AND . This publication will help with the selection of wires for lighting. Automobile shops and car markets are littered with a variety of wires for car lighting.

The price of wires for lighting can range from 500 to several thousand rubles. But among all the variety of starter wires, there are many low-quality Chinese products.

Selection of wires for lighting

How to choose wires for lighting? If you don't have wires yet, we advise you to buy, guided by these simple rules:

- Choose wires for lighting with a large cross section. The cross-section of the wire for lighting should be large enough, we will return to this issue later. Thin wires will not help light the car, since the current strength at a small cross-section will not be enough. The normal wire diameter is 6 to 10 millimeters. This diameter is sufficient for most passenger cars. Of course, if your car has powerful engine, it is better to buy wires with an even larger cross section.

- It is best to buy copper wires, but since this can be expensive, we advise you to be guided by the amount of copper in the alloy. That is, the more copper, the better. It is not worth saving at all on this.

- Pay attention to the insulation. It must tightly protect the wires. Also, the insulation must be able to withstand relatively low and high temperatures. Good choice there will be silicone wire insulation.

- The resistance value depends on the length of the wires. The longer the wire, the higher the resistance.

- Pay attention to the crocodile fasteners. They should hold well in the junction with the wire. They should also have grippy prongs. A flying crocodile during the lighting process can do trouble.

All of these tips have only one drawback. Most of the wires sold in stores are of poor quality. That is, with a sufficiently strong battery discharge, such wires simply will not help, since they will not allow the required current to be passed. There are two options:

- Choose and buy expensive wires with a good cross-section. Moreover, a large section does not always guarantee quality.

- Make battery wires yourself, with your own hands.

Do-it-yourself lighting wires are made quite quickly, so we want to offer instructions on how to create lighting wires yourself.

Homemade wires for lighting it the best way... To do good wires for lighting, you need to buy good blanks with a large section. We recommend buying single-core wires with a cross section of at least 25 mm², for example, as shown in the photo:

The cost of such a wire will most likely be from one hundred rubles per meter. For the convenience of lighting from wires, it is better to choose a length from two to three meters. The photo shows the KG-HL marking wire. "HL" in in this case means frost resistance. This type of wire is often referred to as "welding" wire. As mentioned above, wire insulation plays an important role. It is best to buy wires with silicone or cold-resistant rubber.

We will assume that the wires for lighting the battery have been chosen. Now we will make crocodiles. The size of the wire clamps must be suitable for the current passing through them. The more the clamp touches the battery terminal, the more current it can pass. Therefore, the first option is to buy welding clamps. True, it is not entirely successful, since such crocodiles are very bulky.

Therefore, the second option is to make do-it-yourself wire clips. This option requires some effort to create quality clamps. We buy clips in the store, they are cheap. And we modify them with the help of pliers to this look:

As you can see, the power parts of the clamps are made of copper. The easiest way is to find the copper plates and bend them with pliers to fit the clamps you bought. It is better to get copper plates with a thickness of a millimeter and a half. The teeth of the clips are ground with a file. Blanks from copper plates it is fashionable to attach to the clamps with rivets or put on the screws. The basic rule is that what the workpiece is fastened with should be steel, not aluminum.

Next, you need to solder the workpiece to the clamp and wire. To do this, in any case, you need to use a neutral flux for copper and a powerful soldering iron. Before soldering, everything must be poured, especially for wires that are processed with flux over the entire cross section. A powerful soldering iron or soldering station is needed for high-quality soldering. It is necessary to warm up the wires so that the soldering is reliable.

In order for the second part of the clamp, to which the wire is not soldered, to participate in the car resuscitation process, it is necessary to connect the parts of the clamp with a braided wire of the "AMG" brand.

So that new wires for lighting can "hold" a high current, you can use refractory solder, which will allow the wires to work under an even greater load. That's all, we hope the battery wires will turn out to be great!

Car lighting wires. How to make it yourself, choose the right ready-made

Every self-respecting motorist in his arsenal should have wires for lighting a car. They are necessary:

- on a long journey, especially in an area where the nearest service station or evacuation services may be far away;

- when operating a car in the cold season;

- if the car has a "walked around" battery.

