Stand for testing and adjusting high pressure fuel pumps of diesel engines ДД10-04П with 18kW drive for field repair plants and mobile repair shops.

Stand for testing and adjusting the high pressure fuel pump different types domestic production with a cycle feed of up to 250 mm / cycle with a plunger diameter of up to 12 mm (12-section, asynchronous motor 18 kW, frequency converter KAMS-M). Stand ДД1004П, designed for diagnostics and adjustment of high-pressure fuel pumps of all types and modifications used on AT and armored vehicles, as well as dual-use equipment up to 12 sections inclusive of diesel engines such as YaMZ-236, YaMZ-238, YaMZ-7511, YaMZ-236 BE (NOT) , YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD-31B, SMD-62, SMD-62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A -41E, D-440, SMD-60, SMD-72, SMD-64 TNVD type TN, UTN, ND, 4UNTM, LSTN. TNVD type V-2, V-46, V-243.

The main difference between stand DD1004P and stand DD1004 is:

- The delivery set of the DD1004P stand includes a frame for installing the stand in the body of a repair shop based on a URAL or KAMAZ vehicle, complete with fasteners, screw adjustable supports, and a NYaIB.8400 device for setting up the stand.

- In the basic configuration, the DD1004P stand is supplied with a set of test nozzles, a set of high-pressure pipes and adapters, accessories for all of the above types of high-pressure fuel pumps BAT, BTVT and dual-use equipment.

- A unit with freon for fuel cooling is installed in stand DD1004P.

- Stand DD1004P is equipped inside with devices for heating the stand in field conditions and heating fuel for test tests fuel equipment at subzero temperatures.

- The drive of the DD1004P stand is made as a part of transfer case, through a reduction gear (the DD1004 stand is supplied with a drive directly to the tested injection pump). Thus, the minimum speed crankshaft when simulating at the stand, it can be set at the level of 20-30 rpm versus 50 rpm at the stand DD1004 in 7.5 or 11 kW version.

- Computer control of a tachometer, recording of readings on a PC. (The package includes software for installation on a PC, laptop).

- For the installation of all types of injection pumps for testing, the delivery set includes a complete set of installation equipment.

Preservation for 60 months, increased guarantee for the stand for up to 36 months, wooden packaging in two boxes (a box with a stand is installed on a Euro pallet and packed in a second sealed box.

STAND OPERATING PROCEDURE:

Diagnostics is carried out by reproducing the rotational speed of the drive shaft of the high-pressure fuel pump (injection pump), fuel temperature and pressure, measuring the specified parameters, as well as the cyclic supply, fuel consumption supplied to the test object, the angles of the beginning of fuel injection (injection), turning the injection advance clutch , deviations of the injection (injection) start angles.

The following operations can be carried out at the stand:

Testing and adjusting in-line, V-shaped and F-shaped fuel pumps high pressure (hereinafter, high pressure fuel pump) with an independent lubrication system, with up to twelve sections, as well as distribution type high pressure fuel pump with a number of supply fittings by

control of the following parameters and characteristics:

Size and uniformity fuel supply sections (productivity of pumping sections);

· Frequency of rotation of the injection pump shaft at the moment of the beginning of the regulator action;

· Frequency of rotation of the injection pump shaft at the moment of stopping the fuel supply;

· Opening pressure of discharge valves;

· The angle of the beginning of the injection and the end of the fuel supply according to the rotation of the injection pump shaft and the alternation of the supply by the sections of the injection pump;

The angle of the actual start and end of fuel injection (when diagnosing)

· characteristic of the automatic injection timing clutch.TECHNICAL CHARACTERISTICS STAND DD10-04P

