Service center "RemBytTech" replaces brushes on washing machine engines in Moscow and the region. Call our workshop and call a specialist at home. Choose a convenient date and time, or wait for the master within 24 hours from the date of application. We perform the replacement service at home on automatic machines of any type (with front and vertical loading) and year of manufacture. We issue for work and details warranty card , it acts 12 months.

How much does it cost to change the brushes in the washing machine

The cost of replacing brushes - from 1400 rubles... Parts are paid separately or the master installs the brushes purchased by the client. The specialist calculates the full amount of payment after diagnosing the machine. The price depends on the model, type, brand of "machine" and the year of manufacture.

The service includes:

- disassembly of the machine;

- removing the engine;

- removal and inspection of old brushes;

- installation of new contact elements;

- checking engine operation;

- machine assembly and testing

Attention! Carbon brushes are consumables and cannot be repaired, only replaced.

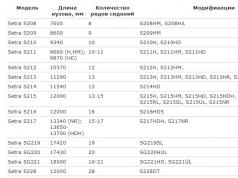

The cost of replacing brushes on washing machines of different brands, see the table

| Washing machine brand | Price* (only for work, no details) |

| Is free | |

| from 1800 rub. | |

| from 1500 rub. | |

| from 1800 rub. | |

| from 1900 rub. | |

| from 1500 rub. | |

| from 1700 rub. | |

| from 1800 rub. | |

| from 2100 rub. | |

| from 2800 rub. | |

| from 1900 rub. | |

| from 1900 rub. | |

| from 2100 rub. | |

| from 1800 rub. | |

| from 2100 rub. | |

| from 1900 rub. | |

| from 1800 rub. | |

| from 2200 rub. | |

| from 1900 rub. | |

| from 1400 rub. |

* Attention! The table shows only the cost of replacement work. If the master installs parts from his stock, then additionally includes their cost in the full amount of payment.

How to call the master

To call a specialist, call the "RemBytTech" service from 8 to 22 o'clock by phones:

Or leave a request through online forms at on the site (around the clock). The service center is open daily. Craftsmen come on weekdays, weekends and during holidays.

When calling a specialist, inform:

- The make and model of the car. The model name is printed on the body of the equipment. Read it on the sticker and tell the dispatcher, for example, Bosch Maxx 5 or Indesit WIU80. Information is needed for the selection of brushes. If you bought the parts yourself, then just name the brand of the car.

- Convenient time and date of repair.

- Contact details. Your name, phone number and address.

The master will call on the appointed day and confirm the time of the visit.

Our advantages

- We advise free of charge. We explain the problem with the technique through the heading "Question-answer". Describe the malfunction in your own words and send a message. The repair specialist will answer the question within 2 days. When making an application, we advise by phone. Tell the dispatcher that you want to talk to the foreman. He will call you back and tell you about a possible breakdown and the cost of repairs.

- We leave for free and diagnose equipment at home. You only pay for replacement parts and new brushes.

- We repair at home 24 hours after the application. We are located throughout the city and in most areas of the region. The master comes to the address from the nearest branch. Therefore, we can be with you on the same day if the application is submitted in the morning. Or the next day, with an evening application. If you have chosen a different date and time, the specialist will arrive at the appointed time. We repair everything at home, without taking it to a workshop.

- We work daily from 8 to 22... Regular schedule - every day, without days off and holidays. We arrive early in the morning and late in the evening, convenient for those who work. Choose the time of the master's visit at your own discretion.

- We guarantee the quality of repairs for 1 year. We are responsible for the work and the replaced brushes. We issue a 1 year warranty. If, during the repair, a part purchased by the client is installed, the warranty is issued only for the work of the master.

The main function of brushes in a washing machine, and why they cannot be repaired

Carbon brushes are the element that rotates the brushed motor. They transfer tension between its parts. Without them, there is no "connection" between the stationary stator and the moving rotor. With weak contact between the brushes and the collector, the electric motor loses power, twitches or stops altogether.