In any case, a set of ready-made wires for lighting a car is inexpensive, it does not take up much space, so it is better to have one. useful device in your glove compartment. Another question: many of the commercially available ignition wires do not meet the requirements imposed on them. Having acquired such wires, and relying on them, they can fail at the most inopportune moment. Many motorists with minimal experience in electrical work are able to make such wires on their own. Not to say that the cost of homemade conductors will be much less, but reliability and parameters will definitely win. Besides, how nice it is to have a self-made product as part of your tool.

If, nevertheless, you decide to buy a ready-made set of wires for lighting, I will give a couple of practical, in my opinion, tips for choosing them.

Appointment of wires for lighting a car

The main purpose of the wires is to ensure that the engine starts when the battery is discharged. Many car enthusiasts ignore wires, relying on a donor battery from another car or garage. The startup process in this case is as follows:

- the terminals are removed from the native discharged battery, snapped onto the charged donor battery;

- the engine of your own car starts;

- after the engine warms up, the terminals are transferred to the native battery.

In no case should this method of starting the engine be performed. When the battery terminals are thrown off on a running engine, all electronics are temporarily powered from the generator. First, the waveform of the voltage taken from the generator approaches the saw, and it will “cut” your electrician. Secondly, the generator voltage, especially when faulty regulator, may be more than 15.5 Volts, which is unacceptable for vehicle control units. The service station regularly receives cars after such "tests"; it is necessary to carry out expensive repairs of control units. On top of that, at the moment of "throwing over" the battery, the free terminals can short out, they can be reversed (connected in reverse polarity). All of this is extremely dangerous. In cars of the last years of production, removing the battery terminals is dumb from the point of view possible problems with immobilizer.

Therefore, the most reliable and simple method of starting the engine when the battery is planted is still "lighting" a car from a battery from another car. Let me remind you of the lighting procedure.

The sequence of actions when lighting a car:

1. Inspect the wires for the integrity of their insulation (if the wires are not yours). The color of the insulation or terminals is usually black for the negative wire and red for the positive wire. It is possible to admit that the insulation of the black wire was slightly broken (red - in no case), but this is also bad.

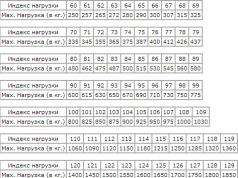

2. Estimate the cross-section of conductors without insulation. This can be done by looking at the stripped wire in the terminal area. Often, especially in Chinese wires, the insulation is as thick as a finger, and the copper core itself is slightly thicker than a hair. You cannot start the engine with such a wire. In most vehicles, the starter motor starting current (cranking current) is more than 200 amperes. It is believed that 1 square millimeter of wire cross-sectional area provides a maximum current of about 10 amperes. The area is determined by the school formula S is equal to Pi multiplied by D squared and divided by 4, where

- S is the cross-sectional area of the wire;

- Pi - 3.14;

- D is the wire diameter.

For example, with a wire core diameter of 5 millimeters, the area will be 5 * 5 * 3.14 / 4 = 19.625 sq. Mm. That is, such a wire will provide about 200 Amperes of inrush current. If more is required, the wire will heat up and is unlikely to provide a reliable start.

3. Check the quality of the clamps. It is better that they have copper "lips" and reliable springs. Go to connection.

4. First, "+" clamps are connected to the positive terminals of the battery, first the "native", then the donor.

5. Having securely installed the positive terminals, install the negative terminals in the same order (to your car, then to the donor). Why are the positive terminals connected first. If you do the opposite (first connect the negative ones), at the moment of connecting the positive terminals, they can slip off and fall on the car body. A short circuit and a big "BOOM!" It is better to involve a partner when connecting, and at the time of starting the car, make sure that the clamps do not come off.

6. Start the engine of the donor car. Within 5 - 10 minutes, the "native" battery is tightened. If this is not done, the entire load at the moment of starting the engine will fall on the donor car and the wires for lighting. If you "tighten" your own battery even a little, at the first moment of launch it will take on part of the effort, and this is very important.

7. Then you can start starting your engine. It is better, of course, to do this with the donor car running. But, if an experienced taxi driver turns you on, he will most likely turn off his engine (I would do the same). If a generator or starter is faulty on the car being started, they can harm the electronics of the donor car. If the engine starts with the donor engine turned off, it is especially important to have good wires. On them, when a large starting current flows, several volts will fall (sometimes up to three to five), and the thinner the wires, the more they will fall. For example, with a donor battery voltage of 12.8 Volts and a drop on the ignition wires of 3 Volts, only 9.8 Volts will reach the native battery, this may not be enough at startup.

