The knock of hydraulic lifters on a 16-valve VAZ 2112 engine differs quite simply, and it is not difficult to determine the cause. So, you can eliminate the cause of the knock in a fairly simple and proven way.

A video about replacing hydraulic lifters, it also shows the possible causes of knocking:

The video plot will tell, as well as diagnose them in the event of extraneous knocks and sounds.

Hydraulic compensators manufactured by AvtoVAZ

The hydraulic compensator is a cylindrical piston that transmits the force of the camshaft follower. The inner part has a plunger that transfers the force to the valve. This is what provides the thermal gap. In order for the valve to open, the piston pushes the camshaft cam, which in turn through the plunger, which acts on the valve. The thermal gap is regulated. The ball valve prevents oil from leaking.

What kind of knocks are there?

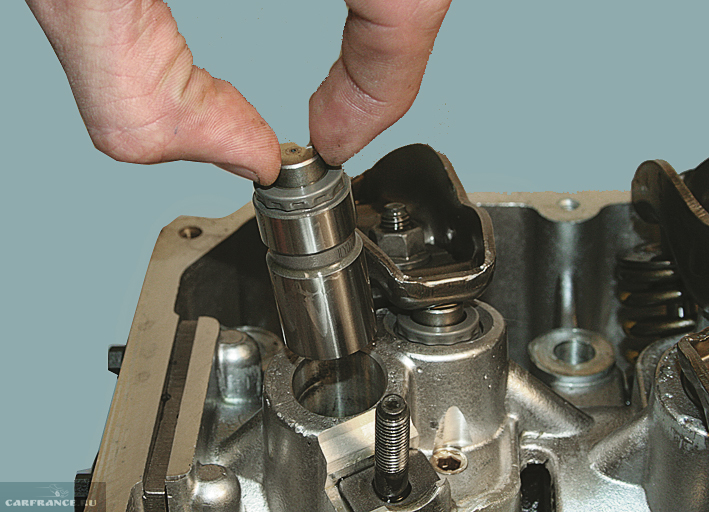

Pulling out the hydraulic lifters piston

Consider all possible options:

- Knock that appears at startup and then disappears abruptly ... This is a normal knock and there is no cause for concern. Simply, the remaining oil flows out of the open ball valve.

- Elevated knocking that can disappear at higher speeds ... This means that the ball piston is defective and the hydraulic lifters need to be replaced.

- Hot knocking, or when it is heard only on a warm engine. This is the wear of the hydraulic lifters themselves.

- Knock that occurs at high speeds ... This is due to the fact that there is an excess of oil in the system, which forms foam when the crankshaft turns. It gets into the cylinder head and disrupts the hydraulic lifters. With this effect, the oil does not get into the "hydric" itself and a knock appears, which leads to increased wear.

Diagnostics of hydraulic lifters

Measurement and diagnostics of "hydric"

- In order to check the hydraulic lifters it is necessary.

- Further, the crankshaft is brought to a position where the cams are not acting on the compensators.

- The next step is to press on the pistons. If the piston is serviceable, then it is fed down under great force. If the piston is locked, then the plunger is seized, but if there is a lack of oil, then it will go down without any problems.

Knock elimination method

Of course, hydraulic lifters cannot be repaired, so they must be replaced.

Some car enthusiasts try to repair them, but experience shows that everything ends with a replacement, after a few thousand kilometers. The second factor that pushes motorists to replace is that the repair of these parts is too expensive and not economically feasible.

conclusions

The reasons for the knock of hydraulic lifters are quite simple, and their classification immediately speaks of the reasons for the occurrence of such an effect. The main method of troubleshooting remains a comprehensive replacement of all products.