To assemble a homemade 4x4 fracture mini-tractor, you will need to draw up a diagram, study design features technology. The need for such a unit arises when it is necessary to cultivate the land, plant or harvest the crop.

Step-by-step instruction

The classics of agricultural machinery are made by hand using a welding machine, disc plate, drill. The assembly of the mechanism begins with the manufacture of the frame. It consists of a side member, front and rear cross member. The spar is made from a channel of size 10 or a square tube 80x80 mm. Use size 16 for the traverse. Any engine is suitable for a 4x4 mini tractor. Most suitable option- 40 h.p. The clutch is required from the GAZ-52, and the gearbox from the GAZ-53.

To connect the basket and the power unit, you need to make a new flywheel. The bridge can be used in any size and is inserted into the mechanism. Cardan shaft make up from different cars... In a homemade 4x4 tractor, the bridge in front is built independently. Use 18-inch tires for good cushioning. On front axle fit 14-inch wheels. If the wheels are smaller, the 4x4 mini tractor will sink into the ground. Otherwise, the technique will be difficult to control.

To connect the basket and the power unit, you need to make a new flywheel. The bridge can be used in any size and is inserted into the mechanism. Cardan shaft make up from different cars... In a homemade 4x4 tractor, the bridge in front is built independently. Use 18-inch tires for good cushioning. On front axle fit 14-inch wheels. If the wheels are smaller, the 4x4 mini tractor will sink into the ground. Otherwise, the technique will be difficult to control.

To reduce the load on the chassis, tires with good lugs are used.

During the manufacture of a mini-tractor for household it is necessary to use the cardan shafts of the final drive with trucks.

In all 4x4 mini tractors, a fracture with their own hands is installed by the gearbox closer to the driver and fixed to the frame. For pedal control of homemade products, it is recommended to use a hydraulic drum brake. Both the steering rack and the pedal control of the fracture will come from a VAZ car.

Assembling equipment

Tractor components are bolted or welded. Combined fastening of parts is sometimes possible. It is important to correctly position the seat removed from the car. Next stage assembly of equipment - installation of the power unit. To attach the motor well to the frame, you need to use a special slotted plate. Then you will need to lay electrical and mechanical system management. In order for such work to be done efficiently, the wiring diagram of the factory mini-tractors is being studied. Next, the body is sheathed, taking into account their wishes.

The next stage is the arrangement of the body and its combination with motor unit... A small trailer from a passenger car can serve as a body. If we briefly discuss the whole process of fractures, we get a simple algorithm: the walk-behind tractor is located on the frame, a drum-type brake system is installed and steering rack from the Zhiguli.

We take any motoblock. If we take the Neva walk-behind tractor, it is more expedient to choose it with a hitch. Then the mini-tractor will carry loads and trailers. Another suitable motoblock is the Centaur diesel block. To decide which walk-behind tractor to choose, you need to figure out the purpose of the mini-tractor. The 4x4 break frame tractor has the main advantage - maneuverability.

Conclusion on the topic

If necessary, you can make a mower, milling cutter, bucket. The main advantage of a break-frame tractor is its maneuverability. Its assembly is simple, so such an agricultural unit can be made by any summer resident who understands technology. Cost price homemade car will be comparatively lower than the price for the Pskov factory analogue.

The minitractor caliber MT 244 can be operated in any conditions and on complete off-road. Air suspension consists of a receiver, an updated vehicle control valve, a compressor. The minitractor caliber MT 244 can be stored in the garage, and due to the presence of a reinforced attachments easy fixation of various devices is provided.

You don't have to buy a tractor - you can assemble it yourself. There is an assembly option with a monolithic frame, which is easier, or with a broken one - you have to tinker with it, but the machine turns out to be maneuverable. A homemade mini-tractor of a break 4x4 is constructed entirely from elements of old cars and equipment.

The tractor got its name "breaking point" because of the frame, which consists of two parts. Before starting the assembly, you need to have a diagram with the dimensions of the nodes so that all the elements fit in size.

