Often customers of cable-conducting products are faced with the task of determining the cable length wound on the drum, and select the appropriate type of transport for its delivery. We take into account the needs of our customers and offer modern ways to solve problems.

The online service "Calculation of the cable length on the drum" is an interactive calculator, with which you can independently calculate the length of the cable / wires. We guarantee the service will be a useful assistant for your work, thanks to him you will save not only your time, but also funds.

How to determine the length of the cable / wires on the drum without resorting to unwind

- For the work of the calculation, enter the cable brand with a cross section to the corresponding field on the service page (just enter the first characters, the service will offer options automatically).

- Select the cable brand of interest to the cross section. Ready!

For convenience, results on request are formed and presented as a table.

The service information is reference and founded on manufacturers. The minimum calculation error is possible, allowed by the manufacturer.

I want this service to my site

Online service code for your site:

Our online services are constantly improving and updated so that customers receive reliable and relevant information. Information is reference and informational.

Set of plates of sliding, crawls of truck crane Motovilih KS-5579, KS-5579.22

Sliders (slip plates) Designed to complete the arrow of the telescopic truck crane Motovilich KS-5579, KS-5579.22 Production of Plant SDM LLC Perm.

install in the root section of the boom and are used for smooth extension / promotion of arrows. The slider is attached to a metal shoe. The main reason for the failure of the crawl - wear. Manifests itself with uneven, jerks movement of arrows .

Slide slabs (sliders) Arrows telescopic truck crane,allow the proper movement of the adjustable section of the arrow at the base of the metal structures,

this eliminates the friction of the arrows sections by one friend.Installed on the shoes of the arrows section in the front and rear. When wearing requires replacement.

As a rule, the reason for the replacement of the sliders (slabs of the slip) of the car crane equipment is their wear, as a result of which the extension and retracting of the arrows sections occurs unevenly, with jerks.

Slide slabs (sliders) Autocran have high antifriction properties and can be made of bronze or polyamide.

Plates of sliding (crawl) truck crane " Motovilich "KS-5579, KS-5579.22 usually made from polyamide glass-filled"Arkim" 1006-block "TU 219140-001-325315614-02 Since this material is much cheaper bronze.

Crawls of the car cranewhich we offer - gives a significant economic effect in many indicators: the interremary equipment interval increases, the wear of the conjugate parts decreases, the noise is significantly reduced, this material is easier bronze in 7-8 times and well refers to fur processing, in many nodes as a lubricant fits running Water (instead of fuels).

Plates of sliding (slider) telescopic sections reduce friction and the smoothness of the stroke when the arrows is extended and retracting, as well as to eliminate the gaps between sections, the construction is provided. polzunov Between the internal and outer walls of the sections. Fixed sliders are installed in the heads of the first, the second and third sections of the boom, and movable, on the upper backs of the second, third and fourth sections.

When moving, the upper section of the boom rests on the sliding plates installed in the lower front of the base, and behind the sliding plates installed at the top of the upper section of the boom

When assembling the gaps between the sliders and the surface of the sections are adjusted by setting the gaskets, as well as gaskets are set additionally as the sliders (sliding supports) are used during operation.

Set of sliders (slabs of sliding) and boom shoes telescopic truck crane

Motovilich KS-5579

Set of telescopic carcraft guns and shoes

Consists of the following names:

