are placed on the second platform.

Reference:

The KS-4361 crane has an improved modification - the KS-4361A model with a modified design of the body and the driver's cab.

The crane is currently not in production.

| Faucet Specifications echo $ name; ?> | |

| Maximum lifting capacity, t | |

| on supports | 16 |

| without supports on wheels and in motion * | 9 |

| Engine | SMD-14A |

| Engine power, h.p. | 75 |

| Hook lifting height, m | |

| with main boom | 10 |

| with full boom equipment | 25 |

| with additional equipment (extension + jib) | 30 |

| Lifting speed (stepless regulation) of load, m / min | |

| with boom length 10.5 m | 0…20 |

| with boom length 15.5 m | 0…35 |

| with boom length 20.5 and 25.5 m | 0…50 |

| Rotational speed of the turntable, rpm | 0,4…2,8 |

| Maximum travel speed, km / h | |

| with a load on a hook | 3 |

| self-propelled without load | 18 |

| Smallest turning radius, m | 12,1 |

| The overcome angle of rise of the path (without load) | 12 ° |

| Permissible high-speed wind pressure, kgf / m 2 | 15 |

| Crane constructive weight, t | 23 |

| when the crane is working | 8 350 |

| when moving a crane with a boom of 10.5 m | 3 950 |

| front | 22 340 |

| rear | 19 040 |

| Overall dimensions, mm: | |

| length | 14 500 |

| width | 3 150 |

| height | 3 900 |

*Lifting capacity in motion is indicated with the boom positioned along the axis of the crane.

The functional crane equipment provides a mixed control system - pneumatic and hydraulic type. The drums and shaft devices are set in active motion by pneumatic chamber couplings, and the crane can be made to move in the other direction by a reversing mechanism. The crane speed can be easily adjusted by means of a turbo converter. This functional element consumes energy from the crane hydraulics.

The undercarriage receives supports with screw jacks. On the site, a heavy car freely moves with a load at a speed of up to three kilometers per hour. The equipment can be transported by rail on a platform. Before loading on it, craftsmen must remove all wheels and separate the boom sections. They need to be stacked from the top to the bottom. For loading, a crane is used, the lifting capacity of which is twenty-five tons.

If you need to transport KS-4361 or KS-4361A for a decent distance, you will need to use a tractor and a towing device, that is, drag it in tow. To do this, the gearbox is set in neutral, the propeller shaft is retracted, and the steering cylinders are deactivated. Movement often develops at speeds of up to twenty kilometers per hour. But when cornering, it is better to reduce it by about six to seven times.

Crane KS-4361 - diesel single-engine with a turbo transformer ( torque converter). Attachment set includes a main boom with a length of 10 m, hook with lifting capacity 16 T and a grab with a capacity of 1.5 m3 mounted on 10- and 15-meter booms. Replaceable equipment are 15, 20 and 25 long booms m obtained from the main boom by inserting 5-meter sections and a 6-meter long jib m... The boom is equipped with a limiter that prevents it from rolling back onto the platform when operating at minimum reach.

The crane uses a mixed control system - pneumohydraulic. The shafts of the winches and reverse, as well as drums, are switched on using pneumatic chamber couplings; the direction of movement of the mechanisms of rotation and movement of the crane is changed by a reversing mechanism and bevel gears. The inclusion of the reversing mechanism is also provided by pneumatic chamber couplings.

The operating speeds of the crane are regulated within wide limits by means of a turbo transformer powered by the hydraulic system of the crane.

Overall dimensions of the pneumatic-wheeled crane KS-4361

The crane running gear is equipped with outriggers with screw jacks with small shoes at the ends.

The crane can move around the site under its own power, including with a load on the hook at a speed of up to 3 km / h... Movement with a load on a hook is allowed on the site with an arrow of 10 - 15 m directed along the longitudinal axis of the crane.

Over long distances by road, the crane is transported in tow to the tractor using a coupling device. In the process of relocating the crane, the gearbox is set to the neutral position, the wheel turning cylinders are turned off, the propeller shaft of one of the axles is removed. Towing speed should not exceed 20 km / h, and on inclines and turns the speed should be reduced to 3 km / h.

The crane is transported by rail on a four-axle platform. Before loading the crane onto the platform, remove all pneumatic wheels, disconnect the boom sections, placing the upper section on the lower one. The crane is loaded onto the platform using an assembly crane with a lifting capacity of 25 T... If there are replaceable boom sections, they are placed on the second platform.

Technical characteristics of the crane KS-4361

| Carrying capacity, T: | |

| ... on supports: | |

| .. | 16 |

| .. | 3,75 |

| ... without supports: | |

| .. at the smallest hook reach | 9 |

| .. at the greatest hook reach | 2,5 |

| Hook reach, m: | |

| .. the smallest | 3,75 |

| .. the greatest | 10 |

| Hook lifting height, m: | |

| .. at the smallest hook reach | 8,8 |

| .. at the greatest hook reach | 4 |

| Speeds: | |

| .. lifting the main hook, m / min | 10 |

| .. sinking, m / min | 0 - 10 |

| .. rotation frequency of the turntable, rpm | 0,5 - 2,8 |

| .. self-propelled crane movement, km / h | 3; 15 | 213 | 150 |

| Smallest turning radius (outside wheel), m | 12,2 |

| The greatest angle of ascent of the path, hail | 15 |

| Engine: | |

| .. brand | SMD-14A |

| .. power, h.p. | 75 |

| Wheel track, m: | |

| .. front | 2,4 |

| .. back | 2,4 |

| Crane weight, T | 23,7 |

| Including counterweight, T | --- |

Carrying capacity when driving and overcoming angle of rise on the way in transport position

*

- The lifting capacity is indicated with the boom positioned along the axis of the crane.

**

- In the denominator - the permissible angle of inclination of the crane when working on outriggers.

Characteristics of the main and replacement boom equipment of the KS-4361 crane

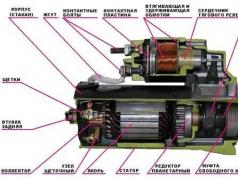

All executive bodies of the mechanisms on the KS-4361 crane are set in motion through a turbo transformer 35

.

