We clean the nozzles (injector) ourselves

Device advantages (diagrams):

1. Easy to assemble

2. Does not need to be configured

3. No scarce items

4. Can be assembled on a breadboard

Working at the service station as an injector, we often encountered the problem that the car was eating fuel, twitching, pulling badly! Basically, the whole problem was in the low-quality fuel that they slip into us. Of course, not always, there were simple and trivial cases when the plug fell off or the candle failed. But this is not the point now.

The quality of gasoline with us leaves much to be desired, the temperature and time on the nozzles of the injectors and on their needles form plaque, dirt. Sometimes a tube and a can for cleaning carburetors with improvised means do not always help. They turn to specialists.

I will now provide a circuit board that replaces the standard program for cleaning the injector (s). Why did I make it, you ask? Due to the fact that our lights were often turned off in winter, and our boss was a little greedy for money to buy a normal generator to run the entire station.

The circuit is powered by 12 volts, any battery. Doesn't need a computer. I did not reinvent the wheel, at first I climbed the sites and forums, but something was too complicated there, or on ancient antediluvian elements. I decided to strain the gyrus a little and do something simpler. No sooner said than done. A day later, I drew a diagram and tested it!

I did not reinvent the wheel, I took the well-known generator on the NE555 microcircuit to everyone, picked up the ratings to get the signal that should go, took the end stages from the same program that was kindly provided to me and I got a circuit that pulls the title of "cheap, but angry "!!! Well, let's not pull the cat for ahem ... hmmm, I provide a diagram:

Injector cleaning diagram

I must say right away that R1 and R2 are composite or you can use variables that we select values with a multimeter. Ideally R1 (30.7 kom), R2 (23.02 kom). These values are not from the ceiling, I took the data from the program, I adjusted everything through the program for NE555. Anyone interested can then give a link. It is advisable to take exact resistors, since the generator signal directly depends on the deviation in these resistors. I can say the same about capacitors C1 and C2. I dropped them out of the audio recorder. R3 and R4 are not critical in this regard. VR1 in the diagram is a roll or a voltage stabilizer of 5 volts, T1 is an amplifying transistor, T2 is a terminal (composite) one. The diode can be ripped out of Chinese power supplies or it costs a penny to buy.

It is imperative to install KRENKA and Transistor T2 on the radiators, a small roll is enough, but KT898 needs somewhere 8 by 8 cm radiator, it heats up well !!!

Unfortunately, I cannot provide a photograph of the assembled device, but it worked for 3 years while I was at the service station, then left it there, I hope it still works. It was assembled on a breadboard so that everyone has room for imagination, and there are not many details there.

There is one more note, before connecting the injector, measure its resistance, if the resistance is less than 8 ohms, then you should not drive them for a long time for a maximum of 30-60 seconds. The rest can even be driven until blue in the face (just kidding) 5-8 minutes is enough.

How to use this pribluda: immerse the nozzle halfway into a solution of acetone, solvent, or the same liquid for cleaning carburetors (by the way, I recommend it). We connect the injector, and then we supply power to the board (you can put the toggle switch =)). The nozzle begins to buzz, bubbles form at the base of its nozzle, this is the effect of cavitation, after a while it begins to drink, so to speak, pumping the solution from the bottom up. If this happens then all the rules.

ATTENTION: Do not use this option on machines older than 2005, some injectors that have already corroded may simply fail. This is found mainly on Korean cars... It is also not advisable to use this method where ceramics are present in the nozzles.

If you have any questions please write. Roughly how to do it from below, I will throw a photo.

Injectors for both injection and diesel engines clogged over time. This is due to the fact that there are small impurities in the fuel that the filter cannot leave on its body (and even more so if it is old and / or of poor quality). There are commercially available, but many of them are quite expensive and show questionable results. Therefore, car owners have come up with several simple methods that allow using improvised means in garage conditions clean the nozzles of the same quality as professional cleaning at the stands. If you have any thoughts or suggestions of your own, share them in the comments.

Method one - using a carburetor cleaner

If instead of special means to clean the nozzles, you have a carbcliner lying around, then you can clean the gasoline injector yourself in a garage environment even with a carburetor cleaner from a can, and not buy liquid for the injector. Next, we will describe one of these methods. To work you will need:

- two pieces of clean rags;

- copper insulated wire of small cross-section with a length of about a meter;

- plastic clamps (ties);

- awl;

- 9 V electric battery (popular "Krona");

- a piece of oxygen hose 4 ... 5 cm long;

- insulating tape;

- (when choosing, pay attention to the working cap of the cylinder in diameter that fits the inner diameter of the oxygen hose so that it can be inserted inside);

- protective goggles and gloves.

