The result of the repair always depends on the determination of the master to achieve a conceived effect and its readiness to spend the right amount of forces, tools and time. The cost of repairing batteries must be specified after a thorough check and installation of the diagnosis of "disease". Repair of the car accumulator with its efforts is justified if the estimate of its repair will be not more than half the price of a similar new product, taking into account that most of the work will be done with their own hands.

Repair of cracks or chip chip, violation of the integrity of contacts will cost symbolic costs. For expensive branded models, shabby, but retained at least half of the planned resource, the repair of batteries are usually carried out in car workshops.

If there is patience and desire to understand the repair of the car battery do it yourself - watch the video:

But it is better to refer to the literature for maintenance and repair automotive technology 60-70s of the last century. Let you not be confused by the age of the source - in the last 30-40 years acid batteries Become perfect, but the main breakdowns and methods of repair remained the same. Usually the topic - how to repair the car battery, decomposed on the shelves to the smallest details.

The acid-lead batteries are sick

Problems with the tightness of the case arise as a result of careless handling of the battery. Modern materials, impact-resistant acid-resistant plastics, for example, polypropylene, well transfer mechanical and thermal impact. The exceptions are cases when the battery case is destroyed due to the internal circuit of the plates of the electrodes when charging the current. Then a lot of heat is released, the excess pressure of gases and water vapor is formed.

For the repair of cracks in the battery case, you will need:

We carry out the repair in the following order:

- if the crack on the housing is below the electrolyte level, drain it from the battery using a large medical syringe with an arched piece of polychlorvinyl tube, 20-25 cm long;

Important! Despite the numerous advice of Internet specialists to drain the electrolyte by simply tipping the battery, it is categorically impossible to do it. When the battery is turned over, the sediment of lead oxide, going in special pockets at the bottom of the housing, is able to cause an interelectrode closure of the plates and finally remove the battery.

- a sharp knife formed along the entire length of the crack V-shaped groove. At the ends of a thin drill, unfold the tiny holes in 1mm. They are needed to prevent the further development of the crack;

- heat the soldering iron or in the flame of the ordinary candle of the bracket to a temperature of 400-450 degrees. Carefully fuse them in the edges of the crack every 12-15 mm. Such a bandage will keep the edges of the crack in contact;

- we make a thermal screen from heat-resistant material, canonite, 10x15 cm. In the sheet cut the slot, dimensions and shape exactly coinciding with the geometry of the crack. We combine cutout with a shape of the groove and securely fix on the battery case;

- for soldering, you can use a special soldering rod or tape, and you can make the solder with your own hands. Cut from the harvested polypropylene thin, like a thread, strips. Their length and quantity should correspond to about the volume of the material required to fill the V-shaped slot. We turn into a thin tight harness;

- heat the halter with a halter, we melt the edge of the solder material and press it with an effort to the beginning of the crack. Warming polypropylene solder and crack, we sequentially close the whole slit;

- in addition to soldering, the crack can be sealed with a polystyrene dissolved in dichloroetane, or solvent KR-30. For the sticker of the patch surface around the crack at a distance of 15-20 mm, it is necessary to handle the sandpaper and degrease the acetone.

Sulfate electrodes

Statistics studies of the Battery Council Int. He speaks - in 80%, the cause of the failure of the battery is plate sulfate.

One of the available types of auto batteries with your own hands is to eliminate the sulfate of the battery plates. The surface of the electrode is covered by a whitening flaw that prevents the normal flow of current. Battery capacity, even after full cycle Drop-charge, smaller than the charge is good for an order.

How to repair the battery with your own hands, knows any experienced motorist. With a low degree of sulfate electrodes, the precipitate on the surface of the plates still has loose and porous consistency.