8. After the engine of the native car has started, you should first disconnect the negative, then the positive clamps. It is better to also do this operation together in order to avoid a short circuit.

At the time of starting the engine, it is necessary to monitor the condition of the ignition wires. If they begin to change shape, color, heat up, the procedure should be stopped immediately. Restarting can be done after 2-3 minutes.

Selection of finished wires

Now you can find a large number of different sets of wires for lighting. What you need to pay attention to first of all.

1. Length of wires. You should not choose wires that are as short as possible and as long as possible. The length of the wires is optimal from 2 to 3 meters. It must provide a connection when the donor's car approaches, both from the side of the hood and from the side in a parking lot. If you choose wires with a length of, for example, five meters, in case of "back" docking, then it must be borne in mind that a certain voltage is lost on each meter of the wire at a high current, and it may not be enough for a successful start. In the case when the battery is installed in the cabin or luggage compartment car, there should be a terminal under the hood in case of "lighting". Many car enthusiasts are not even aware of its existence.

2.

Cross-sectional area of the wire.

The smallest cross-sectional area of the car lighting wire is about 16 sq. Mm. Translated into diameter - more than 4 millimeters.

3. Insulation material, wires, clamps. The conductors are usually made of stranded copper wire. Polyvinyl chloride is more commonly used as insulation. It happens of different quality... When buying, you should check its plasticity. If the wire is "oak" when bent, it is better not to purchase such wires. At minus 30 degrees Celsius, the insulation may crack.

Clamps are steel, copper, brass, bronze, combined. To ensure good contact, copper or alloy (bronze, brass) clamps are better. From the point of view of reliability - steel. The best option- combined clamps (steel with copper teeth).

Wire harness options

One of the budget, but acceptable options

The cross-sectional area of 9.6 square millimeters, according to theory, gives about 100 Amperes of starting current (200 Amperes is written, but at this current the wires will warm up decently). A little better wire, the figure of which is shown below. Copper terminals leave much to be desired here, too.

A decent kit looks something like this.

The cost of such a kit is from 2,500 rubles. The quality can be judged by the weight of the wires. If more than 3 kilograms, then there is enough copper in them.

Self-production of wires

In order to start making wires for lighting a car, you need to stock up on the following set of tools and accessories:

- Copper stranded wire with a cross section of 16 square millimeters of the required length. It is better if the wire is already in PVC insulation of various colors (black and red). You can use thick PVC cambric or heat shrink as insulation.

- Side cutters, knife, pliers.

- Soldering set (high-power soldering iron - from 60 watts, active flux, POS-60 solder).

- Insulation materials - cambric, heat shrinkage with a diameter of 10 mm.

- 4 secure clips with copper lips. You cannot use these options:

The sequence of making wires:

- The conductor is cut to the required length. Remove PVC insulation at a distance of about 1 - 2 cm from both ends of the conductor.

- Tinned (a thin layer of solder is applied) the ends of the conductors and the desoldering points of the terminals using active flux and solder.

- Places of attachment of wires on the clamp are crimped using pliers and a hammer. The attachment point can be reinforced with plastic straps.

4. Carefully solder the conductors to the terminals. It is possible, if possible, to additionally compress the soldering point, insulate it.

The wires are ready to use. It is better to store them in a plastic or special bag.

Almost every motorist has come across a situation in his life when there is vehicle and as a result, the engine does not start. This mostly happens for two reasons: old and weak battery does not withstand prolonged standing of the car in the cold or if the driver, for example, forgot to turn off the headlights. The way to remedy this situation is to contact the owner of another car and start your car from its battery. For this procedure, you must have special wires, the so-called "cigarette lighter". In order not to find yourself in a completely hopeless situation, when neither you nor the other drivers nearby have wires, wires for lighting a car should be in every trunk of the car.

Today you can find cigarette lighters in stores and car markets. different manufacturers with a wide range of prices. In this article, we will try to figure out what you need to pay attention to when choosing the cables we need in the first place and how to choose wires for lighting that will last as long as possible.

