Wind is free energy! So let's use it for personal purposes. If the creation of a wind farm on an industrial scale is very expensive, because in addition to the generator, a number of studies and calculations need to be carried out, the state does not undertake such costs, and for some reason investors in the countries of the former USSR are not interested in this. Then, privately, you can make a mini-windmill for your own needs. It should be understood that the project of transferring your home to alternative energy is very expensive.

As already mentioned: you need to make long-term observations and calculations in order to find the optimal ratio of the size of the wind wheel and generator, suitable for your climate, wind rose and average annual wind speed.

The efficiency of a wind power plant within one region can differ several times, this is due to the fact that the movement of the wind depends not only on the climatic zone, but also on the terrain.

However, you can find out what wind power is with minimal costs by assembling a budget installation to power a low-power load, such as a smartphone, light bulbs or a radio. With the right approach, you can provide electricity to a small house or summer cottage.

Let's look at how you can make the simplest wind power plant with your own hands.

Low-power windmills from improvised means

The computer cooler is a brushless motor, which in its original form is of no practical value.

It needs to be rewound, as in the original the windings are connected in an inappropriate way. Wind the coils alternately:

Clockwise;

Counterclock-wise;

Clockwise;

Counterclock-wise.

It is necessary to connect adjacent coils in series, or even better, wind one piece of wire moving from one groove to another. In this case, the thickness of the wire can be selected arbitrarily, it will be better if you wind as many turns as possible, and this is possible when using the least thin wire.

The output voltage from such a generator will be variable, and its value will depend on the speed (wind speed), install a diode bridge made of Schottky diodes to rectify it to a constant one, ordinary diodes will do, but it will be worse, because voltage will drop on them from 1 to 2 volts.

Lyrical digression, some theory

Remember the EMF value is:

where L is the length of the conductor placed in a magnetic field; V is the rotation speed of the magnetic field;

When upgrading the generator, you can only influence the length of the conductor, that is, the number of turns of each of the coils. The number of turns determines the output voltage, and the thickness of the wire determines the maximum current load.

In practice, the wind speed cannot be influenced. However, there is also a way out of this situation, you can, having learned the typical wind speed for your area, design a propeller suitable in terms of speed for a wind power plant, as well as a gearbox or belt drive, to ensure sufficient speed to generate the required voltage.

IMPORTANT: Faster does not mean better !!! If the speed of rotation of the wind generator is too high, its resource will be reduced, the lubricating properties of the bushings or rotor bearings will deteriorate, and it will jam, and the fastest will be a breakdown of the insulation of the windings in the generator

The generator consists of:

We increase the power of the generator from the computer cooler

Firstly, the more blades and the diameter of the wheel, the better, so take a closer look at 120mm coolers.

Secondly, we have already said that the voltage also depends on the magnetic field, the fact is that industrial generators high power have field windings, and low power - strong magnets. The magnets in the cooler are extremely weak and do not allow achieving good results from the generator, and the gap between the rotor and stator is very large - about 1 mm, and this is with the already weak magnets.

The solution to this problem is to radically change the design of the generator. Rather, only an impeller is required from the cooler; a motor from a printer or any other household appliances is used as the generator itself. The most common brush motors are permanent magnet excitation.

As a result, it will look like this.

The power of such a generator is enough to power the LEDs, a radio receiver. It will not be enough to charge the phone, the phone will display the charging process, but the current will be extremely small, up to 100 Amperes, with a wind of 5-10 meters per second.

Stepper motor as a wind generator

A stepper motor is very often found in computer and household appliances, in various players, floppy drives (old 5.25 ”models are interesting), printers (especially matrix ones), scanners, etc.

These motors can work as a generator without alterations, they are a rotor with permanent magnets, and a stator with windings, a typical connection diagram of a stepper motor in generator mode is shown in the figure.

The circuit has a 5 Volt linear stabilizer, type L7805, which will allow you to safely connect mobile phones to such a wind turbine to charge them.

