Russian manufacturers have created an even more powerful machine with a reinforced metal structure of the supporting part. Factory fitted special hydraulic supports make the machine even more stable than previous models. The EK 18 excavator on wheels, unlike tracked vehicles, has good maneuverability. Due to the increase in the support area, it can work on any landscape areas, even and with large slopes.

Multifunctional earthmoving machine intended both for agricultural work and for almost any construction site of various sizes. Development of foundation pits and digging of wells, leveling and excavation of soils of I-IV categories, reclamation, loading, unloading of materials, planning of territories and demolition of old structures made of reinforced concrete, bricks, loosening of rocks. The model is compact, does not scratch asphalt areas, tiles, easily passes through narrow streets between buildings, therefore, it has been evaluated and put into operation by a number of road and communal services in different cities.

Single-bucket unit with a turntable, reduced in radius to 2000 mm, on a pneumatic wheel running from a standard compressor, equipped with a hydrostatic transmission and a pneumatic brake system.

- Speed - 20 km / h (sufficient for heavy equipment);

- Operational weight - 18,000 kg;

- Turning angle - 177 degrees;

- Bucket capacity - 1 cu. meter;

- Digging depth - 5770 mm;

- Unloading height - 6240 mm;

- Radius - 9100 mm;

- Stick - 2200 mm.

When installing arrows of other sizes, for example, 2800 or 3400 mm, the parameters of work (digging) also change, respectively: radius 9420 and 1020 mm; depth 6370 and 6970 mm; unloading heights 6500 and 6750 mm.

Engine characteristics

Engine type - D 245, diesel, liquid cooling. Fuel tank with a capacity of up to 255 liters; fuel consumption - 236 sq. in hour. Power, at a certain speed of the crankshaft, reaches 105 horsepower. On models equipped with Perkins, 123 horsepower. Some of the equipment was additionally equipped with Hydronic 10 and a starting heater, which will facilitate starting at high subzero temperatures. Recording the operating time will help to properly plan the necessary maintenance. With good maintenance of the equipment and the correct choice of lubricants, it will be possible to extend the service life and guarantee the uninterrupted operation of the unit.

Dimensions and cab

Machine length - 9400 mm, height - 3300 mm, width - 2500 mm. Undercarriage - 4700 mm, track width 1800 mm for the inner and 2100 mm. for the outer part of the wheels.

Safe, single cabin, with a large glazing area for an all-round view of the working area. Equipped with a Zenith heater with an air flow distribution system, which excludes freezing and fogging of glass at any time of the year. With a comfortable driver's seat and additional compartments for storing personal and essentials, tools, to eliminate minor breakdowns. Convenient arrangement of instruments and sensors on the control panel, the interior is made of plastic, the insulated door. Additionally, using hydraulics, the cab can be raised to the required height.

Modification and assembly of similar equipment

Domestic components in cooperation of important units from a foreign manufacturer - an ideal combination of quality and price:

- The EK 18 20 excavator is presented on the market in the basic configuration. Model with a capacity of 77 kW, with German-made hydraulic equipment and the Russian engine MMZ 245, manufactured at the Minsk Tractor Plant.

- As a revision of the previous model with imported mechanisms and a hydraulic system - EK 18 30.

- Additional scrap equipment, a hydraulic lifting cabin and the EK 18 40 went on sale.

- EK 18 44 is equipped with a five-jaw gripper model GP-554.

- Special equipment with a power of 90 kW, a Perkins 1104C-44TA engine and Bosch-Rexroth equipment, the name was given to EK 18 60.

Also, the models EO-3323 and MSU-140 can be called similar.

Replaceable equipment

The working equipment is standardly equipped with an excavating bucket with a maximum load of up to 1 cubic meter. At the request of the customer, it can be replaced with a larger bucket and equipped with a hydraulic front dump. The boom is either monoblock or with variable geometry. It is also possible to use a variety of removable (attachment) equipment for dismantling, destruction, cutting. Of which 90% the company produces independently, which additionally allows you to control quality, compatibility and prices:

- Hydraulic hammer- destruction of buildings, crushing of household stones and frozen ground;

- Hydraulic shears- with a full-revolving rotor for cutting concrete structures, cables and wires;

- Log grapple(lifting capacity up to 3000 kg.) - skidding wood at logging areas, stacking logs, other sawn timber and scrap metal (can also be equipped with a full-revolving rotor);

- Single shank hydraulic ripper- excavation work, dismantling, opening of the asphalt concrete crust;

- Digging and loading grab- moving bulk materials of different consistency.

Average cost of construction equipment

Approximate prices for a new bulldozer are from three to four million rubles, in each region the cost will differ.

Today there are many advertisements for the sale of used construction equipment, someone needed a car for a year or two, different brands, equipment and release dates. In some cases, it makes sense to pay attention not to a new one, but to an already used one. As an example:

Chelyabinsk, 2012 - 3,000,000 rubles;

Novosibirsk, 2009 - 1,460,000 rubles;

Stavropol, 2007 - 1,250,000 rubles;

Tomsk, 2005 - 670,000 rubles;

Irkutsk, 2002 issue. - 300,000 rubles.

The range of prices is rather big, from three million to three hundred thousand rubles, there is an explanation for this. Even if the documents are in complete order, the equipment is working properly and passed MOT on time, first of all, the cost will depend on: year of manufacture, operating time, operating conditions, number and scale of breakdowns, appearance. Place of use and sale (geographically) plus the price policy of the store.

The EK-18 excavator is a wheeled excavator equipped with a bucket. This equipment is produced by the RM-Terex company at the Tverskoy Excavator plant. Special equipment is designed for the development of pits, digging trenches, loosening rocks, loading and unloading bulk materials, for performing other work in industrial, urban, municipal, transport construction.

Scope of use

The line of EK-18 excavators, the technical characteristics of which are constantly being improved, are in high demand among construction companies and government organizations. This demand is based on the fact that EK-230-06 excavators and related models combine versatility, productivity and affordable cost. Today, you can buy machines not only on wheels, but also on caterpillar (LC) for work on difficult terrain.

The EK-18-30 wheeled excavator can be used to perform the following works:

- Arrangement of foundation pits for high-rise buildings. Boom reach and bucket volume allow you to open large pits and depths in a few hours. Excellent maneuverability makes it possible to quickly move both along the edge of the pit and inside it. One of the exchangeable buckets is used depending on the type of soil.

- Trenching in various widths and depths. The use of removable sections of the boom and buckets with a certain width helps to make even trenches with a width of 30 cm and a depth of up to 600 cm. Accurate boom control facilitates high-level repairs.

- Quarry development. The EK 12 excavators have the technical characteristics high enough to remove tough overburden, hard rock and frozen ground. The large bucket volume makes it possible to fill the truck body with sand, gravel or limestone in a matter of minutes.

