In 2006, Toyota's autoconecern presented 10 Corolla family generation: Toyota Corolla X (E140 / 150). The car was produced in a single body performance - sedan, and was distinguished from the previous generation E120 more modern and solid appearance, as well as significantly increased dimensions.

Toyota Corolla X:

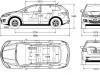

- length - 4540 mm;

- width - 1760 mm;

- height - 1470 mm;

- the magnitude of the wheelbase is 2600 mm;

- clearance of cars intended for the Russian market - 150 mm.

This Corolla model used and continues to enjoy great demand among motorists and, moreover, was highly appreciated by experts. Thus, as a result of crash tests conducted by an independent European organization EURONCAP, Toyota Corolla E140 has become the first car Class C, which received five stars in the entire history of the existence of this organization. This was achieved thanks to an excellent security system: it was installed in cars, depending on the configuration, up to seven airbags; In the front seats there is a device to prevent neck injury; There is a system that is notified about non-unsuccessful safety belts and so on.

The difference between E140 and E150

A common mistake among motorists is a misconception about 140 and 150 Toyota Corolla X models. Many believe that 140 series - dorestayling, and 150 - released since 2010. To dispel this error, you should clarify: this is the same model manufactured for different countries.

Toyota Corolla E140 is shown in the photo below. It was produced for the USA, UAE, Thailand and some other countries and has the following differences:

- Cars were completed with 1.8- and 2.4-liter engines.

- Front optics are equipped with chapal headlights (DRL), the number of reverse lamps pair, fog lights in this version are not provided.

- The rear suspension of most independent cars, spring type.

- Rear brakes disc.

- Body body kites: bumpers, wings and thresholds - Series S and XRS.

- Body marking - E140.

Toyota Corolla E150 cars (see photos) were produced for Europe, England and the countries of the former USSR. They have the following distinctive features:

- The interior is made in dark colors; Optitron dashboard (with displays).

- In the front optics there are no headlights of DRL; Family headlights and one reverse lamp are installed behind.

- Rear suspension is represented by beam. For Russian roads there is a special design of the suspension, in which the rear bumper of the car is slightly raised, and the consumables are more durable.

- Rear brakes only as standard - disk.

- Engines, 1.4 and 1.6 liters.

- Body marking - 150.

- Different from the American model body body bumper and wings.

Appearance 10 generation of Toyota Corolla

Corolla in 150 body survived two updates, and the latter, in 2010, was more cardinal. The changes affected both the appearance of the car and the equipment of the cabin.

As a result of restyling, the car received a bumper of another configuration, an enlarged air intake, a chrome-plated radiator grille, changed the shape of the front and rear headlamps, the design of the wheel drives, on the rearview mirrors appeared repeaters of rotation indicators.

The changes also touched the cabin. It appeared an improved audio system with a USB connector and Bluetooth support. The expensive equipment is obtained by a well-quality reversing chamber with a display integrated into the rearview mirror. The insanity of the cabin was performed by high quality materials, various shades of gray were added in its colors.

The design of the steering wheel also underwent changes: it became flat below and got a thickened rim. The backlight of the devices has changed with orange on white, which improved their visibility.

Updates also touched the control systems: it became possible to open the trunk using the button located on the ignition key, the electrical windows are equipped with front chairs in all configurations.

Specifications Corolor in 150 Body

Toyota Corolla of the tenth generation is equipped with two types of gasoline engines, with working volumes of 1.33 and 1.6 liters. For the first, a six-speed manual gearbox is provided, for the second except "mechanics" is possible to install a four-stage automatic transmission.

Toyota Corolla E150 (2010+). The main fault of the car - part 2

The engine warms up to operating temperature

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Faulty thermostat | Check the thermostat service | Replace faulty thermostat |

| Low air temperature (below -15 ° C) | - | Warm engine: Close the slot on the front bumper with an unproduced material |

Knock and clocks when cornering the car

| Outdoor drive hinge | Remove the drive and check the hinge. If necessary, replace the hinge or drive assembly |

| Lack of lubricant in hinge | Inspect the case. Remove the drive, check the hinge. Load a new lubricant into a hinge in sufficient quantities, replace the damaged hinge case. If you have a backlash, replace the hinge or the drive assembly |

| The intermediate bearing is very worn | Remove the intermediate support bracket, check the backlash in the bearing. If necessary, replace the intermediate bearing |

Vibrations when accelerating and slowing

Battery malfunctions

| Rechargeable battery discharged starter does not turn the crankshaft of the engine or turns slowly, burning lamps burn | |

|---|---|

| Cause of malfunction | Elimination methods |

| The car has not been exploited for a long time | Charge the battery using the charger or on another car |

| Weakened belt tension | Tighten the generator drive belt. |

| When the engine is turned off, there are many consumers of electricity (head system of sound playback system, etc.) | Reduce the number of consumers working from the battery |

| Damage to the insulation of electrical circuits, leakage of current over the surface of the battery | Check the leakage current (not more than 11 mA when the consumers are disconnected), clean the surface of the battery. Caution, acid! |

| Faulty generator | See diagnostics faults generator |

| Short circuit between plates ("boiling" of electrolyte, local heating battery) | Replace the battery |