In the photo, a generator from a stepper motor with installed blades.

The engine, in a specific case, with 4 output wires, the circuit, respectively, for it. An engine with such dimensions in generator mode produces about 2 W in light winds (wind speed of about 3 m / s) and 5 m / s in strong winds (up to 10 m / s).

By the way, here is a similar circuit with a zener diode, instead of the L7805. Allows you to charge Li-ion batteries.

Refinement of a homemade windmill

To make the generator work more efficiently, you need to make it a guide shank and fix it on the mast movably. Then, when the direction of the wind changes, the direction of the wind generator will change. Then the following problem arises - the cable going from the generator to the consumer will twist around the mast. To solve this, you need to provide a movable contact. A turnkey solution is being sold on Ebay and Aliexpress.

The lower three wires are stationary going down, and the upper bundle of wires is movable, a sliding contact or brush mechanism is installed inside. If you do not have the opportunity to buy, be smart, and, inspired by the decision of the designers of the Zhiguli car, namely the implementation of the movable contact of the signal button on the steering wheel, and do something similar. Or use the contact pad from the electric kettle.

By connecting the connectors, you get a moving contact.

Powerful wind generator from available tools.

For more power, you can use two options:

1. Generator from a screwdriver (10-50 W);

Only a motor is needed from a screwdriver, the option is similar to the previous one, as a screw you can use the blades from the fan, this will increase the final power of your installation.

Here is an example of such a project:

Pay attention to how the gear overdrive is implemented here - the shaft of the wind generator is located in the pipe, at its end there is a gear that transfers the rotation of a smaller gear fixed to the motor shaft. An increase in engine speed also occurs in industrial wind power plants. Gearboxes are used everywhere.

However, in a home-made environment, making a gearbox becomes a big problem. You can remove the gearbox from the power tool, it is needed there to lower the high revolutions on the shaft of the collector motor to the normal revolutions of the chuck on the drill, or the grinder's disc:

The drill has a planetary gearbox;

An angular gearbox is installed in the grinder (it will be useful for the installation of some installations and will reduce the load from the tail of the wind turbine);

Gearbox from a hand drill.

This version of a homemade wind generator can already charge 12 V batteries, but a converter is needed to generate the charging current and voltage. This task can be simplified by using a car generator.

The advantage of such a generator is the ability to use it for charging. car batteries, in principle, it is intended for this. Autogenerators have a built-in voltage regulator relay, which eliminates the need to buy additional stabilizers or converters.

However, car enthusiasts know that at low idle, approximately 500-1000 rpm, the power of such a generator is small, and it does not provide the proper current to charge the battery. This leads to the need to connect to the wind wheel through a gearbox or belt drive.

You can adjust the number of revolutions at normal wind speed for your latitudes using the selection gear ratio or with a properly designed propeller.

Useful Tips

Perhaps the most repeatable design of a windmill mast is shown in the picture. This mast is stretched by cables attached to holders in the ground to provide stability.

Important: The height of the mast should be as large as possible, approximately 10 meters. At higher altitudes, the wind is stronger because there are no obstacles for it in the form of terrestrial structures, hills and trees. Never install the wind turbine on the roof of your house. Resonant vibrations of fastening structures can cause destruction of its walls.

Take care of the reliability of the bearing mast, because the design of a wind turbine based on such a generator becomes much heavier and is already a rather serious solution that can provide an autonomous power supply to a summer cottage with a minimum set of electrical appliances. Devices that operate on 220 Volts can be powered from a 12-220 V inverter. The most common version of such an inverter is.

It is better to use diesel generators, incl. trucks because they are designed to operate at low rpm. Average diesel engine a large truck runs in the rpm range of 300 to 3500 rpm.

Modern generators produce 12 or 24 volts, and a current of 100 amperes has long been normal. Having carried out simple calculations, you can determine that such a generator will give you up to 1 kW of power as much as possible, and a generator from Zhiguli (12V 40-60 A) 350-500 W, which is already a pretty decent figure.