- Construction and repair of hydraulic structures. Excavators EK-18-20 have proven themselves well in the construction of bridges, dams and dams. Having good maneuverability and maneuverability, EK-18-60 excavators are used at all stages of construction, from excavation to leveling.

- Public works. Within the city limits EK-14 - wheeled excavator - is an irreplaceable technique. With its help, the repair of sewerage, heating mains and water supply is carried out. Maneuverable equipment quickly and efficiently digs holes for sewer and communication wells.

See also: Excavator-planers for earthmoving work

Excavators EK-8-20 2005 are in demand among owners of summer cottages and country houses. The multifunctional equipment is ideal for the construction of underground structures, the creation of embankments, the laying of communications, the construction of foundation pits.

Dignity

Models 14 and 16, the EK excavator, are developed on the basis of equipment that has passed many years of testing in various climatic and weather conditions. The use of modern technologies has significantly improved the technical characteristics of the EK-270L excavators. The earthmoving units are distinguished by their high reliability and long service life.

The technique has the following positive features:

- Wide temperature range of use. The earthmoving machine can operate at temperatures of -45 ... + 45 ºС. This ensures high demand (including for the EK-400 excavator) throughout Russia, in the near and far abroad.

- Limited platform turning radius. This solution makes it possible to work in confined spaces without the risk of damage to the boom and surrounding objects.

- Increased reliability and durability of the undercarriage. All units and mechanisms are made of high quality steel. The welds are made using an inert gas supply, which gives them solidity and resistance to corrosion.

- Convenient control of working bodies. The EK-270 excavator is equipped with a spacious cabin with panoramic windows. The cabin is completed with an ergonomic chair with several settings. The description of the controls contains precise instructions on how to use them. Levers and buttons are easy to press.

- Increased lifting capacity. The boom is equipped with two cylinders. This allows you to work with massive loads lifted in one step. The performance of the equipment is changing for the better.

- Simplicity of design and reliability. All units of the earthmoving machine are designed to withstand full load over a long period of time. If individual parts fail, repairs are carried out quickly, without sending equipment to a service center.

- High speed performance. Wheeled excavator Kraneks EK-270 can cover long distances, moving under its own power. This allows you to save on transport services by avoiding transportation on a trailer or railway platform.

See also: Single-bucket wheel excavator EO-3322

The parameters of the boom make it possible to attach various modifications of auxiliary equipment to it. At low cost, earthmoving equipment replaces several machines with a narrow specialization.

Optional equipment

Tracked and wheeled units manufactured by the Tver Excavator Plant are adapted to work with attachments of domestic and foreign production. In most cases, they are installed by one operator.

Extending the functionality of the excavator is carried out by installing the following devices:

- Various bucket modifications. They are used to work with bulk material of a certain density and hardness. Narrow buckets are used for trenching and rock removal. Wide buckets are used for stripping, soil and limestone pick-up. The width of the buckets varies between 30-80 cm, and the volume is 0.4-0.85 m³. Buckets provide for the installation of crowns, which significantly increase the resource of the tool.

- Ripper. Made of high strength hardened steel. Designed to demolish asphalt and concrete pavements, curbs and thin walls. When working with soil, it opens the frozen layer, loosens the compacted surface for subsequent excavation with a bucket.

- Drilling rig. It allows you to make holes with a diameter of up to 30 cm and a depth of up to 20 m. It is used for drilling water wells, making holes for poles and supports. In the subsidiary farm, pits for seedlings and supports for the fence are made with the help of a drill.

- Boom sticks. They are used to increase digging depth and lift height. Comes with buckets or separately. The length of the interchangeable handles varies between 220-340 cm.

- Grapple. It is used for loading and earthworks. Creates depressions in soft soil, captures bulky material (hay, branches, tops).

- Magnetic washer. It is used to collect small and large fragments of scrap metal up to 200 cm in size and weighing up to 50 kg.

- Hydraulic hammer. It is a more powerful analog of a jackhammer. It is used for the dismantling of roads, residential buildings and engineering structures. When laying communication lines, it is used to crush rocks and stones. When installing the slab, it is used for compacting the soil.

- Mulcher. It is capable of chopping branches up to 10 cm thick into chips. Destroys wood from the roadside in a strip up to 6 m wide. If necessary, it is used in the process of laying and cleaning glades. In the private sector, he grinds sawn trees without entering the courtyard.

Read Also: All Necessary Excavator Driving Information For Beginners

A truck body or a two-axle trailer is sufficient to transport the entire set of accessories.

Specifications

The manufacturer is constantly working to improve the performance of the EK series excavators. Today, this technique is practically not inferior to foreign counterparts, and in some respects it surpasses them.

The general technical characteristics of the wheeled earthmoving machine are as follows:

- length - 8200 mm;

- width - 2500 mm;

- height - 3140 mm;

- weight without refueling - 14200 kg;

- highway speed - 25 km / h;

- minimum turning radius - 850 cm;

- wheels - pneumatic, with a protector 12.00-20;

- the maximum overcome rise - 32º;

- cruising range - 400 km.

Earthmoving equipment parameters:

- bucket capacity - 0.35-0.85 m³;

- maximum stele throw - 960 cm;

- digging depth - 540 cm;

- bucket lifting height - 650 cm;

- lifting capacity - 1200 kg.

A complete cycle, consisting of lowering the bucket, grabbing material and unloading the soil, takes no more than 15 seconds, which is a very high indicator.

Power plant characteristics:

- engine - diesel MMZ with water cooling;

- power at 2200 rpm - 124 hp;

- engine volume - 4.5 liters;

- fuel tank volume - 250 l;

- fuel consumption on the highway - 25-30 liters per 100 km;

- fuel consumption in excavator mode - 11-13 l / h.

The gearbox has 4 forward gears (including low gear) and 1 reverse gear. The front-wheel drive ensures high cross-country ability of the equipment when working in off-road conditions.

Due to the optimal combination of indicators such as price and quality, the equipment of the Tver Excavator Plant has practically no competitors. Wheeled and tracked excavators of the EK series are highly appreciated all over the world, as evidenced by their large export deliveries.

Digging parameters of the TVEX EK 18 excavator

| Stick, m | 2,2 | 2,8 | 3,4 |

| Digging radius, m | 9,1 | 9,65 | 10,2 |

| Digging radius at parking level, m | 8,85 | 9,42 | 10,0 |

| Kinematic digging depth, m | 5,77 | 3,67 | 6,97 |

| Unloading height, m | 6,24 | 6,5 | 6,75 |

| Bucket swing angle (deg.) | 177 | 177 | 177 |

| Maximum bucket capacity (SAE), m 3 | 1,0 | 0,77 | 0,65 |

| 1 | handle 2.2 m |

| 2 | stick 2.8 m |

| 3 | stick 3.4 m |

- Digging grapple

- Hydraulic hammer

- Hydraulic shears

- Ripper

- Log grapple

- Hydraulic shears NG-1624

- Ripper 225-00-40.17.400

| 1 | handle 2.2 m |

| 2 | stick 2.8 m |

| 3 | stick 3.4 m |

Replaceable types of working equipment for TVEKS EK-18 excavator

- Digging grapple

- Loading grab (five-jaw)

- Hydraulic hammer

- Hydraulic shears

- Ripper

- Log grapple

Dismantling and destruction of brick, concrete and reinforced concrete structures of medium strength, including cutting of reinforcement, destruction of metal structures, cutting of metal scrap, charge. Loading and unloading of bulk and non-bulk cargo from open-top wagons.