Experts are offered to repair a car battery with simple and efficient procedures:

- replace the electrolyte in the battery with warm distilled water. A few hours in the battery will occur chemical reaction Dissolving salts from the surface of the electrodes. Distilled water, as the salts transition to the solution, will turn into an electrolyte, the terminals will have a potential of 7-10 volts;

- drain the resulting solution and rinse the battery several times, first distilled water, and then a clean electrolyte;

- calm the battery capacity with a reduced density electrolyte and put it on charge with a charge current limit no more than 116 nominal capacity by 10-12 hours;

- using a conventional car light bulb, discharge the battery for 7-8 hours. Cycle charge-discharge must be repeated at least 4-5 times.

In the absence of problems with the closure, warping of plates, repair, battery capacity can restore up to 80-85% initial.

Tip! Use asymmetric current to charge the battery, its effectiveness is confirmed by practice, and many manufacturers of specialized chargers implement a similar function in their products.

If sulfate plates reached 30-40% of the electrode surface, repair the battery with your own hands is still possible, but already using chemicals:

- the electrolyte is drained from the charged battery and replace it with 2% aqueous solution of the preparation "Trilon B" with an additive of 5% ammonia;

- after 60 minutes, the solution is drained and the banks are washed with distilled water;

- after washing, the electrolyte is poured and charged to 1/10 from the battery capacity. If necessary, the procedure is repeated two or three times;

- such technology makes it easy and effectively repairing batteries not only by automotive, any similar, most importantly - with their own hands and forces;

Internal closure of electrodes in one of the batteries

The liquidation of internal circuit in the bank is one of the last, available types of repair of the battery with their own hands. The battery has six groups of pairs of electrodes, called banks collected in the hermetic case sequentially. Each of the cans may consist of 6-10 pairs of atolar electrodes separated by special dielectric insulators - separators. If the separator is destroyed, or for any other reasons between a pair of positive and negative electrodes there will be direct contact, the ability of electrodes to accumulate energy will be lost.

How to repair the battery in a similar situation - repair is possible only if the closure is caused by lead microparticles accumulated at the bottom of the battery and formed a kind of jumper between the electrodes. To do this, in the bottom of the closed banks, a small hole is drilled and a flowing electrolyte is washed away by the estimated cause of the closure - bottom sediment of lead slam. If 3-4 one-time flushing did not give the desired results, the battery is selected.

Before making a decision on the possibility and impossibility of repair lithium batteries, consider the health of the control units, controllers, wiring and contact group.

Causes of failure lithium battery some:

- failure of the control system board (BMS), the battery repair is reduced to the usual replacement of the controller;

- fitting wiring, switches and load switching devices. With the help of the car tester, they check serviceability, and if necessary, replace the element;

- if the first two factors are excluded, directly lithium elements are subject to repair, of which the battery is gained.

Comment! In case of failure of part of lithium battery elements, the cost of repair, their revision and replacement will be comparable to the new battery price.

Not every car enthusiast knows how to restore the car battery. And this can extend his life for several years and protect the car owner from unexpected financial expenses. To date, there are four basic ways to extend the operation of any battery.

The battery is responsible for the process of continuous supply of the required voltage. Accordingly, they are an indispensable component of the work of certain mechanisms of machine and its and appliances. Everyone knows that nothing is forever. As a result, each car needs regular technical inspections to identify unfit details. As a rule, any battery (the most common is acidic alkaline and lithium) can be repaired. This option is better than immediately run to the store for a new one.

As for acid-alkaline (they are also called lead-helium), their structure is represented as follows - a pair of plus-minus plates from lead in sulfuric acid. They are most common in the field of automotive industry and in the production of pocket lanterns. Nevertheless, it serves such a battery with respect to long.

The first way to restore the battery is the use of repeated recharging with a short force current. In this case, the charging process should provide temporary segments between recharging. Thus, starting from the first recharging and ending with the latter, the voltage located in the battery is gradually growing and as a result - it will stop perceiving the charge itself.