Landing of drums of boom, cargo and auxiliary (grab) mechanisms - on a common shaft; thus, one three-drum winch is used.

Power take-off from engine to compressor 32

carried out by means of a V-belt transmission 43

- 44

and propeller shaft 33

.

Rotation from the engine 34

turbo transformer 35

transmitted through the clutch 20

, the output shaft of the turbo transformer is connected by a chain drive 15

- 36

with shaft 9

reversing mechanism.

Shaft 10

three-drum winch is connected to the shaft 9

bevel gear reverse gear 16

- 22

and chain drive 18

- 23

, and the gear 16

and an asterisk 23

have a rigid fit on the shafts, and the sprocket 18

and cogwheel 22

rotate freely. They are switched on using pneumatic chamber couplings 19

and 14

planted on shafts. Depending on which gear is engaged (chain or gear), the shaft 10

forward or reverse rotation is reported.

As you can see from the diagram, the boom drum 13

, cargo drum 12

main hoist and cargo drum 11

auxiliary hoists have a free fit on the shaft and are kept from rotation by band brakes. The drums are switched on using pneumatic chamber couplings; the drums are then released.

On the shaft 9

bevel gears rotate freely 8

constantly meshing with a gear wheel 7

vertical shaft 28

... Alternate engagement of pneumatic chamber gear couplings 8

shaft reversal is provided 28

(clockwise or counterclockwise rotation).

Gears 6

, gear wheels 24

and 26

are in constant mesh, and the gearwheel 26

fits loosely on the shaft. It is turned on by means of a cam clutch 27

, while the shaft 29

starts spinning. Together with the shaft, the gear rotates 25

rolling on the ring gear 5

; there is a rotation of the slewing part of the crane.

Gear 24

being in constant mesh with the gear wheel 26

, when it rotates, it also rotates, and since the gear wheel 24

has a keyed connection to the shaft 30

, the shaft also rotates with it. Further, the rotation is transmitted by means of an equalizing coupling to the shaft 31

, bevel gear 45

- 46

and shaft 55

gearbox of the running gear.

Gears 4

and 48

freely rotate on the shaft 55

... They are switched on alternately using a cam clutch 49

... Depending on which gear is engaged by the clutch, the shaft speed changes 53

, and, consequently, the speed of movement of the crane.

Gear 51

the intermediate shaft is in constant mesh with the gear 50

output shaft 54

which using cardan shafts 41

and 52

drives the front and rear axles.

The front and rear axles of the crane include differential devices that allow the right and left wheels to rotate at different speeds, which is very important when the crane moves along curved sections of the track.

Input gear 40

the main gear is in constant mesh with a gear wheel 42

sitting on the splines of the intermediate shaft. From the intermediate shaft of the main gear, rotation is transmitted through the gears 38

and 39

on the differential housing and through the satellites (gears) 3

and sun gear 2

- on the axle of the crane wheels.

On a KS-4361 crane with a single-engine drive, when considering the kinematic diagram of its mechanisms, the concept of a main and auxiliary hoist winch is not fully applicable, since the arrangement of mechanisms with a single-motor drive does not allow one or another winch to be clearly identified; many elements of the kinematic chain of mechanisms are transmissions for a number of executive bodies. Therefore, on this crane, only the design of mechanisms directly related to the executive bodies - drums is considered.

On a common shaft 6

mounted three drums: cargo 3

, auxiliary (grab) 18

and boom 5

... All three drums are ball-bearing and rotate freely on the shaft. The drums are switched on using pneumatic chamber couplings 1

,

7

and 14

rigidly connected to the shaft, but are kept from free rotation or from rotation under the action of loads (loaded ropes) using band brakes.

The shaft rotates in double-row spherical bearings of the bearings 2

and 10

and is powered by an asterisk 9

or cogwheel 11

with ball bearing support. The wheel is driven by a pneumatic clutch 12

... The reversal of the shaft is carried out by engaging a chain transmission using a pneumatic chamber clutch 19

mounted on a reversible shaft, or by switching on a toothed wheel 11

.

The principle of operation of the pneumatic chamber clutch is based on the friction of the tire against the surface of the drum pulley under the action of compressed air. Coupling type by the nature of the connection - frictional; by the nature of the work and the main purpose - to the class of controlled and coupling couplings, which allow you to open and close the connections of the part.

The clutch consists of a pulley 17

, pneumatic chambers 16

and tires 15

... Air is supplied to the pneumatic chambers through rotating articulated joints from the ends of the shaft 6

(through the channels in it) and from the shaft to the chambers (through flexible hoses). When supplying compressed air through a hose

5

the latter expands into the chamber and presses the friction band with a tire 15

to the inner surface of the drum pulley 3

.

The brake band is attached to the outer surface of the drum pulley. ribbon 3

consists of two parts, connected with a tie bolt 1

... One end of the tape is hinged with a finger on the gusset, the other end is connected to the eyelet 12

... The lug is connected to the stem by means of a system of levers 7

hydraulic cylinder 6

... Hydraulic brake control. When the foot is pressed on the pedal of the hydraulic cylinder, the piston moves to the left and through the rod 7

and a plug 9

turns the lever 11

... In this case, the eyelet 12

moves up and the brake is applied (drum braked). If you take your foot off the pedal, the hydraulic cylinder piston is spring-loaded 8

will return to its original position (the drum will be released). A spring is used for uniform movement of the brake band from the drum pulley. 2

.

A brake of a similar design is installed on a grab (auxiliary) drum.

The boom drum has two band brakes: permanently closed and adjustable.

Eye 19

permanently closed brake mounted on the bracket 18

; the running end of the brake band is tensioned by a spring 4

... The drum has a ratchet wheel 16

; with the help of a dog 15

the drum is kept from rotating. If it is necessary to lower the boom, the pawl is disengaged from the ratchet wheel using a pull 1

, lever 2

and pneumatic chambers 3

... The stroke of the pneumatic chamber is limited by an adjustable (screw) stop 17

.

The band of the controlled brake, like the brake band of the cargo winch, consists of two parts, connected by a tie bolt. Uniform tape deviation from the drum is regulated by a guy spring 6

... The brake eyelet is attached to the bracket 10

using a roller on which the lever is also installed 12

connected at one end to the brake band eyelet 14

, the other - with a pneumatic chamber rod 9

.