1. Type ..... Stationary and mobile

2. Drive ..... Electric drive from the industrial power supply network, as well as from field autonomous power units.

3. The number of simultaneously tested high-pressure sections of the high-pressure fuel pump, pcs., No more ... 12

4. Play range:

4.1. Rotation frequency of the drive shaft, min-1 ..... 20 ... 50 ... 70 ... .3000

4.2. Counting the number of revolutions (cycles), rev. (Cycles) ..... 1 ... .9999

4.3. Fuel temperature, 0С ..... + 5 ... .60

4.4. Fuel pressure, MPa (kgf / cm2) ..... 0 ... .10 (0 ... .100)

5. Measuring range:

5.1. Rotation frequency of the drive shaft, min-1 ..... 20 ... .3100

5.2. Fuel volume in STA vessels, ml:

First row ..... 6 ... .135

Second row ..... 2 ... .40

5.3. Fuel temperature, 0С ..... 0 ... .50

5.4. Fuel pressure, MPa (kgf / cm2) ..... -0.1 ... .4 (-1 ... .40)

5.5. Angle of the beginning of fuel injection, deg. ..... 0 ... .360

5.6. The angle of the beginning of fuel injection, deg. ..... 0 ... .360

5.7. Angle of rotation of the half-couplings of the automatic injection advance clutch, deg. ..... 10 ... .0 ... .10

5.8. Cycle feed, mm3 / cycle ..... up to 250

6. Capacity

6.1. Fuel tank, l, ..... 100

7. Powered by AC and direct current

7.1. Voltage, V ..... 380, 3ph

7.2. Frequency, Hz ..... 50 ± 1

8. Installed capacity, kW ..... 21

including the pump drive motor, kW ..... 18

9. Number of attendants, people ..... 1

10. dimensions, mm, no more ..... 1880 x 960 x 2025

11. Dry weight of the stand, kg, no more ... 785

(With a set of accessories), kg no more than ..... 1380

12. Installed trouble-free operating time, h ..... 1000

13. Installed full resource, at least years ..... 10

Stand DD 10-01 (KI15711M-05) (DD1-05)

| Stand DD10-01 designed for testing and adjusting high-pressure fuel pumps of various types of domestic and foreign production with a cycle feed of up to 200 mm / cycle with a plunger diameter of up to 12 mm (8-section, 7.5 kW asynchronous electric motor, MITSUBISHI frequency converter) Stand DD1001 designed for diagnostics and adjustment of high-pressure fuel pumps of domestic and foreign production up to 8 sections inclusive of diesel engines such as YaMZ-236, YaMZ-238, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL- 645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD- 31B, SMD-62, SMD-62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64 TNVD type TN, UTN, ND, 4UNTM, LSTN. Injection pump types PVA, PVB, PESA, PEA, PECM, PPM (f), JPH, WSK, PES, CAV, BOSCH VE are regulated with additional equipment supplied by order. |

Stand DD 10-06 (KI15711M-06) (DD1-06)

Stand ДД 10-05 for diesel engines

Stand DD 10-02

|

Stand DD10-02 for testing and adjusting high-energy injection pumps of various types, including those with high-energy injection of domestic and foreign production with a cyclic feed of up to 250 mm / cycle with a plunger diameter of up to 12 mm (12-section, asynchronous electric motor 18.5 kW, frequency converter MITSUBISHI). Bezelless measuring system. Autonomous thermal stabilization system. Stand DD1002 designed for diagnostics and regulation of high-pressure fuel pumps type 133,175, 185 and their modifications with a cyclic feed up to 250 mm2, injection pressure up to 120 MPa, as well as high-pressure fuel pumps of engines such as YaMZ-238, YaMZ-240, YaMZ-8401.10, YaMZ 850, YaMZ 7511, YaMZ 845.10, YaMZ 8421.10, YaMZ 84 23.10, YaMZ 84 24.10, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ -5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD-31B, SMD-62, SMD-62AT, SMD -31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64. Injection pump type TN, UTN, ND, 4UNTM, LSTN .. Injection pump type PVA, PVB, PESA, PEA, PECM, PPM (f), JPH, WSK, PES, CAV, BOSCH VE, D6, D12 are regulated with additional equipment supplied by order. |