A bucket with a volume of 1 m 3 can be replaced by:

- Replaceable sticks L = 2200 mm, 2800 mm, 3400 mm and with buckets, respectively, V = 0.77 m 3, 0.65 m 3.

- Hydraulic hammer MG-300, designed for the destruction of concrete and reinforced concrete road surfaces, brick structures, unreinforced concrete and other similar works, including loosening frozen soil and compacting loose soil.

- Hydraulic shears NG-1624

- Ripper 225-00-40.17.400

- Log grapple 313-00-40.12.000 with a carrying capacity of 3 tons for loading and unloading operations and stacking of logs and other sawn timber. The log grapple can be equipped with a full-turn rotator.

- Digging grab and grab for bulk materials.

There is an option of execution with two pairs of outriggers.

Engines of the Perkins firm fully comply with all international environmental requirements and have a number of significant advantages:

- twice the resource and warranty period of service in comparison with domestic engines;

- 10% more torque;

- ensuring fuel economy by 10-20%, depending on the type of work;

- reduction of maintenance time by 20% due to increased intervals between maintenance;

- reduction of noise and vibration at the operator's workplace.

Used materials of JSC "Tverskoy Excavator", http://www.tvexc.ru.

Photos TVEKS EK-18 wheeled excavator

Additional Information

The technical characteristics of the Tveks EK-8, EK-12, EK-14, EK-18, EK-18-40 wheeled excavators and the Tveks 5846 (EA-17) car excavator manufactured by the Tverskoy Excavator plant are summarized in one table

In the line of the Tver plant, the EK-18 model is the flagship with the highest carrying capacity. The main features of the technology (reliability and durability) are due to the reinforced structure of the metal structure.

A cubic meter bucket and two boom-lifting cylinders allow the EK-18 to cope with the movement of heavy loads.

This technique is a pneumatic wheeled hydraulic excavator used for demolition and demolition of reinforced concrete, brick and concrete structures with medium strength. The model is also used for the destruction of metal structures, cutting scrap metal, cutting reinforcement and loading and unloading non-flowing and loose soils. The technique has also found application in various tasks of dismantling objects made of concrete and other structures made of similar materials.

EK-18 is designed to work with mounted grabs with different levels of functional orientation. The most popular are mobile modifications with a wheeled chassis, but there are also heavy versions on a tracked chassis.

The EK-18 is a truly multi-purpose earthmoving machine. Through it, you can dig quarries, trenches and pits in soils belonging to I-IV categories, as well as load frozen soils and loosened rocks with a piece of less than 200 mm.

Excavator modifications EK 18-20, 18-30, 18-40, 18-44, 18-60

Tverskoy Excavator produces several modifications of this model:

- classic EK-18;

- EK-18-20 with increased productivity and a bucket with a volume of one cubic meter. Thanks to the additionally reinforced metal structure of the equipment, the technician can work in difficult conditions. For the EK-18-20, the manufacturer offers a huge selection of replacement working equipment. Moreover, the model itself is considered the most powerful multifunctional machine;

- EK-18-30 is an analogue of EK-18-20 with similar characteristics. The only difference is the availability of imported hydraulics;

- EK-18-40 is a hydraulic pneumatic-wheeled excavator equipped with a grab gripper. A special version designed for loading timber and scrap metal. Additionally equipped with a hydraulic lifting cabin and scrap equipment;

- EK-18-44 is a special pneumatic version with a 5-jaw GP-554 grab with a capacity of 0.65 cubic meters, a hydraulic lifting cabin, a full-revolving rotator and scrap equipment. Used for loading / unloading open wagons and loading timber and scrap metal;

- EK-18-60 is equipped with a Bosch-Rexroth travel motor, a hydraulic pump and a Perkins unit.

- Wheeled excavator Tveks EK-18-90 (M) is an evolutionary continuation of the previous model. Redesigned working equipment, more powerful engine.

The main advantages of the EK-18:

- stability;

- powerful motor;

- advanced cockpit;

- long period of operation and reliability;

- high performance;

- ease of management and ease of maintenance;

- multifunctionality;

- thoughtful arrangement of instruments and indicators on the control panel.

Specifications

The excavator weighs 18,000 kg. EK-18 dimensions:

- length - 9400 mm;

- width - 2500 mm;

- height - 3250 mm;

Operational parameters of the model:

- bucket capacity - 0.65 (0.77; 1) cubic meters;

- unloading height - 6240-6750 mm;

- digging radius - 8850-10000 mm;

- digging depth - 5770-6970 mm;

- bucket rotation angle - 177 degrees;

- The maximum vehicle speed is 20 km / h.

Fuel consumption

The fuel consumption of the EK-18 is 236 g / kWh. In this case, the model's fuel tank holds up to 255 liters.

Engine

EK-18 boasts a powerful 4-stroke 4-cylinder diesel unit "D-245" with a liquid cooling system and direct fuel injection. The engine is started through an electric starter. The power plant is equipped with additional elements manufactured in Germany. Some modifications of the EK-18 are equipped with the British "Perkins" unit with increased power.

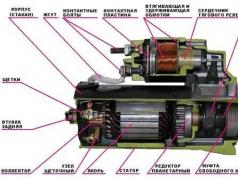

The D-245 motor has a vertical in-line arrangement of cylinders. The main assemblies of a power plant are the crankshaft, cylinder block, flywheel, pistons, cylinder head and connecting rods. The use of a turbocharger with variable boost pressure provides improved throttle response and increased torque.

Engine parameters "D-245":

- working volume - 4.75 l;

- power - 105 hp;

- maximum torque - 385.5 Nm;

- rotation frequency - 2200 rpm;

- cylinder diameter - 110 mm.

Optional equipment

EK-18 can be equipped with additional systems and modules. For this model, Tverskoy Excavator offers:

- ripper 225-00-40.17.400, which allows you to remove various elements from the soil, carrying out global cleaning;

- hydraulic hammer MG-300. It is used for dismantling a variety of wooden, concrete and brick buildings and structures. Also, a hydraulic hammer is used to compact a loose earth layer and loosen frozen soil;

- hydraulic shears IG-821 and IG-811. This element has additional equipment that provides the necessary rotation of the scissors, which allows you to significantly expand the list of operations performed;

- log grab MG-300. It is used for unloading, loading, stacking logs and has a lifting capacity of 3000 kg. Additionally, it can be completed with a full-turn rotator;

- grab GK-221. It is used to perform operations for unloading and loading materials and soil development.