What should be a wind wheel for a home-made wind turbine?

I mentioned in the text that the wind wheel should be large and with a lot of blades, in fact it is not. This statement was true for those micro-generators that do not claim to be serious electrical machines, but rather copies for information and leisure.

In fact, designing, calculating and building a wind turbine is a very difficult task. Wind energy will be used more rationally if it is made very accurately and the "aviation" profile is ideally drawn, while it should be installed with a minimum angle to the plane of rotation of the wheel.

The real power of wind turbines with the same diameter and different number of blades is the same, the only difference is in the speed of their rotation. The fewer the wings, the more rpm, with the same wind and diameter. If you are going to achieve maximum rpm, you must mount the wings as accurately as possible with a minimum angle to the plane of their rotation.

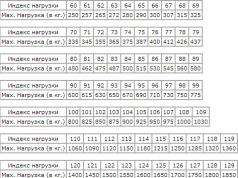

Check out the table from the 1956 book Homemade Wind Farm, ed. DOSAAF Moscow. It shows the relationship between wheel diameter, power and rpm.

At home, these theoretical calculations are of little use, amateurs make wind wheels from improvised means, they use:

Metal sheets;

Plastic sewer pipes.

You can assemble a high-speed 2-4 bladed wind wheel with your own hands from sewer pipes, except for them you need a hacksaw or any other cutting tool. The use of these pipes is due to their shape, after cutting they have a concave shape, which ensures high responsiveness to air currents.

After cutting, they are fixed with BOLTS on a metal, textolite or plywood blank. If you are going to make it out of plywood, it is better to re-glue and twist several layers of plywood on both sides with self-tapping screws, then you will be able to achieve rigidity.

Here is an idea for a two-blade one-piece impeller for a stepper motor generator.

conclusions

You can make a wind power plant starting from low power - units of Watt, for powering individual LED lamps, beacons and small equipment, up to good power values in units of kilowatts, accumulate energy in a battery, use it in its original form or convert it to 220 Volts. The cost of such a project will depend on your needs, perhaps the most expensive element is a mast and batteries, which can be in the range of 300-500 dollars.

While riding a bicycle past the summer cottages, I saw a working wind generator. Large blades slowly but surely rotated, the weather vane oriented the device in the direction of the wind.

I wanted to implement a similar design, albeit not capable of generating enough power to supply "serious" consumers, but still working and, for example, charging batteries or supplying LEDs.

One of the most effective options for a small homemade wind turbine is to use stepper motor(ШД) (eng. stepping (stepper, step) motor) - in such a motor, the rotation of the shaft consists of small steps. The stepper motor windings are in phase. When current is applied to one of the phases, the shaft moves one step.

These engines are low-speed and a generator with such an engine may be gearedlessly connected to a wind turbine, Stirling engine, or other low-speed power source. When used as a generator of a conventional (collector) engine direct current to achieve the same results, a 10-15 times higher speed would be required.

A feature of the shagik is a fairly high starting torque (even without an electrical load connected to the generator), reaching 40 grams of force per centimeter.

The efficiency of the generator with stepper motor reaches 40%.

To check the functionality of the stepper motor, for example, a red LED can be connected. By rotating the motor shaft, you can observe the glow of the LED. The polarity of the LED connection does not matter, as the motor generates alternating current.

We have enough of them powerful engines are five-inch floppy drives, as well as older printers and scanners.

For example, I have a stepper motor from an old 5.25 ″ drive, which was still in operation ZX Spectrum- compatible computer “Byte”.

Such a drive contains two windings, from the ends and the middle of which conclusions are drawn - total is removed from the engine six wires:

first winding (eng. coil 1) - blue (eng. blue) and yellow (eng. yellow);

second winding (eng. coil 2) - red (eng. red) and white (eng. white);

brown (rus. brown) wires - leads from the midpoints of each winding (eng. center taps).

disassembled stepper motor

On the left you can see the rotor of the motor, on which you can see the "striped" magnetic poles - north and south. To the right is the stator winding, which consists of eight coils.

