Greetings. Today we will analyze everything on the topic: "car noise insulation." I will tell you how to do it right and what to make it first. And also share the secrets and tricks. Go!

If you want to build an audio system even an entry level, then Shumka is the first need for a foundation for improving sound in a car. Additionally, a pleasant bonus will be improved comfort at any trip. Well, if the main thing for you is precisely a decrease in the surrounding noise, then the improvement of the sound of even a regular audio system will pleasantly surprise you. But in which volume to make noise insulation of your car everyone will solve himself and I will try to help this decide on it.

For noise insulation works through my hands, no one dozen cars passed, and I think I will succeed to give you some useful information.

Types of insulating materials

Under the general name, noise insulation is combined by several types of materials - these are vibroproos, noise reductants and seals.

Vibration insulating materials

The name speaks for itself, these are materials to reduce the vibrations of the metal surfaces of the car.

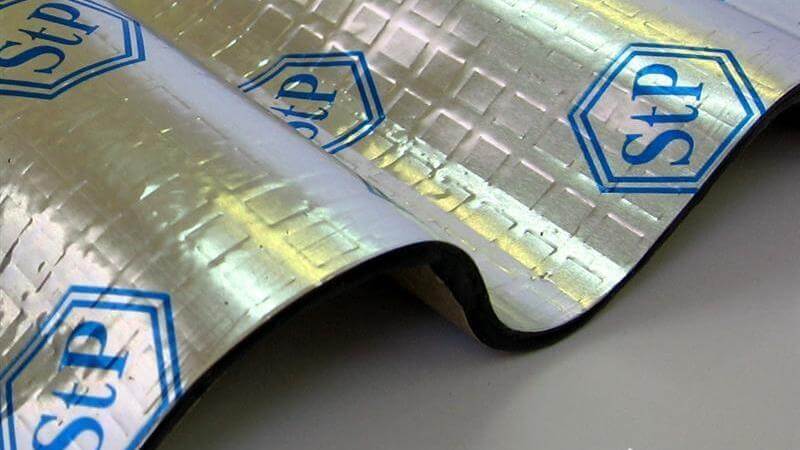

Present mastic on a foil material of different hardness and thickness. "Vibra" - is the basis of any noise insulating "sandwich" of the car. More often, materials are self-adhesive, but there are also those that require heat heating.

- roof;

- hood cover;

- doors;

- trunk lid;

- wheel arches;

- floor cabin;

- partition motor compartment;

Noise insulating materials

As a rule, they are stacked over vibration insulation, performing a double function - noise absorption and thermal insulation. There are two types.

First option Made of foamed materials with clocking structure, has a pronounced thermal insulation effect.

- floor cabin;

- the floor of the trunk;

- roof;

- hood cover.

Second option- Sofa foamed materials with a wave-like or pyramidal surface structure. Not an even facial surface material increases the area, providing a more efficient absorption of sound in comparison with flat analogues of the same thickness. Due to softness and advantage, it facilitates the assembly of parts of the cabin and fills emptiness.

- roof;

- doors;

- trunk lid;

- arches of wheels from the inside;

- motor compartment partition.

Sealing materials (anti-scaffolds)

With the help of these materials are eliminated by all hated "crickets" and, if necessary, an additional seal is created at the joints plastic details Salon. More antiscreps can serve to wind the wiring.

- stakes of plastic panels,

- air ducts

- places of adjustment of door trim.

Manufacturers

On the russian market There are two most famous and common:

"STP"

"Standardplast" on the market since 1996. Distributes its noise insulating, sound insulation and sealing materials through dealerships.

"Shumoff"

It is both the developer and the manufacturer. It has a number very successful materialsthat fully meet the requirements of autochimo insulation.

Of course there are still many manufacturers and types of noise insulation, but I will give examples of materials of these two brands. Because they are most common and known from NC. So it will be easier for you to make an idea of \u200b\u200bthe insulation type for a specific surface.

Car Noise Isolation Tools

For carrying out the car noise insulation, you will need:

- tweet roller **;

- thermal hairdryer, if you need to warm up certain materials;

- scissors and knife for cutting material;

- degreaser (Solvent, White Spirit and TP.);

- ribs for wiping;

- spatula for removing old glue and factory noise insulation;

* Tools for disassembling the cabin. Thanks to the material, the interior details of the car during the assembly and disassembly work remain without scratches, damage is not caused by painted, leather, chromed and other surfaces.

** Paddy roller. A simple tool for rolling material on the surface allows you to avoid bubbles and non-fluxed sections. Do not buy rollers with a plastic roller, they are good shine not to roll, besides, he will definitely not last.

Basic provisions

- Materials are glued exclusively on dry and low-fat surfaces;

- Be sure to carefully turn the vibration insulation over the entire surface;

- Choose the thickness of the material so that the plastic elements of the cabin normally got into their mounting places;

- Be prepared for the fact that several pistons can break during operation, so you can stock otherwise in advance or purchase in the process;

- Carefully follow the fasteners of parts and the location of the electrical wiring plugs, it will not be superfluous to take a picture to not be sealed when assembling;

- Works should be carried out in warm oxide (+20 degrees).