During operation, the brushes rub against the engine manifold and over time become so shortened that they lose contact with it. That is why they are referred to as consumable items, and the worn out "stumps" are replaced with new brushes.

The order of work when replacing brushes by the master of "RemBytTech"

What we do when performing the service at the client's home:

1. We disassemble the washing machine

The engine, most often, stands at the bottom slightly to the right, if you look at the car from the side of the rear wall. To get to the engine, the master removes the back panel. In some washers, you must first remove the top cover.

Disassembly procedure:

- We completely de-energize the machine by pulling out the plug from the socket.

- We remove the back wall. We unscrew the fastening screws with a screwdriver (if the wall is additionally pressed by the top cover, we first remove it).

We shoot drive belt, which is put on the pulleys of the drum and engine. To do this, we turn the drum pulley and slightly pull the belt towards us.

2. Remove the engine and check the brushes

In most models, the motor is “put on” on special holders and fixed with screws or bolts. The sequence of our actions is as follows.

- Disconnect the motor power loop. To do this, pull out the connector from the socket.

- We unscrew the fasteners and take out the engine.

After removal, the master checks that the brushes are worn out and, indeed, it is time to change them. As a rule, this is not difficult to determine by visually looking at them. Experienced craftsmen work in "RemBytTech" appearance understand how critical the wear of the brushes is.

In some older models of washing machines, the brushes may be hidden behind the motor housing. In this case, the master checks them with a multimeter.

Note! Sometimes the design of the washer motor mounting allows the brushes to ring without removing the motor.

3. Change the brushes

The brushes are inserted into special holders. The contact part is in contact with the rotor collector, the wire is connected to the stator. In very old electric motors of "age" machines, access to the graphite brushes is closed by a part of the motor. Therefore, we have to partially disassemble it. But these are rare and usually the order of replacement is as follows:

- We disconnect the wires and dismantle the worn out brushes. To do this, depending on the design, either snap off the pressure plate and take out the brush, or unscrew the holder with the brush with a screwdriver, disassemble it, bite off the wire of the brush coal from the holder and then remove the coal itself. During dismantling, be sure to remember where the bevel of the contact part of the brush was directed. This is necessary for the correct installation of the new part.

- We examine the collector. If it is heavily soiled, we wipe it from dust.

- Install the new part in the reverse order to dismantling. If the design is such that, during dismantling, the wire of the carbon brush was cut off from the holder, then new brushes will need to be soldered to the brush holders. After installation, the master visually assesses how the electric brushes are installed: the end of the holder should protrude about 10 mm. The master also checks the correctness and tightness of the bevels of the brushes to the collector.

- We connect the wires.

Note! In a design where it is necessary to solder a new brush to the holder when replacing, the master often saves time and installs a ready-made holder kit with a brush soldered into it.

4. We put the engine

Now we return the motor to the washing machine.

- We put the electric motor on the mounting lugs and tighten the bolts or screws. We check the stability of the motor so that there is no movement and wobbling.

- We put on the drive belt, first on the motor, then on the tank pulley. We check the tension, otherwise the belt will fly off when the engine is started.

- We connect the power supply, insert the cable into the socket.

5. We collect the car

We put the back panel in place and fasten it. The top cover is put on last, if it was also removed. After assembly, we run the washing machine in test mode to check the operation of the engine with different loads.

Attention! Even with the correct installation of the brushes, they are “lapped” with the collector during 2-3 washes after replacement. Therefore, the washing machine may make a little noise and spark a little at first.

The main signs when you need to change brushes

The exact answer that it is time to change the brushes is given by the diagnostics of the machine. But calling the wizard for the sake of verification is not convenient for everyone. Based on the repair experience, RemBytTech service engineers have prepared a list of signs that may signal the need to replace the electric brushes.

- Drum spinning problems. The drum is barely spinning, and the machine cannot gain momentum during the spin cycle. Or the washer does not rotate the drum at all, immediately draining the water after dialing. Or, it happens that the drum spins a little at the beginning of the wash, after which the machine stops washing and gives an error.

- Unstable work engine... When fully loaded for washing or spinning, the machine loses speed.