Pauses are necessary in order for the potentials of the electrodes that are in the depths of the mass of the plates themselves and on their surface, they leveled, which makes restoring more secure. In parallel, the most dense electrolyte begins to leak directly from the pores of the plates themselves into the space located between the electrodes.

Together with the cyclic charge, and together with the increasing capacity of the battery, the density of the electrolyte itself also rises. It is necessary to wait for the moment when the section voltage is equal to two and a half volt, and the density indicator will reach the normal level. Only then the car battery must "relax." Such a cycle should be repeated up to eight times. Also, the charge current itself should be exactly ten times less than the capacity of the chargeable battery.

Replacing electrolyte

Direct recovery of the battery can be carried out with the method of replacement. To do this, you need to completely merge the electrolyte, and then rinse the battery thoroughly hot water. After that, three teaspoons of ordinary soda will be required, which need to be diluted in a hundred milliliters of water.  The resulting liquid must be boiled, pour instead of electrolyte, and after twenty minutes - to merge. Such an action must be repeated several times, followed by a three-time washing of the same hot water.

The resulting liquid must be boiled, pour instead of electrolyte, and after twenty minutes - to merge. Such an action must be repeated several times, followed by a three-time washing of the same hot water.

This method is great for cars batteries. The last stage of this process ends with the infusion of a new electrolyte and a daily charge. After that, the battery charge for six hours to ten days in a row. The charger must have the following characteristics - the voltage is not more than sixteen volts, but not less than fourteen, and the current is no more than ten amps.

Reverse charging

Recovery with reverse charging is also possible. However, this method provides for a fairly powerful source of the voltage itself (the same welding machine). It must have a tension of at least twenty volts with a current of at least eighty amp. When you need the required device, the next step becomes the opening of the jams of cans and their inverse charge. To carry out such charging, you need to attach a plus charging device To the "minus" battery, and to its "plus" - "minus" of the charging device. It can extend his life for several years and protect the car owner from unexpected financial expenses.

During the charging process, the battery will boil, but nothing terrible. The charging itself should last no less and no more than half an hour, after which the old electrolyte merges, the container is washed with hot water and only then you can pour a new electrolyte. The next action becomes the use of another charging device with a current of up to fifteen amps. They charge the battery a whole day.

Distribution of charge in distilled water

Using the last, fourth method, the battery is realistic to restore in less than one hour. If it is completely discharged, it should be previously charged. After that, the electrolyte is also completely drained and washed several times with water. Next, it is necessary to pour the battery capacity of an ammonium type, which includes two percent of the same trilder and five percent of the ammonia itself, it is necessary to pour into the washed capacity of the battery. When it is assisted, the process of so-called desulfation is carried out, which lasts up to one hour. During this process, the characteristic isolation of the gas and the occurrence of small splashes on the surface of the inflighted solution occurs.

After all of the above, it is necessary to rinse the battery several times with a simple distilled water, followed by the influence of electrolyte acceptable density. Then the battery is charged and it can be considered completely renovated. By summing up, we can say that, in general, the restoration of the car battery can be considered not very difficult.

I can confidently say that the cessation of gas is evidenced by the completion of desulfation. If the sulfate is too strong, then it is necessary to repeat the processing process to restore the battery fully.

Video "How to restore the capacity of an old battery"

The record shows a method for charging a lead battery at home.

If the electrolyte density in one can be much smaller than in others, this indicates a defect in this battery bank.

One of the defects is an increased self-discharge or short circuit in the bank.

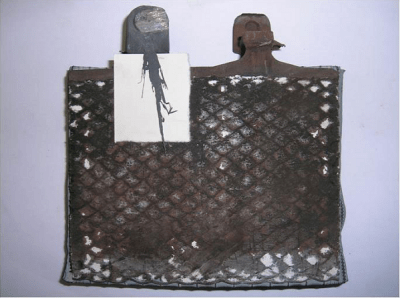

This is the bottom of the plates. The namage of positive plates crept on the bottom of the envelopes. Envelopes burst. Bridges appeared between positive and negative plates, through which the bank is discharged.