Noise insulation doors

Doors need to be cozy necessarily. This is a foundation for building an acoustic system, even the sound of the staff you will not recognize after the door sickness, the external noise will noticeably reduce during the movement, and the sound of their closure will become more pleasant. First of all, I want to note that the processing of doors will be the biggest effect on costs, both financial and physical. From the processing of other surfaces on so much bright effect you are unlikely to feel!

Disassembling doors

In the network you will find a detailed guide for almost any model, on this problems there should be no.

Be sure to use special tools to not damage plastic and paint. If there is no access to them, you can use a screwdriver wrapped with a tape. The main thing is not to scatter bolts with pistons and carefully remember which from where, and also pay attention to the location of the posting plugs. When assembling, you can spend a lot of time, remembering where this or that chip is inserted, and you can also connect anything at all.

Preparation of doors to noise insulation

After disassembly, remove all the factory isolation, remove the remnants of the glue (any solvent will help). When the insides are sufficiently dirty, that is, it makes sense to rinse the metal of the door, and after drying it is carefully deguted both inside and outside. Do not neglect this rule that the materials would be reliably held.

If inner space It closes a solid shield, then it will have to drill it for removal (use the rivet rod diameter drill. In principle, it is even more convenient for the ordering, as it is not always easy to climb into the technological holes, and even with the power to turn the vibrator with a roller.

Vibration isolation of doors

Tip: Initially, apply on the metal frame with an increased stiffness material from those that require heating for installation (for example, "Profuff" from Shumoff).

Then stick and rush the inner surface of the outer wall with vibration insulation as much as possible throughout the area, where you can get. Typically used Materials of 2-3 mm. ( Examples: Shumoff Series M or Light, StP Bimast Bomb or Aero.) With a thicker effect it will be better, but at the same time grows the load on the loop and the complexity of installation increases.

The next stage is the sizing of the outer side of the inner wall. There are several options here:

- standard - everything rolled under the material used and they also close assembly openings;

- strengthened - mounting openings are closed with a material that becomes sticky and mild only when heated, and at standard temperature has increased rigidity;

- professional - holes are rushed with aluminum or lining made from fiberglass, and then vibration insulation is superimposed.

When pattering, leave a place for wiring. You can cut the material and glue it under it, and you can partially remove the wires, completely roll the door (leaving the holes for fasteners) and install the wiring back. Also, do not forget to leave holes for pistons, screws and guides, otherwise then the trim will not wear. Additionally, follow the edges of the insulated area, so that the material would not go abroad covered by the trim. Be sure to pay attention to the moving parts, often the guides of the open / closing mechanical buttons are rushed by inexperience.

Additionally, it is possible to partially enclose the trim from the inside, but do not overdo it.

If you make the doors to improve the quality of music, then be sure to install the wooden spacers between the speaker and the door of the door (in the photo above). Splash heights from the distance to the trim. In order for the assembly she got into place.

Noise insulation doors

Noise absorbers, as a rule, pasted on the inner side of the casing.

But it happens that the form of the sheath is very complex or has a dilated structure. In this case, the material is better pasted on the wall of the door itself over vibration insulation. More efficiently use material with a pyramidal structure ( Example: Bitoplast, Germeton).

Do not use Splin and similar noise insulators, most of low temperatures Just dugs. More than once I had to face.

If you had problems with crickets and screensions on the map, you can smoke the connections to the anti-slip.

Build door

Do not forget to connect all connectors, set all the mechanisms into place. Be careful, do not apply great strength. With a competent sickness, the trim should be satisfied normally. Before complete assembly and stretch fasteners, check all controls (lift, lock, mirrors, columns, etc.)

If everything is done correctly, now you will hear more bass, the music will become collected and more pleasant, as well as the external noise will decrease when moving.

Noise isolation of the trunk

Thanks to the literate root insulation:

- the level of external noise will decrease, especially in hatchbacks and universities;

- qualitatively increase the level of the sound of your subwoofer and the speaker system as a whole (sound will cease to be lost in the vibrations of the baggage compartment metal);

- slow thermal losses

For vibration insulation, the material is usually used 2-3 mm. ( Examples: Shumoff Series M or Light, Stp Bimast Bomb or Aero). To enhance the effect, the resonging surfaces of the large area glued the material is cessing, or the reinforcing grid will be made, as in the case of doors.

Noise insulation for the floor of the trunk is selected from the materials of the smooth structure ( Example: Shumoff series n or isoton from STP).

For walls and covering covers luggage compartment It is purposefully used to use Shumkov with an open structure ( Example: Bitoplast, Germeton).

In the trunk, there are usually many uneven surfaces, so accuracy and patience will be suitable for achieving a good result.

Noise insulation of the roof of a car

Installing additional noise insulation of the roof of the car will significantly reduce heat loss. In the cold time, the car's salon will heat up faster and cool longer, which will undoubtedly add comfort. The overall decline in external noise will be quite difficult, but during the rain it will be possible to experience pleasant sensations. The sound of droplets disappears almost completely. It will also increase the quality of the bass if you have a subwoofer.

The procedure for noise insulation of the roof is not complicated and performing work on the rolling is quite convenient.

Do not strip hard ribs - they must be ventilated. Otherwise, condensate will accumulate inside!

Problems can deliver dismantling. You need to be careful and perform work with the assistant, in order to accidentally go through or not to break it. And be careful with wiring.

Examples of materials: Light or Aero. for vibra and Germeton or Bitoplast For Shumkov.