- Noise and sparking of brushes. It is noticeable by the smell of metal or burning insulation, and in the dark you can see the glow at the bottom of the washing machine, like from sparklers.

The described symptoms may terminate by interrupting the program and displaying an error code. The code is shown on the display (if any) or indicators flash. Most often, the wear of the brushes is signaled by an error in the engine, tacho sensor or spinning.

Reasons for brush failure

Electric brushes "fail" due to marriage, physical wear and tear (ie abrasion) or wedging.

- Marriage... This is a manufacturing flaw and is rare.

- Carbon brushes are worn out. The most common reason for replacement. The average service life of electric brushes is 5-7 years. If you rarely wash and do not overload the machine, then the contact elements can last 10-12 years. After that, the length of the brushes reaches a minimum of 1 cm, and they stop touching the motor manifold.

- Wedging... Sometimes the wear of the brushes is not critical, but they lose contact with the collector. This is due to the fact that they are wedged in the holder. The brushes are pressed against the engine manifold by springs that squeeze them out of the brush holder. Carbon dust gets into the space between the brush and the holder, which is formed in large quantities as a result of the brush rubbing against the collector. She also stops her squeezing out of the holder. This problem is called "wedging brushes".

Note! In case of wedging, the wear of the brushes may not yet reach the minimum permissible value, and by moving the brush in the holder, you can restore its contact with the collector. But, in most cases, a wedge occurs either when 3 - 5 mm remains to the critical length, or when the geometry of the brush is violated. In both cases, it is advisable to replace the brushes with new ones. If this is not done, then the problem will repeat itself in the very near future.

Replacing brushes in a washing machine requires specialized knowledge and experience. Independent work often turns into additional complications, which are difficult to deal with without professional training. The main difficulties are caused by:

- Dismantling the motor old model ... It is impossible to change the brushes in them without removing part of the structure. And when assembling the engine back, laymen often confuse the connection of wires. As a result, the motor burns out and you have to change it completely.

- Correct installation brushes... The part must be placed with the correct side (with a cut to the collector) and the distance must be checked. If the contact element is not properly secured, it will barely touch the collector surface. As a result, the motor, due to weak contact, will not be able to work on full power and may even burn out. And the machine will make noise and spark for a long time. It is also dangerous and can cause a fire.

- Soldering contacts... In some brands of washing machines, the brushes must be soldered to the holders. This requires knowledge of soldering technology.

- Adjusting the motor for belt tension... At repair work removal of the motor, the position of the motor must be adjusted during re-installation to ensure sufficient belt tension. Otherwise, the belt will slide off the pulley when the washing machine is running.

To avoid unnecessary problems with washing machine at self-replacement brushes - contact "RemBytTech". Call the master by phone:

Wait for a specialist 24 hours after the call or on the selected day.

20 May 2017It may happen that the wiper blades need to be replaced more often than you expected. Weren't they replaced last year? But they leave stripes again, no longer clean the windshield efficiently and make annoying sounds. Although "windshield wipers" are not the most expensive element in car maintenance, the cost adds up every time they need to be replaced, which, in general, can be quite expensive.

A clean windshield is not only pleasant to drive, but also has a significant impact on safety, increasing visibility and control over traffic situation... The main signs that the car wipers have deteriorated:

- the appearance of the line / stripes. The rubber element of the wiper blade may harden or become damaged with age or repeated rubbing of foreign objects on windshield;

- noise. Noisy wipers are usually a sign that the wiper has hardened, which will cause the wiper blade structure and attachments to wear out faster;

- vibration. Hardened rubber elements usually cause the cleaner to vibrate.

Do you have such signs? Don't rush to buy new wiper blades right away. In order to save money, you can try to restore them at home. But, first of all, it is worthwhile to deal with the reasons for the rapid deterioration of the wipers.

Restoring the wipers on your own

There are several main ways to restore car wipers and extend their lifespan:

- Hot water... The easiest way to bring the rubber parts of the wipers to a satisfactory condition is to put them in hot water for half an hour. This manipulation will help soften the rubber and remove fatty deposits on its surface. This method will not bring long-term effects, it should be combined with other options.