Stand DD 10-04 (DD10-00) (KI-15711M-01) (DD-1-03)

|

Stand DD10-0 4 for testing and adjusting high-pressure fuel pumps of various types of domestic and foreign production with a cycle feed of up to 250 mm / cycle with a plunger diameter of up to 12 mm (12-section, asynchronous electric motor 11 kW, frequency converter MITSUBISHI) Stand DD1004 designed for diagnostics and adjustment of high-pressure fuel pumps of domestic and foreign production up to 12 sections inclusive of diesel engines such as YaMZ-236, YaMZ-238, YaMZ-7511, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD- 31, SMD-31B, SMD-62, SMD-62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64 TNVD type TN, UTN, ND, 4UNTM, LSTN. Injection pump types PVA, PVB, PESA, PEA, PECM, PPM (f), JPH, WSK, PES, CAV, BOSCH VE are regulated with additional equipment supplied on request. |

Stand DD 10-04K for diesel fuel equipment

|

Stand DD10-04K designed for diagnostics and adjustment of high-pressure fuel pumps of domestic and foreign production up to 12 sections inclusive of diesel engines such as YaMZ-236, YaMZ-238, YaMZ-7511, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD- 31, SMD-31B, SMD-62, SMD-62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64 TNVD type TN, UTN, ND, 4UNTM, LSTN. |

Stand DD 10-05E for diagnostics and adjustment of diesel fuel equipment

|

Stand DD10-05E designed for diagnostics and regulation of high-pressure fuel pumps type 133,175, 185 and their modifications with a cyclic feed up to 250 mm 2, injection pressure up to 120 MPa, as well as high-pressure fuel pumps of engines such as YaMZ-238, YaMZ-240, YaMZ-8401.10, YaMZ 850, YaMZ 7511, YaMZ 845.10, YaMZ 8421.10, YaMZ 84 23.10, YaMZ 84 24.10, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD-31B, SMD-62, SMD-62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64. |

Additional equipment and accessories for diagnostics of high pressure fuel pumps, fuel equipment

Lubrication station DD-3100

Pneumatic tester DD-3200

|

Pneumatic regulator tester TNVD DD-3200 is designed to simulate the real operation of the engine when checking the DD at the test bench of pumps with an automatic smoke control or diesel boost corrector, with an altitude corrector. DD3200 pneumatic tester for TNVD controller designed to simulate the real operation of the engine when checking at the DD-1 stand of pumps with an automatic smoke control or diesel boost corrector, with an altitude corrector, installed on domestic and foreign cars, as well as for checking and adjusting high-pressure fuel pumps with a vacuum regulator (PES pumps, installed on Mercedes vehicles). pneumatic tester DD-3200 |

Set of brackets DD-3500 for attaching imported injection pumps to DD-1

Stand nozzle FSh-22 (DD-3600)

Stand DD-2110 for testing and adjusting diesel injectors

DD-2115 device for assessing the technical condition of the injection pump plunger pairs of YaMZ and KamAZ engines (PO 9691)

Mechanotester of fuel equipment МТА-2 - ДД-2120

Additional equipment for diagnostics of electronically controlled injection pumps and Common Rail injectors

Diesel tester DD-3810 (0 986 610 101)

Power supply unit for diesel tester DD-3820

Universal cable for DD-3810 0 986 610 10 2

Adapter cable for Scania, Volvo, Iveco, John Deere, Mersedes 0 986 610 104, DD-3812

Adapter cable for pumps type М 0 986 610105, DD-3813

Adapter cable for MAN vehicles 0 986 610 107, DD-3814

Device for testing the performance of diesel injectors of the Common Rail system "CR-tester" DD-3900

Additional equipment and accessories for the repair of high pressure fuel pumps, fuel equipment

Set of specials tool for servicing injection pumps of KAMAZ DD-3300 vehicles

Set of specials tool for servicing fuel injection pump of KAMAZ vehicles, application method, manual for repair and adjustment of injection pump KAMAZ

1. And 801.21.000 Puller for pressing out the discharge valves

2. And 801 16 000 Tool for removing and disassembling the injection advance clutch

3. I 801 20 000 Device for disassembling the pump sections of the injection pump and injectors

4. And 801 37 000 Extractor of eccentric and pinion gear from the camshaft of the injection pump

5. I 801 27 000 Device for installing the injection pump camshaft bearing, angular gear bearing

steering gear, power take-off drive shaft bearing

6.I 800 11 000 Remover of injectors from the KAMAZ engine

7. And 801 14 000 Device for adjusting the valves of the engine

8. I 801 26 000 Extractor of the cam shaft drive gear eccentric of the injection pump

9. Technique for using the tool

Stand for disassembly and assembly of fuel injection pump KAMAZ (YAZDA), M-402, DD-3310