Half winding resistance is

I used this engine in the original design of my wind turbine.

Less powerful stepper motor in my possession T1319635 firms Epoch Electronics Corp. from scanner HP Scanjet 2400 It has five conclusions (unipolar motor):

first winding (eng. coil 1) - orange (eng. orange) and black (eng. black);

second winding (eng. coil 2) - brown (eng. brown) and yellow (eng. yellow);

red (eng. red) wire - pins connected together from the midpoint of each winding (eng. center taps).

The resistance of the half winding is 58 ohms, which is indicated on the motor housing.

In the improved version of the wind turbine, I used a stepper motor Robotron SPA 42 / 100-558 produced in the German Democratic Republic and designed for a voltage of 12 V:

There are two options for the location of the impeller (turbine) axis of the wind generator - horizontal and vertical.

The advantage horizontal(most popular) location the axis, located in the direction of the wind, is a more efficient use of wind energy, the disadvantage is the complexity of the design.

I chose vertical arrangement axes - VAWT (vertical axis wind turbine), which greatly simplifies the design and does not require wind orientation ... This option is more suitable for roof mounting, it is much more effective in conditions of rapid and frequent changes in wind direction.

I used a type of wind turbine called the Savonius wind turbine. Savonius wind turbine). It was invented in 1922 Sigurd Johannes Savonius) from Finland.

Sigurd Johannes Savonius

The operation of the Savonius wind turbine is based on the fact that the resistance (eng. drag) to the incident air flow - the wind of the concave surface of the cylinder (blade) is larger than the convex one.

Aerodynamic drag coefficients ( English drag coefficients) $ C_D $

concave half of the cylinder (1) - 2.30

convex half of the cylinder (2) - 1.20

flat square plate - 1.17

concave hollow hemisphere (3) - 1.42

convex hollow hemisphere (4) - 0.38

These values are given for Reynolds numbers (eng. Reynolds numbers) in the range $ 10 ^ 4 - 10 ^ 6 $. The Reynolds number characterizes the behavior of a body in a medium.

Resistance force of the body to the air flow $ =<<1 \over 2>S \ rho

Such a wind turbine rotates in the same direction, regardless of the direction of the wind:

A similar operating principle is used in the cup anemometer (eng. cup anemometer)- a device for measuring wind speed:

Such an anemometer was invented in 1846 by the Irish astronomer John Thomas Romney Robinson ( John Thomas Romney Robinson):

Robinson believed that the cups in his four-cup anemometer moved at a speed equal to one third of the wind speed. In reality, this value ranges from two to a little more than three.

Currently, three-cup anemometers are used to measure wind speed, developed by Canadian meteorologist John Patterson ( John Patterson) in 1926:

Generators on DC brushed motors with vertical microturbine are sold at eBay for about $ 5:

Such a turbine contains four blades located along two perpendicular axes, with an impeller diameter of 100 mm, a blade height of 60 mm, a chord length of 30 mm and a segment height of 11 mm. The impeller is mounted on the shaft of a DC micromotor with the marking JQ24-125p70. Rated voltage power supply of such a motor is 3. 12 B.

The energy generated by such a generator is enough for the glow of the "white" LED.

Rotational speed of the Savonius wind turbine cannot exceed wind speed , but at the same time such a construction is characterized by high torque (eng. torque).

The efficiency of a wind turbine can be estimated by comparing the power generated by the wind turbine with the power contained in the wind blowing through the turbine:

$ P =<1\over 2>\ rho S

Initially, the impeller of my generator used four blades in the form of segments (halves) of cylinders cut from plastic pipes:

segment length - 14 cm;

segment height - 2 cm;

the length of the chord of the segment is 4 cm;

I installed the assembled structure on a fairly high (6 m 70 cm) wooden mast from a bar, attached with self-tapping screws to a metal frame:

The disadvantage of the generator was the rather high wind speed required to spin the blades. To increase the surface area, I used blades cut from plastic bottles:

segment length - 18 cm;

segment height - 5 cm;

segment chord length - 7 cm;

the distance from the beginning of the segment to the center of the axis of rotation is 3 cm.