The tension of the brake band (braking of the boom drum) is carried out by the spring 8 through the rod 13, the release of the band is carried out using a pneumatic chamber.

The main and auxiliary winches of jib cranes are equipped with special devices - rope-laying devices. They ensure the correct laying of the rope in the grooves of the drum and prevent it from coming off the drum.

|

||

| Slewing mechanism and slewing ring | Front axle | Transmission |

Swing mechanism is driven by a common motor of all crane mechanisms. Bevel gear 27

the reversing mechanism of rotation and movement of the crane is in constant engagement with the bevel gears sitting on the reversing shaft. Vertical shaft loads 14

They are taken at the top by a deep groove ball bearing, and at the bottom by a thrust ball bearing and a double row spherical roller bearing. A gear is rigidly seated at the lower end of the vertical shaft 15

toothed wheel 8

sitting freely on a vertical shaft 12

... On the shaft 12

in addition to the cogwheel 8

housed brake pulley 13

, gear coupling 10

and gear 23

; they are all rigidly connected to the shaft. During the rotation of the shaft 14

and with the clutch off 10

the gear wheel rotates freely on the shaft 12

and transfers rotation to the gear wheel 7

rigidly sitting on the shaft 5

... Together with a cogwheel 7

the vertical shaft rotates and thus the power is transferred to the travel mechanism.

When the clutch is turned on 10

the shaft comes into rotation 12

and gear 23

begins to run around the ring gear 22

; the turntable starts to rotate about the central shaft 5

... The ring gear is internally meshed.

As can be seen from the diagram, the platform rotation reducer simultaneously plays the role of the crane movement reducer.

Outer rings 17

,

19

not connected to the frame of the undercarriage, but to the turntable; inner ring 22

connected to the fixed frame of the undercarriage. Thus, the inner ring is stationary, it acts as the base of the slewing ring.

Front axle crane KS-4361 - controlled, leading; its suspension to the frame is balanced, which improves the traction of the wheels to the ground on uneven roads. Power transmission from the propeller shaft by semi-shafts 12

on the front axle it is also carried out by a cylindrical main gear, as well as on the rear. Inner wheels are mounted on the hub 6

, which is fitted with tapered bearings on a trunnion fixed in the frame 17

... With flange 5

hub 6

connected to the semi-axle 4

... Outer wheels are mounted on the hub 2

, which is seated on the hub with the help of plain bearings 6

; thus, the outer wheels are not driving, as they are loose fit.

When the decrease in flotation begins to affect the performance of the crane, the outer wheels are blocked with special inner leashes. 18

mounted on flanges 5

so that the protrusion of the leash falls between the stops of the rim of the wheels. The leash is fixed with a bolt 19

.

Lower body arms 17

interconnected by transverse link 14

steering linkage. The upper levers of the bodies are connected to the rods of the swing cylinders, which are installed on the bracket of the axle body.

Rotation of the driving wheels from the axle shaft 12

to the semi-axis 4

transmitted through articulated joints 15

and 16

.

Rear axle crane KS-4361 - leading. The bridge is of an automobile type, its suspension to the frame is rigid. It uses the assembly units of the KrAZ vehicle, including the main gear with a differential, semi-axles and brakes. Fastening of travel wheels - diskless; it is carried out with clamps and rings.

The main gear of the rear axle is cylindrical. The bevel gear is used to connect intersecting shafts and control movement.

On the KS-4361 crane, between the engine and the transmission, instead of the main friction-type clutch, a special hydraulic device is installed - a torque converter TRK-325 .

The torque converter provides stepless regulation of the speed of lifting and lowering the load, reversing the direction of movement, lifting small loads at an increased speed, changing the speed depending on the resistance to movement.

Torque converter circuit TRK-325

Torque converter TRK-325 includes a housing in which the pumping pump is located coaxially. 1

, turbine 2

and guide 3

(reactor) wheels. The reactor is rigidly connected to the vessel. The driving impeller receives movement from the shaft 4

engine, and the turbine (driven) is connected to the driven shaft.

Radiator 5

serves to cool the working fluid passed through it using a gear pump 6

... The transformer has a bypass valve, filter and hydraulic tank 7

as well as an overrunning clutch. At the same speed of rotation of the turbine and pump wheels, the clutch joins the shafts 4

and 8

.

Turn off the torque converter by removing fluid from the system. On the shaft 8

an operator-controlled brake can be installed. A pneumatic pusher, a spool, an ejector and a diffuser are used to direct the movement of the liquid in the system.

V pneumatic control system boom crane KS-4361 includes the following elements: a compressor, a refrigerator and an oil-moisture separator, a receiver, a control panel with a pneumatic distributor, pipelines and pneumatic chambers mounted on the crane actuators.

Schematic diagram of the pneumatic control of the KS-4361 crane

The air is pre-compressed in the 1st stage of the compressor 13

, passes through the refrigerator and oil-moisture separator and is compressed in the II stage to 0.6 - 0.7 MPa from where it enters the receiver 16

and further through the pipeline 17

to the control panel 3

.

In the oil-moisture separator, the air is purified from moisture and oil, and then enters the II stage of the compressor.

From the control panel air through pipelines and special rotating joints 10

goes to pneumatic chamber couplings

7

crane mechanisms.

When each mechanism is turned off, the air from the pneumatic chamber couplings is released into the atmosphere. For quick braking of crane mechanisms in the systems of the turbo transformer, pneumatic chamber and brake couplings of the boom drum and the crane movement mechanism, special valves are installed 8

.

For smooth rotation of the platform in the systems of the reversing mechanism and swing brake, as well as the movement mechanism, flow regulators are used 18

.

The crane mechanisms are controlled from the control panel with special devices - spools (valves). There are two types of spools: differential and direct acting. Differential spools are used for those valve mechanisms that require external forces to be regulated when they are turned on. Such mechanisms are mechanisms with friction clutches used in cranes with a single-motor drive - an internal combustion engine. For mechanisms that do not require a change in pressure in the system, direct acting spools are used.