Lighting the battery failure

| Lighting the battery charge lack of the battery power supply vehicle is below 15 in | |

|---|---|

| Cause of malfunction | Elimination methods |

| Weakened generator drive belt tension | Tighten the belt |

| Faulty voltage regulator. | Replace the regulator |

| Damaged diodes of rectifier block | Replace rectifying unit |

| Disruled connection of excitation winding conclusions with contact rings, closure or opening in the winding | Sold out the conclusions, replace the generator rotor or the generator assembly |

| Open or short-circuit in the stator winding, closing it on the "mass" (when the generator is closed) | Check the winding in the mesmer. Replace the stator or generator assembly |

Voltage onboard network of the car above 15.1

Noise generator

| Noise generator | |

|---|---|

| Cause of malfunction | Elimination methods |

| The generator bearings (squeal, howl) are damaged. Noise remains when the wires are disconnected from the generator and disappears when removing the drive belt | Replace the rear bearing, front bearing with a lid or generator assembly |

| Short circuit in the stator winding (howl). The noise disappears if you turn off the wires from the generator | Replace the stator or generator assembly |

| Short circuit in one of the diodes. The noise disappears if you turn off the wires from the generator | Replace rectifying unit |

Battery failure no charge warning

| The battery charge lack of the battery does not light up when the ignition is turned on | |

|---|---|

| Cause of malfunction | Elimination methods |

| Fastened fuse F1 mounting block in the car | Find out and eliminate the cause of the brave. Replace fuse |

| Open in the circuit "Switch ignition - a combination of instruments" | Check the wires from the ignition switch to the mounting unit and from the mounting unit to the instrument combination |

| No ignition switch contacts | Check the contact closure tester. Replace the contact part or switch assembly |

Battery No Accumulator Battery Signal Nothing when the ignition is turned on and the engine operating the on-board network is loaded below 14.4 volts

| The battery failure signaling device does not light up when the ignition is turned on and the engine operation of the vehicle is loaded below 14.4 V | |

|---|---|

| Cause of malfunction | Elimination methods |

| Wear or hanging brushes, oxidation of contact rings | Replace the belt holder with brushes, wipe the rings with a clean rag moistened in gasoline |

| The voltage regulator is damaged | Replace voltage regulator |

| Faulty rectifier block | Replace rectifying unit |

| The wire connection with the pin holder is impaired. | Restore the wire connection with the terminal holder |

| Out of conclusions of excitation winding from contact rings | Sold out the conclusions or replace the generator rotor or the generator assembly |

When you press the "Gas" pedal until it stops, Kickdown mode does not turn on

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Low fluid in gearbox | |

| Test the engine control system (in the service center). Replace faulty items | |

| Violated Adjustment of the gear selection lever, faulty gear selection lever position sensor or electrical circuit | Adjust the drive (in the service center), if necessary, replace the faulty cable. Check the sensor (in the service center), replace the faulty sensor |

The engine is started in other modes besides "P" and "N"

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Violated Engine Start Permissions Sensor | Adjust the position of the sensor (in the service center) |

| Faulty engine control system | |

| Violated Adjusting the gear selection lever | Adjust the drive (in the service center), if necessary, replace the cable |

Rods when switching transmissions, the car does not move when the "D" modes are turned on or "R"

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Low fluid level in box | Check the fluid level on the pointer, if necessary, decrease the liquid |

| Faulty gear selection lever position sensor | Diagnose the sensor (in the service center), replace the faulty sensor |

| Faulty engine control system | Diagnose the engine control system (in the service center), replace faulty items |

Lighting and light alarm

Lamps block headlights, lanterns

| Lamps block headlights, lanterns | |

|---|---|

| Cause of malfunction | Elimination methods |

| Overwhelmed the thread lamp | Replace lamp |

| Blocked fuse | Check the chain protected by the blurred fuse on the lack of closure on the "mass", replace the fuse |

| Oxidized relays contacts, overheat the winding relay, the switches are faulty | Clean the contacts, replace the relay, switches |

The rotation pointer signage flashes with double frequency

The rotation pointer switch lever is not returned to its original position, the steering switch lever is not fixed.