Price new and used

The new EK-18 excavator will cost 4-4.5 million rubles. Used options are much more affordable. So, for the 2008-2009 model in good condition, you will have to pay 1-1.8 million rubles. Cars until 2000 are offered for 400-500 thousand rubles. Renting an excavator costs about 8,000-10,000 rubles per shift.

Analogs

The EK-18 analogs are the EO-33211 and EO-4321 models.

In the Tver plant's line of the same name, the Tveks EK 18 wheeled excavator is the most powerful unit, characterized by excellent carrying capacity. The reinforced structure of the metalwork of the working equipment determines the main advantages of the equipment - durability and reliability.

Two boom cylinders and a cubic meter bucket make it easy to handle moving loads. The developers also paid attention to the operator's cabin. In addition to its ergonomics, it is characterized by an excellent overview of the area of excavation and other types of work.

Tveks EK 18 are equipped with the most powerful engine of the D-245 type, the power of which is 105 horsepower. It is equipped with a pre-heater, which the manufacturer receives directly from Germany. By individual order, it is possible to equip equipment with a Perkins diesel engine (Great Britain), as well as imported hydraulics.

Thanks to the possibility of using the sticks in three versions - 3.4, 2.8 and 2.2 meters - it is possible to install buckets with a volume of 1, 0.77 and 0.65 cubic meters. m respectively.

With regard to the "price-quality" indicator, the model under consideration has no domestic analogues on the market. More or less similar solutions can only be offered by a few foreign manufacturers.

It is possible to equip the excavator with replaceable (additional) equipment:

- a hydraulic hammer - destroys road surfaces made of reinforced concrete, concrete (including unreinforced concrete) and brick, loosens the soil (including frozen), ramps up loose earth;

- ripper - breaks open frozen soil and asphalt concrete pavement, is used to remove curb stones;

- grab - necessary for digging and loading and unloading. It can be supplemented with a full-turn hydraulic rotator and an extension;

- with a log gripper with a carrying capacity of 3 tons - stacks logs, participates in the implementation of the PRP;

- hydraulic shears - used in the process of concrete breaking operations. Equipped with a rotator.

Application

The TVEKS 18 excavator easily copes with soils of any category, which makes it possible to use the equipment everywhere. The main works for which the EK-18 is used:

- territory planning;

- loading and unloading operations with pallet cargo;

- demolition of construction sites;

- career work;

- production of excavations - pits, trenches;

- other types of construction and agricultural work.

Modifications

There are several modifications of the equipment, the main distinguishing features of each model are the hydraulic system and the motor. The latter can be installed in foreign or Russian production. The overseas unit is characterized by higher power, economy and longer periods between maintenance.

| Model | EK-18-20 | EK-18-30 | EK-18-60 | EK-18-90 |

|---|---|---|---|---|

| Engine | MMZ 245S | Perkins 1104C-44TA | D-245 2S2 | |

| engine's type | Diesel, liquid cooling | |||

| Engine power, h.p. | 105 | 123 | 122 | |

| Hydraulics | PSM | Bosch-Rexroth | ||

| Stick, m | 2,2/,2,8/3,4 | |||

| Bucket capacity, cubic meters m | 1,0/0,7/0,65 | |||

| Digging depth | 5,77/6,37/6,97 | |||

| Unloading height, m | 6,24/6,5/6,75 | |||

| Cycle duration, s | 18,5 | |||

| Travel speed, km / h | 20 | |||

| Overall dimensions, mm | 9360/2500/3158 | |||

| Equipment weight, t | 18,4 | |||

EK-18 modifications:

- standard model EK-18;

- TVEKS EK-18-20 is characterized by increased efficiency; a standard working body (bucket) with a capacity of 1 cubic meter is installed on it. m. All equipment components are manufactured in Russia. The main frame is reinforced to ensure high performance in tough working conditions. TVEKS 18-20 can be equipped with a large number of additional working bodies. This modification is considered the most powerful and multifunctional;

- EK-18-30 is the previous model with an improved foreign-made hydraulic system;

- EK-18-40 has a clamshell gripper as a working body as standard. This special equipment is most often used in logging and scrap metal recycling enterprises. Optionally, this model can be equipped with a lifting cabin (using hydraulics) and a scrap body;

- EK-18-44 is an improved version of the previous model. Here, a hydraulic lifting cabin, a scrap organ, a five-jaw grab with a capacity of 0.65 m3, and a full-revolving rotator are installed as standard. Its main purpose is loading and unloading of gondola cars, as well as work for which the EK-18-40 modification is intended;

- TVEKS EK-18-60 is equipped with a hydraulic propeller motor jointly produced by Bosch and Rexroth, a hydraulic pump, and a power plant manufactured by Perkins;

- EK-18-90M is the latest development of the manufacturer, in which axles with limited slip differentials are installed, due to which the ability to overcome difficult sections is improved. The steering wheel made in Italy is smaller, which creates a more comfortable working environment for the operator. In addition, the cab has increased rigidity. The power plant is characterized by increased power indicators, which favorably affects the efficiency of the equipment. Sticks of various sizes are optionally installed, 2.2 m is used as a standard one. Increasing its length contributes to deeper digging, but the capacity of the working body is reduced.

Specifications and dimensions

To increase the carrying capacity of TVEKS 18, it is planned to install two boom-lifting hydraulic cylinders and a bucket with a volume of 1 cubic meter. m.

The main technical characteristics of TVEKS EK-18 include:

- weight - 18 tons;

- the capacity of the working body of the standard assembly - 0.65 m3, 0.77 m3, 1 m3;

- unloading height - from 6.24 m to 6.75 m;

- digging radius - from 8.85 m to 10 m;

- digging depth - from 5.77 m to 6.97 m;

- the angle of rotation of the working body - 177 degrees.

The characteristics of heavy construction equipment depend on the modification. The machine demonstrates high performance at ambient temperatures from -40 to +40 degrees. Thus, it can work not only in Russia, but also in other countries.

EK-18 dimensions: 9.4 mx 2.5 mx 3.25 m (5.25 m with the cabin raised). Depending on the modification, the dimensions of the equipment may deviate from those indicated by 0.1 - 0.2 m.

Engine

The high performance of TVEKS 18 is due to the installation of a powerful 4.75 liter D-245 engine. It is a 77 kW or 107 horsepower four-stroke four-cylinder power plant. It is equipped with a water cooling system and a direct fuel mixture supply system. The rotation frequency is 2200 revolutions per minute of operation. Diesel fuel is used, the unit is started by means of an electric starter. The engine accessories are manufactured in Germany. Modifications can be equipped with a Perkins engine, model 1104C-44TA with a capacity of 123 horsepower.