Crane control cabin with a single-motor drive KS-4361

Electrical equipment crane KS-4361 is used to supply internal and external lighting, light and sound alarms, load limiter; provides starting of the starting engine, heating and ventilation of the control cabin, heating of the diesel engine.

The generator G-66 serves as a direct current source, which is also designed to charge the 6ST-42 storage battery. The generator is driven by a diesel engine through a gear train.

To regulate the voltage and protect the generator, a relay-regulator is provided, consisting of a voltage relay, a current limiter and a reverse current relay (prevents the battery from discharging to the generator when the diesel engine is not running). The fuses are used for short-circuit protection.

During the diesel stop period, the electric network of the crane receives power from the battery, which is also used to start the starting engine with an electric starter. The value of the charging and discharging current of the battery is determined using an ammeter.

The crane electrical system includes a set of converters installed on the engine, turbo-converter oil tank and compressor. These converters allow, through appropriate devices, to control the temperature of water and diesel oil, the temperature of the oil in the turbo transformer, the oil pressure in the diesel and compressor systems.

The limit positions of the boom are fixed by a limit switch, which acts on the electromagnet circuit. The latter controls the spool, which, when the boom reaches its end position and the switch is activated, turns off the turbo transformer and turns on the winch brake. The magnet is powered by a running diesel through a relay.

The wiring diagram provides a control button that allows you to bypass the limit switch and return the boom to the operating position, as well as turn on the load limiter when it is triggered.

The control panel has a button to turn on the sound signal. A portable repair lamp is switched on through a power socket.

For carrying capacity limits crane and automatic shutdown of the cargo winch, an electric limiter of the OGP-1 lifting capacity was used.

When the crane is operating at minimum boom outreach, a stop with flexible elements is used to prevent it from tipping over onto the turntable.

Rope traction 2 passes through deflection rollers 1 on the boom 4 and is fixed on the platform. Springs 3 support the rope and prevent it from sagging. When the boom reaches its maximum tilt angle (towards the turntable), the rope is tightened and keeps the boom from further movement.

| The author of the site will be grateful for any information and photos of this crane. Email:[email protected] |

"TUVIS"

CONCLUSION

№ 000

EXPERTISE OF THE INDUSTRIAL

SAFETY AT HAZARDOUS PRODUCTION FACILITY

SELF-PROPELLED JUMP CRANE

FULL ROTARY ON AIR WHEEL

KS - 4361 A ZAV. No. 000 REG. ,

belonging

Registration number No. ________________________

Director of "TUVIS"

“____” ________________ 2009

Surgut

CONCLUSION OF THE EXPERTISE

INDUSTRIAL SAFETY

ON THE RESULTS OF THE TECHNICAL

AIR WHEEL CRANE DIAGNOSIS

КС - 4361 А production number 000 reg.

The conclusion of the industrial safety examination in terms of technical diagnostics of lifting structures that have worked out the standard service life, in order to determine the possibility of their further operation, is a document that determines:

The technical condition of the crane at the time of the examination;

The performance of the crane in accordance with its technical parameters;

Possibility and conditions for further operation of the crane until the next inspection.

This conclusion is an integral part of the crane passport.

Introductory part.The grounds for the examination are:

The contract for the examination from No. 07-09 dated 01/27/2009;

Order for "TUVIS" No. ___ dated 19.02.09. "On the examination of industrial safety of cranes v.

Order No. ____ dated 19.02.09. "On carrying out an expert examination of hoisting machines."

Requirements of PB "Rules for the construction and safe operation of cranes" Art.9.3.21 .;

Requirements of PB "Rules for Conducting Industrial Safety Expertise".

RD "Regulations on the procedure for extending the safe operation period

technical devices of equipment and structures at hazardous industrial

facilities ", approved by the State State Technical Inspection of Russia No. 43 dated 01.01.2001.

I.1.Information about the expert organization.

Title: "TUVIS".

Legal address: Khanty-Mansi Autonomous Okrug, Surgut, Tyumen region,.

Director: .

Telephone/, .

I.2.Information about the license for the right to conduct industrial safety expertise:

"TUVIS" has a license -002560 (K), issued by the Gosgortekhnadzor of Russia for the right to carry out activities for the examination of industrial safety [examination of technical devices used at a hazardous production facility; buildings and structures at a hazardous production facility].

The license is valid from 09.04.2004. to 09.year.

I.4.Information about experts:

Order No. 6 /NS dated 01.01.2001, a commission was appointed for TUVIS in the following composition:

– Level III specialist in the field of industrial expertise (hereinafter referred to as a specialist in the field of industrial safety equipment) of the safety of lifting structures, beats No. of PS. TD.0383, protocol dated 01.01.2001, level II specialist in VIC, UK, PVK beats. No. dated 01.01.2001, valid until 21.01.2012

Commission members:

– specialist of III level in the field of EPB PS, beats. No. of PS. TP / PD.0756.19.09.08, protocol a dated 09.19.08, valid until 09.19.11, VIC specialist level II, beats. No. dated 01.01.2001 valid until 21.01.2012

- II level specialist in the field of EPB PS, beats. No. of PS. TD.0625.27.06.08, minutes dated 01.01.2001, valid until 27.06.2011, specialist in VIC, UK II level, beats. from 01.01.2001 valid until 19.05.2009

- specialist of the I level in the field of EPB PS, beats. No. of PS. TD.0757.19.09.08, protocol dated 09.19.08, valid until 09.19.2011, specialist in VIC, UK II level, beats. No. dated 01.01.2001 valid until 21.01.2012

I.5.Customer details:

Name: .

Mailing address: Langepas city Northern industrial zone 77.

Phone fax: (346

The purpose of the examination.Conformity assessment of the technical condition of the boom pneumatic crane KS-4361 A normative and technical documentation and the possibility of its further operation beyond the established period

service.

Expertise of industrial safety of boom pneumatic crane KS-4361 A was carried out in accordance with the requirements of the normative and technical documentation (for the list of used literature see Appendix 16).