Plates of sliding (sliders) Autocran KS-5579 Production of Plant SDM LLC Perm

|

No. p / p |

Name |

Chop |

|

1 |

|

6 |

|

2 |

Slide support SMZ- 3.400.00.12 |

2 |

|

3 |

Slip support SMZ- 3.400.00.12-01 |

2 |

|

4 |

|

2 |

|

5 |

|

2 |

|

6 |

Slide support SMZ- 3.400.00.21 |

2 |

|

7 |

Slip support for SMZ- 3.400.00.24 |

2 |

|

8 |

Slip support SMZ- 3.430.00.03 |

2 |

|

9 |

|

2 |

Plates of sliding (sliders) Autocran KS-5579.22 Production of Plant SDM LLC Perm

|

No. p / p |

Name |

Chop |

|

1 |

Slip support for SMZ- 3.400.00.10 |

6 |

|

2 |

Slip support SMZ- 5.400.00.10 |

2 |

|

3 |

Slip support SMZ- 3.400.00.18 |

2 |

|

4 |

Slip support SMZ- 5.400.00.08-01 |

1 |

|

5 |

Slip support for SMZ- 5.400.00.08 |

1 |

|

6 |

Support support SMZ- 5.400.00.05-01 |

2 |

|

7 |

Slip support for SMZ- 3.400.00.14 |

2 |

|

8 |

Slip support SMZ- 5.400.00.05 |

2 |

|

9 |

Support support SMZ- 3.430.00.05 |

2 |

|

10. |

Slip support-SMZ-5.400.00.03 |

2 |

Plates of sliding (slider)autocran

Install in the root section of the boom and are used for smooth extension / promotion of arrows. The slider is attached to a metal shoe. The main reason for the failure of the crawl - wear. It is manifested with uneven, jerks movement of arrows.Slip support (sliding plate) is designed for Reducing forces

friction on the arrows of the car cranes . To prevent lateral displacement in the front of the sections, side stops are provided with the possibility of adjusting the gap, side linings are installed in the rear sections. On some models, the cranes provides a mechanism for fixing sections in the extended state.Polyamide - antifriction self-lubricating composite material, mechanical properties Approprifying to metals, but by friction conditions - to polymers, used for the manufacture of parts of friction nodes, rotation, working both with oil lubrication, fresh water, and without lubrication. Products made of polyamide have a smaller weight, excellent antifriction properties, high resistance to shock loads, wear resistance, resistance to corrosion and long term operation.

Among the advantages of using polyamide slabs of sliding (crawls of the truck crane)

· Reducing the noise of work

· Reducing weight (density of material Lamigamid ρ \u003d 1.15 g / cm 3)

· High wear resistance

· High corrosive stability

· Economical operation

· No service required

· High mechanical strength, rigidity, hardness and viscosity

· Good fatigue strength

· High mechanical damping ability

· Good glide properties

· Very high wear resistance

· Good insulating properties

· Good workability

· High resistance to high radiation energy (gamma - and X-rays)

Our enterprise specializes in the development and production of various products from this modern material. Specialists take an active part in the study of operating conditions, in industrial tests of products and help to find the necessary technical solutions to the complete implementation of parts into operation.

Set of sliding plates, crawls of the Motovilki KS-5579 truck crane, KS-5579.22 (slip plates) are designed for configuration of the arrow of the telescopic truck cracker Motovilih KS-5579, KS-5579.22 production of the production of Plant SDM G. Perm.plirt of Slip (Cleans) of the Autocran Motovilich "KS-5579, KS-5579.22 are installed in the root section of the boom and are used for smooth extension / promotion of arrows. The slider is attached to a metal shoe. Major Cause Exit .. / Steel rope, steel rope characteristics

Steel ropes - The main load-consuming element of most of the lifting, transport, road construction, earthmoving machines and mechanisms that are one of the most common types of hardware and are widely used in various industries: coal, mining, oil - gas-producing and processing, transport and agricultural engineering , construction industry, sea, river transport, etc.

In our assortment: steel crane ropes, freight trucks, for tale, lifting for mine installations, for excavators, traction for suspended roads and cable cranes, for silent lifts of blast furnaces, for ship lifting devices, for standing hardware, spiral, spiral, mooring, towing, marine, for tale, cranes and winches, etc.

Cut a steel rope of any length, packing orders with non-standard length.

Steel ropes are a complex and responsible type of wire products. They have a large number of types and structures and differ in form cross section both the rope itself and its elements, as well as on the physico-mechanical characteristics of wires and cores.