Movies the diffuser block headlights

Windshield cleaner

The electric motor of the cleaner does not work, the chain protection fuse in the mounting unit is correct

| The electric motor of the cleaner does not work, the chain protection fuse in the mounting unit is correct | |

|---|---|

| Cause of malfunction | Elimination methods |

| Fault of a steering wheel switch | Replace the faulty cleaner switch |

| The brushes of the electric motor were hung, heavily dirty or burned collector | Eliminate brushes hang, clean the collector or replace the gear motor |

| Open in the winding of an anchor of the electric motor | Replace the gear motor |

| Faulty additional relay | Replace relay |

The electric motor of the cleaner does not work, burns out the chain protection fuse in the mounting unit

| The electric motor of the cleaner does not work, burns out the chain protection fuse in the mounting unit | |

|---|---|

| Cause of malfunction | Elimination methods |

| Brushes face to glass | Turning off the cleaner, carefully separate brushes from glass, make sure the integrity of the rubber scraper, restore the mobility of the brush connections |

| Purifier brushes tight for body parts | Check that the levers are installed correctly, straighten the deformed levers or replace the cleaner. |

| Short circuit in the winding of the electric motor | Replace the gear motor |

The electric motor of the cleaner does not work in the intermittent mode

The electric motor of the cleaner does not stop in the intermittent mode

| The electric motor of the cleaner does not stop in the intermittent mode | |

|---|---|

| Cause of malfunction | Elimination methods |

| Faulty cleaner relay | Replace relay |

| The end switch's petals are poorly pressed against the gear gear gear | Check the contact paths of the limit switch |

| Oxidized or burned contacts of the limit switch | Clean contacts or replace the cleaner gear motor |

Brushes stop in an arbitrary position

Brushes do not work synchronously

The electric motor of the cleaner works, but the brushes do not move

Separate threads of heating element of the rear glass of heating are not heated

No thread of the heating element is not heated

| No thread of the heating element is not heated | |

|---|---|

| Cause of malfunction | Elimination methods |

| Faulty switch, relay, rear window heating fuse, damaged wires, oxidized or poorly connected tips, torn contact from glass heating element | Faulty switch, relay, fuse, wires replace. Clean, degenerate tips. Replace glass with heating element |

The electric motor of the heater does not work

| The electric motor of the heater does not work | |

|---|---|

| Cause of malfunction | Elimination methods |

| Damaged wires, oxidized or loosely put their tips | Cut and clean the tips, replace faulty wires |

| Wear, hangover brushes, break or closure in anchor winding, oxidation or collector wear | Clean the collector or replace the electric motor |

| Faulty switch | Replace switch |

The electric motor of the heater fan does not work at low speed

Coolant temperature pointer or fuel level index

| Coolant temperature pointer or fuel level index | |

|---|---|

| Cause of malfunction | Elimination methods |

| Faulty pointer | Replace the combination of instruments |

| Faulty sensor | Replace the indicator sensor |

| Damaged wires, oxidized or loosely put their tips | Cut the tips, replace faulty wires |

Constantly burning fuel reserve alarm

The arrow of the fuel level pointer twitches and often deviates to the zero mark

The alarms do not light up

Speedometer does not work

| Speedometer does not work | |

|---|---|

| Cause of malfunction | Elimination methods |

| Faulty speed sensor | Replace speed sensor |

| Speedometer defective | Replace the combination of instruments |

Tachometer does not work

Sound signal faults

| The horn does not work | |

|---|---|

| Cause of malfunction | Elimination methods |

| Faulty signal, its switch, relay, blocked the fuse, damaged wires, oxidized or poorly connected their tips | Try to restore the sound, turning the screw on the signal housing. Clean, degenerate wire tips. Faulty Signal, Switch, Relay, Wires, Furious Fuse - Replace |

| Weak, hoarse signal | |

| Cause of malfunction | Elimination methods |

| Faulty signal, damaged wires, oxidized or poorly connected their tips | Adjust the sound by turning the screw on the signal housing. Clean, degenerate wire tips. Faulty Signal, Switch, Wires - Replace |

Algae of the car from straight movement (on a flat road)

| Algae of the car from straight movement (on a flat road) | |

|---|---|

| Cause of malfunction | Elimination methods |

| Single air pressure in tires | |

| Violation of the corners of the longitudinal tilt axis of the axis of rotation and / or the collapse of the front wheels | Adjust the corners of the tilt axis and / or the collapse of the front wheels |

| Replace the worn tire | |

| Replace both springs | |

| Deformed parts of the suspension and / or car body | Relay or replace the deformed parts and body panels |

| Displacement of the rear axle due to wear of the silent blocks of the rear suspension beam | Replace Silent Blocks |

| Wheel bravery due to wheel cylinder piston | Replace cylinder |

| Drinking the front wheel due to the weakening of the filling bolts of the guide pad to the twilty fist (the caliper is shifted) | Tighten the bolts |

| Rear wheel braking due to loosening or breakage of the rear brake pads springs | Replace spring |

| Increased front wheel imbalance | Balance the wheels |

Fast tire tread wear

| Fast tire tread wear | |

|---|---|

| Cause of malfunction | Elimination methods |

| High speed, starts with slip wheels, braking "on the UZ", passing turns with a drift or demolition of wheels | |

| Tire pressure is different from the norm | Set normal pressure |

| Hitting the protector of aggressive with respect to rubber materials - bitumen, oil, gasoline, solvents, acids, etc. | Replace tire |