DIY 4x4 tractor with a fracture frame

This process can be described general scheme, but in practice, almost every self-taught assembler makes his own adjustments to the design.

To assemble a mini-tractor, do-it-yourself fractures usually adhere to the following requirements:

- The frame has a 3-stage spar system. For the front ones, take channels # 10. The third stage is made from a pipe with a cut of 8 by 8 cm.

- The front traverse can be made from channel # 12, for the rear one it is best to use # 16.

- The crossbeams are built according to the same system.

- The engine is selected according to suitable characteristics - size, power, type of attachment.

- The most commonly chosen 40 hp 4-cylinder diesel engine. with.

- Liquid cooling allows the equipment to work all day without overheating.

- The next step is to install the power take-off shaft, gearbox, transfer case... The parts of the old GAZ-53 truck are ideal.

To connect the motor and clutch, you will need to rework the flywheel - trimming its rear part and grinding a new span. Upgrading the casing consists of adjusting to the desired size.

Cardan shaft and rear axle suitable for any car, you do not need to change anything in it.

How to install a wheelbase with your own hands?

The main thing here is to choose the correct wheel diameter. For a mini-tractor with a break frame, it can be taken from passenger car mobile if the disc diameter is at least 14 inches. Wheels that are too small will get stuck in the ground, and large ones will make it difficult to control the equipment. The use of the tractor can be facilitated by installing a hydraulic system. It can be completely removed from any decommissioned agricultural machinery.

- The front axle can be easily constructed from a pipe by installing bearings on it. Another option is to take from another, unnecessary technique.

- Tires should be chosen with a deep tread pattern - this increases the maneuverability of the tractor.

- Good cushioning is provided by 18-inch tires.

Rear wheels are mounted on the axle hub in a simple way: the center of the disc with the mounting holes is cut out, and the same part from the ZIL-130 is welded to this place.

How to set the steering correctly?

Anyone is suitable for assembling a mini-tractor with your own hands steering taken from a car. The most successful option will be with hydraulic system- this will improve the controllability of the tractor.

An oil pump is also needed - it is started by the engine. The main wheels are best connected through a gearbox.

An important element of the system is a hydromechanical drum brake. It connects with a pedal rod.

After all parts of the structure are assembled, workplace operator. For this, an adjustable seat is installed. You can build a canopy with your own hands by fixing it on 4 welded uprights.

To ensure safety, the engine and all internal elements are hidden under a steel casing - it is usually bent out of a sheet of galvanized steel. To work in dark time for 24 hours the tractor is equipped with a headlight and a battery for it.

Rural life presupposes the performance of a large number of works typical for this type of terrain. Nobody disputes the honor of manual labor, but the use of small-scale mechanization means, in in this case, can only be welcomed. However, not all categories of citizens have the opportunity to purchase a ready-made four-wheel drive mini-tractor in a special store, because the price of even the "cheapest" model can be at least 50 thousand rubles.

Here all sorts of craftsmen appear who have adapted to make such units out of all the rubbish that they have in the garage.

What a careless owner would have thrown into a landfill, a savvy and resourceful person is able to make a completely workable device out of this that can perform basic agricultural work.

Quite popular among such craftsmen is the do-it-yourself 4x4 fracture mini-tractor, which is a rather bizarre design.

An all-wheel drive mini-tractor, made by hand, has quite good cross-country characteristics, which makes it possible to perform virtually the same front of work as shop counterparts, such as,.

Homemade mini tractor with a breaking frame

When there is a need for quality mechanical device, which is indispensable when digging up the soil, planting a variety of crops, it is obvious that for buying a colossus in a store, you need to pay a large sum. In order not to waste the family budget, you can build a fracture mini-tractor with your own hands.

What is he like?

Homemade mini tractor The break 4X4 looks like a standard tractor built on a walk-behind tractor. There are three types of tractors:

- homemade;

- factory;

- converted with factory tools.

Self-assembled mini tractor

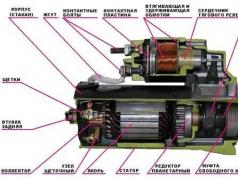

Assembling a tractor with your own hands is not an easy, but rather interesting activity that requires diligence and concentration. There are a large number of assembly variations, but there is an optimal design, not only for experienced but also for novice designers. The design is shown in the photo.