The core in the steel rope serves as a support for strands, gives the rope flexibility and holds the lubricant. It can be metallic in the form of a separate strand or an organic single and double extension.

The main requirement when installing the rope is to protect it from spinning. To do this, it is necessary: \u200b\u200bto set a drum with a rope on an unlooking device so that the axis of the drum is in a horizontal position. The consistent end of the rope should go from the bottom or above the drum, which in the process of the rope is needed to be treated. The distance between the drums should be at least 300 diameters of the rope. In the installation process, the rope must undergo the minimum number of beggars, especially alternating.

The surface density of zinc steel ropes.

| Nominal diameter, mm | Superficial zinc density, g / sq.m, no less, for wires | ||

|---|---|---|---|

| FROM | J. | OK. | |

| 0.20 to 0.24. | 15 | 20 | 30 |

| \u003e 0.24 to 0.32 | 20 | 25 | 45 |

| \u003e 0.32 to 0.38 | 20 | 25 | 60 |

| \u003e 0.38 to 0.45 | 30 | 40 | 75 |

| \u003e 0.45 to 0.55 | 35 | 40 | 90 |

| \u003e 0.55 to 0.65 | 40 | 50 | 110 |

| \u003e 0.65 to 0.75 | 40 | 60 | 120 |

| \u003e 0.75 to 0.95 | 50 | 70 | 130 |

| \u003e 0.95 to 1.15 | 60 | 80 | 150 |

| \u003e 1, 15 to 1.40 | 60 | 90 | 165 |

| \u003e 1.40 to 1.80 | 70 | 100 | 180 |

| \u003e 1, 80 to 2.40 | 80 | 110 | 205 |

| \u003e 2.40 to 3.00 | 90 | 125 | 230 |

Unwinding steel ropes from Bay and Lebetok's drums is made so that the ropes have all the time in the stretched state.

Unwind the rope from the drum, dropping the rings to the ground, is not permissible, since with the subsequent stretching on the rope, extinguishes are formed in the form of loops.

Otherwise, the wigs remain and significantly weakened the cable.

Put the Bay to the Earth and unwind the rope exactly, in a straight line, following the pollution of the rope with soil, metal crumb, moisture and other harmful substances (Fig. 1). The bay can be put on the swivel spool and pull the outer end of the rope, rotating the bay.

Never unwind the rope from the stationary bay, as this can lead to the twisting of the rope and the formation of the loops, which will significantly reduce the working capacity of the rope (Fig. 2). Pay attention to the formation of loops.

If it is necessary, the rope wheel on separate segments at a given length should be supplied with a knitted wire on the right and to the left of the scene.

The direction of the deposit (turns) of the wire should be taken opposite to the direction of the rope swing so that when the rope is promoting, the bandage sought to compare.

Conacts and sequence of rope dressing operations, number and dressing width.

| Rope diameter, mm | Number of dressings | Lining length, mm | Dressing distance between dressings, mm | |

| Rope switches with an organic core | Ropes Multiparty one-sided swing without an organic core | |||

| Up to 15 | 2 | 3 | 15 | 25 |

| 15-24 | 3 | 3 | 25 | 50 |

| 25-30 | 3 | 4 | 40 | 50 |

| 31-44 | 3 | 4 | 50 | 50 |

Skip the shaft through the axial hole of the drum and put it on the support that allows you to rotate the drum and inhibit its rotation to avoid the rope running. With a multi-layer Navivka, it is necessary to place the drum on the device, which will ensure the possibility of returning the rope during its rewinding from the transport drum to the drum of the lifting unit. This will help make sure that the lower turns are tightly wound on the drum (Fig. 3).

The angle of deviation should not exceed 1.5 ° in the case of the use of a smooth drum and 2.5 ° when using a drum with a screw cutting, in order to provide a minimal side wear of the rope when friction about the adjacent turn in the case of a smooth drum, and the side surface of the sliced Grooves in the case of using a drum with screw cutting.