3. Brief description of the object of examination (extract from the crane passport).

Crane type ……………………………… | Pneumatic |

Purpose of the crane ……………………… | |

Manufacturer …………………… | Yurginsky machine-building plant |

Year of issue…………………………… | |

Factory number……………………… | |

Registration number……………… | |

Commissioning year …………… | |

Crane operating mode (passport) ... | |

Operating temperature range (ºС) ... | |

Lifting speed, m / min ……………………… .. | |

Lowering speed, m / min …………………… .. | |

Landing speed, m / min ………………………. | |

Crane travel speed, m / min: Self-propelled with a load of 10 t at the boom position along the longitudinal axis of the chassis Self-propelled without cargo | |

Carrying capacity (t) …………………………… .. | |

Lift height (m) ……………… Departure, m …………………………………………… ... | |

Swing speed, rpm ……………………… .. | |

Material data of the main elements Crane steel structures: | |

Main boom angles …… .. ………………… | 15HSND-12 GOST |

Lower frame…. ………………………………… .. | 15HSND-12 GOST |

Upper frame ……………………………………… | Vst3gps - 5 GOST 380-71 |

Front portal pillar ……………………… .. | 09G2S-12 GOST |

4. The results of the examination

An expert examination of the crane KS-4361 A head. No. 22205,

reg. No. 7646-LH, while it was established:

4.1. The technical documentation complies with the requirements of PB "Rules for the construction and safe operation of cranes".

4.2. Service personnel trained, certified and assigned as required

PB, section 9.4

4.3. The crane is in working order. Violations indicated in the "List of defects" and "Agreed measures" from February 19, 2009 are eliminated.

4.4. The crane has been tested. The test results are satisfactory.

5. Final part.

Commission "TUVIS" February 24, 2009 examined the results of the examination of the pneumatic-wheeled crane KS - 4361 A head. No. 22205 , reg. No. 7646-LH, worked out the standard service life, and came to the following conclusion:

The crane complies with the industrial safety requirements imposed on it and can be approved for operation in accordance with the passport cargo characteristics for a period up to 24.02.2011.

6.1. Operate the crane in accordance with the requirements of industrial safety, operating instructions of the manufacturer and section No. 7 of the Act - inspection.

6.2. After the expiry of the permitted service life, the crane should be presented for re-examination to the Expert Organization.

To be written off

Chairman of the Commission: _________________

Commission members: __________________

__________________

__________________

Application

Agreed: Approved:

General Director Director

_____________ ______________

"__" ___________________ 2009 "___" _______________ 2009

Expert examination program

pneumatic crane KS-4361 A head. No. 000, reg.

1. Checking that the "Customer" has the necessary documentation for the survey.

2. Analysis of the actual operating conditions and maintenance of the crane:

2.2. Crane operating mode.

2.3. Crane working environment.

2.4. Supervising the technical condition, maintenance and repair of the crane,

fulfillment of previously issued instructions.

3. Checking the technical condition of the crane:

3.1. Checking the condition of the electrical hydraulic equipment of the crane installation.

3.2. Visual and measuring control of crane metal structures, hook suspension.

3.3. Visual-measuring quality control of the connection of crane elements

(welded, bolted, hinged, etc.).

3.4. Checking the technical condition of mechanisms, rope-block system and others

units of the crane installation.

3.5. Ultrasonic thickness measurement of crane metal structures.

3.6 Checking the condition and operability of safety devices, terminal

switches and limiters.

3.7. Measurement of the skew of the OPU.

5. Coordination with the "Customer" of the terms of elimination of the detected defects.

6. Additional examination after elimination of the identified defects.

7. Test of the crane for compliance with the requirements of industrial safety and passport

characteristics.

8. Estimation of the residual resource (in points).

9. Registration of technical documentation based on the results of the survey, issuance

The program was developed by

Application

SCROLL

documentation reviewed during the expert examination of the crane

KS - 4361 A head. No. 000, reg.

Title of the document | The owner has it |

|

Insurance policy for high-risk facilities within the framework of the Federal Law “On Industrial Safety of Hazardous Production Facilities” dated 01.01.2001, as amended. | ||

Availability of valid "Rules for the construction and safe operation of cranes" with changes and additions. | ||

Availability of information letters and directives of the Gosgortekhnadzor of Russia. | ||

Order of the state inspector of Gosgortekhnadzor based on the results of the last inspection. | ||

Order on the organization of technical supervision over the safe operation of cranes. | ||

Protocols for checking knowledge of industrial safety and instructions from engineers and maintenance personnel. | ||

Order on admission to work of crane operators. | ||

Job descriptions and guidelines for the safe operation of hoisting machines for responsible persons. | ||

Manufacturing instructions for service personnel. | ||

Log book for accounting and inspection of removable load-gripping devices and containers. | ||

The magazine of inspections and repairs of the hoisting machine. | ||

PPR schedule. | ||

Log book. | ||

Help on the nature of the crane. | ||

Grounding resistance measurement protocol. | not required |

|

Insulation resistance measurement protocol. | not required |

|

Work production project (technological maps). | ||

Cargo slinging schemes (typical). | ||

The passport for the crane with the documentation supplied with the passport of the crane specified in the list. | ||

The crane operating manual supplied by the manufacturer. |

Checked the documentation:

Level III Specialist in the field of EPB PS

Application

LABORATORY

"TUVIS"

PROTOCOL No. 000-1

VISUAL AND MEASUREMENT CONTROL

1.According to the contract No. 07-09 dated 27.01.09. with, visual and measuring control of welded seams, metal structures and mechanisms available for inspection has been carried out pneumatic crane KS-4361 A head No. 22205 , reg. No. 7646-LG. The control was carried out in accordance with the requirements of the RD "Instructions for visual and measuring control" approved by the Resolution of the Gosgortekhnadzor of 11.06.03, No. 92, registered with the Ministry of Justice of the Russian Federation on 20.06.2003, No. 000, with an assessment according to the following standards:

RD 24.090.97-98 “Hoisting and transport equipment. Requirements for the manufacture, repair and reconstruction of lifting cranes ", PB" Rules for the construction and safe operation of lifting cranes ", RD" Methodological guidelines for the inspection of hoisting machines with expired service life. General Provisions "and RD" Guidelines for the inspection of hoisting machines with expired service life. Part II. General purpose self-propelled jib cranes ".