Stand for disassembly-assembly of fuel injection pump MAZ (YAMZ), M-403, DD-3420

|

Stand М403, ДД3420 for disassembly and assembly of MAZ injection pump (YaMZ) designed for disassembly and assembly of V-shaped high-pressure fuel pumps manufactured by JSC Yazta, used on engines manufactured by JSC MAZ at service stations. The stand consists of a base that is screwed to the table; a tilt-and-rotate platform, on which the support legs are fixed (the platform allows the pump to rotate around its axis and to tilt the pump at angles of 0, 45 and 90 degrees); platform rotation lock; clamps. |

Stand for disassembly-assembly of high-pressure fuel pump (UTN), M-404, DD-3430

The workbench of the fuel operator with a cassette holder (1500x850x650), two-bollard ШП-17-03

The workbench of the fuel operator (1500х850х650), one-pillar, ШП-17-06

Set of specials tools for disassembling and assembling high-pressure fuel pump type BOSCH VE DD-3700.01, DD-3700

|

Set of specials tool DD3700 for disassembling and assembling the injection pump type BOSCH VE |

Set of specials tool for adjusting injection pump type BOSCH VE DD-3710

Diesel Engine Diagnostic Equipment

Set "Standard-diesel" ST-DR DD-4100

Set "Standard-diesel" ST-DI DD-4120

Set "Standard-diesel" article ST-DU DD-4130

|

Set "Standard-diesel" STDU DD4130, cylinder tightness analyzer of imported and domestic cars(g / l, l / a), those. documentation, reference values |

Cylinder pneumatic density indicator (compressometer) (diesel) IPTs-DR DD-4200

Cylinder pneumatic density indicator (compressometer) (diesel) IPTs-DI DD-4210

Cylinder pneumatic density indicator (compressometer) (diesel) IPC-DU DD-4220

|

Cylinder pneumatic density indicator (compressometer) (diesel) IPTSDU DD4220 imported and domestic cars (g / l, l / a) |

Professional equipment for working with gasoline fuel equipment

Stand DD-2200 for checking and cleaning gasoline injectors (injectors)

Professional cleaning liquid for RAS for the DD-2200 stand Technician Z

|

Traditional liquids for removing tar and carbon deposits from nozzles using ultrasound are often laborious and unsafe for humans (requires hand and eye protection). |

Technik Z cleaner actions

Ultrasonic cleaning uses high quality sound waves generated by a transducer built into the cleaning tank below the surface of the cleaning liquid. Ultrasonic waves create microscopic vacuum holes (air bubbles and steam) under the pollution, which explode. Air bubbles circulate in the solution and, thanks to the high penetrating ability of the TECHNIK Z liquid cleaner, get between the surface to be cleaned and the dirt covering it. Bubbles adhere to dirt and tear off dirt particles when vacuum holes explode. The explosion pressure can be up to 1000 bar without causing damage to the surface. The result is excellent cleaning performance even in labor-intensive areas.

One refueling of the ultrasonic chamber is enough for 6 - 8 cleanings of 8 sets of nozzles. Before filling the ultrasonic chamber with heating, it is necessary to dilute the liquid by 30% with distilled water. Application in unheated ultrasonic chambers is ready-made.