The strength of the blade holders proved to be an issue. At first I used perforated aluminum strips from the Soviet children's designer 1 mm thick. After several days of operation, strong gusts of wind led to the break of the planks (1). After this failure, I decided to cut out the blade holders from foil-coated PCB (2) 1.8 mm thick:

The flexural strength of the PCB perpendicular to the plate is 204 MPa and is comparable to the flexural strength of aluminum - 275 MPa. But the modulus of elasticity of aluminum $ E $ (70,000 MPa) is much higher than that of textolite (10,000 MPa), i.e. texolite is much more elastic than aluminum. This, in my opinion, taking into account the greater thickness of the textolite holders, will provide a much greater reliability of fastening the blades of the wind generator.

The wind generator is mounted on a mast:

The trial operation of the new version of the wind turbine has shown its reliability even under strong gusts of wind.

The disadvantage of the Savonius turbine is low efficiency - only about 15% of wind energy is converted into shaft rotation energy (this is much less than can be achieved with wind turbine Daria(eng. Darrieus wind turbine)), using lift (eng. lift). This type of wind turbine was invented by the French aircraft designer Georges Darier. (Georges Jean Marie Darrieus) - US patent of 1931 No. 1,835,018 .

The disadvantage of the Darrieus turbine is that it has a very poor self-start (to generate torque from the wind, the turbine must already be spun).

Conversion of electricity generated by a stepper motor

The stepper motor leads can be connected to two bridge rectifiers, assembled from Schottky diodes to reduce the voltage drop across the diodes.

Popular Schottky diodes can be used 1N5817 with a maximum reverse voltage of 20 V, 1N5819- 40 V and a maximum forward average rectified current of 1 A. I connected the outputs of the rectifiers in series in order to increase the output voltage.

It is also possible to use two midpoint rectifiers. Such a rectifier requires half as many diodes, but at the same time the output voltage is reduced by half.

Then the ripple voltage is smoothed using a capacitive filter - a 1000 μF capacitor at 25 V. To protect against an increased generated voltage, a 25 V zener diode is connected in parallel to the capacitor.

diagram of my wind turbine

electronic unit of my wind generator

In windy conditions, the open circuit voltage at the output electronic unit the wind generator reaches 10 V, and the short circuit current is 10 mA.

CONNECTING TO JOULE THIEF

Then the smoothed voltage from the capacitor can be applied to Joule thief- low voltage DC-DC converter. I assembled such a converter based on germanium pnp-transistor GT308V ( VT) and a pulse transformer MIT-4V (coil L1- conclusions 2-3, L2- conclusions 5-6):

Resistor value R is selected experimentally (depending on the type of transistor) - it is advisable to use a variable resistor of 4.7 kOhm and gradually reduce its resistance, achieving stable work converter.

my converter Joule thief

CHARGE OF IONISTORS (SUPERCONDENSERS)

Supercapacitor (supercapacitor) supercapacitor) is a hybrid of a capacitor and chemical source current.

Supercapacitor - non-polar cell, but one of the terminals may be marked with an “arrow” to indicate the polarity of the residual voltage after it has been charged at the factory.

For the initial research, I used a supercapacitor 5R5D11F22H with a capacity of 0.22 F for a voltage of 5.5 V (diameter 11.5 mm, height 3.5 mm):

I connected it through a diode to the output Joule thief through the germanium diode D310.

To limit the maximum charging voltage of the supercapacitor, you can use a zener diode or a chain of LEDs - I use a chain of two red LEDs:

To prevent the discharge of an already charged supercapacitor through the limiting LEDs HL1 and HL2 I added another diode - VD2.