In the area of \u200b\u200bthe Arch, the main external noise accumulates and, moreover, this is a sufficiently vibration-loaded surface. Comprehensive noise insulation Arch will make it possible to noticeably reduce the noise level and improve acoustic comfort.

Noise Isolation Arch Outside

If your car has installed sings, you will need to dismantle them. Clean the outer metal arches with vibroproomer (3 mm). For the sneakers, you can use the material easier. Example: Shumoff Series M., STP BIMAST BOMB..

Sivegasheels are not used outside, even if they are moisture-resistant. Practice shows that it is little effectively and best result It will give proper noise insulation from the cabin.

If there are no sinks in your car, then we also put the outer metal with vibration insulation. We need to very carefully roll out the material for the formation of a homogeneous surface. Then, liquid rubber and similar materials are used on top ( Noxudol 3100, Sumuloff Layer and TP.), they will further protect against sandblasting, reduce the noise from the blows of small particles and disguise the vibration insulation.

Noise insulation Arch from salon

From the inside the process of cloaking standard. The first layer is vibration isolation ( example: Shumoff Series M, STP BIMAST BOMB), second noise insulation ( example: Bitoplast, Germeton). Shumka is better pasted on the details of the cabin, which close the arches. But if their material does not allow to secure isolation securely, then mount it directly to the vibration.

It should be noted that a noticeable effect is achieved only with an integrated approach. If you apply only one of the options presented, you will most likely be disappointed with the result.

Noise insulation of the floor of the car

The floor of the car is characterized by a large area. The main labor costs the salon disassembly, removal of seats, etc. Glue material B. this case Convenient, unlike working with doors and trunk.

Since the area is relatively smooth and large, then for the first layer it is better to use the vibra thoroughly ( example: Chemoboff Mixf, Stp Aero Plus) For the most resonant seats, you can apply materials requiring heating when installing.

The second layer is rocked by waterproof noise insulation with a closed structure ( example: Shumoff Comfort 10, Germeton L; STP accent or isoton).

Be careful and do not stick the mounting holes, so if not to look for them under the thickness of the material.

It should be noted that, oddly enough, often noise insulation of the floor does not justify the expectations of the average owner. The effect is noticeable, especially against the background of the large work done and material costs. But as an additional plus you will get improved insulation of the cabin, if this is relevant for your region.

The best effect to reduce the engine noise is achieved when the engine compartment noise insulation is made from both the cabin and outside.

This process is perhaps the most difficult compared to work on other parts of the body. The main difficulty is the disassembly of the instrument panel. Because modern cars There are many electrical equipment, which is located in the Torpedo area. Therefore, the process of removal and reverse assembly will require very great accuracy and care. Also, you need to take into account that in one day to conduct noise insulation of the engine is unlikely to succeed.

From the side of the engine compartment, it is advisable to use vibration insulation thoroughly, it will not be superfluous to use the material that requires heating. It is necessary to cover the maximum area, including in the most hard-to-reach places. The material with a reflective surface is suitable as noise insulation in order to prevent possible overheating.

From the Salon side, the thickness of the materials is chosen so that the dashboard would get into place.

If all the work is carried out correctly, the level of noise from the engine in the cabin will decrease significantly (up to 50%). Additionally, vibration will decrease, it will be possible to feel on the steering wheel. In addition, if the assembly uses such a material, such as, for example, modern etc., then you can get rid of squeaks and annoying "crickets" in Torpedo, if such were.

The main drawback is the risk of damaging expensive equipment. It often happens that after noise insulation of the instrument panel, there are failures in electronics.

Therefore, before the decision to spend these works, you need to weigh everything well.

I will not linger on noise insulation of the hood for a long time. You can make it as the insulation of the engine compartment, but it is better to use a car-blanket or something like that.

The noise of the motor in the cabin this procedure practically does not reduce. Here on the drive, the guy spent informative measurements: .

I would advise you to conduct noise insulation of the hood in case you have a diesel and he tahachtitis loudly. Also, the hood can be processed if it vibrates noticeably when driving and you do not like it. Standard materials: Shumoff Series M or Light, STP BIMAST BOMB or AERO For vibration insulation and closed types for Shumkov: Shumoff Series P or Isoton from STP.

Noise isolation is better glued to the standard noise insulation of the hood, it will be more convenient. And thus, ventilation openings will not be covered.

RESULTS

In what volume to carry out noise insulation, each will solve himself.

I would advise the following:

Noise isolation of doors - "Masthev"It should be done even if you are not going to change your speaker system. The effect compared to the cost is wonderful.

An important element of acoustic tuning is noise insulation of the car doors. When installing any musical system in a car, complete noise insulation if it is not necessary, it is very desirable. But the preparation of the doors of the car under acoustics should be carried out anyway. Because without this, the music will play bad.

If you do not often listen to music in the car, and the main goal with which you do noise insulation is to make a car quieter, getting rid of a significant number of external noises, then the doors should also pay close attention, because it is through them in the salon that penetrates about 30 % of all noise.

How to make noise insulation car doors?

It all depends on your goals. If you just want to achieve noise reduction while driving, you will need one way, to process the doors to the music, you will need another technique and the materials used.

Conditionally you can highlight four different options Noise insulation of the doors of the car, depending on what you do it.

The first option is the noise insulation of the doors of the car is minimal.