Homemade mini tractor design

Let's take a look at the frame design first. Without looking at the angularity with outside, all nodes that connect and chassis parts are distributed efficiently.

Main frame parts:

- spars;

- traverse.

The tractor spars have a three-stage assembled structure. The steps in the front are made of channels of the tenth size, the last one is made of a square-shaped pipe (material steel), with sides 80X80 mm. The traverse at the back is also made of a sixteenth channel, and in the front, a twelfth. The exact same system is also suitable for the preparation of the cross member.

For the tractor, you can choose any engine that suits the power. The best option is a 4-cylinder water-cooled diesel engine. In terms of power - 40 hp, but as for a self-made model of a minitractor for the purpose of working on home areas, this is quite enough.

The PTO transfer case and gearbox will fit from an ownerless GAZ-53 (or a similar model), and the clutch will fit from a GAZ-52. For joining the clutch basket with power unit it is important to re-make the engine flywheel and build an updated basket cover in order to fit required size... The flywheel is machined on a lathe. You need to cut off the area at the back and carve another span in the middle.

The bridge is integrated into the mechanism without significant changes. It can be used in any size. Four ladders facilitate attachment to the frame. The propeller shaft can be assembled from different vehicles. Good shock absorption is achieved by fitting 18-inch tires.

Fitting wheels to hubs is easy. You can see that a part of it is cut out of the disk in the center with a hole for installation, instead of which the central part of the disk from the ZIL-130 is welded. The bridge in front is under construction on their own- you do not need to have serious skills for this, since he is not the leader. To simplify the assembly process, you can move the bridge from other machines.

Wheelbase

Wheelbase, for a mini tractor, it is important to pay Special attention... Of course, it is sufficient to use wheels made of passenger car, but here it is worth going measured. The required dimensions of the wheel disks for the front axle are approximately 14 inches. If you choose a smaller diameter, then there is a risk of incorrect operation of the mini tractor in the future. After all, it is important for us that the tractor does not sink into the ground. But there is another side of the coin - if the front wheels are too huge, the driver will have to gain strength to perform certain maneuvers. It will be physically difficult. But this process can be simplified by using the power steering.

It is important that the tires of the wheels in a homemade minitractor have good lugs. This will make the tractor more maneuverable, less stress on the undercarriage and easier work.

Steering wheel control

To increase the maneuverability of the tractor, it is necessary to install the hydraulic steering on the steering wheel. You can use the equipment that was written off in agriculture find hydraulics. To assemble it, you need an oil pump, which will be put into operation thanks to the engine. It provides the required pressure in the hydraulic motors. It is good when the wheels of the main shaft are to be controlled by a gearbox. The direction of rotation is due to a simple valve with four working positions.

Photo of drawings of nodes

Suspension front wheel(pos. 2,3,4,5,6,7.8,9,11,12,13,15 - from the car ZAZ-968): 1 - frame portal; 2 - suspension arm (from the Zaporozhets car); 3 - rubber buffer; 4 - flange; 5 - shock absorber; 6 - lower spring cup; 7 - spring; 8 - the upper glass of the shock absorber; 9 - screw with washer: 10 - rubber gasket; 11 - nut with washer; 12 - shock absorber silent block; 13 - pin bracket of the suspension arm; 14 - a bolt with a split nut (2 sets); 15 - silent block of the lever (2 pcs.)