My homemade wind turbine on a stepper motor, My Fascinating and Dangerous Experiments

My self-made wind turbine with a stepper motor While cycling past summer cottages, I saw a working wind generator. The big blades were spinning slowly but surely, the weather vane

A stepper motor as a generator?

I had a stepper motor lying around and I decided to try to use it as a generator. The motor was removed from an old dot matrix printer, the inscriptions on it are as follows: EPM-142 EPM-4260 7410. The motor is unipolar, which means that this motor has 2 windings with a tap from the middle, the resistance of the windings was 2x6 ohms.

The test requires another motor to spin the stepper. The construction and mounting of the motors are shown in the figures below:

We smoothly start the engine so that the rubber band does not fly off. I must say that at high speeds it still flies, so it did not raise the voltage above 6 volts.

We smoothly start the engine so that the rubber band does not fly off. I must say that at high speeds it still flies, so it did not raise the voltage above 6 volts.

We connect a voltmeter and start testing, first we measure the voltage.

We connect a voltmeter and start testing, first we measure the voltage.

I think there is no need to explain anything and everything is clear from the photo below. The voltage was 16 volts, the speed of the spinning engine is not large, I think if you spin it harder, you can squeeze out all 20 volts.

I think there is no need to explain anything and everything is clear from the photo below. The voltage was 16 volts, the speed of the spinning engine is not large, I think if you spin it harder, you can squeeze out all 20 volts.

We set the voltage to a little less than 5 volts, so that the stepper motor after the bridge gives out about 12 volts.

Shines! At the same time, the voltage dropped from 12 volts to 8 and the engine began to spin a little more slowly. Short-circuit current without led strip was 0.08A - let me remind you that the unwinding motor did NOT work on full power, and do not forget about the second winding of the stepper motor, it is just impossible to parallel them, and I did not want to assemble the circuit.

Shines! At the same time, the voltage dropped from 12 volts to 8 and the engine began to spin a little more slowly. Short-circuit current without led strip was 0.08A - let me remind you that the unwinding motor did NOT work on full power, and do not forget about the second winding of the stepper motor, it is just impossible to parallel them, and I did not want to assemble the circuit.

I think you can make a good generator from a stepper motor, attach it to a bicycle, or make a wind generator based on it.

I think you can make a good generator from a stepper motor, attach it to a bicycle, or make a wind generator based on it.

A stepper motor as a generator? Meander - entertaining electronics

A stepper motor as a generator? I had a stepper motor lying around and I decided to try to use it as a generator. The engine was removed from an old dot matrix printer, lettering

Creation of a wind generator does not necessarily mean the manufacture of a large and powerful complex capable of providing electricity to an entire house or a group of consumers. Can be made, which is, in fact, a working model of a serious installation. The purpose of such an event may be:

- Familiarization with the basics of wind energy.

- Joint learning activities with children.

- An experimental prototype prior to the construction of a large facility.

The creation of such a wind turbine does not require the use of a large number of materials or tools; you can do with the means at hand. It is not necessary to count on the generation of serious amounts of energy, but it may be enough to power a small LED lamp. The main problem with creation is the generator. It is difficult to create it yourself, since the size of the device is small. Easiest to use, allowing you to use it in generator mode.

Homemade windmill based on a stepper motor

Most often, with making low-power wind turbines use stepper motors. The peculiarity of their design consists in the presence of several windings. Usually, depending on the size and purpose, motors are made with 2, 4 or 8 windings (phases). When voltage is applied to them, in turn, the shaft rotates accordingly by a certain angle (step).

The advantage of stepper motors is the ability to produce a fairly high current at low speeds. An impeller can be installed on a generator from a stepper motor without any intermediate devices - gears, gearboxes, etc. Electricity generation will be carried out with the same efficiency as with devices of other design using overdrive gears.

The difference in speed is quite significant - to obtain the same result, for example, on a brushed motor, a rotation speed of 10 or 15 times is required.

It is believed that a stepper motor generator can be used to charge rechargeable batteries or batteries mobile phones, but in practice, positive results are extremely rare. Basically, power supplies for small luminaires are obtained.