2. During visual and measuring control of metal structures and crane mechanisms

installation revealed the following:

2.1. UCP does not work. Violation of the requirements of clause 2.12.7. PB.

2.2. There is no crane tilt indicator in the driver's cab and on the base frame.

Violation of the requirements of clause 2.12.21. PB.

2.3. Limit switch on hook lift mechanism does not work.

Violation of the requirements of clause 2.12.2. (a). PB.

3. Conclusions based on the results of visual and measuring control: Steel structures, welded seams and mechanisms meet the requirements of NTD. Violations specified in clauses 2.1.-2.2. of this Protocol, to be eliminated within the time specified in the List of defects.

Control performed by: _____________________

VIC Specialist Level II

Visual work supervisor

and measuring control _____________________

Application

LABORATORY

NON-DESTRUCTIVE CONTROL AND DIAGNOSTICS

"TUVIS"

PROTOCOL No. 000-2

based on the results of non-destructive testing

Control date: 19.02.09 g.

Customer enterprise: .

Control object: pneumatic wheel crane KS - 4361 A head. No. 000, reg. ...

Thickness gauge:"VZLOT UT", head. No. verified until December 22, 2009

Converter: P / 2-A-003, head. No. 000, verified until 22.12.2009 .

Control was carried out according to RD ROSEK-006-97 “Hoisting machines. Metal structures. Ultrasonic thickness measurement. Basic Provisions ". At each control point, measurements were carried out at least 3 (three) times, the smallest values were taken as the final thickness.

Control results table

Measurement objects (element, part, assembly unit) | Passport metal thickness of the element (mm) | Metal structure element material | Position of measurement points on the element (see Appendix No. 13) | Thickness measurement result, (mm) | Corrosion wear% | Permissible wear% | Quality control |

Left side (in the direction of the crane) |

|||||||

Lower frame | |||||||

Arrow | |||||||

Right side (in the direction of the crane) |

|||||||

Lower frame | |||||||

Arrow |

Measurement points see Appendix No. 13.

Control results: corrosive wear of the frame and boom metal structures does not exceed

2.5% (maximum permissible norms 10 % p. 5.4 Appendix 9, RD).

Conclusion: The metal structures of the crane are suitable for further operation without any restrictions.

Specialist. Level II Of the Criminal Code

Application

NOTICE OF DEFECTS from 19.02.09

Hoisting machine type | ||||

Manufactured in 1992 by the manufacturer: Yurginskiy machine-building plant |

||||

Belongs. Owner's address: Langepas, Northern Industrial Zone 77 |

||||

Node, element name | Defect description | Maximum allowable defect rates | Conclusion on the necessity and timeframe for the elimination of the defect |

|

Documentation and organization of supervision | Compliant with NTD. | |||

|

constructions | Compliant with NTD. | |||

Rope-block | Complies with NTD. | |||

Mechanisms | Complies with NTD. | |||

Bolted and finger joints | Complies with NTD. | |||

Hydraulic equipment | Complies with NTD. | |||

Safety devices | UCP does not work. | Violation of requirements | Repair or replace safety devices until 24.02.2009 |

|

There is no crane tilt indicator in the driver's cab and on the base frame. | Violation of requirements | Install until 24.02.2009 |

||

Limit switch on hook lift mechanism does not work. | Violation of requirements p. 2.12.2. a). | Renovate until 24.02.2009 |

||

Chairman of the Commission _________________

Responsible for

working condition

capacity of cranes. _____________________________________________

Application

Agreed arrangements for the end of the examination process

industrial safety

on pneumatic crane

KS - 4361 A head. No. 000 reg.

___________________________ 19.02.09 Langepas____________________

(date, place)

The customer's representative confirms with his signature that the agreed activities will be carried out, and a written message about the work performed has been sent to the expert organization.

Application

CALCULATION OF SKETCH

Date: February 19, 2009

Customer enterprise:.

Control object: pneumatic crane KS-4361 A head. No. 000, reg. ...

Calculation completed: according to the requirements of the RD “Methodological guidelines for the inspection of hoisting machines with an expired service life. Part 2. Self-propelled jib cranes for general use. "

D is the diameter of the half-holders;

Δℓ is the distance from the half-ring to the axis of the indicator leg;

ℓ - distance between indicator legs;

a and b - linear displacements (on the scale of indicators);

0 - indicator mounting height.

The displacements are determined as the arithmetic mean value (Ac and Bs) according to the indicator readings during three-fold lifting and lowering of the load.

The distance ℓ between the points where the measurements are made is equal to:

ℓ = D + 2 Δℓ = 1400 + 2 x 100 = 1600 mm,

where: D is the outer diameter of the half-holders; D = 1400 mm;

Δℓ is the distance from the half-holders to the axis of the indicator leg, Δℓ = 100 mm;

The skew φ is determined by the formula:

0 "style =" margin-left: -. 75pt; border-collapse: collapse ">

Name

Mark

to eliminate

Repair the UCP.

Completed

A crane tilt indicator was installed in the driver's cab and on the support frame.

Completed

Repair the limit switch on the hook lift.

Completed

Commission chairman:

Responsible for

supervision of the CPC ____________________________________________

Application

Protocol No. 000-3

on carrying out static and dynamic tests

Test date: 24.02.2009

Commission consisting of: representative of "TUVIS", special. III level in the field of EPB PS, the representative responsible for the supervision of g / c cranes _____________________________, after eliminating the violations indicated in the List of defects dated 02.19.09, conducted static and dynamic tests of the crane KS-4361 A head. No. 000, reg. ...

The tests were carried out on the territory of the base on a horizontal platform in the absence of wind in accordance with the requirements of the PB "Rules for the construction and safe operation of hoisting cranes", RD "Methodological guidelines for the examination of hoisting machines with expired service life. Part II. Self-propelled jib cranes, general purpose and factory operating instructions for the crane. "

Statistical test carried out with main boom ℓ = 10.5 m with 4 m outreach load kg lifted to a height of 150 mm and held in this position for 10 minutes. No residual deformation or lowering of the load was observed.