It is not suitable for installation of acoustics. But to make outdoor noises less, it is enough. In order to minimize the doors, it is necessary to stick to the outer panel of the door, a solid layer, or at least 70-80%, vibrating absorbing material (STP vibroplast, noiseoff).

You can use a vibration-hammer 2 mm thick. And noise insulating material (accent, splang) can be pasted on the inner panel of the door card, it will reflect noise, as well as serve as a kind of dust and moisture protection. Pruning the vibration-absorbing material can be pasted on flat venue of the door card.

Such an option is the cheapest price. But this allows you to improve the noise picture inside the cabin, without spending a significant amount of money.

The second option is the noise insulation of the doors of the car medium.

It can be said that such noise insulation of the car doors is optimal in terms of price / quality ratio. In this method, more special materials are used, and they are mounted a little differently. This allows you to seriously reduce the noise from the road, and also makes it possible to install acoustics in the door and get good returns from it.

The first layer, on the outer fillet of the door, it is worth using a 2 mm thick vibrating detergent (vibroplast from STP, Shumoff M2). And in the place, which is opposite the dynamics, can be glued with a sheet of 3 mm (Shumoff M3). It is also desirable to add an acoustic lens here. On top "Vibra" can be glued with noise insulating material, and you can do without it. There is no single opinion on this.

For the speakers played well, you need to do something similar to acoustic speakers from the door. To do this, an outer vibrating detergent must be placed on the outer fillet (for example, a MP visomat), closing the technological holes.

Door cards themselves should be sampled by a thin vibration unit, the thickness of 2 mm is suitable (Vibroplast Silver, Gold, Shumoff M2). And then the entire inner surface is placed with a noise absorber with a thickness of 5-10 mm (Bitoplast from STP, Hermeton from Sumoff).

The third option is noise insulation of the car doors.

Such. Used when you plan to install a powerful speaker system with good midbas on the door. In this case, the doors must be prepared for such speakers. External noise is no longer the main goal. Although with such a processing you are guaranteed to get rid of most of them.

- The first layer, on the outer fillet, you can use a vibrop absorbing material, a thickness of 3 mm (noise m3), but not thicker, so as not to grow too much doors.

- On top, it is possible to glue a leaf of noise insulating material with a water-resistant adhesive layer (Shumoff P4, P8).

- The technological holes in the inner filin can be closed with a special aluminum foil on adhesive basis, and from above to told a hard vibration, a thickness of 2-3 mm.

- over - noise insulating material, 4-5 thickness (Splang, Shumoff P4).

The door card also needs to be treated with 2 mm "Vibra". And under it glue a noise absorber, a thickness of 10-15 mm, with a wavy surface (type of germeton).

The fourth view of the noise insulation of the car doors is extreme.

It is intended for such noise insulation of the doors of the car for processing doors under powerful acoustics, the so-called "loud front". These are the systems with which the competence on the volume of front acoustics, or by sound pressure. The door is treated with the most thick and efficient materials. The risk that it will take them too much, is not taken into account.

- First, the door must be reinforced. This can be done either strips of hard "vibra", or aluminum planks, which are pasted with small gaps, to the outer panel.

- Then the thick vibrating detergent with a thickness of 4 mm is rolled between them (Bimast Bombers, Sumuloff Mix F, Shumoff Prof.).

- The next layer is noise insulation of the doors of a car or a noise absorber with waterproof glue, or latex film (Germeton). Technological windows are also closed on the outer fillet. Here you can use polyester resin or aluminum sheets. From above, they roll in thick "vibra", 3-4 mm (bimst bombs, noise m3, m4). After that, a layer of noise insulator is pasted (Splang, Shumoff P4).

- The door card is processed by pieces of vibra to get rid of vibrations and dresseng. And under it, the maximum thick noise absorber is glued, which is placed (for example, Germeton A15, A30).

The area that is covered with a noise absorber depends on how many speakers will be in the door. Since the door card may contain several midbasov, "middle", it is attached to the door of the door through bolts, and the acoustics are installed later.

Before implementing any option noise insulation of doors in the car, described here, think well which one you need, under your car and goals. Remember, no matter how well you have not handled the doors, with windows you can not do anything. And the big percentage of noise will fall into the salon through them.

The road canvas on which the vehicle is operated is far from always high quality. In the aggregate with the fact that automakers rarely pay due attention to high-quality noise insulation of doors, frequent trips from a bad surface lead to loosening the fastening elements of the body, trunk, hood and doors. About the presence of problems The driver learns only for the second year of operation of the car, if initially it was purchased new. It is the doors that make themselves known in the first place. How is the noise insulation of the doors of the car, and what materials are needed for this?

Functions noise insulation doors

Noise insulating work should be done immediately after purchasing a car, even if it is new. Improvements will be as follows:

- significant increase in driving comfort and reducing the risk of an accident, while extraneous noises annoy the driver and make a trip unsafe;

- acoustic capabilities of the salon increase, the sound quality increases, the vibration and rattling while driving are eliminated;

- heat loss is reduced, which leads to long-term preservation of the necessary air temperature, even when the engine is turned off.

Choosing materials

The key goal of vibrating absorbing materials is to reduce the structural noise caused by the vibration of metal parts vehicle (suspension, transmission, engine). When choosing a specific material, it is necessary to navigate the mechanical loss factor. It must be as high as possible. The materials under consideration due to the adhesive base are quickly mounted and have additional sealing properties for anti-corrosion protection of metal elements of the body. The basis for the manufacture of the materials presented below is a mastic or bitumen, possibly addition of aluminum foil, but there are options without it.