You need to work with the carbcliner carefully, using funds individual protection, therefore, you must first put on glasses and gloves... Work algorithm:

- remove the nozzle from the fuel manifold and use a rag to clean it from the outside (it is better to first remove the rubber seals from it);

- cut a piece of wire into equal parts and clean the insulation on one side of the resulting wires with a knife;

- using electrical tape, connect the stripped ends of the wires to the battery;

- on the opposite ends of the wires, using an awl, slightly expand the insulation for further connection to the nozzle;

- make a hole in the carbcliner cap using an awl in its upper part;

- insert the cap into the rubber hose (in this case, the “native” hole of the cap will be plugged by the hose) and clamp them with a plastic clamp;

- install the resulting adapter on the carbcliner cylinder;

- connect the externally cleaned nozzle to the adapter from the rubber hose and squeeze it with a clamp;

- connect the injector to the battery, while you will hear a click, signaling that the injector has opened;

- put the adapter with the nozzle on the carburetor cleaner cylinder;

- gently apply pressure (press);

- this will cause the carburetor cleaner to come out vertically through the nozzle (that's what glasses are for!).

Clean until the torch is even. After one cleaning, turn the nozzle upside down and repeat the operation. Then you can proceed to cleaning the remaining nozzles.

Method two - using a flushing cylinder

This method can also be performed in the garage with the help of improvised means, it is good because there is no need to dismantle the engine nozzles, but as a cleaning composition you will need to purchase a solvent (Vince, Laurel, high gear or other). To work you will need:

Filter cylinder

- A clean 2 liter plastic bottle with a tight screw cap

- compressor (to be able to deliver 3 atmospheres);

- flushing liquid (about one liter);

- drill and drill with a diameter of 13 mm;

- two clamps (12 ... 14 mm);

- fuel filter;

- two automotive nipples;

- a hose with a diameter of 12 mm and a length of about a meter;

The work algorithm is as follows:

After that, start the engine and let it run for 15 minutes for idle and rest for 15 minutes. Then start the engine again and let it run until the bottle runs out of cleaning fluid. When the engine stalls, you must carefully bleed the pressure from the bottle! This can be done either with a nipple or simply by gently unscrewing the cap.

After that, you can disassemble the resulting system, connect the fuel hose to its place, and return the chip to its original position. After everything is assembled, you need to start the engine and let the machine run for 5 ... 10 minutes. It is highly advisable to change the oil and candles (especially candles) after performing the described procedure.

The cleaning method is quite simple, but it has a significant drawback - the lack of visual control of the condition of the injectors. It is quite possible to use it for preventive purposes if there is a suspicion that the nozzles are clogged.

Method three - adding acetone

On numerous forums on the Internet, you can find many topics about whether to add acetone to the gas tank. Despite the fact that the official representatives of automakers and oil refineries do not say a word about this, many domestic (and not only) car owners add a small amount of pure acetone to the gasoline they use.

This action leads, firstly, to an increase in the octane number of gasoline, and secondly, it causes a cleaning effect for the elements of the fuel system (washes away carbon deposits), and also binds water in gasoline and removes it along with exhaust gases. As a rule, the effect of using acetone is felt after it was added to a full (or almost full) tank of gasoline, and this fuel was subsequently burned during driving.

A few words about proportions. The amount of acetone added to gasoline depends, firstly, on the octane number, and secondly, on the quality of the fuel (impurities of water and harmful impurities in it). If the gasoline is good, then it is enough to add 30 ml for every 10 liters of gasoline. As it deteriorates, the amount of acetone can increase up to 150 ml per 10 liters of gasoline. However, don't get too carried away with adding acetone! This is due to the fact that since this agent increases octane number, then if its value is exceeded in comparison with that for which the engine is designed, this can lead to a gradual failure of the motor. And the higher the value is exceeded, the faster the engine “knocks”.

Method four - the use of Dimexidum

To clean the nozzles, you can also use the popular drug Dimexide, which is sold in any pharmacy, and is very inexpensive. So, for work you will need:

Flushing plant

- Dimexide drug (500 ml or more, depending on the degree of contamination);

- A clean container for liquid with a lid, such as a bottle with a tight-fitting lid of about 500 ml;

- two nipples;

- a drill (screwdriver) and a 13 mm drill (for the nipple diameter);

- four containers in the form of test tubes, where the contaminated liquid from the nozzles will be collected (separately for each nozzle);

- battery or power supply unit 12 V;

- air hose;

- clamps;

- solvent "Solvent".

The cleaning procedure consists of the following stages:

- Dismantling the ramp with injectors.

- Construction of a flushing stand.