The photo shows how the adjacent plates are contacted among themselves, although they must be isolated.

Previously, separators in car batteries were in the form of plates. Sleeping active mass went to the sludge well. Now the separator in the form of envelopes and ... there is practically no sludge well.

Therefore, the sludge accumulates at the bottom of the envelope, driving it. The envelope bursts and the plate is cryotitis.

Since the resistance of the sludge is relatively large, then an increased self-discharge occurs. That is, the battery section still perceives the charge, but quickly discharged.

With a short circuit, for example, if the lead grills are shortwood, the charge section does not perceive anymore. On the battery, with a short closure in one bank, the voltage is below 2 volts.

How in this case cure the battery?

Mean what can be done:

1) buy new battery - Not our case (as it does not work on the business).

3) Disassemble and clean - difficult, it is possible, but we will not.

4) To do something with him so that these jumpers themselves disappear - this option will consider below

How can you restore the short battery bank

These jumpers can be smelted with a large current.

But where to take it?

Welding will still leave alone - we have a powerful current source - this is the battery itself.

The method is dangerous, so safety should be followed.

Instruction: How to restore the battery bank.

We carry out work on the street or in a well-ventilated room.

ATTENTION: The battery can explode !!!

1) Charge the battery.

2) unscrew the plugs.

3) blow all battery banks from a mixture of hydrogen with air.

4) We run all curious.

5) Take through a rag (so as not to burn) the wire is thickening - squares 16mm2 or more.

6) hide the face for an angle and for a couple of seconds, you are crying the battery terminals - extra jumpers inside the cans should / may (as lucky) to burn out.

7) We again blow banks and if you need to repeat the operation.

If after subsequent charging, the battery voltage is kept more than 12V, then you can start

It is not necessary to immediately throw the battery if I started to disappear or scroll after the starter. In many cases, the battery is subject to repairs. Knowing how to restore the car battery, you can extend its operation for another few seasons.

Battery defects

Battery malfunctions can be caused by both external and internal reasons. To the first one can attribute:

- Damage (cracks) of the plastic battery case caused by external influences or processes in the battery itself (overheating, bloating, etc.). With significant damage, repair is inappropriate and better to purchase a new battery. Minor damage can be eliminated independently with the help of improvised tools and materials, pre-drained the entire electrolyte. At the end repair work You should pour fresh electrolyte and charge the battery.

- Oxidation of contact terminals. Repair comes down to stripping oxides with sandpaper and rag or cloth. We will not be cleaned with contacts and on connected cables. Upon completion of stripping, contacts and terminals can be treated with a small portion of the engine oil.

The list of internal faults looks slightly impressive, and some of them do not allow recover the battery at all:

- For incorrect use Batteries, for example, deep discharge or systematic subwage, may damage the elements. And in case of finding a discharged battery in the cold freezes the electrolyte, which causes damage to the plates or housing. The restoration of the battery in such cases is inappropriate.

- Sowing of coal plates is diamed with electrolyte. The restoration of the battery in this case is also unreal and should be purchased new.

- Sulfate plates is the most common internal malfunction of the battery. At its initial stage, the battery is reduced and slightly below will be indicated, as is done.

- Circuit plates. The sign of this defect is overheating by one of the cans and boiling in it electrolyte. In some cases, salvation is the replacement of lead plates, but you need to be prepared and to a complete replacement of the battery.

Recovery methods

Sulfation

The manifestation of this defect is the white beam of a large-crystal sulfate lead on the plates. The crystal layer covers the pores of the active substance, preventing the passage of electrolyte when charging the battery. Because of this fault, resistance inside the battery with a simultaneous decrease in its capacity increases sharply. As a result, the battery begins to rapidly charge. The values \u200b\u200bof electrolyte and voltage temperatures are also noticeably growing, which entails a sharp release of gases. After installing in the car, such a battery is extremely quickly discharged.