Protective rope lubricants.

The choice of the type of cable lubrication and methods for its application during the production process is attached great importance, as the reliability of the rope and the possibility of using it is largely dependent technical resource and.

The lubricant is designed not only to protect the metal from corrosion, but also to ensure the long-term preservation of the organic core in the rope, reduce friction and wear of both internal and external wires during the operation of the rope in blocks.

Packaging of ropes.

The length of the rope is set by the consumer. The permissible deviation in length should be no more for the ropes in length:

- less than 400 m + 5%

- more than 400 m +20 m for every 1000 m or their parts

In the absence of indication of the length of the length, the rope is made by a length of at least 200 m. The ropes of less than 200 m are delivered by consumer coordination. In case the multiple or mounting length is indicated, and the rope is manufactured with a total length, the manufacturer imposes wire mating on the specified lengths.

The ropes are wound on wooden drums according to GOST 11127-78 or metal drums, as well as on return drums using them in the prescribed manner, or in the bay.

- the outer diameter is not more than 1200 mm.

- bay height is not more than 800 mm.

- the internal diameter of the bay must be at least 15 nominal diameters of the rope.

Steel ropes are supplied wrapped on wooden drums, circumferentially are trimmed with wooden planks.

| Rope GOST | Type of rope | The ratio of the diameter of the drum to the diameter of the rope | |

|---|---|---|---|

| Recommended | Minimally admissible | ||

| GOST 2688-80 | LK-R. | 32 | 27 |

| GOST 3077-80 | LK-O. | 36 | 31 |

| GOST 7665-80 | LK-Z. | 41 | 26 |

| GOST 16853-88 | LK-RO | 40 | 23 |

| GOST 7668-80 | LK-RO | 28 | 22 |

| GOST 3079-80 | TLK-O. | 27 | 22 |

| GOST 3069-80 | LK-O. | 70 | 40 |

| GOST 3066-80 | LK-O. | 75 | 44 |

| GOST 14954-80 | LK-R. | 34 | 29 |

| GOST 7667-80 | LK-Z. | 42 | 28 |

| GOST 16853-88 | LK-RO | 41 | 25 |

| GOST 7669-80 | LK-RO | 35 | 23 |

| GOST 3083-80 | LK-O. | 40 | 28 |

| GOST 3081-80 | LK-O. | 42 | 37 |

| GOST 3070-88. | TK | 34 | 29 |

| GOST 3071-88 | TK | 21 | 18 |

| GOST 3067-88 | TK | 40 | 34 |

| GOST 3068-88. | TK | 25 | 21 |

Autocran KS-5579.22 Designed to perform various loading and unloading and construction and installation work on dispersed objects. Loading machines This model is distinguished by their reliability, quality, performance, high high-speed indicators, as well as internship and the possibility of being profitable in almost any weather and climatic conditions. In the construction of autocranne KS-5579.22 There are a number of features that distinguish this machine from other production.

One of distinctive features The KS-5579.22 truck crane is the ability to work in a circular zone of 360 degrees, which allows you to minimize the amount of crane permutation during operation. With such an extensive area of \u200b\u200bthe service area KS-5579.22 It is almost 2000 m2. These properties speak of high tap performance and allow you to most rationally use its capabilities. Another difference is the feature of the construct of outriggers: the reference circuit is located crosswise and equipped with hydraulic drives, which makes it possible to work in cramped conditions. Undoubtedly, all of the above features inclined the choice in favor of buying a KS-5579.22 car crane.

Crane installation KS-5579.22 Mounted on chassis domestic production KAMAZ-53229 brands with wheel formula 6x4. The chassis is equipped with a productive diesel turbo engine KAMAZ-740.31-240, which meets all standards and safety requirements, including the content of substances in EURO-3 exhaust gases. The chassis engine generates operational power in 240 horse power. The chassis allows with efficiency to use the COP-5579.22 auto crane in hard-to-reach due to the state of the access paths. Including when laying gas and oil pipelines, the development of mineral deposits. Meanwhile, this model can work in the urban feature, which contributes to the compactness of the chassis and the crane installation.