| Uneven wear of tire tread | |

|---|---|

| Cause of malfunction | Elimination methods |

| Elevated wheel imbalance | Balance the wheels |

| Tire deformation, rim | Replace wheel |

| Different tire pressure | Set normal pressure |

| The angles of the installation of the front wheels are impaired | Adjust wheel installation angles |

| High speed in turns, their passage with drift or wheels | Observe the normal speed mode |

| Wire of hinges, deformation of the parts of the suspension or body | Replace hinges, deformed pendants, spars, body panels |

| Schedule in the steering control (see also "Enlarged free steering wheel") | Replace worn hinges, tighten the threaded connections, adjust the gap between the gear and rack in the steering mechanism |

| Faulty shock absorber | Replace both shock absorbers |

| Increased steering wheel | |

|---|---|

| Cause of malfunction | Elimination methods |

| Weakened tightening nuts fastening ball fingers | Tighten the nuts |

| Increased clearance in ball joints, wear of rubberometallic hinges | Replace the tips of the cray |

| Big gap between the Reiki and Nut | Adjust the gap in the steering mechanism |

| Steering wheel rotates tight | |

|---|---|

| Cause of malfunction | Elimination methods |

| Faulty electric power steering | Replace the electricuster |

| No power steering power supply | Check the power of the electric powerful, its control unit (fuse F31, F5) |

| Damaged front suspension bearing | Replace Bearing or Support |

| Damaged support sleeve or recking | Replace damaged parts, label |

| Low pressure in front wheels | Set normal pressure |

| Damaged steering hinges | Replace the tips of the cray |

| Power steering gear bearings damaged | Replace bearings |

Skyrp, braking screech

| Skyrp, braking screech | |

|---|---|

| Cause of malfunction | Elimination methods |

| Brake lining | Replace brake pads (at the same time all on one axis) |

| Inclusion in the material of the lining of foreign particles (sand) | As a rule, it does not require intervention (you can clean the lining with a metal brush) |

| Low quality material lining | |

| Strong corrosion of the brake disc (due to the poor quality of the disk material and / or lining) | Replace brake discs |

| Replace pads (at the same time all on one axis) | |

| Replace spring | |

| Brake with wheel lock | Do not overheat, use tires that match the conditions of movement |

Vibration when braking

| Vibration when braking | |

|---|---|

| Cause of malfunction | Elimination methods |

| Deformation of the brake disc | Replace both disk |

| Elevated axial leaf wheels (strong wear of the front wheels bearing or weakening the hub nut mounting) | Tighten the wheel nut nut, replace the bearing if necessary. |

| Slipped piston in the rear wheel cylinder | Replace cylinder |

| The laying of the brake pad peelled from the base | Replace pads (at the same time all on one axis) |

| Weakening or broken braking springs rear brake pads | Replace spring |

| Ovivo or car drift when braking | |

|---|---|

| Cause of malfunction | Elimination methods |

| Replace cylinder | |

| Blocking brake lines: tubes or hoses | |

| Pad delay from the base of the brake pad | Replace the block (better at the same time on one axis) |

| Milling brake discs, drums, lining | Ground discs and drums Clean the pads replace. Eliminate the cause of grinding |

| On the surface of the lining, ice or hydrochloric crust (winter) was formed. Pads Namocley | At the beginning of the movement, at low speed, check the brakes. In the rain and after the departure of deep puddle, dry the brakes with light pressed brake pedals |

| Miscellaneous pressure in the tires of the left and right wheels | Set normal pressure |

| Significant tire wear | Replace the worn tire |

| Incorrectly adjusted pressure regulator drive | Adjust the drive |

| Replace the regulator | |

| One of the circuits of the working brake system does not work (braking efficiency is significantly reduced) | Eliminate leakage of fluid from the brake system, pump the system |

| Deformation of the brake disc | Replace both disk |

| Axial backlash wheels (strong wear of the front wheels or attenuation of the hub nut fastening) | Tighten the wheel nut nut, replace the bearing if necessary. |

| Oval brake drum | Crush or replace the drum |

| Faulty rack shock absorber | Replace both shock absorbers |

| Spring Springs No Distribution Springs | Replace both springs |

| Violated wheel installation angles | Adjust wheel installation angles |

Increased brake pedal

| The enlarged move of the brake pedal (the "soft" pedal or "falls") | |

|---|---|

| Cause of malfunction | Elimination methods |

| Air in the brake system, leakage of brake fluid through looseness of hydraulic pipe compounds, damage cuffs in the main brake cylinder, pressure regulator, damage to brake tubes and hoses | Inspect all highways, their threaded connections and cylinders, eliminate leaks. Restore the normal fluid level in the brake tank and pump the system. When damaged damage to brake hoses (cracks, fuses or traces of brake fluid), replace the hoses. When suspected defects in the main brake cylinder, replace it with a good |