Diameter or section of wires

This parameter is one of the most important when choosing a "cigarette lighter". On the market you can find products with a cross-section of wires for lighting cars from 5 mm. up to 10 mm.

When deciding which wires to choose, you need to understand how it happens in a similar situation. At the time when the flywheel of the car engine is spinning, the starter requires about 200 A. In severe frosts, consumption doubles. Based on this, it can be understood that in our situation, conductors are required through which current will be conducted, with a maximum low resistance... This result can be achieved using wires with cores having a diameter of 8-10 mm. In the event that the vein is with a smaller diameter, "cigarette lighters" can get very hot and consume more energy. Experts advise giving preference to Russian manufacturer, since the Chinese is trying to save as much as possible and a very small cross-section of the wire, often hides behind thick insulation.

Materials from which the wires are made

Most often, manufacturers use copper for the manufacture of conductors. This is a rather expensive material, but it conducts electricity very well. In some models, you can find aluminum filling. This metal has even less resistance, but, unfortunately, it is very brittle and melts quickly. Such "cigarette lighters" have only one big plus - the cost is as low as possible. Aluminum filling can most often be found in Chinese models, therefore, when choosing a higher quality cable, it is better to give preference to Russian manufacturers.

Unfortunately, you can often find fakes on the market. Unscrupulous manufacturers can use aluminum or steel as a current conductor by copper plating or even simple painting.

Braid

Any wire is covered with insulation on top. Certain requirements are also imposed on it. The protection must have the necessary flexibility and at the same time be as thick as possible. Based on these requirements, it is better not to buy wires with a plastic coating, but to give preference to products with a silicone or rubber sheath. Rubber and silicone will remain soft and flexible even in extreme cold. When choosing between these two coatings, you need to give preference to silicone, because it still has the best characteristics.

Another nuance is the color of the wires. Some manufacturers find it necessary to paint the positive and negative wires in contrasting colors. This is very convenient when lighting a cigarette - it avoids mistakes.

Wire Clamping Requirements

Clips or so-called "crocodiles" have a very big influence on the quality of "cigarette lighters". The main requirement for them is strength and high rigidity. The combination of these qualities allows you to avoid risk, harm the product.

The crocodiles themselves can be from various materials steel, brass or even plastic, but all of them will have to have thick copper lining in the parts to conduct the current.

The next thing to look out for is where the clamps and wires are connected. A good indicator is the presence of a braided train. When choosing soldering or crimping, preference should be given to the first option, since crimping does not give full contact, and this increases resistance and voltage loss.

Optimal wire length

When choosing the length of the wires, it is extremely important to find the golden mean... It is important to remember here that the longer the cable is, the higher the current loss will be, which is completely unnecessary for us. At the same time, a short wire will create a lot of inconvenience in connecting the two batteries. Drivers most often point out the optimal length of cigarette lighters of 2-3 meters. Most suitable option needs to be installed only empirically. A lot will depend on and on where exactly the battery is installed.

What the market offers

In stores you can find the manufacturers' products we need different countries... It should be noted here that very good feedback has domestic products. In many respects, it often surpasses the models of foreign manufacturers. When buying wires for lighting a car, you can pay attention to the following manufacturers:

- Auto electrician - Russia.

- Phoenix - Russia.

- Heyner - Germany.

- Alca - Germany.

- AVS - China.

- AIRLINE - China.

- Lampa - Italy.

These options, of course, are also not ideal, but according to many reviews they have an optimal ratio of quality and price.

- King Tools Nova Bright Smart Power Tiikeri - China.

- Heyner AkkuEnergy - Germany.

- The ringleader, Orion, Start - Russia.

How to make "cigarette lighters" yourself

Those who are afraid to make a mistake and choose a low-quality product can be advised to make a device for themselves. The driver will need to prepare:

- Two wires with copper filling and a cross section of 8 - 10 mm., More than two meters long and having an insulating PVC coating. It is highly desirable that the wires are in contrasting colors, for example, black and yellow or red.

- Knife or side cutters required to strip the insulation.

- A soldering iron with a power of 60 watts and the ingredients required for the soldering process.

- Heat shrinkage, which is used to insulate joints.

- 4 quality crocodiles.