The KS-5579.22 truck crane is equipped with a three-seen telescopic hydraulic arrow, which allows it to deliver goods to a height of about 25 meters, with appropriate equipment, this indicator increases to 37 meters. It is possible to equip the KS-5579.22 auto crane with a lattice arrow extension, which is designed to increase the shooting space and the height of the lifting of goods. Gusёk can be attached at an angle of 0 ... 15 ... 30 degrees. Notable is the fact that there is an arrow telescopy with a weight-free weight of up to 6000 kg, which allows the truck crane to perform some special tasks, for example, deliver the goods into a hard-to-reach place or carry it among mounted metal structures. Possessing a load capacity of 32 tons, the maximum cargo moment of the truck crane KS-5579.22 It is 105 TM, which is an excellent result. The arrow in the transport position is placed on the rack, and the hook coil - in the niche for the cabin, this operation is carried out without the help of the solver. All these features leave no doubt to buy a truck crane KS-5579.22.

In our company Sale of autocrants KS-5579.22 carried out by comparative low pricesThe technique is available to most interested citizens. If you decide to buy a KS-5579.22 truck crane, you need to contact us by phone or by email, the numbers and the address of which are in the "Contacts" section.

Mobile cranes

Metallurgical cranes

Tower cranes

1. Transportation and storage of ropes.

1.1. When delivering the rope to the place of storage or hide, the drum should be removed from vehicle With lifting mechanisms in such a way as to avoid damage to the rope and the drum. It is prohibited to drop a drum with a rope from the vehicle or the removal of methods that lead to its damage or disruption of the conservation lubrication layer.

1.2. Related ropes need to be inspected; Called during the transportation and loading and unloading operations of the rope sections with cable lubricant. In this case, the lubricant must be compatible with the type of lubricant applied during the manufacture of ropes. Measure the diameter of the rope.

1.3. With long-term storage, the ropes should be viewed along the outer layer and lubant at least than 6 months.

1.4. The ropes should be stored in ventilated rooms or under a canopy under conditions that exclude atmospheric precipitation, away from vapor and corrosion atmosphere. The axis of the drum should be parallel to the floor on which the drum is installed. You can not put the drums directly to the ground. They must be installed on special flooring, lining-bars or racks.

2. Hit the ropes.

2.1. The mood of the ropes should be made by the team of workers familiarized with the guide instruction, developed and approved in the prescribed manner for this enterprise.

2.2. When carrying out work on the hitch or replacement of the rope, it is necessary to ensure measures to prevent the abrasive and pollutant rope from entering the surface. For this work it is recommended to conduct on a special booth from the boards.

2.3. Selection of the direction of swing when winding on the drum. The rope is wound on the drum along the screw line, and at the same time tests the deformations of bending, contact and twist, which cause a rotation around the axis. It is necessary to select such a direction of swing, in which the rope in the process of winding the rope before laying on the drum was twisted; This will contribute to the preservation of the pig density.

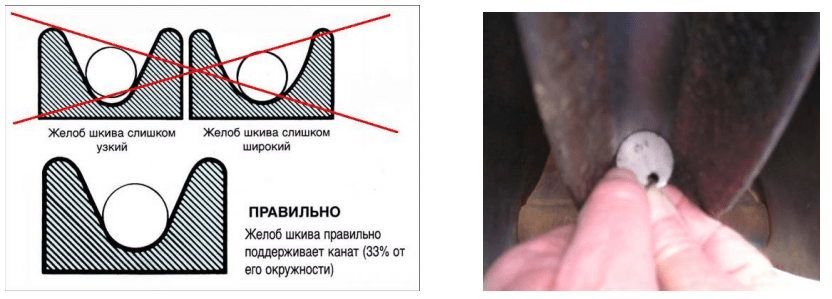

2.4. The new rope must be preceded by a thorough check of the state of streams of blocks of the system and streams of drums of the corresponding winch. The diameter of the stream should be at 5% -7.5%

more nominal rope diameter. Too narrow streams of blocks pinch and deform the rope, disturbing its structural integrity, which can lead to premature rope outlet. Too large streams of blocks create an insufficient support for the rope, which leads to an increase in the contact pressure and premature destruction of the rope wire.