- Bimers are represented by two layers - bituminous and mastic. Thickness is 2 - 4 mm, the external coating can be made of aluminum, paper or tissue.

- The visomat is a vibrating absorbing material based on bitumen, performed on an adhesive basis. Vibration absorption provides a combination of bitumen with a foamed polymer. The MP series is distinguished by the presence of a foil coating.

- Vibroplast is distinguished by high elasticity and flexibility. The structure is represented by aluminum foil, polymer and self-adhesive basis.

Sound-absorbing and soundproofing materials, in turn, isolate sounds, made on the basis of polyethylene. Categories the category of additional materials used after vibration insulators.

Technologically correct operation of noise insulation works in the door zone requires the preparation of the following materials and tools:

- noise elevators and vibration insulators;

- rolling roller;

- solvent;

- scissors or construction knife;

- construction or household hair dryer;

- screwdriver Set.

The preparatory stage requires the following work:

- Disassembling the door is performed in the open state. The trim must be removed in a well-lit room, the process is monotonous and long. Try not to damage the fasteners and remember the disassembly process. The glass lift mechanism can not be dismantled.

- Second preparatory stage Requires the removal of factory isolation and anti-corrosion protection.

- At the final stage, the clean metal obtained after dismantling must be deguted.

Phased noise insulation depending on the degree

Phased noise insulation of the doors of the car with their own hands directly depends on the degree of sound insulation, which must be achieved.

Minimum noise insulation

it a budget optionAnd it will not suit the improvement of acoustic properties, but noise is reduced. Door processing is minimal and involves sticking the vibration-absorbing material to the outer panel of the door with a solid layer or 70% at least. It is allowed to use a 2 mm vibration-pulp. To reflect noise, it is necessary to process and the inner fillet of the door card, for this you can use noise insulating material. Additionally, this measure will serve protection against moisture and dust.

Flat door map can be treated with trimming.

Average noise insulation

The optimal relationship between quality and price can be achieved by means of medium noise insulation. Special materials In this case, more and the principle of installation is somewhat different. The noise from the road is significantly reduced, and in the door you can install acoustics, which will be able to get a good return. The procedure here will be the following:

- The first layer is represented by a 2-millimeter vibration unit. In the zone opposite the dynamics, it is possible to use a thickness of 3 mm and add an acoustic lens. From above, you can glue a noise insulating material, but this stage is not mandatory.

- Use a hard vibrating unit for processing the external philine and the closure of all technological holes.

- Thin vibrating detergent (2 mm) is suitable for processing door cards.

- A five- or ten-minute meal noise absorber is used for the final processing of the entire inner surface.

Maximum noise insulation

The underlisted level of noise insulation will be appropriate if necessary, to mount a powerful speaker system with midbas in doorways. Under such speakers should carefully prepare doors. The main goal in this case will be not to suppress the external noise, although with this function this processing will cope perfectly. Features of the installation of such isolation:

- Vibrating absorbing material with a thickness of 3 mm is worth using as a first layer for processing an external philus. The material is not worth choosing a greater thickness, otherwise the door will become too hard.

- As a second layer, use noise insulating material with a layer of waterproof glue.

- Prepare an aluminum adhesive foil for processing technological holes in the inner filin. Turn on top of the foil Turn the hard vibration insulating material with a thickness of 2 - 3 mm.

- A four-or-five-millimeter noise insulating material will become a finish layer.

- Do not forget to handle the door card. First, cover a noise absorber with a wavy surface (10 - 15 mm), and on top of it vibration insulation with a thickness of 2 mm.

Extreme noise insulation

The key destination of the sound isolation of a given degree is presented by the preparation of the car before the sound pressure competitions or the volume of the front acoustics. To handle the door in this case, you must use the most thick materials to provide the greatest efficiency. The probability of excessive weighting of the doors is too high, but this risk with such tuning is no longer taken into account. Stages of installation of such insulation will be as follows:

- At the first stage, the door reinforcement through aluminum planks pasted on the outer fillet with small intervals. Also, the role of the reinforcing material can be carried out strips of rigid vibration insulating material.

- On the next Stage Between the intervals, the vibrating absorbing material is 4 mm thick.

- The following layer is represented by a noise absorber or noise insulating material based on latex film or waterproof glue. Do not forget about the closure of technological windows by aluminum sheets or polyester resin. The upper layer will be represented by vibration insulation with a thickness of 3 - 4 mm.

- Slices of vibration insulation are also used to process the door card, but it is pre-sticking a noise absorber. Its thickness must be the maximum possible. The area covered with a noise absorber directly depends on the amount of speakers installed in the door. Since Midbasov can be several, the door card is fixed on the door of the door through through bolts and only then an acoustic system is mounted.

A significant amount of external noise arrives through the door to the car's salon. It is after noise insulation car doors There is a tangible decrease in external noise. In addition, the doors can always be completely "to do" and do it yourself. There are no supernatural difficulties here.