The disadvantages of stepper motors include the significant effort required to start rotating. This circumstance reduces the sensitivity of the whole, which can be somewhat corrected by increasing the area and span of the blades.

You can find these motors in old floppy drives, scanners, or printers. Alternatively, you can purchase new engine if the required device is not in stock. For greater effect, larger motors should be chosen, they are capable of delivering a high enough voltage so that it can be used somehow.

Wind generator from parts from the printer

One of suitable options- using a stepper motor from a printer. It can be removed from a broken old device; there are at least two such motors in each printer. Alternatively, you can purchase a new, not used one. It is capable of generating a power of about 3 watts even in weak winds, which are typical for most regions of Russia. The voltage that can be reached is 12 V or more, which makes it possible to consider the device as a possibility of charging batteries.

Stepper motor gives out alternating voltage. For the user, first of all, it is necessary to straighten it. You will need to create a diode rectifier, which will require 2 diodes per coil. You can also directly connect the LED to the terminals of the coil, if the rotation speed is sufficient, this will be enough.

The rotor impeller is easiest to install directly onto the motor shaft. To do this, it is necessary to make a central part that can fit tightly on the shaft. To strengthen the fixation of the impeller, it is necessary to drill a hole and cut a thread in it. Subsequently, a locking screw will be screwed into it.

For the manufacture of blades, polypropylene sewer pipes or other suitable materials are usually used. The main condition is low weight and sufficient strength, since the blades sometimes pick up quite a decent speed. The use of unreliable materials can create the undesirable situation of the impeller falling apart on the fly.

Blades

Usually 2 blades are made, but more can be made. It must be remembered that large area of the blades increases the KIEV of the wind turbine, but in parallel with this, the frontal load on the impeller, which is transmitted to the motor shaft, increases. Making small blades is also not recommended, as they will not be able to overcome the sticking of the shaft when starting rotation.

To be able to rotate the windmill around the vertical axis, you need to make a special knot. The difficulty in this lies in the need to ensure the immobility of the cable coming from the generator. Since the device has, rather, a decorative purpose, they usually approach the issue more simply - they install the consumer directly on the generator case, excluding the presence of a long cable. Otherwise, you will have to mount the system like a brush collector, which is irrational and time-consuming.

Mast

The assembled wind turbine must be installed at a height of at least 3 meters. Wind currents near the earth's surface are unstable due to turbulence. Climbing to a certain height will help to get more uniform flows. For self-installation to the wind, a tail stabilizer is installed along the axis of rotation, which plays the role of a weather vane. It is made from any piece of plastic, aluminum plate or other available material.

Tigrezno

Below is an instruction with which you can "recycle" old scanner into an impressive electricity generator.

We will need:

- Old scanner;

- Rectifying diodes (8 1N4007 diodes were used in the project);

- Capacitor 1000 uF;

- PVC pipe;

- Plastic parts(see below);

- Aluminum plates (any others can be used).

In addition to the fluorescent tube and electronic components, the scanner has a stepper motor, which is what we need. The photo shows a four-phase stepper motor.

Note 3. Free software was used to develop the schema http://qucs.sourceforge.net/.

We collect the blades. In details .

Unfortunately, there is no diagram of the device, but it is not so difficult to assemble something similar from a photograph.

End! Now it remains to wait for the windy day and try the device, as you can see in the photo - the device generates a stable voltage of 4.95 V. Now you can charge your MP3 player or phone for free!

- Here. Excellent man said. The question is not about the "fabulous efficiency": the energy is still free. The planet will not become poorer from such Kulibins. The question is in labor costs and the cost of everything used. The question is very controversial: a vertical line of creepy dimensions, or a horizontal line, but rotatable. This is a topic for controversy (or better, if someone extinguishes them with practical experience and shares).

- Hello everybody. I have a little more complicated. courtyard lighting with LED flashlights (5 pcs. 7 LEDs). the battery costs 7.2 volts 700 ma. collected according to the voltage doubling scheme. :).