| The rubber cylinder cylinder cylinder cylinder swells were sweeping due to oil, gasoline and som. | |

| Overheating brake mechanisms | Give cool brakes. Use DOT-4 brake fluids in the system. Replace brake fluid on time |

| The gap between the pads and the drum is increased (the automatic clearance control device does not work) | Replace the wheel cylinder, pump the system |

| One of the circuits of the working brake system does not work | Eliminate leakage of fluid from the brake system, pump the system |

| Increased (more than 0.15 mm) brake disc | Replace both disk |

The car brakes bad

| Brake pedal stroke within the norm (tough pedal), but the car slows down bad | |

|---|---|

| Cause of malfunction | Elimination methods |

| Wheel cylinder piston jam | Replace cylinder |

| Replace damaged tubes and hoses | |

| Milling brake discs, drums, lining | |

| Full brake linings (brake crosses) | Replace brake pads (at the same time all on one axis) |

| Low quality material lining | |

| Strong corrosion of the brake disc (due to the poor quality of the disk material and / or lining) | Replace discs |

| The laying of the brake pad peelled from the base | Replace pads (at the same time all on one axis) |

| Incorrectly adjusted pressure regulator drive | Adjust the drive |

| Defective pressure regulator | Replace the regulator |

| Faulty vacuum amplifier or a non-grinding hose connecting the amplifier with Rexiver | Check the hose integrity, landing it on fittings, tightening clamps. Check the operation of the amplifier |

| Incomplete disbursement of all wheels | |

|---|---|

| Cause of malfunction | Elimination methods |

| There is no free brake pedal | Adjust the free pedal |

| Replace cylinders, hoses, completely drain the brake fluid, rinse the system with fresh liquid and pump | |

| Slined the piston of the main cylinder (due to corrosion, breakdowns of return springs) | Replace the main cylinder, pump the system |

| Turning one of the wheels when the brake pedal is released | |

|---|---|

| Cause of malfunction | Elimination methods |

| Wheel cylinder piston jam | Replace cylinder |

| The rubber cylinder cylinder cylinder cylinder was swelling due to oil, gasoline, and the like in the brake fluid. | Replace cylinders, hoses, completely drain the brake fluid, rinse the system with fresh liquid and pump |

| Blocking brake lines: tubes (due to dents) or hoses (due to swelling or rubber bundle) | Replace damaged tubes and hoses |

| Singing the pads due to severe contamination of the support surfaces of the caliper | Remove the pads, clean the support surfaces of the shoe and caliper |

| Single overlay rear brake pads | Replace pads (at the same time all on one axis) |

| Weakening or broken braking springs rear brake pads | Replace spring |

| Deformation of the spacer plank, skew the pads due to the deformation of the brake shield | Get or replace the spacer, brake shield |

| Weak the fastening of the guide pads to the swivel fist | Tighten the bolts |

| The parking brake is pulled, cables are flared in shells | Adjust the tension of the cables, lubricate them with engine oil if the shell is damaged or the cable wires are damaged, as well as with a strong corrosion, replace the cable |

| Insufficient performance of the parking brake system | |

|---|---|

| Cause of malfunction | Elimination methods |

| Adjust the drive | |

| Drive cables are stacked in shells | Lubricate the cables with engine oil, if the shell is damaged or disheveled the wire of the cable, as well as with a strong corrosion, replace the cable |

| Brushed brake drums, lining | Ground discs and drums Clean the pads replace. Eliminate the cause of grinding |

| On the surface of the lining, ice or hydrochloric crust (winter) was formed. Pads Namocley | At the beginning of the movement, at low speed, check the brakes. In the rain and after the departure of deep puddle, dry the brakes with light pressed brake pedals |

When releasing the lever of the parking brake, the wheels are not disseminated

| When releasing the lever of the parking brake, the wheels are not disseminated | |

|---|---|

| Cause of malfunction | Elimination methods |

| Incorrect drive adjustment | Adjust the drive |

| After the long parking lot of the car pads stick (or cameras) to the drum | Drechaya for the lever or cables, try carefully (so as not to break the brake linings) Turn the wheel. When setting the machine to parking, if possible, do not tighten the brake, but turn on the transfer |

Constant technical improvement and compliance with customer requirements. Here is the main principle of development of the Toyota automotive industry, which is formulated by Tatsuo Hacegawa, the main engineer of the first generation of the machine. Toyota Corolla 2008 is another confirmation of the incarnation of this concept in the tenth generation Corolla X. It is thanks to this principle Toyota leads on sales of its cars in the world and in Russia. In this lead, a solid place was held by Corolla 150. It was said enough to give a description of this car several lines.

Toyota Corolla 150 after updating

The E150 model to restyling has a distinguished body appearance and the appearance of the Corolla 2008 model turned out to be dynamic and rapid. Front optics have become more elongated to the grid and narrow, the rear lights also changed the form.