In this article, we will talk about how to make such wires for lighting yourself so that you can start a car with a completely dead battery. This can happen if you leave for a long time and forget to turn off the light. Or in severe frosts. That just happened in central Russia a couple of weeks ago - when the temperature suddenly dropped to -27 and many could not start, including my neighbor.

For this reason, at his request, I made him lighting wires, which will be discussed in the article.

(Picture taken from liveinternet.ru)

For residents of Siberia and the northern regions of Russia, frost is a common thing and, as a rule, their cars are well prepared for winter (see the last section of the article). But for residents of the middle zone, especially those living in large cities, an unexpected frost can present a serious problem.

Why not “buy finished wires"? The point is that there are simply no quality products on sale. Of all those seen, something more or less decent was in the review of the magazine "Behind the wheel" and was called "advice of an auto electrician." But this product was specially made by the manufacturer for the test. of this magazine- therefore, there are doubts that standard products are of the same workmanship.

Why not on sale? The fact is that a high-quality cigarette lighter, taking into account the many market markups, will cost the buyer such an amount that no one will buy it.

Therefore, the shelves of car dealerships are bursting with expensive and at the same time low-quality junk, mainly Chinese (but there is also Russian) production. The currents of 500, 600 and even 1000 amperes are written on the packages, but these are all "Chinese" amperes and they must be divided by at least 10.

Of course, these cigarette lighters help, but only if the battery is only slightly discharged. Or if charging takes a long time (at least 6-10 hours). But is someone ready to light your car during such a time? Usually, if the car does not start in 20-30 minutes, then the owner closes the car and goes by bus.

What is a quality cigarette lighter and why is it needed?

I previously wrote about Chinese and Russian cigarette lighters and wrote that, unfortunately, almost always, they are of poor quality.Even the cigarette lighter from the famous American brand Snap-On, costing 12 thousand rubles (as of January 2017), according to the test results, turned out to be of poor quality (which is doubly offensive given such a high price).

Here is the opinion of the magazine "Za Rulem" on the test results:

The biggest disappointment of the test. A big name and a deafening price are all that the product was remembered for. A soft frost-resistant wire is good, but already at a modest current of 480 A, the voltage drop exceeded 2.0 V.What is a quality cigarette lighter?

A high-quality cigarette lighter is a cigarette lighter that, due to its design, is capable of transmitting the rated current of the acceptor car starter with a minimum voltage drop (less than 1V) for a time sufficient to start the acceptor car engine (this time is considered equal to 30 seconds). Further I will write "donor" - the one who gives a light, "acceptor" - who is given a light.

The quality of a cigarette lighter is determined by the following components:

- Wire, namely core and insulation.

- Clips - "crocodiles"

- Connections

For example, PVC insulation dulls in frost and cracks when the wire is bent. Therefore, rubber or silicone insulation is used for the cigarette lighter wires. But many manufacturers, in order to save money, make PVC insulation with the addition of additional plasticizers. As a result, at -30 the insulation on the wires cracks and it is simply dangerous to use such a cigarette lighter (despite low voltage at 12 volts, short-circuiting the plus of the battery to the car body through a crack in the insulation will lead to sad consequences).

Battery passenger car mobile has Rated voltage 12 volts, with an average starter passenger car has a power comparable to a hob. For example, about 7 kilowatts (approximately this power is required to crank the crankshaft of a two-liter engine). From here, by simple calculations, we obtain the rated starter current equal to 7000/12 = 583 amperes. In fact, the voltage on a charged battery is more than 12V (usually 12.7), therefore, the current is less, but this is not so important - it is important to understand where such huge currents come from.

This is the current that the battery must deliver in order for the engine to start. This current is listed on the battery itself as the cold start current. And if the battery is strongly discharged, then to start the engine, such a current must be able to withstand not only the cigarette lighter cable, but also the "crocodiles", all transit connections in the cigarette lighter, connections to car batteries, etc.

If there is a weak link somewhere, the voltage will drop due to its resistance, and the connection itself will get very hot. As a result, with a dead battery, the acceptor engine will not be able to start.

It is also obvious that the cross-section of the wire must be copper, have a sufficiently large cross-section and at the same time be as short as possible (but at the same time so that it is possible to reach from the battery terminals of one car to the terminals of another - therefore such wires are usually not made shorter than 2.5 meters). Crocodiles must have powerful clips with a large contact area, and the connections must be reliable and have low contact resistance.