The System of Mobil Cleaning, SMC installation (DD-2300)

Set of adapters for servicing fuel systems of American cars for DD-2300, SMC-1001

Set for measuring pressure in the fuel system of domestic cars SMC-101

|

Set for measuring pressure in the fuel system of domestic cars SMC-101 |

A set for measuring the pressure in the fuel system of any cars of foreign and domestic production SMC-1002

|

SMC1002 kit for measuring the pressure in the fuel system of any imported and domestic production |

Ultrasonic bath, 3 l. UZV-103

Ultrasonic bath, 4 l. UZV-104

Diesel Tester for Testing Electronically Controlled Pumps

Compressor KA-6719K for diesel vehicles (trucks)

Compressor KA-6720K for diesel cars (passenger cars)

S-110 light device

ASKAN-8 diagnostic tester for VAZ and GAZ control units

Set of accessories and tools OR-15727M

|

Price: RUB 320,000.00

Buy

In order to buy this product, fill out the application below

By clicking the "Submit" button, you accept the terms and conditions and consent to the processing of your personal data, in accordance with the Federal Law of July 27, 2006 No. 152-FZ "On Personal Data", on the terms and for the purposes specified.

Photos of completed worksFuel equipment stand

The stand is designed for diagnostics and adjustment of diesel fuel equipment up to 8 sections inclusive.

The following diesel engines of the type: YaMZ-236, YaMZ-238, YaMZ-7511, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ- 5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD-31B, SMD-62, SMD- 62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64 TNVD type TN, UTN, ND, 4UNTM , LSTN. Injection pump type Bosch K, M, MW, A, B, BV, P; MOTORPAL; Distribution injection pumps: Bosch, Lucas, Zexel, Denso are diagnosed with additional equipment supplied on request.

In the fuel stand ДД 10-01 for diagnostics of high-pressure fuel pumps, the following are used:

- 7.5KW High Torque AC Electric Motor

- Direct Drive System - DDS

- System of autonomous thermal stabilization of fuel

- High and low fuel delivery system

- Backlash-free drive clutch

- DC power supply with two voltages 12 and 24 V

- Control system from an electronic programmable tachometer

- 8-section volumetric loop metering system with small and large beakers

- The system for stabilizing the speed of rotation of the drive with feedback allowing to maintain the set speed regardless of the load

- flywheel with high inertial moment

- Basic complete set: a set of brackets, couplings and high-pressure pipes for diagnostics of domestic high-pressure fuel pumps

The following operations can be carried out on the fuel stand DD 10-01:

- Testing and adjustment of in-line fuel pumps of high

- pressure (hereinafter injection pump) with an independent lubrication system,

- the number of sections up to eight, as well as the distribution pump

- type with the number of supply connections up to eight ways

- control of the following parameters and characteristics:

- size and uniformity of fuel supply

- sections (productivity of pumping sections);

- frequency of rotation of the injection pump shaft at the start

- the actions of the regulator;

- frequency of rotation of the injection pump shaft at the moment of termination

- fuel supply;

- opening pressure of discharge valves;

- the angle of the beginning of discharge and the end of the fuel supply

- rotation at the injection pump shaft and alternation of supply by sections of the injection pump;

- angle of actual start and end of injection

- fuel (when diagnosing)

- characteristic of the automatic injection advance clutch.

Standard equipment of the fuel stand DD 10-01:

- 1- bracket ДД 10-00.940.000М for fastening fuel pumps such as TN, UTN-5, ND-21; 4TH10; 6MTNM, 58;

- 2- bracket ДД 10-00.950.000 for fastening fuel pumps of type НД-22; PES, PVA, VE;

- 3- bracket ДД 10-00.930.000 for fastening fuel pumps of 6ТН type; 33, 60, 80, 90, YAZTA; PVA (ZIL-645, Tatra); engine pumps: YaMZ-236; YaMZ-238; YMZ-740; S6A950 (Ikarus);

Coupling adapters:

- 1. adapter for pumps, type ND-21 DD10-00.1010.000M;

- 2.adapter of pumps, type UTN-5 DD10-00.1011.000M;

- 3. adapter for high pressure fuel pump for engines of the YaMZ-236,238, DD10-00.1012.000 type;

- 4. adapter for high-pressure fuel pump for engines of YaMZ-840, ND-22, DD10-00.1015.000M type;

- 5. adapter for high pressure fuel pump for engines of the YaMZ-740 type with MOV DD10-00.000.052;

- 6.adapter for injection pump KAMAZ 337-40, 337-70, 337-80; DD10-00.1013.001;

- 7.Adapter for high-pressure fuel pump for pumps of type 4UTN DD10-00.1014.001.