After updating the Corolla model in 2010, the forms of the front, as well as the rear bumpers were changed, the chrome grille of the radiator and the new 16-inch alloy discs were installed. Cosmetic improvements not just improved design, but made the view rich and prestigious.

There were other renovations: direction indicators were installed on the rearview mirrors, a slightly changed form of the front and rear headlights. The rearview mirror became darkening itself, in addition, the screen is mounted in it, which shows a picture from the rear view camera. Recent design changes were implemented in Corolla 2010.

Salon body E150

Thanks to changes in the Corolla 2008 and Corolla 2009, the interior is not only improved, but also the comfort of the driver and passengers. The steering wheel was flat on the bottom, and the rim thickened. Changed the color of the dashboard lighting with orange on white, which improved its visibility. The second row of the chairs has become more comfortable for the seating of three people. In the absence of a third passenger on the second row, you can use a folding armrest with two cup holders. If necessary, the rear seats can be folded.

Beige Leather Salon in Corolla 150 Meet not often

Constructive changes are made to the control of the interior functions. Thus, the opening button of the trunk is placed on the ignition key, the electrical windows control buttons are also installed on the front chairs. The audio system is improved by installing USB and bluetooth communication with external devices. The Salon began to beat the best quality material.

Pay attention to the "petals". Why are they Corolla 150?

Corolla specifications in 150 body

Motors of six types can be installed on Toyota Corolla. In Russia, walking in Russia with the following characteristics: 1.4 4ZZ-FE 97 horsepower, 1.3 liters. 101 hp 1NR-FE, 2ZR-FE has a volume of 1797 cm3 Power 133 hp and 1ZR-FE 1.6 l. 124 horses.

Corolla 2008 is installed three types of gearboxes (gearbox): mechanical 6-step, automatic 4-speed and carton variator. Mechanics, equipped with motors 1.3 1NR-Fe, 1.4 4zz-Fe, 1.5 NZ-FE, 1.6 1ZR-FE, 1.8 2ZR-FE, D4D. The automatic box is installed with a 1.6 1ZR-FE engine. The variator for Corolla 2008 is only available in the configuration with 1.5 1NZ-FE engine.

It should be said about the gearbox robot, as an unsuccessful design version, which is finally removed from the restaurant Toyota Corolla 2010.

The constructing of the 2008 Korop Pendant is typical for this car class and is characterized by enviable endurance. Designs of springs and shock absorbers when clearance height 150 mm. allow you to comfortably ride in uneven roads. The control of the car is carried out using the steering control "gear - rack" with an amplifier on an electrical or hydraulic drive. The reversal radius of the machine is 5.2 m.

Corolla 150 may look epic)

According to the fuel consumption of Toyota Corolla, economical car. Depending on the type of engine, fuel consumption per city ranges from 4.9 l to 6 liters. per 100 km. In urban environments, this indicator varies from 7.3 to 9.3 l., And in a mixed mode of driving - from 5.8 to 7.2 liters. The diesel engine is the most economical, it consumes 4.4 liters, 7 liters, 5.3 liters in the country, in the city and mixed modes, respectively. Cars with 1.6 l engines, 1.8 l complete with automatic checkpoints. Most expendable. The volume of the fuel tank is 55 liters. Recommended for refueling standard brand of gasoline AI-95.

Dimensions Toyota Corolla 150

The changes were also the dimensions of Corolla 2008, they grew up. Their values \u200b\u200bwere: length, width, height - 4540 mm, 1760 mm, 1470 mm, respectively. The increase in the dimensions gave an impressive view of the car, allowed to increase the salon and make it more comfortable, as well as to increase the volume of the trunk to 450 liters

Typical breakdowns and problems in operation

Of course, every year the car becomes better and, of course, Corolla 2011 is better than Corolla 120. Nevertheless, some drawbacks take place throughout the entire period of operating Toyota Corolla 2008.

Swift Toyota Corolla 150

Corolla minuses are generated by small constructive flaws, which should be attributed to the vibration in the doorway, noises in the control panel, are not justified with a bulky magnet. Corolla is a city type machine, it is a little adapted for driving on country roads.

But its disadvantages are the result of more serious constructive miscalculations and flaws that are then caused by typical repairs. Among them can be called: a breakdown of the gearbox robot, raw wear of the plastic sleeve of the steering rack. When running about one hundred thousand kilometers, there may be a refusal to work bendix starter, or water pump. The shortcomings can also be attributed to low-power engines, weak speakers, not the best head lighting.

Fur Toyota Corolla 150

But the advantages of Toyota Corolla:

High security;

low fuel consumption;

high level of environmental friendliness;

Modern attractive external and interior machine design;

Emergency reliability of Corolla X, if not take into account the robot.

Named positive moments ultimately provide her indisputable advantages on the market, thanks to which Toyota Corolla in the sales leaders for many years.