Dynamic tests carried out by load 17 600 kg, all mechanisms and safety devices functioned satisfactorily. During dynamic tests, the load was raised and lowered three times, as well as the operation of all other crane mechanisms was checked when the working movements were combined.

Test results.

During the tests, the efficiency of crane mechanisms and brakes was confirmed. After the test, the crane was inspected, the bolt and finger joints of the metal structures were loosened, the mechanisms of the crane installation were not found.

Conclusions.

Boom pneumatic wheel crane KS - 4361 A head. No. 000, reg. manufactured by the Yurginsky machine-building plant (Yurga), has passed static and dynamic tests in accordance with the requirements of the Industrial Safety Rules and the international standard ISO 4310.

Note: The sets of test weights were provided by the crane owner and was responsible for their compliance with the actual weight (weight) requirements of the "Rules".

Application

ORDER No. ___________

Langepas 19.02.09

In order to extend the possibility of further use hoisting cranes in the period from 19.02.09 to 24.02.09, an inspection of the lifting machines of our enterprise is carried out. To ensure the specified examination, I order:

1. Take out of service during the inspection period the following hoisting machines:

2. Entrust to ______________________ responsibilities for the preparation of technical documentation and the necessary certificates for the work of the commission, ensuring the conditions for conducting the survey, providing the surveyed cranes with service personnel, test loads, assisting the commission in its work, allocating premises for the commission and ensuring the protection of the commission's property.

3. Assign responsibility and supervision for compliance with the Safety Rules during the survey on responsible for the supervision of g / p mechanisms ________________________ and specialist. ILevel II in the field of electronic safety of the substation "TUVIS"

4. The report of the survey, after its approval, submit to me for consideration.

General manager

Application

REFERENCE

about the nature of the work performed

pneumatic crane KS - 4361 A, head. No. 000, reg.

Maximum weight of the load lifted by the crane 16 t.

The total operating time of the crane since the beginning of operation (years) tk 17 full years.

The number of days in a year when the crane is in operation H 250 days

Number of crane operation cycles per day Сс 20 .

The amount of cargo handled per day 112 T.

Temperature conditions of the crane min. -40 ºС

swing. +40 ºС

Characteristics of the environment in which the crane operates

humidity.

Place of installation: base.

The certificate was compiled by: ________________________

Application

Crane operating mode

The group of the crane operating mode is determined depending on the class of use and the class of loading in accordance with the requirements of ISO 4301/1 Appendix No. 4 PB.

The class of use is characterized by the total number of crane cycles during its operation.

St = Cc h tk = 20 x 250 x 17 = 8.5 x 10 = U3

Where Cc is the average daily number of crane operation cycles;

h is the number of working days in a year;

tk is the total operating time of the crane since the beginning of operation in years.

The total number of crane cycles.

St = 8.5104 corresponds to the class of use U3

According to table 1 of ISO 4301/1

The load class is determined by the load factor:

https://pandia.ru/text/78/041/images/image007_48.gif "width =" 12 "height =" 23 src = ">

Рmax - rated lifting capacity of the crane, t;

Ci is the number of crane operation cycles with uniform loading of the crane over the shift during

St is the average daily number of crane cycles. St = ∑ C і

Loading coefficient Кр = Q1 corresponds to the loading class according to table 1 of ISO 4301/1

With utilization class - U3 and load mode - Q 1

Crane operating mode group - A2 (light)

OUTPUT: Valid Mode Group corresponds to the passport.

(match / not match)

The calculation made

Application

0 "style =" margin-left: -. 25pt; border-collapse: collapse "> boom tilt Nominal Loading UCP loading degree results trials serviceable serviceable serviceable Notes. In the columns “boom length, reach, boom tilt angle, test load”, the index 0 denotes the measured values, and the index 1 denotes the data on the OGP device. In the column "rated lifting capacity" index 0 indicates the lifting capacity corresponding to the measured reach, and index 1 - the lifting capacity of the device. 3. In the column "degree of loading" C0 = QH0 / QH1; C1 - reading of the device

Commission members (signature)

(signature)

table 2

model KS-4361A, reg.

the results of testing the limiters of working movements.

Chairman of the Commission (signature)

Commission members (signature)

(signature)

Table 3

To the test report of crane safety devices and devices

model KS-4361A, registration number 7646-LH

Signaling devices test results.

Chairman of the Commission (signature)

Commission members (signature)

(signature)

Table 6

To the test report of crane safety devices and devices

model KS-4361A, reg. No. 7646-LH

Pointer test results.

Chairman of the Commission (signature)

Commission members (signature)

(signature)

Appendix # 15

Assessment of the residual life of the crane KS - 4361 A head. No. 000 reg. ,

The residual life of the crane was assessed in accordance with

RD7 and RD.

1. Introductory part.

Resource of any crane is defined as the total estimated operating time of the hoisting machine from the start of its operation or from its resumption of operation after repair to the transition to the limit state.

Residual resource - The estimated value of the operating time of the hoisting machine (from the moment of the survey) until the limiting state of its base parts (load-bearing metal structures) is reached according to the criteria of fatigue.

For the inspected crane, the basic parts are:

Boom, elements of its fastening

Outriggers

Support frame

Swing frame

The residual resource will be assessed based on the state of the above-mentioned load-bearing metal structures of the crane.

Basic provisions.

The residual resource is assessed depending on the type of damage according to the following criteria:

Fatigue

Corrosion

For limited fatigue from the action of loads, the working state is checked by calculation:

Boom and elements of its fastening

Outriggers

Fixed frame

Swing frame

According to RD7, for cranes with a lifting capacity of up to 50 tons, it is allowed to determine the possibility of their further operation according to the point system.

In this case, defects belong to three groups

1. Defects in workmanship and installation

Defects caused by gross violation of normal operation.

Defects that have arisen under normal operating conditions in the absence of manufacturing and installation defects.

Each defect corresponds to a certain number of points, determined according to a special table.

If the number of points is 5, the residual life of the crane is sufficient until the next inspection (after repair, the service life can be extended by 2 years).

With a score of 5 to 10, defective load-bearing structures are replaced or repaired.

If the number of points is 10, it is considered that the crane has fully exhausted its resource.