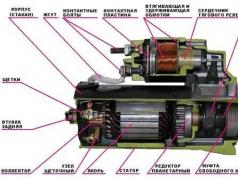

1- cooler; 2- fuel tank; 3- pipelines; 4- electrical cabinet; 5, 6, 7 - choke; 8 - support of the measuring block; 9- output shaft with bracket; 10-dimensional block; 11- control panel; 12- tachometer; 13, 14 - pressure gauge; 15- thermometer; 16- dirty fuel tank; 17- frame; 18- handle; 19- grounding bolt; 20- dirty fuel drain valve

In our company you can buy fuel stand dd 10-01 on favorable price manufacturer. The goods are shipped from the company's warehouse located in Vladimir. Also, you can order the delivery of equipment to your city using the services of a transport company.

Delivery of equipment purchased from our company is carried out to all regions of Russia, Belarus and Kazakhstan. Delivery regions

Moscow, Ufa, Sevastopol, Saratov, Krasnoyarsk, St. Petersburg, Volgograd, Novosibirsk, Kaliningrad, Tomsk, Arkhangelsk, Sochi, Vladivostok, Yaroslavl, Murmansk, Voronezh, Nizhny Novgorod , Yekaterinburg, Omsk, Perm, Belgorod, Kazan, Pyatigorsk, Ryazan, Novorossiysk, Samara, Bryansk, Krasnodar, Tver, Tomsk, Kislovodsk, Chelyabinsk, Yalta, Astrakhan.

see alsoIn case of delays in invoicing and quotation, as well as in the event of complaints about the work of the sales department, contact the senior manager.

Attention! All prices on the website are indicated without VAT.

Extended information

A stand for testing and adjusting high-pressure fuel pumps of various types, including those with high-energy injection of domestic and foreign production with a cycle feed of up to 250 mm / cycle with a plunger diameter of up to 12 mm (12-section, asynchronous electric motor 15 kW, frequency converter MITSUBISHI ). Beaker measuring system (injection angle sensor, front injectors). Autonomous thermal stabilization system.

The stand is designed for diagnostics and regulation of high-pressure fuel pumps type 133,175, 185 and their modifications with cyclic feed up to 250 mm2, injection pressure up to 120 MPa, as well as high-pressure fuel pumps of engines of the type YaMZ-238, YaMZ-240, YaMZ-8401.10, YaMZ 850, YaMZ 7511, YaMZ 845.10, YaMZ 8421.10, YaMZ 84 23.10, YaMZ 84 24.10, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD-31B, SMD-62, SMD-62AT, SMD-31/32, A-01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64. Injection pump type TN, UTN, ND, 4UNTM, LSTN .. Injection pump type PVA, PVB, PESA, PEA, PECM, PPM (f), JPH, WSK, PES, CAV, BOSCH VE, D6, D12 are regulated with additional equipment supplied by order.

Stand DD10-05 with a graduated measuring system (injection angle sensor, front location of injectors), installed power of an electric drive of 15 kW, consisting of an asynchronous electric motor and a MITSUBISHI ELECTRICS frequency converter. Diagnostics of high-pressure fuel pumps up to 12 sections, built-in lubrication station, built-in pressurization system, autonomous thermal stabilization system.

Diagnostics of pumps is carried out by reproducing the speed of the drive shaft of the high-pressure fuel pump (high pressure fuel pump), fuel temperature and pressure, measuring these parameters, as well as the cycle flow, fuel consumption supplied to the test object, the angles of the beginning of fuel injection (injection), turning the lead clutch injection, deviations of the angles of the beginning of injection (injection).

The following operations can be carried out at the stand:

Testing and adjustment of high pressure in-line fuel pumps

(hereinafter injection pump) with independent and compulsory system lubricants, with the number of sections up to twelve, as well as the distribution type injection pump with the number of supply pipes up to twelve by monitoring the following parameters and characteristics:

... size and uniformity of fuel supply by sections

(productivity of pumping sections);

... frequency of rotation of the injection pump shaft at the moment of the start of action

regulator;

... frequency of rotation of the injection pump shaft at the moment of termination

fuel supply;

... opening pressure of discharge valves;

... the angle of the beginning of injection and the end of fuel delivery

by turning the injection pump shaft and alternating the supply by the injection pump sections;

... angle of actual start and end of fuel injection

(when diagnosing);

... characteristic of the automatic injection advance clutch;

... maintaining the set temperature.