Test Drive

High qualities of Corolla 2008, Corolla 2009, as well as subsequent Corolla E150 issues confirm numerous test drives. They showed excellent car handling in a wide variety of conditions: in winter in the snow and on ice, in summer in the conditions of the desert. But regardless of conditions outside Toyota Corolla maintains sufficient comfort in the cabin.

Toyota Corolla E150 Sedan

Toyota Corolla X entered the European market in 2007. At the same time, Corolla 2007 began to produce in several configurations.

Comfort equipment - basic equipment of the car. It includes air conditioning, front windows, headlight glasses, front seat heating systems and mirrors. The car has a central lock.

Restyling Toyota Corolla 150

Higher level of configuration - Elegance. In addition to the above, it includes the windows in the rear doors, automatic climate control, improved radio tape recorder with additional speakers. The steering wheel sets the control keys of the audio system and fog.

The highest level of completing prestige. It assumes additionally cast wheeled discs, light and rain sensors, engine start button.

There are still intermediate configurations: Comfort Plus and Elegance Plus. Since the differences between the intermediate types from the main types of minor, we do not give them description.

Will Toyota Corolla X

It is clear that it is not about the Corolla 120 IX generation or the Corolla of 120 generation it is an outdated version. But in a larger account, buying a car for the overwhelming majority of users a costly event and with long-term consequences associated with the operation of the car. Therefore, of course, doubts may remain some time after buying a car until it dispels them to you. Of course, anything can be, but in favor of a positive decision to buy Corolla 2008 can speak a long-term championship of this car for sales.

What to buy instead of Toyota Corolla Review of Competitors

But, if for various reasons, Corolla did not like the same reason, the market selection is presented widespread. For the same money instead of Corolla 2009 or Toyota Corolla 2011 you can buy Chevrolet Cruze, Hyundai Elantra, Ford Focus, Kia Ceed, Kia Cerato or Volkswagen Golf. But only causes doubt whether they will be able to make a worthy competition of Corolla in reliability.

Dimensions of Toyota Corolla The current generation increased, if we compare the sided dimensions with the last version of Corolla. Perhaps the most significant increase in dimensions occurred in the cabin, as the wheelbase (the distance between the front and rear axles) rose by 10 centimeters.

The total length of the new Toyota Corolla 4 620 mm body is 4,620 mm, while the past generation of the sedan had only 4,540 mm long. The base of the defining space in the cabin increased from 2 600 mm to 2,700 mm, making the leader in his class in its class. The width of the new version of the car is 1,775 mm, against 1,760 mm. In order to improve the aerodynamic indicator, the height of the body was reduced by 5 mm.

Dimensions, Dimensions Toyota Corolla

- Length - 4620 mm

- Width - 1775 mm

- Height - 1465 mm

- Wheel base - 2700 mm

- King of the front and rear wheels - 1535/1535 mm

- Front Svet / Rear - 940/980 mm

- Length of the cabin - 1930 mm

- Salon width - 1485 mm

- Salon height - 1190 mm

- Toyota Corolla trunk volume - 452 liters

- Fuel tank volume - 55 liters

- Tire size - 195/65 R15, 205/55 R16

- Road clearance or clearance TOYOTA COROLLA - 150 mm

Clearance Toyota Corolla It is 150 mm, in the ages of the left as for European consumers, this indicator is slightly less and is 145 mm. The manufacturer specially increased the road clearance due to the peculiar feature in our country.

Trunk Toyota Corolla The new generation also became a little more and accommodates 452 liters of volume, given the fact that under the floor of the luggage compartment there is also a full-sized spare wheel, then a fairly decent indicator is obtained. The backrest of the rear seat Corolla add up in proportion to 40 to 60, making the transportation of various things much more convenient, watch photos.

By the way, the volume of the trunk of the sedan of the last 10 generation was 450 liters. In this regard, little has changed. Loading opening is quite wide, which is very convenient for the transport of all sorts of volumetric suitcases and boxes.

Toyota Corolla E150 (2010+). Main car faults - part 1

Falling the coolant level in the expansion tank

| Diagnostics | Elimination methods | |

|---|---|---|

| Damage to the radiator, expansion tank, hoses, weakening their landing on the nozzles | Inspection. Tightness of radiators (engine and heater) is checked in a bath with water with compressed air under pressure 1 bar | Replace damaged details |

| Liquid leak through coolant pumping liquid | Inspection | Replace the pump |

| The cylinder head gasket is damaged. Block defect or cylinder head | On the oil level index, an emulsion with a whiten tint. It is possible to appear abundant white smoke from the muffler and oil spots on the surface of the coolant (in the expansion tank). Coolant drums on the outer surface of the engine | Damaged details replace. Do not use water in the cooling system, pour the cooling fluid corresponding to climatic conditions |