Before noise insulation - disassembly doors

The first stage is a complete disassembly of the door, namely, the removal of the external sheaving. This stage is the most difficult, but not the most difficult. It is necessary to remember (and it is better to write), what kind of screw or the screw was in what a hole in order to make it easier to make it easier to build a reverse door assembly. The mechanism of opening and closing the door, as well as the device of the window regulator, can not be removed, because put them back extremely difficult. These nodes will not interfere with self-insulation Doors.

The second stage it is necessary to clean the metal of the door from the factory noise insulation and the wall of the door, close to the outside - from the factory anti-corrosion processing. It is important that the surface is clean and degreased - the White Spirit will help in this. The main thing is not to scratch the paint in order to avoid corrosion.

Getting to noise insulation doors

Next follows the inner side of the door (side to the road) to plunge the vibration-fixing material. Gold Vibroplast is best suited, while you need to try to take the maximum area, which technical holes will allow in the door. It is not very convenient to be done there, so not to scratch your hands about sharp edges of the technical holes, it is better to work in cotton gloves. Door Amplifier is not needed. Currently, AERO and AEROPLUS from STP are increasingly used to vibration insulation of metal. They are easier than the Vibroplast Gold, which will have a positive effect on the resource of the door loops. The high KMP will make the door "wooden" onto a knock, close the doors will become like a car above the class with a pleasant sound "PHF" instead of BDZYN. In addition, the new Aero line has been expanded the temperature range, which is especially important for the cold season.

Opposite the dynamics, it is recommended to stick a circle from the bitoplast so that the speaker becomes better to play and the sound waves reflected from the door are not accepted. You do not need to damop the entire surface of the bitoplast, because This material absorbs moisture, and breed the dampness inside the door - the first step towards corrosion. The second layer on top of the vibration insulation used to be splated for silence, since the usual emphasis could not cope with moisture appearing in the door during the rain. In addition, on some cars, Splin 8 mm could not withstand the operating conditions and tritely dug out due to non-water-resistant glue. Now the material of the new generation is available - the focus of premium, which is completely not afraid of water: outside the material is covered with a black film, and with back side Moisture-resistant adhesive layer of green color is used. Therefore, the inner part of the door can be safely accumulated by a premium accent.

For music lovers, the use of any material (except for vibration insulation) inside the door is undesirable, so because of it, unpleasant extensions will begin to appear and the quality of music will deteriorate.

If the quality of the sound of acoustics is not important, then the entire inner surface of the door should be tightened with an accent of premium or splane on a mastic basis. It is necessary to glue the maximum slice, ideal - one whole one. Will be quieter.

Vibration Isolation of All Door Holes

Go to the inside of the door - close to the cabin. Here are two options here.

If the car is preparing for the installation of powerful acoustics, and from Midbas installed in the door, await a juicy game, then it is necessary to close the process hole in the door with a dense and solid material. Depending on the sizes of the holes, sheet aluminum or dense fiberglass can be used, which is then covered with a powerful vibro-reader, for example, bimavo bomb premium or visomat. It is important to improve the quality of the sound of music - from the door there should be something like a rigid closed box. It is important to check the performance of the door opening mechanism and windows - so that nothing bothered. The use of bimaste when embelling technological windows can significantly increase the mass of the door, you have to choose: or loops, or music.

If the sound quality of acoustics is not important, then the technological windows are closed with waterproofing: it is important that the moisture does not go into the cabin. For this will suit STP AERO: lightweight and durable to break. Many slightly glue vibration insulation is not worth it, because Increases the mass of the doors and loops may not withstand heavy loads.

There is also a compromise option applied to noise insulation of civil car doors: we close the technological holes in the Foil Watch, and then rolling the Aero Plus on it. Thus, we obtain sufficient rigidity for the acoustics of medium power, excellent waterproofing and a small increase in mass.

Then it should be saved this surface of the door to the material to the focus or focus of Premium, as a last resort - bitoplast 10 mm, making the necessary slots to all mechanisms. It should be accumulated by an area close to 100%, leaving space for wires (if the power windows is installed) and the speaker.

Noise isolation of door sheathing

It is finished with the door, go to its trim. On the surface of the trim, it is recommended to glue several pieces of vibration-pulp (enough STP Aero or Silver vibroplast) to reduce the vibrations of the trim. Special attention should be paid to the joints in plastic. Then the entire surface of the skin is covered with a biplast 10K with a margin along the edges of several centimeters. After trimming the bitoplast on the contour of the trim, it will perform the role of antiskrip - all the stuffing knobs about the door itself will disappear. Another option is possible: in the places of fitting the door sheathing to the metal of the door to the trim on its perimeter, Madeline strips are glued, and the inner part of the trim is filled with biplast.

On this noise insulation of the doors of the car do it yourself Finished, you can proceed to the installation of the trim back. On the different cars The door disassembled in different ways, but the principle is the same one and the same. With noise insulation, the doors from the splash is better to completely refuse, because Inside the door from it only disadvantages (the quality of the sound of acoustics is spoiled, it can fall off from moisture), and outside (between the bitoplast layers) it can interfere with the reverse assembly.

As a result of the "Shumkov" doors in the car, it will be sweeteringly quiet, and the doors will be closed easier by increasing the mass.

The main purpose of noise insulation is to get rid of noise arising when moving the car in the cabin. Any car even new passes a certain amount of noise from the engine operation, rolling wheels, noise from wind and sound stream created by passing and counter transport.

