Obviously, the oil pump (MN) in the system of car VAZ 2110 serves to run a lubricant.

It is not rare, sitting behind the wheel and running engine, on the dashboard lights the test lamp with an image of the oilbox that does not go out. In this case, the probable cause of the signal can be the resulting pump.

troubleshooting

Do not hurry with conclusions and immediately blame the pump. It is necessary to organize a full check to make sure that the signal appears on the dashboard.

|

Check area |

Your actions |

|

Check electriable |

You need to check the efficiency of the electrical circuit, which comes from the sensor to the instrument panel. The wire that comes from the regulator to the engine must be transferred to the ground. If the chain is good, the lamp will go out |

|

Check oil filter |

Just unscrew the oil pressure sensor. If it is moistened in a lubricant substance, everything is fine. If he is dry, then the filter has been hammered or filter valve stalled |

|

Checking internal elements |

You will need to replace the filter if there are problems with it. Next, the pallet opens, inspected the state of the oil worker and rubber seals |

If the events did not give a result, the lamp still does not go out, which means the culprit of the current situation is the pump.

Useful information

Let's tell a little about the principles of the device and the operation of the oil pump. It can help you in the process of repair.

- On domestic "dozens" uses a combined lubricant system.

- The design of the car provides for the presence of a gear oil pump. It is installed on the front end side of the cylinder block.

- Special gears with trocoidal internal engagement help reduce mechanical losses during rotation.

- The pump is equipped with a full-flow filter with an unbeling structure. It is present in it by contravert and bypass valve.

- This design ensures efficient lubrication circulation across all engine nodes.

- The work of the pump is carried out due to the rotation of the crankshaft. The connection is direct.

- The operational period of the pump is about 120 thousand kilometers.

Location

Not everyone knows where to look for this oil filter. It is not in a prominent place, because to gain access to the device will have to try.

It is placed directly inside the engine oil crankcase. To get to it, it is sure to merge the oil from the motor.

Consider if your engine uses high-quality oil, which only recently was flooded, while dragging use the clean package so that you can re-pour the same substance. If the oil is old, the pump replacement is a great reason to change the lubricant.

Dismantling

Depending on the situation, the oil pump can be completely replaced, or to perform repair work - change the gears, return the performance of the pump reduction valve.

But let's talk about everything in order. Work begins in any case with dismantling oil pump.

- Before removing the pallet for accessing the pump, you will definitely drain the oil.

- To do this, heal the motor to the operating temperature, open the drain hole and wait until the whole liquid flows out.

- Drain can be performed on the cold, only because of the high viscosity, the oil can flow for a very long time and its most part will still remain inside the crankcase.

- Drain oil, dismantle the three mounting bolts with a key of 8 millimeters from the protection of the crankcase. Protection overlaps access to flywheel near Carter.

- Remove the protection from the flywheel, and then dismantle the bolts from the crankcase. Everything, now Carter can be removed.

- Before you are the crankshaft and the oil bar, where the desired pump is located.

- By revealing the three fastening bolts, you still be able to dismantle the fence from the pump.

- Go to the pumproom space. Raising the hood, remove the plastic casing. This is a protection that closes the timing belt.

- Next, you need to remove the front right wheel to dismail the puck of the pulley fixation, and then remove the pulley itself.

- Remove the timing belt and unscrew the six mounting bolts that hold the oil pump. Here you will need the key to 8 millimeters.

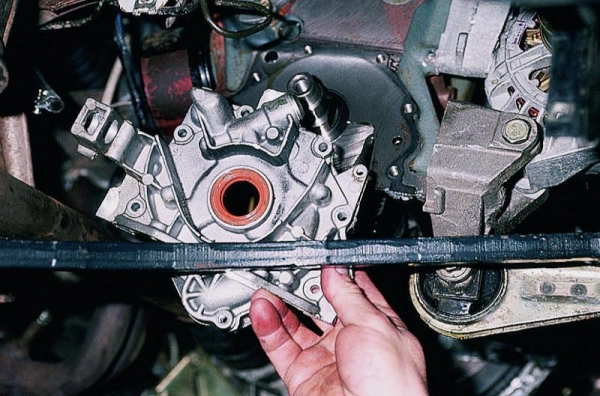

- Remove the oil pump from the crankshaft.

Disassembly

If you do not want or can not buy a new pump, you can try to repair. Perhaps the problem lies in the non-working valve or worn gears.

- Remove the gasket from the pump;

- Unscrew the bolt holding the crankshaft position sensor;

- By revealing the six fasteners, you can remove the cover from the pump;

- Using a pair of screwdrivers, lift the case in such a way that the pins on it freely come out of their holes;

- Remove the housing, disconnect it with the lid;

- Now you need to remove two gears from the cover. The first one gets the lead, and then the slave gear is removed;

- Next to the queue reduction valve. Need to unscrew the plug under which the sealing ring is located;

- Check the condition of this seal. If the ring has traces of damage, too squeezed, be sure to change to the new one;

- Remove the valve spring;

- Now you can remove the valve itself. To do this, gently knock the body along the pure tree stand;

- The valve can be stuck. Do not worry. Take any subtle sharp object, pitch and remove the item. It is better not to use metal objects in order not to damage the surface;

- Check the current condition of the lid made of aluminum. If there are deep scratches, traces of wear, replace it;

- If there are traces of wear on the pump housing, do not even attempt to repair anything. The only right solution will be his complete replacement;

- It is also necessary to make sure that the gears and the diameter of their nests meet the standards;

- The maximum diameter of the slot gear socket is 75.1 millimeter. If he is more, the case goes under the replacement;

- Measure the width of the case in the middle. If the indicator is less than 3.4 mm, it worn, needs to be replaced;

- As for the thickness of the gear, according to the requirements, the thickness of the master is at least 7.42 mm, and the slave is 7.35 mm. When deviating from the norm of the gear change.

Assembly and installation

If you managed to repair the oil pump, then it remains to collect it and install the unit in place. If you decide to completely replace the device, check the first part of the further instructions.

- Install the led gear on the body of the flacks on the teeth.

- Also, the headsets on the teeth returns the new leading gear of the pump.

- Be sure to do not forget to lubricate the gear oil so that they are more reliable and longer worked.

- Return the pump cover, tighten all the fasteners.

- Lubricate a new or repaired old reducing valve before installing it on the place.

- The valve stacked in its nest. Make sure the installation is carried out bottom down.

- Now a turn over a spring and a plug, which worst with a sealing ring. Again, these elements are pre-lubricated with engine oil.

- Using the oil truck tube, the oil is poured back into the unit.

- After completing the assembly, check the pump gears into several complete revolutions. So you will provide effective lubrication of all surfaces inside the pump.

The unit is assembled, you can return it to the place. For this:

- Return the timing belt in place, pulling it on the rollers. Do not forget to set according to the labels;

- Return the plastic strap protection to its rightful place, install the wheel;

- Now you need to climb under the car to install the oil pump on the pump;

- Be sure to treat the carcase with the compositions, removing all fat. Treat sealant;

- At Carter we advise you to put a new gasket, after which the sealant layer is applied;

- Block degreases, the crankcase returns to the right place;

- To easier to be attached to, wrap in different points several bolts, then screw all the rest;

- A protection is installed on the flywheel, the crankcase protection returns to its places;

- Fill oil back oil, start the engine, allow the oil to host the nodes.

If you carry out all the manipulations correctly and pre-determine what exactly the pump failed, the test lamp on the dashboard will go out.

Oil pump plays a huge role in the functioning of the lubricant engine system, because at the first signs of its breakdowns immediately go to the garage, or trust the replacement for specialists of proven maintenance stations.