The cylinders of the domestic engine with a diameter of 110 mm are arranged in a row, vertically. The main components of the motor are connecting rods, pistons, cylinder block, cylinder head, flywheel, crankshaft. They are all serviceable. To increase the performance of the power plant, turbocharging is used, which ensures an increase in torque to a maximum value (386 Nm) and acceleration. The blowing force is controlled by the operator.

To start the engine in frosty weather, a prestarting heater made in Germany "Hydronic 10" is provided.

The EK-18 fuel consumption is 236 g / kW per hour of operation, the diesel fuel tank holds 255 liters.

PRICE PER CHANGE 10 000 RUB.

Specifications: Digging parameters:

- Weight, t 14

- Bucket capacity (SAE), m3 0.8 (0.4; 0.5; 0.65)

- Length, mm 8200

- Width, mm 2500

- Height, mm 3140

- D-245 engine

- Engine power, hp with. 105

- Cycle time, s 16

- Hydraulic system pressure, MPa 28

- Travel speed, km / h 25 (20)

- Stick, m 1.9

- Digging radius, m 8.2

- Digging radius at the parking level, m 7.92

- Kinematic digging depth, m 4.89

- Dumping height, m 5.72

- Bucket swing angle (degrees) 173

- Maximum bucket capacity 0.8

The EK-18 hydraulic wheeled excavator is rightfully called the flagship among similar special equipment. It is distinguished by its high load-carrying capacity and reliability in operation. Its design has a solid reinforced base, which allows the representatives of this model to be used for work on the dismantling of buildings and other objects.

Excavator EK 18-20

The EK 18-20 multifunctional excavator is designed to perform versatile functions. The main one is earthmoving. It can be used to dig:

- foundation pit;

- trenches for laying communications;

- quarries.

The durable material from which the attachment is made is suitable for digging frozen soils. Also, this excavator can be used for loading loosened rock, if the size of one piece does not exceed 20 centimeters.

This model is considered the most powerful of the entire family and is recommended for working with loads of increased mass, destruction of reinforced concrete structures and brick walls, cutting reinforcement and unloading bulk materials.

Excavator EK 18-20, prices

The advantages of the EK 18-20 excavator, the prices of which we offer to find out by phone from our managers, include the duration of operation and reliability. It is stable on any soil, has a powerful motor and shows high performance results. It is not only easy to operate, but also easy to maintain. Its cab provides the operator with a wide view of the terrain. Its arrangement is unique in that the manufacturer has focused on the safety and comfort of operating the equipment.

Single bucket excavator EK-18

The main orientation of the machine is to work with attachment grabs. Special equipment is a versatile machine that has a wide range of applications. A well-equipped cab is installed on the machine. The engineers developing this technique paid great attention to the control, which was reflected in the maneuverability of the excavator. The layout of the cab itself has been revised to significantly increase the operator's maximum visibility. A large number of additional removable attachments are provided. This made it possible to make the EK-18 excavator a rather competitive machine in relation to advanced foreign counterparts.

Design features

A special steel cabin is installed on the excavator, which has a load-bearing frame made of a tubular profile. It is glazed from four sides and from above. The upper part of the front window can be slid under the roof and the lower part can be removed using a lever mechanism. There is a top hatch on the roof. A heater is installed inside, the narrow steering column is adjustable in tilt angle. The seat is equipped with a mechanical suspension, it is possible to adjust the armrests and the headrest. There is a compartment for the driver's personal belongings, a place for a drinking water tank, there is also a first-aid kit and a fire extinguisher. The cab itself is mounted on hydraulic vibration dampers.

To monitor the operating parameters of the machine, there is a dashboard on which an hour meter, an indicator of the temperature of the hydraulic oil, and an indicator of the voltage of the on-board network are installed.

The Tveks EK-18 excavator has a pneumatic running device, the features of which are expressed by steel wheel fenders with an anti-slip surface, there are footboards on the right and left sides, a steel basket for canisters is provided on the left footboard, on the right there is a toolbox, the blade is parallelly lowered forward, behind outriggers are provided.

The hydraulic system is used for smooth operation of the machine, ensuring high productivity. At the request of the customer, instead of the standard configuration, the equipment can be equipped with Bosch-Rexrot hydraulic equipment, which includes a hydraulic valve, a pump unit, hydraulic motors, and control units.

The turntable is represented by an independent liquid preheater for the engine, anti-slip gaskets in the access points, handrails located on the right side of the platform itself, and a fuel water separating filter.

Specifications

This technique is presented in various modifications, so the EK-18 excavator has different technical characteristics, but they do not differ much from each other. The main difference between the manufactured models is the installed engine and hydraulic system, which can be of domestic or foreign production.

The EK-18, EK 18-20, EK 18-30 models are equipped with a D-245 four-stroke four-cylinder diesel engine with a liquid cooling system. With the help of an electric starter, the motor is started. This engine has a vertical in-line arrangement of cylinders. The increased torque is achieved through the use of a pressurized turbocharger.

The EK 18-60, EK 18-47 models are equipped with an English Perkins 1104C-44TA engine produced by the company of the same name. It is a horizontal four-cylinder turbocharged diesel engine. It is distinguished by a cast cylinder block, a cast-iron exhaust manifold, reduced emission of harmful substances into the atmosphere, and reduced fuel consumption.

- work in quarries;

- align sites;

Optional equipment

The EK 18-60, EK 18-47 models are equipped with an English Perkins 1104C-44TA engine produced by the company of the same name. It is a horizontal four-cylinder turbocharged diesel engine. It is distinguished by a cast cylinder block, a cast-iron exhaust manifold, reduced emission of harmful substances into the atmosphere, and reduced fuel consumption.

The mass of the base model is 18 tons, the fuel consumption of the EK-18 is 236 g / kW per hour, the length is 9.4 meters, its width is 2.5 meters, and its height is 3.25 meters, the capacity of a standard bucket is 0.65 meters. cub. The maximum unloading height reaches 6.75 meters.

Scope of use of the Tveks excavator

The universal technique has a wide field of application, which affects the increased interest in it from buyers who want to buy a Tveks EK-18 excavator to solve certain problems. With the help of special equipment, you can perform:

- work in quarries;

- align sites;

- development of soil of all four categories;

- destroy structures of medium strength;

- loading and unloading of various materials;

- loading and unloading, stacking of various sawn timber, logs;

- performance of other works in municipal, forestry, agriculture, used in industrial enterprises, in construction.

Optional equipment

For this special equipment "Tverskoy Excavator" offers additional equipment, upon purchasing which from Tveks EK-18 the price will be higher, and its scope of use will also expand. Attachments are represented by the following types:

- Hydraulic hammer MG-300. They are used for demolition work of concrete, brick, wooden structures and buildings. It can also be used to loosen frozen ground layers, compact loose soil.