- the wind is average, I don’t know how to measure it ... it stopped a little, and it’s worth it.

- and here is the "head". (removed the multiplier, sticking is much more greasy with it and the difference is minimal, and it does not make noise). The vertical one doesn’t make any noise for me at all and has been shining for 1.5 years without a battery (also SD).

- mba1 is right, and over 200 rpm is in doubt.

- It seems to me that your blades are large for such an engine. Adjust the size to the power, you see, there will be a completely correct windmill. Didn't you measure the parameters?

- Made the blades narrower and shortened, the diameter is about 1.1m, the speed increased, and it spins when the wind is not felt. fanars already 6 :). here is the video - http://depositfiles.com/files/18bs0ha7b

- I don’t remember the parameters, with an average wind of about 8 volts, ma -hz, now I don’t really want to climb there, and the head is full of others, I’m waiting for neodymium magnets (24pcs), they will come one of these days :), I’ll make a generator :).

- If you need a stepper motor, then not from the scanner, but from the printer, there are two of them in the matrix, even during maintenance with a quick movement of the head, the LEDs began to light up. I think to start not with a serious craft, but to start with engines from a Zhiguli stove, or a motor from a glass cleaner in the garage is lying around.

- There are collector motors (for example, DP ..., DPM ...) with a centrifugal speed limiter. Maybe you have any ideas how to adapt this for the inverse problem in the generator? I don't think so right off the bat ...

- And from ШД3-ШД5 someone can stir up?

- Or with motors from aircraft models, small sizes, big power?

- http://vkontakte.ru/club11998700 - THERE IS A PHOTO AND VIDEO shd, neodymium, links ....

- And what are the parameters of the engines? volts per coil? amperage? how many coils (leads?) and what degree of rotation?

- It is advisable to select shd - less winding resistance, higher operating voltage, then a decent impulse will give a step :)

- If there is less resistance at a higher voltage, then the power is more. So you can select by SIZE :)

- http://www.youtube.com/watch?v=7WgS4kxobI0&feature=channel_video_title

- This is my video.

- Who knows, any stepper motor can be used as a generator, if you buy something more powerful than a printer.

- It is difficult to use a powerful stepper motor as a generator. The reason is the big start-off moment.

I had a stepper motor lying around and I decided to try to use it as a generator. The motor was removed from an old dot matrix printer, the inscriptions on it are as follows: EPM-142 EPM-4260 7410. The motor is unipolar, which means that this motor has 2 windings with a tap from the middle, the resistance of the windings was 2x6 ohms.

The test requires another motor to spin the stepper. The construction and mounting of the motors are shown in the figures below:

I lost the roller from the engine, so I put on the paste ...

We smoothly start the engine so that the rubber band does not fly off. I must say that at high speeds it still flies, so it did not raise the voltage above 6 volts.

We connect a voltmeter and start testing, first we measure the voltage.

We set the voltage on the PSU to about 6 volts, while the engine consumes 0.2 Amperes, for comparison, Idling the engine ate 0.09A

I think there is no need to explain anything and everything is clear from the photo below. The voltage was 16 volts, the speed of the spinning engine is not large, I think if you spin it harder, you can squeeze out all 20 volts ...

We connect through a diode bridge (and do not forget the capacitor, otherwise you can burn the LEDs) a tape with super-bright LEDs, the power of which is 0.5 watts.

We set the voltage to a little less than 5 volts, so that the stepper motor after the bridge gives out about 12 volts.

Shines! At the same time, the voltage dropped from 12 volts to 8 and the engine began to spin a little more slowly. The short-circuit current without the LED strip was 0.08A - let me remind you that the unwinding motor did NOT work at full power, and do not forget about the second winding of the stepper motor, you just cannot parallel them, and I did not want to assemble the circuit.

I think you can make a good generator from a stepper motor, attach it to a bicycle, or make a wind generator based on it.