TECHNICAL CHARACTERISTICS OF STAND DD10-05

|

Stationary |

|

|

Electric drive |

|

|

Number of simultaneously tested high-pressure fuel pump sections, pcs., No more |

|

|

Play range: |

|

|

The counting of the number of revolutions (cycles), about. (Cycles) |

|

|

Cyclic fuel supply, mm3 cycle |

|

|

Fuel temperature, 0С |

|

|

Fuel pressure, MPa (kgf / cm2) |

0….3 (0….30) |

|

0…0,16 (0…1,6) |

|

|

Oil pressure, MPa (kgf / cm2) |

|

|

Limits of permissible deviations of the measured values: |

|

|

Rotation frequency of the drive shaft, from 70 to 800 min-1, min-1 |

|

|

over 800 min-1,% |

|

|

Cyclic fuel supply,% |

|

|

Angles of the beginning of fuel injection, degree |

|

|

Counting the number of cycles, cycle |

|

|

Fuel temperature, 0С |

|

|

Throughput of the fuel line sections of the test bench, cm3 |

|

|

Measurement error limits: |

|

|

Rotation frequency of the drive shaft, min-1 |

|

|

Cycle feed cm3 / 1000 cycles |

|

|

Counting the number of cycles, cycle |

|

|

Fuel temperature, 0С |

|

|

Fuel pressure in the range from 0.1 to 0.6 MPa (from 1 to 6 kgf / cm2) |

± 0.015 (± 0.15) |

|

Fuel pressure in the range from 0.6 to 4.0 MPa (from 6 to 40 kgf / cm2) |

|

|

Oil pressure, MPa (kgf / cm2) |

± 0.015 (± 0.15) |

|

Air pressure, MPa (kgf / cm2) |

± 0.001 (± 0.01) |

|

Angles of the beginning of fuel injection, degree |

|

|

Capacity |

|

|

Fuel tank, l, not more |

|

|

Oil tank of hydraulic drive, l, not more |

|

|

Water tank, l, no more |

|

|

AC power |

|

|

Voltage, V |

|

|

frequency Hz |

|

|

Power consumption, drive electric motor, kW |

|

|

Electric motor fuel system, kW |

|

|

Lubrication system electric motor, kW |

|

|

Refrigeration unit, kW |

|

|

Fuel heater, kW |

|

|

Total power, kW |

|

|

Number of attendants, people |

|

|

Overall dimensions, mm, no more |

2600 x 970 x 1540 |

|

Dry weight of the stand, kg, no more |

|

Computer stand DD 10-05E for testing and adjusting the high pressure fuel pump of various types, including high-energy injection of domestic and foreign production with a cyclic feed of up to 250 mm / cycle with a plunger diameter of up to 12 mm (12-section, asynchronous electric motor 15 kW, frequency converter). Beaker measuring system. Thermal stabilization system. Built-in pressurization system. Built-in flowmeter. Control through the monitor. Autonomous thermal stabilization system, upper arrangement of the measuring unit nozzles. Complete set of brackets for piping and imp. cars. Built-in boost corrector. Built-in flowmeter.

The stand is designed for diagnostics and regulation of high-pressure fuel pumps of the type:

133,175, 185 and their modifications with a cyclic feed up to 250 mm2, injection pressure up to 120 MPa, as well as high-pressure fuel pumps for engines such as YaMZ-238, YaMZ-240, YaMZ-8401.10, YaMZ 850, YaMZ 7511, YaMZ 845.10, YaMZ 8421.10, YaMZ 84 23.10, YaMZ 84 24.10, YaMZ-236 BE (NOT), YaMZ-236 M2, YaMZ-236A, KamAZ-740, KamAZ 7408, ZIL-645, ZIL-0550, GAZ-5424, GAZ-5441, KDZ-744, D-65, D-260, 64NSP 18/22, 6DM-21A, DGR 200/750, D-245.12, SMD-31, SMD-31B, SMD-62, SMD-62AT, SMD-31/32, A- 01M, A-01 ML, A-01 MTG, A-41E, D-440, SMD-60, SMD-72, SMD-64.