- Log grapple MG-300. It has a lifting capacity of up to 3 tons, it is designed for various loading and unloading operations with logs, their stacking. Also, at the request of the customer, the manufacturer can complete it with a full-revolving rotor.

- Ripper 225. Designed to remove various elements from the soil by carrying out a complete cleaning.

- Grab GK-221. It is in demand when carrying out work on loading and unloading materials, and is also used for soil development.

- Hydraulic shears NG-1624. Thanks to additional equipment, the scissors can be rotated, which significantly expands the operations performed.

- Loading grab (five-jaw).

Excavator performance

Designers are constantly improving the workflow of this machine, with the main goal of increasing its productivity. This is reflected in the increased cross-country ability and good maneuverability of the machine, which were achieved thanks to the use of limited slip differentials used in the construction of the running axle. Bucket capacity, hydraulic transmission, powerful engine, use of additional equipment provide this technique with the highest performance and increase its productivity.

The EK-18 earthmoving machine, manufactured by RM-Terex, is a universal technique with a wide field of application, distinguished by the quality of production of all units and assemblies, good technical characteristics, and the ability to compete with any modern counterparts, both domestic and, accordingly, and foreign production ...

The EK-18 excavator is a wheel-type vehicle manufactured by the Tver plant (known as TVEKS). This excavator is often used in various construction works, both large-scale objects and roads. Unlike its tracked counterparts, the EK-18 has a fairly high travel speed, at least for an excavator. And also it does not damage the area on which it works, thanks to which this excavator can be used on asphalt areas and other similar surfaces. It is worth noting that of the entire line of machines of this manufacturer, the EK-18 excavator is the most popular, since it differs from the others in its increased carrying capacity, reliability and durability. The base model is equipped with a D-245 diesel engine developed at the Minsk Motor Plant, which is often found in MTZ tractors. This engine is capable of delivering maximum power at a certain crankshaft speed, 77.2 kilowatts or 105 horsepower. But on some modifications, a power unit from the manufacturer Perkins is installed, this engine is slightly more powerful than the previous one and is capable of delivering a maximum power of 90 kilowatts or 123 horsepower. An excavating bucket with a volume of one cubic meter is installed from the factory, but if necessary, it can be replaced with a larger one and vice versa.

Navigating the article

Appointment

The main field of this excavator is construction. The EK-18 has proven itself quite well due to its versatility, since almost all construction and dismantling work can be performed using this machine. First of all, it is intended for carrying out earthmoving processes, namely, this is the digging of trenches and pits, as well as their filling (due to the presence of a hydraulic frontal blade). The standard cubic meter bucket can also be used for loading and unloading bulk cargo.

In order for it to be used in the process of dismantling work, special equipment is installed to it, with the help of which it performs such work as the destruction of brick and concrete structures, cutting scrap metal and much more.

Attachments

As we can see, the EK-18 excavator has a fairly wide purpose. This is due to the presence of additional equipment necessary to perform a certain job. This machine uses the following attachments:

As standard, the excavator is equipped with a front hydraulic blade, which is used to level the working area and fill various holes (including trenches). It also has an excavating bucket, the volume of which is one cubic meter, but if necessary, this bucket can be replaced with a larger one or vice versa, depending on the type of work.

When doing earthmoving, almost every technique needs high stability in order to avoid tipping the machine. For this, special hydraulic supports are installed as standard, usually located at the rear of the excavator, on the sides. Also, the EK-18 has these supports from the factory.

In addition to the basic equipment, this excavator also uses additional attachments, with which it mainly performs dismantling types of work. This set consists of the following hydraulic attachments:

- Hydraulic hammer model MG-300. It is the main unit that is used to destroy various road surfaces, both concrete and reinforced concrete. It can also be used for construction purposes, namely for loosening frozen soil, and for tamping soil with a loose structure. Installed on an excavator boom instead of a bucket.

- Hydraulic shears or concrete breaking equipment. There are only two models of these units, namely IG-811 and IG-821. It is also used for dismantling purposes, namely the destruction of brick structures and biting of scrap metal. It can also be used for the complete dismantling of railways, where an excavator with this equipment cuts the rails and moves them for further loading. The scissors have a rotator that allows you to turn not any required angle. They are installed in the same way on the excavator boom instead of the excavation bucket.

- Loosening equipment. It is used not only for dismantling purposes, but also in construction, where it loosens frozen soil for further operations. For any excavator, including the EK-18, there is only one-shank hydraulic ripper. The installation is exactly the same as with the previous units - on the boom instead of the bucket.

In forestry, the EK-18 excavator uses a hydraulic log gripper, which, like the shears, has a full-turn rotator. It is mainly used for loading and unloading operations, but also, using this equipment, the excavator is capable of stacking logs. Installed on the boom instead of an excavating bucket without the use of a special adapter (however, other units do not need it either).

Modifications

The EK-18 excavator, like all other special equipment, has modified versions designed for a certain type of work. In total, six modified versions have been developed, such as:

- Modification EK-18-20. From the factory, this version of the excavator is equipped with an excavating bucket with a volume of one cubic meter. In contrast to the base machine, this modification has increased productivity, and is also adapted for doing work with a fairly high load. This is due to the additional structural reinforcement of all excavator equipment. And it can also be aggregated with all available additional attachments, which made it possible to expand the range of tasks performed by this model. Among all the modifications, the EK-18-20 is a multifunctional and most powerful technique.

- Modification EK-18-30. In fact, this is a revision of the previous version of the excavator, in which an imported hydraulic system is installed, including its mechanisms. In terms of technical characteristics and appearance, the excavator of this model is completely identical to the previous one.

- Modification EK-18-40. It is a hydraulic pneumatic wheeled excavator, which has a special grab gripper from the factory. This model has found its application in all areas where loading of various materials is required, but mainly timber and scrap metal. Also, of the main differences of this version from the previous ones, it should be noted that a hydraulic lifting cabin and scrap equipment are installed on the EK-18-40. In technical terms, there are no changes.

- Modification EK-18-44. It is a special pneumatic modified version, which is equipped with a five-jaw gripper model GP-554. This equipment has a volume of 650 cubic centimeters. The cab of this model is hydraulic lifting. There is a special full-revolving rotator for mounted hydraulic units. Scrap equipment is also installed, as in the previous modification,

- Modification EK-18-60. It differs from the previous ones by another power unit, namely this four-cylinder diesel from the manufacturer Perkins. There is a Bosch-Rexroth travel motor and a dedicated hydraulic pump. There are no more changes.

- Modification of EK-18-90M. It is a deep revision of the EK-18-60 modification, in which the design of the working units of the excavator was changed and an improved engine was installed, which differs from other units with increased productivity (the manufacturer is the same - Perkins).