Factory isolation in most cars weakly copes with this task. An exception can be recognized only by the models of the premium sector. Than lowestly car, the weaker he has protection against extraneous noise. This is due to the fact that the installation of quality noise insulation costs quite expensive, and in economy class can be up to 10%. Fighting the buyer, the manufacturer reduces production costs and primarily on noise insulation.

Than older carMoreover, noise penetrates his salon from the side, and even inside the extra symptoms and rattling, which cause irritation of the driver and passengers. Excessive noise in the cabin is the reason that the driver quickly gets tired and the safety of road traffic is reduced.

The only way out to solve the problem with increased noise - install extra noise insulation in the car.

Soundproofing car in service

The fastest and easiest way to get rid of extraneous noise in the cabin, make noise insulation of the car in the car service of experienced specialists.

But this method has one significant disadvantage - the cost of the work performed. The second problem is the choice of car service itself, many promise to do high quality and on time, but not many are implemented in practice.

The best way to choose a workshop is the reviews of familiar car owners who have fulfilled the car insulation on this service. Internet reviews There are no importance, as in order to attract potential customers, managers independently write praise on sites.

Before starting work, you should visit the service and ask the Wizard, as with what materials will be performed. Well, if workshop will be conducted on noise insulation, it will be possible to assess the level of skill of specialists and their attitude to the work carried out. In the presence of funds and high-quality service it. best option To perform noise insulation of the car.

How to glue noise insulation in the car, video:

Noise insulation with your own hands

For people who love to do everything on their own or not have enough funds to perform work in the service, the car's noise isolation can be made with their own hands. This method is convenient because the work can be performed not in a hurry and parts. To perform work, no special skills and complex equipment will be required.

This will require:

- Noise insulating material;

- Solvent or White spirit;

- Scissors and a stationery knife for cutting;

- Industrial dryer;

- Gas cylinder with burner;

- Roller roller;

- Set of a plumbing tool.

The high-quality noise insulation of the car largely depends on the selected material. Industry suggests big choice These materials, and get confused simply enough. How and what material is better for car noise insulation.

The main property of any noise insulating material for sound insulation is lack of hygroscopicity. So choosing material special attention We draw on it, since the accumulated moisture leads to corrosion of the metal.

Noise insulating materials for cars

Materials for soundproofing vehicles can be divided into the following types:

- Bituminous shale;

- Polyurethane;

- Felt;

- Liquid car soundproofing.

Vibroplast

The main material for protecting the noise of doors, gender, cabin, trunk lids and hood. It is a polymer, bitumen-shale composition with an adhesive layer to facilitate applying to protected surfaces.

Aluminum foil is applied to the top layer of pressed duplication. To facilitate the cutting, the foil surface has a pattern in the form of square sizes of 5 × 5 centimeters. The adhesive layer is protected by a special film.

The material does not accumulate and does not absorb moisture, is not subject to decomposition from the effects of external factors, with proper application, protects the metal from corrosion, has seal properties.

The material is easily applied to the surface, repeating its contours. There are several types of bitoplast, the differences are used fillers and layer thickness. The main disadvantage of this material is its weight.

With a thickness of a 2 millimeter, the weight of one square meter will be 3 kilograms, and the material with a layer of 4.5 mm weighs already 6 kilos.

The thicker layer, the better the vibro-noise insulating characteristics of the vibroplast. But for car processing, it takes from 8 to 10 square meters, so the weight of the car will increase depending on the thickness of the material used.

Splane

This material due to its excellent noise insulation characteristics was widespread. The material additionally has good thermal insulation indicators, does not absorb moisture, has low weight and is easily mounted thanks to a special adhesive layer.

Operating temperatures in the range from -45 to 64ºC, wearless. It is used to protect the most noisy sites in the car: Arches of wheels, tunnels, doors, side racks and other elements at discretion.

Depending on the purpose of Splen, it is 2, 4 and 8 millimeters thick. The last digit in the marking indicates its thickness, for example, Splane 3004. It has a thickness of 4 mm.

Thanks to a special adhesive layer, the noise insulation of the car's salon is quite simple, it repeats all surface contours, and excess and folds are easily cut off with scissors at the place. The material has low weight and does not reduce the payload of the car.

Felt

Widespread material for noise insulation. It has high indicators for the absorption of sound, has a small cost. In addition to sound absorption, synthetic and natural felts have high thermal insulation indicators and can be used in any temperature range.

Restriction in the use of felt has become its ability to accumulate moisture. Felt has a porous system, well absorbing moisture and condensate.

It is almost impossible to dry felt during operation, so it is necessary to apply it only in places where there is no possibility of access to the moisture.

The use of felt isolation under rugs leads to a rapid damage to the bottom of the car corrosion. Having accumulated moisture, the material not only largely loses its sound-absorbing characteristics, but also becomes an ideal environment for the development of mold and fungus. Raw felt leads to constant fogging of the glass, appearance unpleasant odor In the car.

The second main disadvantage of this means of noise insulation is the complexity of the installation, applied to felt adhesive coating very poorly and often leaves against the surface. Given the above to use felt for noise insulation of the car better limit.

Liquid noise insulation.

The correct noise insulation of the car should be carried out comprehensively and inside the car and outside. Outside, noise-absorbing masts should be treated with the bottom and wheel arches, which are the main noise suppliers to the salon.