- Checking the injectors for performance (mounted with a ramp on a stand with transparent containers, to assess the spray pattern and the amount of fuel emitted).

- Soaking individual nozzles in a container with Dimexide (always in a vertical position so that this aggressive agent does not get on the rubber seals).

- Rinsing of injection nozzles with Dimexide under pressure for 10-15 minutes.

- Flushing with solvent and blowing with compressed air (so that there is no money left in the nozzle).

Conclusion

As you can see, self cleaning injector nozzles in garage conditions are quite acceptable and effective. However, it must be performed, firstly, provided that you are sure that you will do everything correctly, that is, you have experience in performing such renovation works... Secondly, the degree of contamination of the nozzles is medium to low. If the injector is clogged very badly, then it makes sense to seek help from a car service, where the nozzles will be washed with the help of a liquid or ultrasonic cleaning unit.

Anyone who knows a little about a car knows that one of the essential elements in the injection system are injectors. The well-being of the whole car depends on their serviceability. And therefore, every novice driver should know how to clean the injector himself and how to keep it in good condition.

An important element of the car's power supply system is the injectors Fuel system modern engine- delicate, complex and sensitive mechanism. In the fuel system of the engine, obvious malfunctions of its operation immediately appear, especially due to the use of low-quality fuel. It often contains a lot of all kinds of impurities with which manufacturers are trying to increase the octane number of their fuel.

The need to flush the injector

Chemical compounds such as olefin, benzene, sulfur, and others form tarry deposits in fuel lines, rail. And during combustion - on the outer and inner surfaces of the nozzles. Deposits formed on the injectors are a black-brown crust that does not dissolve with gasoline, making it very difficult to rinse the injector with your own hands. This procedure, as a rule, does not give tangible results. Flush fuel system only needed in a car repair shop or at a service station at professional equipment... Currently, injector flushing is carried out on professional equipment, which requires certain skills and experience.

How can you tell if it's time to clean your injector? Contamination of the system can be easily identified by the operation of the engine: with a decrease in the performance of the injectors and an incorrect spray angle, an increase in fuel consumption occurs, the car jerks, there are dips during acceleration, unstable idle speed, the engine does not start well, especially in winter.

When and how should the injector be flushed?

Cleaning the injector is necessary with certain signals from your car. These are increased consumption fuel pointed to on-board computer, poor engine starting and uneven engine operation while driving, when there are dips and jerks in its operation. And do not rush to get into this system if you have only one sign, for example, fuel consumption. This may be due to driving behavior, flat tires, and many other factors.

An additional way to check the correctness of your guesses will be to contact a service station where the necessary testers for injectors are available injection engines... They will also advise you on what can be done if they have really become unusable due to fuel coking at the holes. There are two fundamentally different ways of flushing today: with a special liquid directly into the car and with ultrasound with preliminary removal of the nozzles.

An additional way to check the correctness of your guesses will be to contact a service station where the necessary testers for injectors are available injection engines... They will also advise you on what can be done if they have really become unusable due to fuel coking at the holes. There are two fundamentally different ways of flushing today: with a special liquid directly into the car and with ultrasound with preliminary removal of the nozzles.

The easiest way to clean the fuel system is to use additives. They are inexpensive, always commercially available, and the injector is flushed independently. You just need to pour the additive into the gas tank and do it every 5,000 - 6,000 km mileage. In this case, virtually the entire fuel system is cleaned: starting with the gas tank and ending with the piston cylinders. However, this method can only be recommended as a preventive measure. An attempt to clean the contaminated injector in this way will lead to contamination settling in stagnant zones, in pipelines, on injector filters. For vehicles with high mileage such a purification gives nothing.

A moderately clogged injector can be cleaned without removing the injectors. Flushing plant is connected to the fuel system of the vehicle and is supplied to the injector special liquid which dissolves deposits formed in the nozzles. In 20 minutes of engine operation on this fluid with a pressure of 5-6 atmospheres and the question of how to flush the nozzles with your own hands has already been resolved. The combustion chamber, ramp, valves are effectively cleaned. Injector flushing solvents are available today in a wide range. Experts recommend Wynns liquid (Vince). But, having the indicated advantages, such a procedure is powerless in case of heavy pollution.

In addition, such an event is accompanied by the replacement of candles, since the mixture used is very aggressive. Cleaning the injectors without removing: ultrasonic cleaning of the injector. The meaning of this procedure is in rinsing the nozzles in a special bath using a special suspension and exposure to an ultrasonic installation. Even very difficult contaminants that cannot be chemically cleaned are separated. The advantage can also be called the ability to control the patency, tightness and spray pattern of the nozzles. Such a fine washing of the nozzles affected the price of this service: it is higher than the chemical one. Another way is ultrasonic cleaning of nozzles. Ultrasonic cleaning is applicable for heavily soiled injectors caused by the use of low-octane or low-quality gasoline. If the car has traveled much more than 30,000 kilometers after flushing or cleaning the injector, this is the way to clean it.