Specifications

The operating weight of the EK-18 excavator (basic model, as well as modified versions) is 18,000 kilograms. In length, this machine, taking into account the boom, has a value of 9400 millimeters. The width is 2500 mm. The height of the excavator is 3300 millimeters.

With a 2200 mm stick installed, the digging parameters have the following values:

The digging radius is 9100 millimeters when the radius at the parking level is 8850 millimeters. Digging depth (kinematic) has a value of 5770 millimeters. The unloading height of various cargo is 6240 millimeters, which is quite enough for a full-fledged earthmoving work. The angle of rotation of the excavating bucket is 177 degrees. The maximum capacity of a standard excavating bucket (calculated in SAE) is exactly one cubic meter.

With a 2800mm stick installed, the digging parameters are as follows:

The digging radius has a value of 9650 millimeters. The digging radius at the parking level is 9420 millimeters. The kinematic digging depth is 6370 millimeters. The maximum unloading height has a value of 6500 millimeters. The angle of rotation of the excavating bucket is also 177 degrees. The bucket used with this stick has a volume of 770 cc.

With the largest, 3400mm stick installed, the digging values are as follows:

The maximum digging radius is 10,200 millimeters, at the parking level it is exactly 10,000 millimeters. The kinematic digging depth, which is also the maximum achievable, has a value of 6970 millimeters. The maximum dumping height is 6750 millimeters. The maximum bucket swing angle is 177 degrees. In this case, the standard bucket has a volume of 650 millimeters.

The base model and some modifications (EK-18-20, EK-18-30) are equipped with a four-cylinder diesel unit developed by the Minsk Motor Plant. This engine is named as D-245. It is capable of delivering rated power at a certain crankshaft speed, 77.2 kilowatts or 105 horsepower. Modifications such as EK-18-60 and EK-18-90M are equipped with a 1104C-44TA power plant, developed by the manufacturer Perkins. This engine is capable of developing a rated power (also at certain crankshaft speeds) of 90 kilowatts or 123 horsepower. This car can reach a maximum speed of 20 kilometers per hour.

The base excavator is equipped with a hydraulic system of the PSM model. On the modifications (EK-18-60 and EK-18-90M), a German-made hydraulic system, the Bosch-Rexroth model, is installed. The maximum achievable pressure in the hydraulic system of the excavator is 28 megapascals.

Peculiarities

As described earlier, this excavator can be used on various surfaces (asphalt areas and similar areas), since it does not cause severe damage to the road surface, as, for example, tracked vehicles. Eco is explained by the wheeled chassis. The scope of the EK-18 is quite large, not only due to its high technical characteristics, but also the ability to use a large number of various additional attachments in the working process, with the help of which the excavator is able to perform all the necessary work, both for construction purposes and for dismantling. It should be noted that the EK-18 excavator was originally intended only for construction work, but later, with the advent of a log gripper (with a carrying capacity of 3000 kilograms), forestry also turned their attention to this machine.

The excavator is designed for tough jobs, as the auxiliary reinforcement will make the machine withstand the high loads that are common in the construction industry. It also has high reliability and durability of all units and mechanisms, which is an important parameter in any heavy equipment. But in case of detection of problems associated with the operation of any mechanisms, they can be eliminated in a short time without much effort, since the parts are arranged in a convenient order for the mechanic. Also, it is worth noting that on some modifications a special cabin is installed, which, if necessary, can be raised during work, while providing an even greater view. The cabin is raised due to special hydraulics.

Video

Engine

The EK-18 excavator is equipped with the development of the Minsk Motor Plant, namely, this is the power unit of the D-245 model (also known as the MMZ 245). This engine, like many other power units, is equipped with a turbocharging system, which has an effect when the exhaust gases accelerate the turbine impeller. This allows it, at maximum crankshaft revolutions (2200 rpm), to develop a maximum power of 77.2 kilowatts or 105 horsepower. Also, at a certain speed (1400 rpm), it produces 384 Nm of torque. In total, the engine has four cylinders with a diameter of 110 millimeters, which have an in-line vertical arrangement. The piston stroke of this unit is 125 millimeters. The total working volume is equal to 4750 cubic millimeters. At average loads for one hour of operation, it consumes about 162 grams of fuel per horsepower or 220 grams per kilowatt. Cooling system of liquid type with forced circulation of liquid. When assembled and completely ready for operation, the engine has a mass of 490 kilograms.

Some modifications are equipped with a different model, namely this Perkins 1104C-44TA. This engine is also an in-line four-cylinder, equipped with a turbocharging system of the same type as the previous unit. The maximum power at 2200 rpm is 90 kilowatts or 123 horsepower. The working volume is equal to 4400 cubic centimeters. Each cylinder has a diameter of 105 millimeters. The piston stroke is 127 millimeters. At a certain speed of the crankshaft, it is capable of delivering exactly 500 Nm of torque. Fuel injection into direct combustion chambers. The cooling system is liquid. In a ready-to-use condition, it weighs 306 kilograms. Its length is 663 millimeters, width is 620 millimeters, and its height is 810 millimeters.

Price new and used

At the moment, the cost of the new EK-18 excavator starts from three million and reaches four million Russian rubles. The price depends directly on the year of production, version (basic or modified), and of the complete set.

A cheaper option is to purchase supported equipment. The cost of a used car starts from 359 thousand rubles and reaches 1.4 million Russian rubles. The main points affecting the cost are the year of manufacture and the general condition of the excavator.

In the line of the Tver plant, the EK-18 model is the flagship with the highest carrying capacity. The main features of the technology (reliability and durability) are due to the reinforced structure of the metal structure.

In the line of the Tver plant, the EK-18 model is the flagship with the highest carrying capacity. The main features of the technology (reliability and durability) are due to the reinforced structure of the metal structure.

A cubic meter bucket and two boom-lifting cylinders allow the EK-18 to cope with the movement of heavy loads.

This technique is a pneumatic wheeled hydraulic excavator used for demolition and demolition of reinforced concrete, brick and concrete structures with medium strength. The model is also used for the destruction of metal structures, cutting scrap metal, cutting reinforcement and loading and unloading non-flowing and loose soils. The technique has also found application in various tasks of dismantling objects made of concrete and other structures made of similar materials.

EK-18 is designed to work with mounted grabs with different levels of functional orientation. The most popular are mobile modifications with a wheeled chassis, but there are also heavy versions on a tracked chassis.

The EK-18 is a truly multi-purpose earthmoving machine. Through it, you can dig quarries, trenches and pits in soils belonging to I-IV categories, as well as load frozen soils and loosened rocks with a piece of less than 200 mm.