The processing of the outdoor elements of the car by mastic not only reduces the noise level, but also protects metal elements from corrosion.

Modern manufacturers offer a large selection of liquid shchus insulation: bituminous and shale and resinobitume mastics, two-component and foaming compositions.

Liquid noise insulation should be applied to clean, low-fat surfaces. In some cases, to apply a sound insulation coating to apply primer for better adhesion.

Liquid compositions are well fill it all joints and provide additional protection against noise penetration. The liquid compositions are applied on the surface with a spacing or bruster. When working with compositions, it should be borne in mind that most of them have a long duration of drying up to several days.

Preparatory work

Noise-insulation work should be carried out in the warm season or in heated and well ventilated room.

Car treatment can be carried out both entirely and small elements. For example, at the initial stage, you can handle the bottom and wheel arches of the car with liquid noise insulation, then the trunk and doors.

The most costly time is the work on the protection of the internal elements of the car interior: floor, roofs and racks.

Before making noise insulation with your own hands, the car should be washed, so it is protected from damage paintworkYes, and with a clean machine to work more pleasant. When processing the bottoms, the car should be installed on the lift, the observation pit or the overpass.

Starting work with a lack of experience best with simple and smooth surfaces. For testing of their forces, the luggage compartment and the lid of the trunk will fit well. Preparing noise insulating materials For auto, equipment and tools and customizable on a long and painstaking process to reduce the noise level in the car.

Performance

Treatment of the bottom and wheeled arches

These work will slightly reduce the noise level in the car, but it is better to hold them first for additional protection of the car from corrosion. Before starting work, the surfaced surfaces are thoroughly detergent using automotive shampoos.

We should pay special attention to the hidden cavities, the moisture arising from them will not allow high-qualityly infect noise insulating materials.

The surfaces are inspected, all corrosion sediments and rust are removed using abrasive materials or rust converter. The surface is degreased and mastic is applied using a pulverizer or ordinary tassel.

Processing the outer surfaces of the car with sound insulation compositions follows 2-3 layers, with intervals between the application of the layers of 2-4 hours.

Noise isolation of the wheel arches of the car with your own hands, as well as the bottom of the car, the process is simple, especially if you use the lift. In this case, all four wheels are turned away, otherwise it will have to turn off each wheel separately with the hanging of the car using a jack.

After the work, you can assess the quality, in the cabin should be a bit quieter, especially in the field of wheel arches.

Noise insulation of the wheel arches of the car do it yourself, video:

Trunk and trunk lid.

Before starting work, we take out everything from the trunk and remove the inner cladding. We remove all the garbage and dust, for these works you can use a household vacuum cleaner. We look at the surface, when the rust is detected, we clean or process the rust converter, soil.

Degrease the surface with white Spirita And we apply a vibroplast carved. Vibro-noise insulation materials should be applied as accurately as possible to each other, without leaving the gaps. For a better fit, heated the material with a construction dryer and press the special roller.

The main sources of noise penetrating the car, are wheeled arches and a spare wheel niche, they should be protected as carefully.

After the vibroplast is fully laid, the adhesive layer is imposed on it. Before smoking this insulating material from it, remove the protective film closing the adhesive layer. Surplus splash is cut with a stationery knife.

we look at the quality of work, and if everything has passed satisfactorily proceed to the processing of the following vehicles.

Noise insulation of the doors of the car do it yourself

About how to properly make noise insulation of the doors of the car there are many opinions, but everyone recognize that it is through these elements to the cabin that a significant part of noise penetrates and work is very difficult there.

To perform work, remove the door trim, dismantle the built-in speakers ( in the presence of), if possible, to remove electrical equipment and wiring as possible. We remove garbage, dust and degrease.

Fully process the inner surface of the door with vibroplast is not possible due to the inconvenience of the structure. Therefore, untreated faters are missing any mastic. We stick the vibroplast on top of the vibroplast.

It should be noted that after the work, therefore, it is not worth applying strongly heavy materials.

The outer surface of the door is cleaned with a thin splena or bitoplast. Inner side Doors covering also sample with thin spleen or bitoplast. After processing all doors, the sound insulation of the car will improve significantly.

Video on how to sick the doors:

Roof and floor of the cabin

Clamping the car is noise insulation with your own hands inside the cabin is not as difficult as dismantling the elements of the skin. Therefore, work on the processing of the roof and gender should be carried out simultaneously.

The front panel itself is better not to touch or entrust it to experts. Work is better to start with the roof, gradually going down. For the roof processing, a thin vibroplast can be used, a spill on which you can stick felt.

To process car racks, splented or vibroplast is used. To protect the floor, a vibroplast applies, on top of which Splane is superimposed. If the factory noise insulation of the floor is made from felt, it is better to replace it with synthetic materials.

When processing the cabin should pay attention to the following nuances:

- When processing the roof, it is not necessary to use a lot of thick vibratinglast, the center of gravity will shift and the car will lose in controllability.

- The use of too thick insulating materials can create problems with the installation of the floor covering.

With properly conducted works, noise insulation in the car will significantly improve, and the journey on it will deliver true pleasure.

After conducting work on noise insulation, the sound of speakers will significantly improve, and the noise of the road will not interfere normally talk in the cabin.

Is it worth doing no insulation of the car, like what materials, to apply for sound insulation depends only on the owner of the car, its financial capabilities and skills.