In addition, such an event is accompanied by the replacement of candles, since the mixture used is very aggressive. Cleaning the injectors without removing: ultrasonic cleaning of the injector. The meaning of this procedure is in rinsing the nozzles in a special bath using a special suspension and exposure to an ultrasonic installation. Even very difficult contaminants that cannot be chemically cleaned are separated. The advantage can also be called the ability to control the patency, tightness and spray pattern of the nozzles. Such a fine washing of the nozzles affected the price of this service: it is higher than the chemical one. Another way is ultrasonic cleaning of nozzles. Ultrasonic cleaning is applicable for heavily soiled injectors caused by the use of low-octane or low-quality gasoline. If the car has traveled much more than 30,000 kilometers after flushing or cleaning the injector, this is the way to clean it.

Cleaning the injector with ultrasound - preparatory measures

For work, you will need a power source, which can even be used as a battery of your car, an ultrasonic device Pulsar and a container for flushed injectors. First, you should wait until the engine has cooled down if you have recently operated the machine. Disconnect the battery (remove the "+" terminal) or remove it altogether and place it next to the workplace, if it is your power source. Next, you need to remove the fuel rail so that nothing interferes, turn off all surrounding devices (hoses, filters, valve, etc.).

There is a valve at the end of the rail, with its help you can relieve the pressure, after which you can disconnect the fuel line from the rail. Now wait a while for the remaining gasoline to drain from the fuel hoses. Then the rail can be removed and the drops of fuel can also be allowed to drain into a separate can. Now you have access to the intake manifold, you can start cleaning there. Seating places where the nozzles are located must be cleaned, because there are already enough deposits and slag around them. This is done first with a screwdriver, and then blown out, you can use a compressor, but you can not be smart and use your mouth or a pear.

There is a valve at the end of the rail, with its help you can relieve the pressure, after which you can disconnect the fuel line from the rail. Now wait a while for the remaining gasoline to drain from the fuel hoses. Then the rail can be removed and the drops of fuel can also be allowed to drain into a separate can. Now you have access to the intake manifold, you can start cleaning there. Seating places where the nozzles are located must be cleaned, because there are already enough deposits and slag around them. This is done first with a screwdriver, and then blown out, you can use a compressor, but you can not be smart and use your mouth or a pear.

Now remove the nozzles from the rail, remove the O-rings, check them for damage. They may need to be replaced. Take an ordinary medical syringe of at least 5 ml volume and put it on each nozzle, and also connect the terminals from the device with ultrasound to each of them. Place the resulting structures in a half-liter jar in an upright position. Pour 5 ml of solvent into the syringes. Now everything is ready for cleaning.

Ultrasonic cleaning of the injector - work progress

The Pulsar device is connected to the network or to the car battery (red terminal to "+", black - to "-"). Flushing the nozzles is done in several stages.... Check first idling the appliance, you will hear a characteristic clatter. Stop operation by pressing the two bottom buttons. For the first cycle, start the cavitation mode (pressing 4 buttons simultaneously). When the solvent has passed the nozzles, turn off the appliance, remove the nozzles, drain the dirty solvent, soak a cloth in the solvent, and walk over the nozzles.

Now put the syringes back on, add the solvent, connect the device and repeat the cycle. Then do it a third time. If the solvent continues to come out dirty, continue to cycle until it comes out of its natural clear color. You can add a little cleaning liquid to each syringe. If a few additional cycles did not help, then carry out a forced flushing at the maximum speed of the device. If it was possible to achieve the purity of the solvent at the exit without this measure, then one forced cycle still needs to be done, for the final chord, so to speak.

Now put the syringes back on, add the solvent, connect the device and repeat the cycle. Then do it a third time. If the solvent continues to come out dirty, continue to cycle until it comes out of its natural clear color. You can add a little cleaning liquid to each syringe. If a few additional cycles did not help, then carry out a forced flushing at the maximum speed of the device. If it was possible to achieve the purity of the solvent at the exit without this measure, then one forced cycle still needs to be done, for the final chord, so to speak.

Now disconnect the Pulsar from the battery or the network, also disconnect the contact sockets of the injectors from it, work with it is completed. Free each nozzle from the syringe, wipe dry, provide O-rings (observe their color accessory: black - bottom, brown - top), lubricate them. Now install everything that was taken apart into the car, observing the reverse order of disassembly. Insert the battery, tighten all the pipes, pump fuel into the rail by turning the ignition on five times (without starting the starter). Now start the engine and test its obedience.