How typical wires for lighting are arranged. commercially available?

Let's consider a typical cigarette lighter costing from 500 to 1500 rubles with a declared rated current of 400-600-1000 amperes. They almost all look like this:

(Photo taken from dvizhok.su)

Such cigarette lighters consist of copper-coated tin crocodiles, as well as wires with a cross section of 2.5 to 4 squares (it all depends on the generosity of both Uncle Liao and the Russian seller who ordered this wire from the Chinese). At the same time, the wires have abnormally thick insulation - it is obvious that this is done with the aim of deceiving the buyer (an attempt to show that the cross section is actually larger than it is). Insulation usually consists of PVC with a high content of plasticizers. The wires are attached to the crocodiles by pressing with staples covered with the insulation of the handles.

Naturally, there can be no question of any current of 600 amperes (or even 100!). Such cigarette lighters are only suitable for lighting up batteries that are not very dry. Or it is necessary to charge the battery of the acceptor car with low currents for a long time (for many hours).

Let's take a closer look:

The design of the "crocodile" does not inspire confidence - everything dangles. The crocodiles themselves are made of copper-plated tin with a very small contact area (in fact, the crocodile contacts the battery terminal only with the thin side surface of one clamp).

Copper conductors of the wire are pressed against the surface of the "crocodile" with a bundle (as in the photo below). In this case, the wire itself is behind the insulation. press the staples inside the crocodile handle (unfortunately, I didn't take a photo of the mount, but take my word for it - it's just awful). Due to a poor-quality wire, the cores and insulation are easily frayed, as can be seen in the photo:

Now let's look at the “minus” wire in section. Nearby, for comparison, a PGV wire with a cross section of only 10 mm2, which is used to assemble apartment boards with currents up to 63 amperes. Absolutely most of the Chinese wire is occupied by hypertrophied insulation, and the copper cross-section is about 2.5-3 squares.

Should you waste your money on such junk? After all, it is obvious that even a current of 100 amperes (and even 50!) Such a design will not withstand.

Such cigarette lighters are only suitable for "lighting" slightly dead batteries.

Choice of accessories for cigarette lighter wires.

First, you should start by understanding what rated current it should be designed for. This information is written on the battery itself (cold cranking current). Take 530 amps per starter as an example.Accordingly, all components are selected for a given current. Due to the very limited range of products offered on Russian market devices, you sometimes have to take components designed for a slightly lower current. But with the right approach, there is nothing to worry about.

Clips manufactured by the Italian company AE with a rated current of 500 amperes were selected as "crocodiles". Crocodiles consist of solid brass, have a contact area corresponding to the current. Each of the handles has a hole for an M4 screw for attaching the wire, one of the holes is threaded. There are red and black options.

These "crocodiles" were ordered in the online store 12vi.ru. If you have a big black jeep or you are a happy owner of a truck or a van, this store has several crocodile options in the assortment for rated currents up to 850 amperes.

These "crocodiles" were ordered in the online store 12vi.ru. If you have a big black jeep or you are a happy owner of a truck or a van, this store has several crocodile options in the assortment for rated currents up to 850 amperes.

The next step is to select the wire. There are several options, including those with silicone insulation (operation at temperatures down to -60). But such temperatures do not exist in the central part of Russia, therefore, a cheaper (and most importantly, available in Electrical Installation for a cut) flexible cable for rubber-insulated welding machines - KG / KOG1 made by U production was chosen, from my point of view, the best of the cable plant among the Rossiys - Kolchugino. Operating temperature - up to -40 degrees, which is more than enough for this region. For perfectionists or residents of Siberia / northern regions, it makes sense to choose a cable in the HL version or a wire with silicone insulation.

The cable cross-section is 35 mm2. It was also necessary to solve the following two problems - the 35 squares cable is very thick, it is impossible to attach it to these "crocodiles" directly. In addition, a high-quality connection of the "crocodile" with the battery terminal can only be ensured if the voltage is applied simultaneously to both sides of the clamp, and not to just one, as is done on all cigarette lighters I have seen.

For these purposes, the KOG1 1x16 cable, also produced by Kolchugino, was chosen. It is more flexible than KG, and besides, it will allow connecting the main wire to crocodiles (16 squares of copper will fit each half of one “crocodile”).