The initial data for the assessment of the residual resource are:

Inspection results of the hoisting machine according to RD7

Number and results of previous crane surveys

Data characterizing the use of the hoisting machine for the entire period of its operation (the number of cycles, the distribution of transported goods by weight, the degree of aggressiveness of the environment, etc.).

Data on the geometry of design elements of a metal structure, taking into account corrosion.

For this crane, the total number of points, according to the table below, is ___ 0,2 ______. This means that the resource of the crane is sufficient until the next examination in ____ 2 _____ years, subject to the elimination of defects identified during the examination.

Defect type | Characteristics of defects |

|||

Manufacturing or installation defects | Defects due to gross violation of normal operation | Defects caused by normal use | Defects identified during examination |

|

Number of points |

||||

1. Violation of paintwork | ||||

2. Corrosion of critical elements up to 5% of element thickness incl. up to 10% of element thickness incl. over 10% of the element thickness | ||||

3. Cracks, breaks in the seams or in the near-weld zone | ||||

4. Cracks, gaps in areas remote from welded seams | ||||

5. Loosening of bolted joints in which the bolts work in tension (as well as wear of the thread of the screw bearings) | ||||

6. Loosening of bolted connections in which bolts are sheared | ||||

7. Deformations of elements of lattice structures exceeding the limit values: 7.2. Lattice elements | ||||

8. Deformations of elements of sheet structures exceeding the limit values | ||||

9. Metal delamination | ||||

10. Crushed eyes and development of holes in the hinges, exceeding the limit values | ||||

11. Any defects arising in the place of the previous repair | ||||

Total points | ||||

Assessed by a Level III specialist

___________________________________

Application

List of used literature

Federal Law "On Industrial Safety of Hazardous Industrial

objects ", dated 01.01.2001, with changes and additions.

2. Federal Law "On Licensing Certain Types of Activities", dated 01.01.2001, dated 01.01.2001.

3. PB "Rules for the examination of industrial safety", (with Amendments No. 1 (PBI 03-490- (246) -02)), approved by the Resolution of the GGTN of Russia dated 01.01.2001 No. 48.

4. RD "Regulations for the examination of industrial safety of lifting structures", adopted by the GGTN of Russia Resolution No. 4 of 01.01.2001.

5. RD "Regulations on the examination of industrial safety of lifting structures", approved by the GGTN of Russia Resolution No. 5 dated 01.01.2001, registered with the Ministry of Justice on 28.03.03, No. 000.

6. PB "Rules for the design and safe operation of cranes", approved by the State State Technical Committee of Russia No. 98 dated 01.01.2001.

7. RD "Instructions for visual and measuring control" approved by the resolution of Gosgortekhnadzor dated 01.01.2001. No. 92, registered with the Ministry of Justice of the Russian Federation on 20.06.2003. No. 000.

8. RD “Guidelines for the inspection of hoisting machines with expired service life. Part 1. General Provisions ", approved by the Resolution of the GGTN of Russia No. 12 dated 01.01.2001.

9. RD “Guidelines for the inspection of hoisting machines with expired service life. Part II. General purpose self-propelled jib cranes ", agreed with the State State Technical University of Russia on 13.11.1997.

10. RD "Typical instructions for engineering and technical workers responsible for the maintenance of hoisting machines in good condition", with amendments RDI 10-395 (30) -00.

11. RD "Standard instruction for persons responsible for the safe production of work by cranes", with amendments RDI 10-406 (34) -01.

12. RD "Standard instruction for engineers and technicians on supervision of the safe operation of hoisting machines", as amended

RDI 10-388 (40) -00.

13. RD "Regulations on the procedure for extending the safe operation period of technical devices, equipment and structures at hazardous production facilities", approved by the GGTN of Russia No. 43 dated 01.01.2001.

14. RD "Hoisting cranes. Typical programs and test methods ", Moscow, PIO MBT, 2002.

15. RD ROSEK-006-97 “Hoisting machines. Metal structures. Ultrasonic thickness measurement. Basic Provisions ".

16. RD "Lifting equipment". General technical requirements.

17. ISO 4310/1 "Cranes, rules and test methods".

18. ISO 4301/1 Hoisting cranes. Classification".

19. GOST "General purpose self-propelled jib cranes". Technical conditions.

Application

LIST of devices and equipment,

used in the survey of the CRANE

1. Ultrasonic thickness gauge "VZLET UT" head. No. 000

with a converter. Verified before December 22, 2009

2. A set of keys and other tools.

3. Visual inspection kit VIK-1... Verified until 22.12.2009:

3 3.1. Universal welder template UShS - 3 - w / n.

3.2. Measuring magnifier LI - 2- 8 * (LI *) - No. 000

3.3. Vernier caliper ШЦ - I -, 1 № 000 with a depth gauge.

3.4. Testing elbow 90º - w / n.

3.5. Metal ruler L - mm) - w / n.

3.6. A set of radius templates No. 1 and No. 3 - unnumbered.

3.7. A set of probes No. 4 - unnumbered.

3.8. Roulette 3 m - w / o

3.9. Flashlight of local lighting.

3.10. Metal marker.

4. Universal welder template (USHS). Verified until December 22, 2009

SPTK "TUVIS"

P R I K A Z

"On the inspection of cranes

expired "

In order to determine the possibility of further use of hoisting cranes that have expired their service life, and in accordance with the contract from No. 07-09 dated 01.01.2001;

P R I K A Z Y V A Y:

2. Appoint a commission for the inspection of cranes in the following composition:

Commission chairman:

passed certification as a specialist in the field

II according to the Criminal Code,

VIK, PVK).

Commission members:

passed certification as a specialist in the field

examination of industrial safety of lifting structures

III level of qualification, specialistII according to VIC)

- passed certification as

specialist in the field industrial safety expertise

lifting structuresII qualification level specialistII according to the Criminal Code,

- passed certification as a specialist in the field examination of industrial safety of lifting structuresI qualification level, specialistII according to the Criminal Code, VIC.

3. Commission to inspect the following cranes v

Hoisting machine type | ||

In the period from February 19, 2009 to April 19, 2009

4. Based on the results of the inspection of the machines, the commission draw up an inspection report and submit it to me for approval.