- White Spirit (white spirit)... White Spirit, a popular gasoline-based solvent, will help to effectively remove grease from the surface of the working part of the wipers. This oily liquid also has lubricating properties, which will greatly facilitate the sliding of the brushes on the windshield. The way to use white spirit is to wet a piece of cotton rag or synthetic washcloth with liquid and wipe the rubber surface of the wiper blade.

- Petrol... If you put the rubber bands of the windshield wiper for a while in gasoline, the effect of softening the rubber is achieved, which significantly increases its elasticity. The effect of restoring the properties of windshield wipers is also increased by the degreasing properties of gasoline.

- Glycerol... To soften the hardened rubber of the brushes, glycerin will help. You can buy this remedy at a pharmacy. To achieve the greatest positive effect, the working surface of the wipers should be cleaned of dust and dirt, washed and dried. The essence of the method is to apply glycerin to the surface and let it soak into the rubber. This method can be combined with degreasing with gasoline or white spirit.

- Mechanical restoration... If the rubber bands on the wipers are damaged and have irregularities on the surface, you can try to level them. In this case, it makes sense to use fine sandpaper to eliminate defects. Subsequently, it is recommended to degrease and soften the brushes using the methods presented above.

Important! All manipulations with chemical means it is recommended to carry out in a well-ventilated area and use rubber gloves to protect the skin of the hands

Here are five simple ways to get the most out of your wiper blades:

- Raise or remove the wiper blades when it snows. It may seem like an unnecessary step, but, in fact, you save yourself from potential headaches and additional costs of replacing wipers. The thing is that repeated thawing / freezing can destroy the structural integrity of rubber. Potential danger is the inclusion of wipers frozen to the windshield

- Do not use windscreen wipers to remove icing from your windshield. This will inevitably damage the rubber from the sharp edges of the ice crust.

- Wipe down and clean the wiper blades. Together with water, dirt, sand, small debris gets on the windshield. It can jam into the grooves of the rubber, gradually destroying it.

- Park your car in the shade. Ultraviolet radiation destroys the rubber structure of the wiper blades, making it hard and brittle. To avoid the negative effects of sunlight, you should park your car in the shade whenever possible.

- Do not use "dry" windshield wipers. The wipers are designed to clean extremely damp surfaces. In dry weather, their use is possible only in combination with the operation of the windshield washer.

Summary

Wiper blades will last much longer if you follow basic operating rules. But, failures in the work of the janitors are not a sentence. The simplest ways to resuscitate them will help to significantly extend their service life. An important factor is right choice manufacturer. Buy only high-quality brushes, trusted brands, provide quality care, and the wipers will last more than one season.

Windshield wipers are popularly called wipers for a reason: they ensure the cleanliness and transparency of the windshield and rear windows of the car. If the windows are clean, it means that the driver perceives everything that happens on the road without distortion, in full. The adequacy and speed of his reaction in the event of a dangerous situation depends on this. The view through the cleaned glass allows the driver to not strain their eyesight. Only unlike real janitors who work with a broom in the yards, mostly early in the morning, at car wipers responsibility is imposed every second in any weather, if the car is on the way.

In spring, autumn, in summer rain, windshield wipers are constantly in demand. They come to the rescue in snowfall and blizzard. However, the cold winter season and all the ensuing consequences on the wipers themselves have an extremely negative effect. The rubber from which the windshield wipers are made hardens, ice forms on top, and as a result, the cleaning task becomes beyond the power of the "wipers", and sometimes they can even scratch the glass with the sharp edges of the ice. Such windshield wipers do not clear the necessary visibility well.

What if there is no way to purchase and install new ones?

Experienced drivers offer to carry out resuscitation measures with old wipers using glycerin, which can be purchased at any pharmacy. The windshield wipers must be carefully removed, and having disconnected their rubber part, thoroughly rinse from dirt and clogged dust. After waiting for the gum to dry, they are treated with glycerin on all sides. After that, the rubber should lie down so that the glycerin is absorbed. The procedure for impregnating the rubber bands can be repeated, wait again until the compound is absorbed, and then wipe dry, removing all residues. The rubber elements can then be returned to the wiper and placed on the glass.