Total: 4 meters KG 1x35, 2 meters KOG 1x16, All the cable was purchased from the Electrical installation store. There were also purchased additional parts for the manufacture of cigarette lighter wires - 4 GML sleeves for 35 mm2, 8 TML type tips for 16 squares for the M8 screw, as well as M8 screws with a full thread as short as possible. I bought tips of the TML type from Italy, manufactured by VM - since in the assortment of KBT there are no tips that would be short enough and fit in width. If you buy tips, be sure to check that they fit - these "crocodiles" have bumpers along the edges!

All goodness in one photo. An adhesive heat shrinkage of two sections will also be used, but I did not buy it since I have it in stock. Unfortunately, if you have to buy it "from scratch", it will be very expensive - especially when it comes to heat shrinkage to protect the GML, very little is required, and it is sold at least one meter long. As an option to save money - do not heat-shrink the wire coming from the TML tips, but insulate the GML sleeves with hb-insulating tape and fix it to glue.

I had big doubts about the correctness of buying tinned parts (namely GML and TML). Since tin at low temperatures is at risk of "contamination" with tin plague. But on the other hand, on the Internet, I found the operating temperature of TML up to -70, and in any car there are a lot of soldered parts and somehow all this does not fall apart, and satellites with a lot of soldered joints fly into space.

By the way, here are the sections of KOG1 1x16 and KG 1x35 for comparison with Chinese products:

Assembling the wires for the cigarette lighter

Crocodiles have factory holes for M4 screws, but this is no good! The holes are drilled with a drill, then a thread is cut into them with a baster for M8. The hole, respectively, must be drilled a millimeter narrower, that is, with a 7 mm drill.

As a result, all screws are shortened. Unfortunately, I did not find such short screws on sale, so I had to collective farm:

Crocodiles with handles removed and short screws installed:

Next, the KOG1 cable is cut into 8 equal parts (25 cm each) and stripped. The length of the "pigtail" should be such that it would fit into the TML, screwed to the hole, and the insulation started right where the plastic of the handles ends. It is impossible to leave the insulation - it is too thick, the cable will not fit into the lumen of the crocodile handle, in addition, in this case, the plastic insulation of the handles will not fit.

Of course, it would be better to press not with a point, but with a hexagon using hydraulics, but by the nature of my work I do not work with large sections and do not have hydraulic press tongs. However, point crimping also provides excellent contact.

And put on the handle insulation. If everything is done correctly, there is no need to cut holes in the insulation:

After that, using the GML sleeves, the main connection is made. In order for two veins of 16 squares to fit normally, on one side the sleeve is slightly clamped with pliers.

It is pressurized with the same PK-35. I was even surprised at how easy it is to do this for a cut like this:

After that, the sleeve and wire sections on both sides are insulated with adhesive heat shrinkage. Here's what happened (negative wire). The total length is 2.5 meters (and if you count from the "noses" of the "crocodiles", then even a little more):

The second wire (positive) is made in the same way:

And this is what happened;

The wires for the cigarette lighter turned out to be very heavy, but reliable. Periodic maintenance - only tightening the bolts.

I also decided to make additional protection against overcurrents (in case of an erroneous connection or short circuit) - unlike the Chinese, such a cable will not burn out with a short circuit, but it’s better not to think about what will happen to the battery. For these purposes, Polish fuses with a rating of 500 amperes were purchased, as well as TML tips with a cross section of 35 squares:

Fuses are inserted in the middle of each wire on a bolted connection with an M8 screw and insulated with heat shrink. But until the time was completed, besides, nowhere are there manuals about what the time-current characteristic of these fuses is and what voltage drops across them at the rated current. I decided to wait for now.

How to avoid or minimize the use of wires for lighting?

In order for the car to start in frost in the middle lane, three rules should be observed: have a not very old and charged battery (the higher the battery charge, the better it tolerates frost) with clean terminals and blocks (oxidation leads to a strong voltage drop), into the engine "winter" less viscous oil must be filled, the candles must be "fresh" (if their service life is coming to an end, it is better to replace).To do this, the battery should be recharged from the 230 volt network before winter using a special charger for batteries. The point is that given the realities modern cars and cities, the generator current after deducting the consumption of all consumers (headlights, air conditioner, fan, on-board electronics, etc.) may be insufficient to fully charge the battery during the trip.