Do-it-yourself chemical cleaning of the injector

In common people this technique is called "enema". To "do an enema" you will need:

- good quality flushing fluid;

New candles included;

1.5-2 liters of normally filled gasoline;

Syringe (bought at the pharmacy);

Assistant to step on the gas pedal.

Mix flushing fluid and gasoline. Lift the hood and find the hose that goes from the "vacuum cleaner" to the intake manifold. Remove the adapter, it looks like a rubber tube. Pour a mixture of gasoline and flushing liquid into the syringe, pour it into the tube under pressure. Wait for 10-15 minutes, during this time everything that the liquid got out will oxidize. Now we connect the assistant. He starts the car, which is not easy because the tube is disconnected. The engine does not keep revs, stalls, you have to constantly press on the gas, maintaining the level of 2500-2800 Rpm. On next step again inject a mixture of gasoline with flushing liquid. It's not easy because of the pressure inside the tube, pulling the syringe inward. At this time, the muffler makes various sounds: from pops to a terrible roar. There may be puffs of smoke white or black carbon deposits fall out. It is not necessary to pour in a lot of wash mixture at once. Better to take the time and dose. Let everything rinse out better. Observe safety precautions when cleaning the injectors. After pouring in the entire mixture, turn off the engine, when it cools down, unscrew the spark plugs and replace them with new ones. This method does not flush the entire system, but this is the best alternative to a trip to the service.

Mix flushing fluid and gasoline. Lift the hood and find the hose that goes from the "vacuum cleaner" to the intake manifold. Remove the adapter, it looks like a rubber tube. Pour a mixture of gasoline and flushing liquid into the syringe, pour it into the tube under pressure. Wait for 10-15 minutes, during this time everything that the liquid got out will oxidize. Now we connect the assistant. He starts the car, which is not easy because the tube is disconnected. The engine does not keep revs, stalls, you have to constantly press on the gas, maintaining the level of 2500-2800 Rpm. On next step again inject a mixture of gasoline with flushing liquid. It's not easy because of the pressure inside the tube, pulling the syringe inward. At this time, the muffler makes various sounds: from pops to a terrible roar. There may be puffs of smoke white or black carbon deposits fall out. It is not necessary to pour in a lot of wash mixture at once. Better to take the time and dose. Let everything rinse out better. Observe safety precautions when cleaning the injectors. After pouring in the entire mixture, turn off the engine, when it cools down, unscrew the spark plugs and replace them with new ones. This method does not flush the entire system, but this is the best alternative to a trip to the service.

Best Injector Flush Products

A well-known Internet portal dedicated to the problems of motorists has tested various flushing fluids and published its recommendations. Here is some of them.

STP SUPERCONCENTRATED FUEL INJECTOR CLEANER

DOSAGE: the whole bottle is 364 ml.

FEATURES OF APPLICATION: poured before refueling in order to evenly distribute the additive in the fuel and achieve maximum efficiency.

TEST RESULT: the liquid has shown very high detergency. It easily dissolves deposits and to a suspended state, but it is recommended to use it only if you are sure that the gas tank is absolutely clean, otherwise dirt can clog the intake mesh in the gas pump and disable it.

STP Super Concentrated Fuel Injector Cleaner More than 80% of impurities are washed away. During the subsequent flushing with a special solution, the remaining deposits were removed. This aggressive flushing can be recommended for low mileage, the best option how to rinse the injector yourself with a preparation of this type.

STP Super Concentrated Fuel Injector Cleaner More than 80% of impurities are washed away. During the subsequent flushing with a special solution, the remaining deposits were removed. This aggressive flushing can be recommended for low mileage, the best option how to rinse the injector yourself with a preparation of this type.

KERRY KR-315

DOSAGE: 355 ml.

FEATURES OF APPLICATION: the drug is very cheap because it is produced domestically.

TEST RESULT: more than 60% of pollution was washed, and heavy deposits also succumbed. Subsequent flushing did not reveal the presence of indelible deposits. Despite its low cost, excellent results have been shown, and its use is limited only by the cleanliness of the tank. COMMA PETROL MAGIC

DOSAGE: 400 ml.

FEATURES OF APPLICATION: long-acting additive, one bottle for 60 liters of fuel. Small flakes float in the container with the preparation. This is a feature of the additive, and you should not be afraid of it.

COMMA PETROL MAGIC- perfectly cleans the injector nozzles.