Sulfate battery plates

Sulfate may occur due to the discharge of the battery less than 10.2 V, its long-term storage is in a state of discharge, too low level Electrolyte in banks, its low density or contamination by third-party impurities.

The battery is reduced only with a slight sulfate. If the process went far, then the battery will have to be changed. The recovery process is to carry out multiple charging cycles - battery discharges.

First you need to make a complete charge of the battery and bring the density value of the electrolyte to a value of 1.285 g / cm3. This can be done, poured a more dense (1.4 g / cm3) electrolyte.

Attention! In no case do not add acid! It will only aggravate the situation.

If there is a need to reduce density, it will be necessary to add distilled water.

After that, it is necessary to retail the time and discharge the current with a current of about 0.5 A, using the incandescent lamp. It is necessary to achieve a reduction in voltage in each bank to 1.7 V either to 10.2 V in the entire battery. Next, using the size of the discharge current and the time spent, the real capacity of the battery should be determined. If its value is lower than the nominal, then the charge-discharge procedure will have to be repeated. Practice shows that in most cases it is enough to carry out 3-4 charge-discharge cycles. Having achieved the nominal value of the container, you can read the battery restored, put it for charging and, at its end, operate in normal mode.

Short circuit

This defect may occur when separators malfunction or plates in the process of discharged with high-pressure current (long-term use of the starter, or a schrah sample). The active substance begins to penetrate the crack through the crack plate. Slipping down, it fills inner space and connects the diverse plates. The value of the discharge current increases, which leads to the output of the battery.

Damage to the separators of the battery plates

Troubleshooting consists in adding a special desulfatoric additive to the electrolyte. Previously, its density must be brought to 1.28 g / cm3. The resulting mixture for complete dissolution should be left for 48 hours, and then pour into the battery and again measure the density value.

If its value has not changed noticeably, then you can proceed to the charging process - discharge, which should be repeated several times. If the battery does not heat the battery in the charging process, and the electrolyte does not boil, then the current strength can be half reduced. If two hours later, the density value has not changed, the charging can be stopped.

With a noticeable change in the density value, more than 1.28 g / cm3 in the electrolyte it is necessary to add water, and with a deviation in a smaller side - sulfuric acid. By bringing the density value to the nominal level, you can repeat the charging process.

There are also cases when dirt, fat and moisture create a conductive layer, which will slowly kill your battery, and discharge under the "zero" in the winter. This phenomenon is quite rare and the mechanic may not know about him or simply miss that in the end will lead to an erroneous recommendation on the replacement of the battery. Leakage is easy to check with the help of a multimeter, eliminating premature spending.

Battery leakage

Reverse charging

The process consists in changing the polarity of the battery. Before restoring the car battery in this way, it is necessary to find a powerful voltage source of at least 20 V and current at least 80 A. It is quite suitable for the welding machine.

To begin, it is necessary to open the jacks of cans and connect the "plus" of the voltage source to the "minus" battery, and the "minus" of the source to its "plus". Then you can proceed to the charging process for half an hour. The electrolyte will boil violently. At the end of the charging, turn off the equipment, drain the electrolyte, rinse the hot water battery and pour fresh electrolyte.

After that, using the usual 10-15 ampere charger, the ACB should be charged during the day. It should be remembered that the polarity of the battery has already changed.

After performing this process, the battery when properly operation May serve for a few more years.

Unqualified AKB

Almost all new models of cars are established so-called, which, according to manufacturers, should not distract attention. However, their operation and charging is characterized by some nuances.

First of all, it should be remembered that in the warm season such batteries are recharged in the car constantly. But their charging with a special device is more gentle and correct than a constant feeding from the autogenerator.

The situation varies significantly with the arrival of winter. In the frost, the lubricant in the engine is thick and the start current of the larger value is required for its launch. This can lead to a rapid battery discharge. Therefore, charging a non-servant battery in winter is an urgent need.