After the treatment with glycerin, the rubber will soften significantly and will remove dust and debris from the glass without any "dips". But this method of restoring the original qualities of the "windshield wipers" is suitable only for non-cracked rubber that does not have breaks. This is enough effective method... After processing, the wipers do not freeze to the glass, do not leave traces.

Disadvantages of glycerin treatment of windshield wipers

However, this method of resuscitation of windshield wipers has a number of disadvantages. For example, glycerin is washed out by an anti-freeze liquid, which is plentifully poured on glass in cold weather. In addition, the savior itself, glycerin, over time can become the culprit for cracks and tears on the rubber parts of the wipers. So the method of resuscitation of windshield wipers with glycerin can be considered a one-time application in conditions when it is impossible to fix the work of the wipers in any other way.

When the windshield wipers do their job extremely poorly, it makes no sense to try to restore them, and more than once. This can lead to unforeseen situations, after which the wipers themselves may not be needed. Moreover, the worn out rubber components of the windshield wiper can leave small cracks and scratches on the windshield, which significantly reduces visibility, and, accordingly, affects the safety of the car, especially at night, when microcracks give glare from the lights of cars moving in the opposite direction.

Right choice

In order for problems with windshield wipers to occur as rarely as possible, you need to choose them very carefully. Of course, you can first ask the neighbors in the parking lot: what kind of wipers they bought and how long they serve them. The varieties can be found on auto sites on the Internet. You should pay attention to the cost of the proposed options and at the same time remember that there is not much difference between expensive and relatively cheap wipers.

The fact is that among the expensive windshield wipers there are those that car owners were unhappy with, and worthy ones can also be found among inexpensive options. Some wipers with average cost even have heating.

When choosing wipers, be sure to pay attention to moving elements. Make sure that they do not make sounds during operation. They must be set in motion without any effort or jerk. It is necessary to inspect the rubber: the tightness of its adhesion to the very structure of the wipers should not be in doubt. The rubber components of the new wipers, of course, should not have distortions, scratches and burrs.

Care

Usually, having bought and installed new windshield wipers, car owners consider the job done and forget that they need the same care as all other elements of the car. But the service life of the wipers can be significantly increased! For example, it is suggested to regularly spray the rubber wipers with silicone spray. It is not as harmful to rubber as glycerin. To improve the sliding of the wipers on the glass, it is advised to add dishwashing detergent to the liquid in the washer reservoir. The detergent improves the cleaning of the glass from dirt. And the car owner will feel the smooth movement of the wipers "like clockwork" right away.

Also, the wear of the wipers is reduced by special chemicals such as Anti-Rain. The glass is thoroughly washed with detergent, wiped dry, and only after it is completely dry, the Anti-Rain applied to the velvet cloth is distributed over the glass. After that, the glass is washed again using detergent. "Anti-rain" fills all the microcracks of the glass and creates an invisible film, which minimizes the area of contact with the glass and the raindrops falling on it. Contamination is significantly reduced, and with it the load on the wipers is reduced. A method of making "Anti-Rain" at home has already been invented. Ordinary candles are crushed on a grater, mixed with white spirit (1x20) and the resulting solution is distributed over the glass. It turns out no worse than the composition made in the factory.

And finally - recommendations for car owners who do not want to change windshield wipers every season. Windshield wipers should not scrape off ice on glass. For this, scrapers were invented, which cost mere pennies. It is not recommended to use windscreen wipers without washer fluid, because the “dry” operation of the rubber affects its quality. In severe frosts, the wipers do not need to be left on the glass - they will freeze, and tearing them off can damage the rubber. Better to take them home, in the warmth. Windshield wipers require maintenance: they need to be cleaned of dirt all the time, at least as often as the glass itself. These simple truths will help extend the life of any wipers. Well-groomed windshield wipers lend themselves to restoration, and maybe even repeated.