TEST RESULT: this "soft" additive showed by no means brilliant results, washing out only 30% of deposits, it can be conditionally recommended for permanent use for cars with fuel tanks, not shining with purity.

HI-GEAR FORMULA INJECTOR

DOSAGE: 946 ml.

FEATURES OF APPLICATION: the liquid is poured into the tank, the bottle is designed for 2 washes truck or 3 car washings. This flushing liquid can be applied using any container with a measuring scale. Since the bottle is for several washes, and you need to accurately measure the required amount of liquid.

Cleaning the nozzles of the injection power system is not an easy operation, therefore they are far from daring to do it on their own, preferring to rely on the services of service centers and service stations. Some simply do not want to bother, arguing everything by the lack of time, others are simply not sure that they will be able to do everything right. For those who want to service their car themselves, without spending money on service station services (which are not always done with high quality), consider the technology of cleaning the injector in a garage.

Frequency of cleaning

Automakers usually indicate in the technical documentation after how many kilometers the injector needs to be cleaned. But here it is worth noting that they do not take into account the peculiarities of car operation, or rather the fact that the fuel that is sold at our gas stations is not always of high quality. And such gasoline primarily affects the speed of clogging of the injectors.

Experienced mechanics have found that in our conditions it is necessary to clean the injector nozzles approximately every 10 thousand kilometers. But this figure is conditional, since everything depends on the quality of the fuel being poured. Some may not need such an operation even after 15 thousand km, while others are forced to do the cleaning after 5 thousand km. Therefore, it is better for the car owner to navigate the car itself, the behavior of which itself will tell you that there are problems with the power system.

The main signs of clogged injector nozzles are:

- "Gaps" appeared when pressing the gas pedal;

- The power plant is functioning intermittently;

- Increased smoke when the engine is running;

- Drop in power and dynamics;

If all this is there, and the on-board computer does not show any errors, it is most likely that the nozzles are clogged and require cleaning.

To understand why contamination of the injector affects the operation of the power plant, let's briefly consider the principle of its operation. The task of the injectors is the timely supply of finely dispersed fuel to the intake manifold or directly to the cylinder so that it mixes with air before combustion.

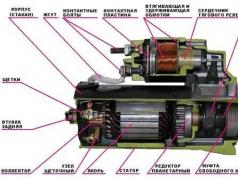

In order to ensure this, a shut-off valve with a needle is used in the nozzle design. When no fuel is supplied, the needle closes the nozzle (small holes). Also includes a solenoid and a core. The latter is connected to the valve. When voltage is applied to the solenoid, the resulting electromagnetic field acts on the core, which ensures its movement (retraction). At the same time, he pulls a valve with a needle, as a result, the fuel under pressure passes through the channels to the atomizer, from where it is already injected into the manifold.

To ensure high-quality mixture formation, gasoline must be injected in a finely dispersed state (in the form of a fog). Only under such conditions a high-quality combustion of the mixture is ensured. The holes in the nozzle provide good atomization, but they have very small cross-sections. Dirt, getting into the nozzle along with gasoline, clogs these holes, which immediately affects the quality of the spraying. Because of this, the fuel no longer comes in the form of a fog, but a jet, therefore it mixes much worse with air. As a result, gasoline does not completely burn out and some of it simply flies out into the pipe. Hence the drop in power, and an increase in gas mileage, and interruptions in the operation of the engine.

Cleaning methods

To remove dirt and deposits from the injectors of the fuel injection system, two methods are used - ultrasonic and liquid.

The first method is based on the phenomenon of cavitation, in which ultrasound acting on a liquid leads to the formation of microexcites. The essence of such cleaning boils down to the fact that the nozzles are placed in a bath with a cleaning liquid, and then the effect of ultrasound is provided. This cleaning method is very effective, but the equipment is expensive and therefore more suitable for the workshop.

The liquid method does not require special devices, and it can be carried out in a garage environment, that is, rinse the nozzles with your own hands. The essence of the method is very simple - all contaminants are removed by flushing with a cleaning liquid supplied under pressure.

DIY nozzle cleaning

In order to clean the injector nozzles yourself, you will need:

- Means for washing carburetors;

- Connecting tubes;

- Clamps;

- Wires with clips ("crocodiles");

As you can see, it will take a little, which is why this method is acceptable for garage conditions.

Cleaning of injectors is carried out only with elements removed from the car. And we do it like this:

- We relieve the pressure in the fuel system (we are looking in mounting block the fuse responsible for the operation of the fuel pump and remove it. Launch power plant and wait until it stops, having run out gasoline from the fuel rail);

- Disconnect the pipelines leading to the fuel rail;

- Disconnect the wiring from the injectors;

- We dismantle the fuel rail with the injectors from the car;

- We remove the nozzles from the ramp (before that they should be marked so that during installation they do not confuse where which one was);

After removing the nozzles, you can start cleaning. But for this you need to prepare everything correctly. For cleaning, it is necessary that the nozzle with a spray of cleaning agent has a tight connection. And for this you need a prepared tube and clamps.