Naturally, for residents, for example, of Norilsk, with their frosts, this will not be enough - as far as I know, there, or even in winter, they take the battery into the heat for the night or use a special alarm that starts the engine several times during the night to warm up.

Important! If you make such wires for yourself and use them, remember that when the "acceptor" engine starts, the "donor" motor must be turned off! And, before starting the "acceptor" car, at least 15-20 minutes it follows through the cigarette lighter wires to recharge its battery (the "donor" motor must work at the same time).

Hope the article was interesting.

Sincerely, Alex.

Almost every car enthusiast is faced with a situation when he urgently needs to go, but, alas, the engine will not start. Most often, the problem is obvious: the battery is dead. This is especially true in winter, when the temperature drops below minus 15 degrees. There may be several ways out in this situation, but the most universal is "lighting" from another car. And for this, the motorist needs to have starting wires.

The starting wires are used to supply the starting current to the terminals of the discharged car battery... The power source can be either another car or a charged accumulator battery... Starting wires can be useful not only for you, but also for another car that gets into a difficult situation, so you should always have them with you. At first glance, it may seem that when choosing starting wires there is nothing to study: this is such a trifle! But you need to keep in mind that there are enough low-quality starting wires on the market, which can, at best, burn out, or even ruin your battery. Therefore, it is still worthwhile to figure out by what parameters to choose the starting wires.

What is the difference between starting wires

Length

When choosing the length of the starting wires, it is necessary to keep in mind a number of features. On the one hand, it must be taken into account that the shorter the length of the wires, the lower their resistance. In this case, when the wire is lengthened, voltage losses increase. On the other hand, in urban conditions, in a situation where the car is parked in a tight parking lot, and the donor car can only drive up from the trunk side, the length of wires is at least 4 or 5 meters (depending on the length of the car).On sale, starting wires with a length of 2 to 5 meters are most often found. Residents of megalopolises should purchase wires 4-5 meters long, while everyone else is better off following the rule: the longer the wire, the greater the voltage loss.

Current and voltage

This parameter means the amperage allowed for the wire. The amperage is calculated in amperes and depends on the volume and type of the car's motor. When starting the engine, the starter consumes a very large current, which on some cars can reach up to 800 A, so for a passenger car it is better to count on a starting current of at least 200 A. It is worth focusing on this characteristic of your starter. It's the same with voltage: it all depends on the parameters of your battery, but most often 12V is suitable.Wire thickness

it important parameter, since the larger the cross-sectional area, the greater the current strength the wire will withstand. Unscrupulous manufacturers often increase the thickness of the insulating material to make the wire appear larger. But in reality, the copper core is thin and not of high quality. Therefore, you should pay attention to the soldering at the clamp, where you can see the thickness of the core. Optimum diameter- 9.5 mm. It is also important that the wire is copper."Crocodiles"

The so-called "crocodiles" are clips that stick to the terminals of a car battery. When choosing starter wires, you need to pay attention to two important characteristics.The first is connecting the jump leads and clamps. It must be performed on soldering, since at the junction points due to increased resistance, voltage loss is possible.

Second, the wires must be connected to both halves of the clamp. Also, the crocodiles should be insulated to avoid overheating or sparking. One more point: the larger the contact area of the "crocodile" with the terminal, the better.

Insulation

Poor insulation can start to crumble or crack. This is especially true in cold weather. Insulation must withstand temperatures from -40 to 80 degrees, be flexible, resilient and durable. An important factor is its thickness: too thick insulation will deprive the wire of flexibility, which will increase the space for its storage.

Colour

No, this characteristic is important not only for the visual appeal of the starting wires. The color is needed so as not to confuse the poles: red usually means "plus", and black - "minus".Criterias of choice

There are a huge number of models of starting wires on the market, but not all of them are of high quality. To select the optimal model, you must, first of all, be guided by the characteristics of your starter - this is the only way to understand the required parameters of current and voltage. The next step is to decide on the length. And in the end, you need to check the wire itself so that it is of proper quality: good insulation, a large cross-sectional area of the copper core, the quality of the copper, the size and quality of the "crocodiles".For daily trips to big city

it is worth paying attention to the starting wires 4 - 5 m long and 400 - 700 A.

Residents of small towns and villages it is better to choose among