This process must be carried out very carefully, as it is impossible to determine the value of the electrolyte density. You can rely only on the value of residual voltage and draw conclusions from the current situation.

A partially charged battery should be continuously charged about three hours of voltage supply of 14-14.5 V, controlling only the value of the current for the current - from 25 A at the very beginning of the process to 0.20 and with full charge.

For a fully discharged battery, the charging cycle should last no less than a day and is carried out with a maximum of attention. The voltage regulator must be set to a value, numerically equal to ten percent of the capacitance of the charged battery in the amps-hours. At the first signs of active gas formation, the process should be discontinued. Upon completion of the charging, it is necessary to check the voltage value for compliance with the nominal value.

Oxidation of terminals

To prevent most of the problems of the automotive battery, it is enough to periodically clean contact terminals and conclusions, and once every six months to carry out its full charging using a stationary device. A regular care for rotating and driving parts of the engine and starter will extend the battery life of at least up to 5 years.

Due to the "death" of the battery. This is one of the minor problems that can be solved on their own. For this you do not need to contact a hundred or run to the store for a new battery. Let's figure out how to charge a non-servant battery (or served), which lay in your garage long term Or simply discharged during the natural process of operation.

Why break the battery?

Before you understand how to reanimate the battery, you need to understand why it generally fails. There may be several reasons:

- Sulfate plates. This is one of the most common reasons that the consequence of which is the rapid loss of charge battery. Most often, the battery capacity can be restored.

- One block stops working as a result of a short circuit. Due to the closure of two contact plates, one of the battery cans is strongly overheated, the battery capacity is reduced, and often charge is not enough even in order to start the car.

- Frozening electrolyte. When using a low-density battery, the electrolyte can freeze. The battery case may crack, because of which the plates will be deformed. When the electrolyte freezing inside in 90% of cases, the battery has to throw out and buy a new one.

- Sowing coal plates. In this case, the battery is also not restored.

If we generalize, then there are only two reasons for the failure of the battery:

- Marriage in production (poor-quality coating of plates, for example).

- Incorrect operation. Most often it entails sulfate plates.

Note that it is sulfation - the most common cause bad work non-servant car batteries. Therefore, let's consider such a malfunction more. Note that the following tips are suitable only for acid batteries. Alkaline batteries are repaired differently, but they are practically not used in cars.

Sulfate plates

The principle of operation of any battery for the car is based on the use of liquid electrolyte. The main characteristic of the electrolyte is a density that the charged battery should be around 1.25-1.27 g / cm3.

When charging on lead plates, active substances accumulate, the electrolyte density is growing due to the absorption of distilled water. When the battery is discharged, the density drops, the sulfuric acid is absorbed, and the distillate is distinguished.

In the process of absorbing energy on the plates, lead sulfates are formed - crystals that do not have a negative impact during battery operation. These crystals at a small charge are small, and with systematic use of the battery, they simply blur. However, with a deep discharge, the crystals are greatly increasing and reach a large volume, due to which they do not dissolve in electrolyte. Consequently, the work surface of the plates decreases due to lead sulfates, the battery capacity drops. This process is called sulfate.

Unqualified batteries

Unnwided batteries differ from those serviced by the fact that there is no access to banks. Therefore, the electrolyte density cannot be checked. Some recommend to make holes from above to get to the internships, but there may be a system of a gas feed. Determine the level of electrolyte in banks with a bright flashlight, which shines through the battery. If the level is below the norm, the hole is made in the housing (above the electrolyte level) and distilled water is added the syringe. The hole is searched. In the rest unqualified batteries Do not differ from those serviced, and their recovery is carried out by the same methods.

Desulfation

Before charging the maintenance-free batteries with low capacity, it is necessary to perform the desulfate of the plates. To do this, one of the following three methods can be used:

- Physical cleaning of plates.