Scheme brake system: 1 - handle; 2 - leash for removing the stopper; 3 - toothed sector; 4 - stopper dog; 5 - rod with adjustable fork tip; 6 - drive lever; 7 - drum with brake mechanism; 8 - gearbox; nine - cardan joint; 10 - lever travel stop; 11 - bolt of fastening of the gear sector to the gearbox housing; 12 - lever axis

Steering diagram (a - left turn; b - right turn): 1 - steering wheel with a hydraulic cylinder; 2 - vertical rack of the front half-frame; 3 - bracket for the rod of the working cylinder, 4 - the working cylinder; 5 - rear semi-frame; 6 - articulating hinge; 7 - hydraulic hoses

Steering diagram (a - left turn; b - right turn): 1 - steering wheel with a hydraulic cylinder; 2 - vertical rack of the front half-frame; 3 - bracket for the rod of the working cylinder, 4 - the working cylinder; 5 - rear semi-frame; 6 - articulating hinge; 7 - hydraulic hosesWith your own hands, you can design a 4x4 mini tractor with a breaking frame.

The four-wheel drive tractor with a breakable frame 4x4 has the main advantage - good maneuverability. This, of course, complicates the assembly, since it is necessary to design a correct and high-quality shaft with connections.

During manufacture homemade tractor with a breaking frame, it is necessary to use the cardans of the main drive from trucks. There are many videos on making tractors yourself.

But the principles of manufacturing are used almost the same everywhere. In all tractors, the gearbox is retracted to the driver and fixed to the frame, the steering rods facilitate steering. Everywhere there is a hydraulic drum brake, which, like the clutch, has a pedal control. The accelerator and attachments are used manually.

Different parts are needed to design a mini tractor. Automotive fit perfectly. For example, a drum brake will fit the front wheels. The steering rack and pedal control will fit from a small VAZ car. According to the principle of searching for spare parts on the market, you can choose manual control, seat and other necessary parts for a mini tractor.Construction tools

In addition to spare parts, it is important to use a wide range of tools:

In addition to spare parts, it is important to use a wide range of tools:

- welding machine;

- drill;

- spanners;

- disc plate and many others.

Sometimes, when designing, you may need to contact a welding professional or auto repair. Here you need to build on your own skills and capabilities.

Control and seat

Usually they start installing the control system and kinematic diagram after the design of the chassis. An important point in this matter, a correctly placed seat. For this case, a passenger car seat is perfect. It is easy to find in auto workshops or auto repair shops. It is important that the steering wheel is attached at a comfortable height for the driver. The steering wheel should not press against the knees, so it should be mounted so that the labor process does not provoke any sensations of discomfort.

Engine and bodywork

After chassis assembled, the kinematic plan is implemented, the seat is installed, you can begin to mount the main part of the mini-tractor - the engine. In order to properly fix it on the frame, it is necessary to use a specialized slotted plate. It also provides the necessary rigidity to the chassis. Then the electrical and mechanical circuits of the control system are laid. The body is sheathed according to the manufacturer's wishes. But it is better to hide certain components and body parts in order to prevent clogging and breakage in contact with the ground and unnecessary objects.

Assembly technology

Before you create this colossus with your own hands, you should decide for what specific purposes it is intended. Perhaps in a certain case, mowers, milling cutters, shovels are important. The process of fracture itself is described by a simple, concise method: the walk-behind tractor is located on a frame built on its own. As for the brake system, it must be of a drum type, and the steering rack can be used from domestic Zhiguli.

When the Neva walk-behind tractor is taken as the basis of the tractor, it is more expedient to choose it with a coupling, thanks to which it will be able to transport loads and trailers with a body. Of course, the machine, which was designed on a profile, high-quality walk-behind tractor, will become a strong, strong and durable model of a fracture tractor. Proceeding from this, the efficiency of the tractor and the resource of operation will increase. One of the many suitable types of such devices can be a motoblock powered by a Centaur diesel engine with a capacity of 9 hp. When choosing such an important component as a walk-behind tractor, it is worth understanding the purpose and functions that you want to assign to the mini tractor. It is necessary to analyze in detail the arrangement of the body. Consider how it will be combined with the motor unit. In the manufacture of the body and frame, profiled pipes or metal corners will help. By setting strong engine, the body can be built from a small trailer to the car. It is important to consider in advance how to attach it to the walk-behind tractor.

A self-built 4x4 breakaway mini-tractor will be indispensable for working in summer cottages, small rural gardens. It is important to know that the cost of this colossus will be small compared to the cost of a mini tractor in specialized retail outlets.