In the theory and practice of car maintenance, there are operations, the necessity and frequency of which is questionable. Cleaning and flushing the fuel injection nozzles is one of them. A rare manufacturer indicates such an operation in the service books and assigns an interval to it, but if you listen to the workers of unofficial services, then you need to flush and clean the injectors almost every 20 thousand kilometers, especially “on our gasoline”. For service centers, this is a profitable recommendation, because it provides them with a volume of work, but it is not necessary to go somewhere and pay someone to clean the injectors. This can be done on your own.

Why are injectors clogged and how to diagnose it?

The essence fuel injector- spraying fuel either into the intake manifold or directly into the engine cylinder. The construction is rather primitive: from electronic unit control, a small current is supplied to the nozzle, a special mechanism opens the nozzles and gasoline is sprayed from the nozzle under pressure. Its volume is regulated by the ECU by the pulse duration, the more fuel needs to be injected into the engine, the longer the injector is “open”. The amount of fuel injected during the time interval has been calculated in advance, therefore car computer based on the pulse time, it can easily calculate the fuel consumption.

When everything is normal, there are no problems, but over time, the nozzle can become clogged with dirt and deposits. Most often this happens due to low-quality gasoline, which contains a lot of sulfur and various additives.... The section through which the fuel passes becomes smaller, the mechanism that opens and closes the "passage" for the fuel works worse. The nozzle begins to inject less gasoline than necessary, and most importantly, it switches from the spray to the jet, seriously impairing the mixture formation necessary for complete combustion of the mixture and the smooth operation of the engine. Clogged injectors manifest themselves with a number of problems:

3. Noticeably drop in power and increase in fuel consumption.

4. There is a noticeable "plug" or even jerking when trying to accelerate.

In fairness, it must be said that all these problems can be caused by a bunch of other reasons, among which clogged nozzles are not the most likely. But with serious diagnostics, specialists often start with flushing the nozzles, primarily because this is a relatively simple operation, and it is better to exclude probable causes, starting with the lungs. If cleaning the nozzles did not help, then they look for more serious problems.

Do you need prevention?

It would seem that it is best to flush the nozzles directly during operation. This idea seems to be a winning one: everyone knows that it is better to deal with small blockages than to solve the problem when the nozzle stops passing gasoline through itself at all. Car chemical manufacturers massively support this impulse, and on store shelves you can find a large number of fuel system washers under the brands Vince, Hado, Liquid Molly, Hi-Gear, RVS and others, which need to be added to fuel and burned along with gasoline.

In the photo - Lavr for cleaning injector nozzles

In the photo - Lavr for cleaning injector nozzles

Do they help? It is difficult to confirm or deny this, because no one knows what is happening inside. Maybe there is an effect, but maybe not. Considering that, depending on the volume, you need to buy such funds for 400-1000 rubles for a car tank, and you cannot help with one tank, you need to search for 2-3, the economic meaning of such prevention is questionable - it turns out to be cheaper to clean the nozzles when they get clogged than pouring different chemicals to avoid potential problems.

Cleaning injectors without dismantling

How is cleaning done? There are three common methods, two of which can be used at home. They are not very complicated, but they will require a lot of technical savvy to implement them.

The essence of the first method is to flush the injectors with a special mixture while the engine is running. To do this, you will need to assemble a simple stand, which will be a primitive analogue of the car's fuel system. You can solve this problem different ways, we will present the most popular one.

To assemble the stand you will need:

Air pumping compressor

2 liter plastic bottle

Two car nipples

Hose about a meter long

We assemble the system in the following sequence.

1. Close the plastic bottle with a lid and we drill two holes in it, one at the bottom and the other in the lid. It is better to use a drill with a diameter of 13 mm. We insert nipples into the resulting holes, and you need to insert into the cover with the valve unscrewed.

Homemade nozzle cleaning system. Photo - drive2

Homemade nozzle cleaning system. Photo - drive2

2. On the nipple, which is screwed into the cover, put on the hose and fix it with a clamp.

3. At the other end of the hose attach the fuel filter and also fix it with a clamp.

4. Pour the cleaner into the bottle. Usually, one liter of the composition is enough for a four-cylinder 1.6-2 liter engine. The most popular company is Vince (it is good in terms of price / quality ratio), but Hado, Liquid Molly and Laurel are also suitable, they just (especially the last one) are more expensive.