Excavator modifications EK 18-20, 18-30, 18-40, 18-44, 18-60

Tverskoy Excavator produces several modifications of this model:

- classic EK-18;

- EK-18-20 with increased productivity and a bucket with a volume of one cubic meter. Thanks to the additionally reinforced metal structure of the equipment, the technician can work in difficult conditions. For the EK-18-20, the manufacturer offers a huge selection of replacement working equipment. Moreover, the model itself is considered the most powerful multifunctional machine;

- EK-18-30 is an analogue of EK-18-20 with similar characteristics. The only difference is the availability of imported hydraulics;

- EK-18-40 is a hydraulic pneumatic-wheeled excavator equipped with a grab gripper. A special version designed for loading timber and scrap metal. Additionally equipped with a hydraulic lifting cabin and scrap equipment;

- EK-18-44 is a special pneumatic version with a 5-jaw GP-554 grab with a capacity of 0.65 cubic meters, a hydraulic lifting cabin, a full-revolving rotator and scrap equipment. Used for loading / unloading open wagons and loading timber and scrap metal;

- EK-18-60 is equipped with a Bosch-Rexroth travel motor, a hydraulic pump and a Perkins unit.

- Wheeled excavator Tveks EK-18-90 (M) is an evolutionary continuation of the previous model. Redesigned working equipment, more powerful engine.

The main advantages of the EK-18:

- stability;

- powerful motor;

- advanced cockpit;

- long period of operation and reliability;

- high performance;

- ease of management and ease of maintenance;

- multifunctionality;

- thoughtful arrangement of instruments and indicators on the control panel.

Specifications

The excavator weighs 18,000 kg. EK-18 dimensions:

- length - 9400 mm;

- width - 2500 mm;

- height - 3250 mm;

Operational parameters of the model:

- bucket capacity - 0.65 (0.77; 1) cubic meters;

- unloading height - 6240-6750 mm;

- digging radius - 8850-10000 mm;

- digging depth - 5770-6970 mm;

- bucket rotation angle - 177 degrees;

- The maximum vehicle speed is 20 km / h.

Fuel consumption

The fuel consumption of the EK-18 is 236 g / kWh. In this case, the model's fuel tank holds up to 255 liters.

Engine

EK-18 boasts a powerful 4-stroke 4-cylinder diesel unit "D-245" with a liquid cooling system and direct fuel injection. The engine is started through an electric starter. The power plant is equipped with additional elements manufactured in Germany. Some modifications of the EK-18 are equipped with the British "Perkins" unit with increased power.

The D-245 motor has a vertical in-line arrangement of cylinders. The main assemblies of a power plant are the crankshaft, cylinder block, flywheel, pistons, cylinder head and connecting rods. The use of a turbocharger with variable boost pressure provides improved throttle response and increased torque.

Engine parameters "D-245":

- working volume - 4.75 l;

- power - 105 hp;

- maximum torque - 385.5 Nm;

- rotation frequency - 2200 rpm;

- cylinder diameter - 110 mm.

Photo

Device

One of the main features of the EK-18 is the unique arrangement of the cab, which has been redesigned as much as possible for convenient and safe operation of equipment. The engineers of Tverskoy Excavator have significantly changed this element in terms of management. For the rest (individual controls, levers), there have been no cardinal changes.

The layout of the EK-18 cockpit has also been revised. It now provides the operator with maximum visibility. In terms of this indicator, the Tver equipment may well compete with the advanced foreign counterparts. At the same time, in the ratio of quality and price, it surpasses many of them.

Optional equipment

EK-18 can be equipped with additional systems and modules. For this model, Tverskoy Excavator offers:

- ripper 225-00-40.17.400, which allows you to remove various elements from the soil, carrying out global cleaning;

- hydraulic hammer MG-300. It is used for dismantling a variety of wooden, concrete and brick buildings and structures. Also, a hydraulic hammer is used to compact a loose earth layer and loosen frozen soil;

- hydraulic shears IG-821 and IG-811. This element has additional equipment that provides the necessary rotation of the scissors, which allows you to significantly expand the list of operations performed;

- log grab MG-300. It is used for unloading, loading, stacking logs and has a lifting capacity of 3000 kg. Additionally, it can be completed with a full-turn rotator;

- grab GK-221. It is used to perform operations for unloading and loading materials and soil development.

Price new and used

The new EK-18 excavator will cost 4-4.5 million rubles. Used options are much more affordable. So, for the 2008-2009 model in good condition, you will have to pay 1-1.8 million rubles. Cars until 2000 are offered for 400-500 thousand rubles. Renting an excavator costs about 8,000-10,000 rubles per shift.

Analogs

The EK-18 analogs are the EO-33211 and EO-4321 models.

Domestic equipment at construction sites has always been in demand for the reason that it is much easier to look for components for it, especially when equipment fails at the height of the construction season. Excavator EK-18 refers specifically to the domestic segment of the construction equipment market. However, in addition to readily available spare parts, it is also distinguished by a wide range of compatible attachments for literally all occasions.

Excavator EK-18-20

The EK-18-20 excavator is the basic configuration of the machine. In this configuration, the device has a domestic-made D-245 engine. It has liquid cooling and direct fuel injection. It differs from the younger models of the series in a capacious bucket with a volume of 1 m3, as well as a reinforced metal structure.

For this model, such types of equipment as hydraulic hammers, rippers, grapples, log grapples and hydraulic shears are successfully used. And modern modifications of the car are equipped with a comfortable cab.

Features of the EK-18-30 excavator

The EK-18-30 excavator is an improved modification of the EK-18-20 model. Along with all the advantages of the basic design, the device received a number of improvements through the introduction of imported hydraulics. Except for the engine, its design is as similar as possible to the EK-18-60 excavator model.

Excavator device EK-18-40

The device of the EK-18-40 excavator model deserves special attention. This construction and repair vehicle is mounted on pneumatic wheels. A grab gripper is included as a working body. Such a design, of course, will be useful in the processing of recyclable materials, for example, scrap metal, or when loading timber, however, a special configuration of this machine is more adapted for these needs, which also includes a hydraulic lifting cabin, as well as scrap equipment. The cab is used for filling open wagons, as well as for unloading them.

Features of the EK-18-60 excavator

Among other modifications, the model of the EK-18-60 excavator stands out. Its design is distinguished by the presence of a set of hydraulic equipment. It includes a hydraulic pump as well as a Bosch-Rexroth hydraulic travel motor. In order to balance the power of the unit and the hydraulic equipment, the manufacturer also replaced the stock engine with a Perkins model.

Technical characteristics of the EK-18 excavator

- Operational weight, kg 18000

- Travel speed, km / h 20

- Bucket capacity, m3 1.00 (0.65; 0.77)

- D-245 / Perkins 1104C-44TA engine

- Power, h.p. 105/123

- Hydraulic system pressure, MPa 28

- Length, mm 9400

- Width, mm 2500

- Height, mm 3300

Video about the EK-18 excavator