- Chemical cleaning.

- Using a charger.

Each methods will understand more.

Physical cleaning

This method is one of the extreme, and it implies a manual cleaning of contact plates. It is called an extreme due to the fact that the acid is in the battery, and it can harm when contact with the skin. So perform the following actions need very carefully:

- The entire electrolyte merges.

- In the top cover you need to make windows. This is done with a soldering iron or an electric bike.

- Now the plates are removed through the hole made, purified.

- After that, they are thoroughly washed with distilled water.

- Inside the cans are also washed with distillate.

- Plates are placed back to the jar, the windows are sealed with plastic.

- The battery poured the electrolyte to the required level.

- The battery is postponed.

It seems to be nothing complicated here, however, lead plates are rather fragile, especially after long operation. Therefore, before reanimating the battery in this way, first try to perform chemical cleaning.

Chemical method

For desulfation, this method will require a chemical solution "Trilon B". This process takes only 1-2 hours, but the complexity lies in the preparation of the solution. The cleaning process is as follows:

- The battery is fully charged for the car.

- Electrolyte merges.

- Banks are washed with distilled water.

- The "Trilon B solution" is poured inside. It must be within about one hour. The process of dissolving sulfates should be accompanied by boiling and gas release. The reaction will end within an hour. The solution of the old "trillion B" merges. You can pour a new portion of the solution, although it is not necessary, since the first had to cope.

- The battery is washed again by distilled water.

- Electrolite poured.

- The battery is postponed again.

With this method, many car owners try to understand whether it is possible to charge the maintenance-free battery. Of course, you can and in this case it's necessary. This restoration method is very effective after a very deep battery discharge.

How to charge the battery charged?

The easiest way to use charging to restore the capacity and desulfation of the battery is. This process is simple, but long. There are several ways to repair, but both are based on the alternation of a complete discharge with the charge of the car battery.

Because of the frequent discharge and charge of the battery sulfates on the plates will be dissolved naturally, as is the actively used batteries. However, before charging a non-listed battery, it is necessary to check the electrolyte level inside. And if the level will be below the norm, then it is necessary to add distilled water. It is impossible to add the electrolyte, since during the desulfation process its density will rise.

For desulfation, only special will be required. charger With the function of desulfation. It connects to the battery, and nothing more is required of the user. The device itself charges the battery, then supplies the load with the purpose of its discharge. Charging and load intervals can be different, but the essence does not change much. The lack of such a method is the value of the charger itself - its price can reach 5-10 thousand rubles.

Recovery of the usual charger

Of course, if the battery is completely discharged due to sulfates, you can try and independently get rid of these crystals using an ordinary "charger". How to charge a non-servant battery in this case? To do this, you need to charge the battery, turn off the charging, connect some household appliance to its discharge, then connect the charger again, etc. This may leave a lot of time, but the point is to charge and discharge the battery, which will result in dissolving sulfates on the plates.

- The battery is charged at low current. We install on the charger 14 V and 0.8-1 A. So the battery must be charged within 8 hours. If the electrolyte starts boiled, you need to slow down the current.

- Voltage will grow in the battery. After 8-hour charging, turn off the device and wait for the day.

- Now I am recovering 7-8 hours with high current (2-2.5 A).

- As a result, the voltage and density of the electrolyte will grow.

- Now we discharge the battery to 9 V. We connect the usual lamp far Light (automotive) and wait until the battery is discharged.

- This cycle is repeated until the voltage is obtained 12 V and normal electrolyte density.

Such a method showed high efficiency and allowed to revitalize very running batteries. Its disadvantage is the duration of the process itself and user intervention. It is much easier to connect a charger with the function of desulfation.

Finally

Now you know how to charge maintenance-free batteries, and you can produce this process yourself. But even if the methods described above did not help, you will have to go to the store for new battery. And in general, the battery is consumableswhich sooner or later has to change.