2.5. On the winch with a single-layer full of the drum, a spiral cutting is recommended. With a multilayer pump, a parallel cutting is needed or one of the typical systems (for example, the cutting of the Lebus, etc.). In all cases, the corresponding step of cutting, the gap and the depth of the streams are of the main value to obtain a good rope work.

the auxiliary winches The size of the rope pump bodies must comply with the requirement of GOST3241: the diameter of the cervix must be at least 15 nominal diameters of the rope.

2.7. Before unwinding, the transport drum with a rope must be installed on an unwinding device that provides the horizontal location of the drum axis and equipped with

the brake device for creating the necessary tension of the rope and in order to avoid the formation of the loops and the chances. The slab or the non-uniformity of the winding of the rope leads to excessive wear, crushing and deformation of the rope.

2.8. The drum into the unwinding device should be installed in such a way that the formation of alternate beggars was excluded, for example, for the boar of the winch with the top winding of the rope, it is necessary to unwind the rope from the transport drum from above.

2.9. In case of unwinding the rope from the bay of a pre-sliced \u200b\u200bsliced \u200b\u200bpiece, it must be installed on the rotary dispersion and drag over the outer end of the rope, rotating the bay.

It is forbidden to unwind the rope from the stationary bay, as this can lead to the twisting of the rope and the formation of the loops, which can lead to the formation of structural defects on the rope and a significant reduction in the duration of the rope service.

2.10. The unwinding device must be installed in such a way that the anemium angle is not exceeded 1.5 degrees in the case of the use of a smooth drum and2.5 ° using a drum with a screw cutting, in order to provide a minimal side wear of the rope when friction about the adjacent turn in the case of a smooth drum, And about the side surface of the sliced \u200b\u200bgroove in the case of using a drum with a screw cutting.

At Shkiva

If when you enter the rope in the pulley there is an angle of deviation, then the rope is first in contact with the pulley flange. As it turns through the pulley, the rope is lowered down the pulley until it goes down to the bottom of the gutter. During this process, even under the tension, the rope will rotate and slide. As a result of rotation, the rope twists, i.e. In the rope forms a twist or twist comes out of it, shortening or extending the pitch of the exterior layer of strands. With an increase in the angle of deviation, the volume of twist increases. To reduce this volume to an acceptable level, limit the angle of deviation to 2,5 ° for drums with cutting and 1,5 ° for smooth drums. When using unloading, small ropes and parallel in retinable ropes (i.e., ropes in which

the strands and core are twisted into the rope per surgery) the angle of deviation must be limited to 1.5 °. However, for some cranes and lifting installations, it is not always possible to comply with these general recommendations that affect the service life of the rope.

At Barabana

without returning to the drum.

In this situation, the problem can be reduced by installing the "folder" or increasing the angle of deviation by installing the pulley or the emerging mechanism. If you allow the rope to be pulled, then, ultimately, it will roll from the flange and create a shock load, both in the rope and in the design of the mechanism, which is undesirable and unsafe for operation. Too big corners of deviations will be

return the rope on the drum prematurely, and create gaps between the rope turns near the flanges, as well as to increase the pressure on the rope at the intersection points. Even where there is a spiral cutting, big deviation angles will inevitably lead to localized sections of mechanical damage, since the wire is "cling" for each other. This phenomenon is often called "interference", but its volume can be reduced by the choice of the rope of one-sided swing, if the stock allows. The effect of "interference" can also be reduced using the rope from plastically compressed strands, which has much more smooth surfacethan ropes of ordinary designs. You can also use floating pulleys or specially designed compensating devices to reduce the effects of the angle of deviation.