5. We warm up the car, turn off, release the pressure in the fuel line and disconnect it from the injectors.

6. Remove the fuel pump fuse to de-energize it.

7. If the fuel system of the car provides for a return to the tank, then it must be pinched or drowned in another way.

8. We connect the hose of the newly assembled system to the nozzles.

9. We connect a compressor or a conventional one to the second nipple in the bottle. car pump with a pressure gauge and create a pressure in the bottle of about three atmospheres.

10. We hang the bottle under the hood, with the lid down, so as not to hold it in our hands.

11. We start the car and leave it idling. It will operate on a purifier, which, under the pressure created by us in the bottle, enters the nozzles, passes through them and cleans.

13. After all the liquid has been used up, you need to turn off the engine, disassemble the stand (while releasing the pressure from the bottle very carefully!), Connect the fuel line back to the injectors, return the power fuel pump and don't forget about the return line.

This cleaning method is good for its low cost and relatively low labor intensity. A washer bank costs 300-500 rubles, 100 rubles will have to be spent on nipples and clamps - that's all the waste. The disadvantages of this method are that we will not be able to quickly find out about the quality of cleaning, it will be possible to judge it only by indirect signs after a few hundred kilometers.

Cleaning nozzles with dismantling

This method seems more complicated, but it allows you to visually assess the quality of cleaning and the condition of the nozzles, so many people prefer it. For flushing, you also need to assemble a small system, and it is even simpler than in the first version, but you will need to dismantle the nozzles, and this is very difficult on some cars. We will not dwell on this issue in detail, information about dismantling can be found in repair books dedicated to your particular car model.

For this method of cleaning, you can use any composition that says "rinsing the carburetor" or "rinsing the injector", even domestic preparations for several hundred rubles per bottle are suitable. The fundamental difference with expensive means it won't be easy to notice. Usually two bottles are enough for all nozzles.

For flushing system would need:

Copper wire with insulation, not less than a meter in length

A piece of hose that matches the diameter of the sprayer on the spray can of the cleaner

Electric battery with voltage not less than 9V or spare car

The scheme of work is very simple.

1. We put one piece of hose on the cleaner spray, and the second on the nozzle(with which we first shoot rubber compressor). Perhaps the diameters do not match, then you will need to come up with some kind of adapter by cutting it out, for example, from the cap of a bottle with a cleaner. Even the most primitive adapters will do, because there will not be much pressure in such a system.

2. We clean the insulation on the wire and we supply plus and minus to the nozzle from the power source... It is better to use a battery, because usually the injectors work with a voltage of 9V, with car battery(which, we recall, has 12V) the system will also work, but there is a small risk of melting the insides of the nozzle from long work. After we apply voltage to the injector, it should open, which will be clearly audible thanks to a click.

3. Click on the spray can, the liquid, passing through the hose, enters the nozzle, and then begins to pass through the outlet nozzles. By the shape of the "exhaust", we draw conclusions about the contamination of the nozzle.

The main advantage of this method is that we can control the quality of cleaning. Just a stream will come out of the contaminated nozzle, you need to clean it until the agent starts to spray from the nozzles. In advanced cases, you can and should take a break, giving the electrical part of the nozzle "rest", and the cleaning compound to "soak" the growths a little. This is how each nozzle should be treated. Then they need to be installed on the car.

Tip: The flushing liquid is very corrosive and it is highly undesirable for it to come into contact with the skin, so you need to take care of protecting your hands and body, using gloves and some kind of protective clothing.

It must be admitted that this cleaning method is not easy. It requires dismantling the nozzles, and then washing each one almost by hand for a long time until it is completely cleaned, but with it you can be convinced of the cleaning efficiency and understand if it did not help. This is a very nice bonus.

Ultrasonic cleaning

Ultrasonic cleaning is considered the most effective. We do not talk about it in detail, because it is available only in the conditions of service stations (and even then not all of them). Depending on the service and the number of cylinders, such cleaning can take from 2 to 5 thousand rubles. It is most reasonable to try it when the flushing methods described above did not help. It is not recommended to constantly clean with ultrasound - it is believed that due to the aggressive effect of ultrasound, the inside of the nozzle begins to deteriorate quickly.

conclusions

The cleaning interval for the injectors is a tricky issue. They are clogged, no doubt, but an attempt to enter some averaged parameters seems utopian - someone often encounters problems, while someone drives hundreds of thousands of kilometers and does not look into the fuel system. Too many parameters affect this. So we would not recommend flushing the nozzles just like that, without good reason. Well, if a reason appears, you can always flush on your own - both cheaper and better, and you can understand yourself if it's time to change the nozzles.