Bosch in-line: K, M, MW, A, B, BV, P. Distribution injection pump: Bosch, Lucas, Zexel, Denso.

Diagnosis is made by reproducing speed of rotation of the drive shaft of the high-pressure fuel pump (high pressure fuel pump), temperature and pressure of the fuel, measurement of the specified parameters, as well as cyclic supply, fuel consumption supplied to the test object, injection (injection) start angles, injection advance clutch rotation, deviations of the start angles injection (injection).

Stand 05E computer stand for testing and adjusting the injection pump of various types, including high-energy injection of domestic and foreign production with a cyclic feed of up to 250 mm / cycle with a plunger diameter of up to 12 mm (12-section, asynchronous electric motor 15 kW, frequency converter).

Stand 05E of the stand includes:

A set of brackets, adapter couplings, flanges for installation on a stand of almost all types of high-pressure fuel pumps of foreign and domestic production. The basic configuration includes 12 bench injectors, to measure the injection angles and the end of the fuel supply in sections, a static method of measuring the hydraulic density (drop per second) is used, to characterize the injection advance couplings on domestic high-pressure fuel pumps in basic configuration the stroboscope is on. The basic configuration of the stand includes a PE 3810 diesel tester, a special set. tool for injection pumps of the Bosch-P series. Built-in boost corrector. Built-in flowmeter. Diesel tester 3810 (PE injection pump), tool for disassembly, assembly and adjustment of PE, MW series injection pumpStand 05E applies:

- AC motor with a power of 15 kW

- Direct connection of the motor shaft to the adapter coupling

- Autonomous system of thermal stabilization of fuel

- High and low fuel delivery

- DC power supply with two voltages 12 and 24 V

- Conclusion of the main operational parameters of the stand on a 15-inch display (display with touch screen function)

- Displacement sensor of the rack travel of in-line injection pumps with display on the screen

- 12-section measuring block for measuring cyclic feeds with beakers of small and large volume moving in two planes

- The system of stabilization of the speed of rotation of the drive with feedback, which allows you to maintain a given speed regardless of the load

- Built-in boost corrector

- Built-in rotameter

- Lubrication system of the high pressure fuel pump with a circulating lubrication system

- Equipment for diagnostics of injection pumps Bosch with electronic control

- A set of special tools for disassembling, assembling Bosch high-pressure fuel pumps of the P series

Systems checked by stand 05E

Testing and adjustment of high-pressure in-line fuel pumps with an independent lubrication system, with up to twelve sections, as well as a distribution type injection pump by monitoring the following parameters and characteristics:the size and uniformity of the fuel supply by the sections (the productivity of the pumping sections);

the frequency of rotation of the injection pump shaft at the moment the regulator starts to operate;

the frequency of rotation of the injection pump shaft at the moment of stopping the fuel supply;

opening pressure of discharge valves;

the angle of the beginning of the injection and the end of the fuel supply according to the rotation of the injection pump shaft and the alternation of the supply by the sections of the injection pump;

the angle of the actual start and end of fuel injection (when diagnosed)

characteristic of the automatic injection advance clutch.

pneumatic regulators for in-line and distribution injection pumps

Technical characteristics of TNVD 05E

Number of simultaneously tested high pressure sections 12

Reproduction range of values:

Rotation frequency of the drive shaft, rpm 70-3000

Counting the number of cycles, cycle 50-9999

Cyclic fuel supply, mm? / Cycle 0-250

Fuel temperature, ° С 20-45

Angles of the beginning of injection (injection) of fuel, degrees 0-360

Angles of rotation of the half-couplings of the automatic fuel injection advance clutch, degrees 10-0-10

Fuel pressure, MPa 0-3

Air pressure, MPa 0-30

kgf / cm? 0-2

Volume of measuring vessels of STA fuel, ml 2-40