return the rope on the drum prematurely, and create gaps between the rope turns near the flanges, as well as to increase the pressure on the rope at the intersection points. Even where there is a spiral cutting, big deviation angles will inevitably lead to localized sections of mechanical damage, since the wire is "cling" for each other. This phenomenon is often called "interference", but its volume can be reduced by the choice of the rope of one-sided swing, if the stock allows. The effect of "interference" can also be reduced using the rope from plastically compressed strands, which has much more smooth surfacethan ropes of ordinary designs. You can also use floating pulleys or specially designed compensating devices to reduce the effects of the angle of deviation.

2.10. If you need to cut the rope on it on each side of the section of the section, it is pre-embedded from a soft wire of at least three dressings, a length of two or three diameters of the rope. Cutting the rope to produce electric welding with simultaneous turning of the end.

2.11. For the sample of a new rope with the help of the old, the following types of seedings of the ends and connections are recommended:

seeling on cone

chopping loop

unjugible sealing for standard ropes

sealing for standard and uninusted ropes with swivel for transshipment

for rope with loop

"Chinese stocking"

It is impossible Connect the rope with the right swivel - with a rope with left-handed extension

2.12. Types of seals:

Coupling for pouring steel rope

| Step 1 | Step2. | Step3. |

The method of sealing the steel rope in the coupling for filling with a low-melting alloy or polymer.

Wedge clamp.

Method of sealing steel rope in a wedge coupling

Coupling for crimping steel rope

|

|

| Open | Closed |

Types of steel couplings for crimping steel rope

3. Rope running and tightness

3.1. So as in the initial period of operation, there is a constructive elongation of the rope and the redistribution of voltages in the rope, then after the new rope, it is necessary to run it and crap. The rope rope and tightness should be made, simultaneously starting with a low speed and load, with a further increase in load and speed. This will provide a gradual stabilization of internal stresses in the rope and will allow it to adapt to the working conditions.

1. Rope running and tightness without load:

- ƒС The minimum speed is produced2-3 cycles (the cycle includes a wearing rope to the winch drum and watching the rope during the inverse);

- with a nominal speed of movement, 2-3 cycles are carried out.

2. Rope running and tightness with a load on 1/4

- at the nominal speed of movement produced2-3 cycles.

3. Rope rope and rubbing when loading at 1/2:

- with minimal speed produced2-3 cycles;

- ƒ at a rated speed of movement produced2-3 cycles.

4. Rope rope and rubbing at full load:

- ƒ at minimum speed produced2-3 cycles;

- ƒ Next, work is performed at full load at rated speed.

4. Operation of ropes

4.1. After hiding, running and rubbing ropes, to inspect the ropes, fastening places and in the absence of deviations to carry out their operation as usual.

4.2. The ends of the resulting external wires must be removed from the rope, bending them back and forth the pliers until the wire breaks deep into

the gap between two outer strands.

4.3. . CANATE During operation, it should regularly be lubricated with uniform intervals. The operational lubrication must be compatible with the type of lubricant applied during the manufacturing process, which is specified in the Certificate on the rope.

- Before applying a fresh layer of lubricant to the rope, it is necessary to clean it from extraneous elements, such as dust, sand, pieces of breed, etc.

- The type and method of applying lubrication must ensure a uniform coating of all wire wire with a thin layer.

- It is not allowed to use crude or used in use of lubricant, because They can be contaminated with their wrinkled particles or acids, which may also have a negative effect on the rope

4.4. It is necessary to follow the condition of the streams on the drums and blocks. The operation of the rope under worn streams leads to a decrease in contact area and, as a result, to deformation and

violation of the rope design. In the process of operation of the crane, as well as during its transportation and installation, the cable block systems

can have the following faults, the loss of the rope from the block stream; jammed ropes on blocks; twisting of the cargo rope; ropes; Washes, strands and ropes

generally; Wearing the stream and reducing blocks; breakdown blocks. The loss, the rope from the stream of blocks leads to its overwhelming of it about sharp edges of metal structures, cliff and drop in cargo or arrows. The rope may fall out due to the fact that the enclosing devices bent, the Kosos rope is tensioned with respect to the block or incorrectly stored. In the latter case, the rope, encouraging between the flange and the fence, fits it.

The jams of the ropes on the blocks can occur if the block bearings are jammed or the rope hits behind the block enclosing device. Due to the fact that these faults lead to intensive wear of the stream of blocks and rope, they must be immediately eliminated. If the fence is bent, it should be fixed or dispersed, ensuring the free passage of the rope. Blocks of blocks need to be cleared and fill clean lubricant Or replace new. If lubricants have been hampered, they must be cleared.

Wear a stream and rebound, blocks, as a rule, occurs if the bearings of the block or the osos are tensioned by the rope. When the bearings are poorly lubricated and the rope slides across the block, which under the conditions of the abrasive medium (dust, sand) leads to rapidly generating the stream or reducing block. Especially quickly produced blocks

with a small corner of the coverage of their rope, since the power of the rope pressure is insufficient for rotating the block. In the oblique direction of the rope, one-sided wear of the side surface of the blocks of blocks occurs. To prevent this, you should avoid work that causes oblique tension of the rope, the cargo delay, lifting the hook suspension to the limit.

4.5. The twist of the cargo rope is observed with a large suspension length. This usually occurs due to the fact that the rope is incorrectly unwinded from the bay during its stocks in blocks or with a large rigidity of the rope. Prevent a malfunction can be customized by a rope or applying a device against twisting.

Rope mistakes occurs, as a rule, with their incorrect

stock. In this case, during the work of the crane, the ropes relate to

each other and metal structures. The ropes are overwhelmed also when an attempt is made to raise the goods when the rope is swirling. Since the work of the crane with a flutter rope can lead to a drop in cargo or arrows, it is necessary to prevent this malfunction. To do this, we need to divide the ropes for the distance at which they will not be able to touch for the metal and touch each other.

4.6. Defects of steel ropes formed during operation

|

looping wire |

|

bulletination of the core |

|

local abbreviation diameter |

|

pumping strands |

|

localized wear |

|

inflection education |

|

education in Wave or Corkscrew Defect Channels |

|

basket of deformation |

|

exterior wear |

|

surface corrosion |

|

gust wires |

|

bullething core rope |

|

local increase in rope diameter |

|

the loop |

|

significant Wire Wire Rope |

|

strong internal corrosion. |

ATTACHMENT 1

Minimum coefficients for selecting the diameters of the drum (H1), block (H2) and the equalization unit (H3).

|

Group of classification |

Selection coefficients diameters | ||

| H1. | H2. | H3. | |

| M1. | 11,2 | 12,5 | 11,2 |

| M2. | 12,5 | 14,0 | 12,5 |

| M3. | 14,0 | 16,0 | 12,5 |

| M4. | 16,0 | 18,0 | 14,0 |

| M5 | 18,0 | 20,0 | 14,0 |

| M6 | 20,0 | 22,4 | 16,0 |

| M7. | 22,4 | 25,0 | 16,0 |

| M8. | 25,0 | 28,0 | 18,0 |

The minimum diameters of the drums, blocks and equalized blocks enveloped by steel ropes are determined by formulas:

D1 \u003d h1 * d; D2 \u003d h2 * d; D3 \u003d h3 * d. where D is the diameter of the rope, mm d1, d2, d3 diameters, respectively, the drum, block and the equalization unit along the midline of the pound rope, mm H1, H2, H3 - the selection coefficients of the diameters, respectively, the drum, block and the equalization unit (according to Table 1) .

Single Nnah

* D - Drum diameter, mm;

d - rope diameter, mm.