Foreign noise and knobs in the engine

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Check the gaps | Adjust the gaps | |

| Repair the engine | ||

| A toothed tape drive belt of the gas distribution mechanism is worn. Faulty tension or support drive rollers | Inspection | Replace the belt. Replace the faulty tensioning or supporting rollers of the gas distribution mechanism |

| Wear bearings and camshaft camshafts, connecting rod and native crankshaft bearings, pistons, piston fingers, backlash or jamming in generator bearings, coolant pumps and steering hydraulic power | Check | Repair or replacement of parts |

| Lost elasticity or collapsed by one or more supports of the force aggregate | Inspection | Replace support |

| Low pressure in the oil line (with a minimum rotation frequency of the crankshaft at idle the pressure in the grease system of the heated engine should be at least 1.0 bar) | Check the pressure in the lubrication system. You can measure the pressure by connecting the pressure gauge to the oil line by typing the oil pressure sensor | Eliminate malfunctions in the lubrication system |

| Wear oil pump drive chain | Checking the tension of the chain after removing the palter pallet | Replace oil pump drive chain |

Strong engine vibration

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Uneven compression of cylinder compression more than 2.0 bar: no clearances in the valve drive, wear or damage to valves, saddles are not adjusted; wear, location or breakdown of piston rings | Check compression. Compression should be at least 11.0 bar | |

| Ommeter Check for a break or "breakdown" winding of the ignition coil and high-voltage wires | Replace the faulty ignition coil, damaged high-voltage wires. With severe operating conditions (salt on the roads, frost alternating with thaws), it is advisable to replace the wires every 3 - 5 years | |

| High-voltage wires are connected to the ignition coil in the wrong order; disconnected one or more wires | Inspection | Connect the wires according to the markings on the ignition coil |

| Check out the candles | Replace defective candles | |

| Open or closure in the windings of nozzles or their chains | Check the nozzle winding inlet and their chains | |

| Lost elasticity or collapsed supports of the power unit, weakened their mount | Inspection | Replace supports, tighten the mounts |

Increased content of harmful substances in exhaust gases

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Exact nozzles (overflow) or polluted their sprayers | Check the tightness and shape of the torch of the nozzles | Contaminated nozzles can be rinsed on a special booth. Lengthetic and strongly polluted nozzles replace |

| Damage to the isolation of high-voltage devices and chains - interruptions in sparking | To check high-voltage wires and ignition coils, replace them with obviously good | Replace the faulty ignition coil, damaged high-voltage wires. In severe operating conditions (salt on the roads, frost, alternating with thaws), it is advisable to replace once in 3-5 years |

| Defective spark plugs: current leakage on cracks in an insulator or by car on a thermal cone, poor contact of the central electrode | Check out the candles | Replace defective candles |

| Fortified air temperature sensor in the inlet pipe or its chain | Tester Check the function of the sensor | |

| Faulty coolant temperature sensor | Replace faulty sensor | |

| Check the correctness of the throttle position sensor | Restore contact in electrical circuits, replace the faulty sensor | |

| Faulty oxygen concentration sensor or its chain | Evaluate the performance of the oxygen concentration sensor and the reliability of its electrical caps with the help of diagnostic equipment | |

| The absolute air pressure sensor and its chain are faulty. | Check the health of the absolute air pressure sensor can be used using diagnostic equipment. | Restore contacts in electrical circuits. Replace faulty sensor |

| Faulty ECU or his chain | Restore contacts in electrical circuits. Replace defective EBU | |

| The leakage of the exhaust gas release system on the site between the outlet collector and the receiving pipe | Inspection with medium crankshaft revolutions | Replace the defective gasket, tighten the threaded connections. |

| Faulty catalytic displacement neutralizer | Check the health of the catalytic neutralizer of exhaust gases can be used using diagnostic equipment. | Replace the catalytic dishevement neutralizer |

| Increased pressure in the fuel system due to the malfunction of the pressure regulator | Inspection, check pressure gauge in the fuel system (no more than 3.5 bar) at idle | |

| Increased air flow resistance in the inlet tract | Check the element of the air filter, intake tract (no foreign objects, leaves, etc.) | Clean the intake tract, contaminated by the air filter element Replace |

| Most of the oil in the engine combustion chambers due to wear or damage to oil recovery caps, valve rods that guide valve sleeves, piston rings, pistons and cylinders | Inspection after engine disassembly | Repair the engine |

The clutch does not fully turn on (ranks)

| LED disk linings are very worn | Replace slave disk |

| Completion of flywheel, drive disc, friction linings | Rinse the slave and driven wheels White spirit or gasoline, wipe the working surfaces of the discs and flywheel. Eliminate the cause of grinding (replace the glands) |

| Breakdown of the slave disk | Replace slave disk |

| Faulty Diaphragm Spring Drive Disc |

The clutch does not turn off (leads)

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Air in the clutch shutdown hydraulic | Pump the clutch shutdown hydraulic |

| Dissue or slave disc | Replace slave disk |

| Wearing the petals of the diaphragm spring at the point of contact with the extrusion bearing | Replace the drive disc assembly |

| Showing the hub of the slave disk on the slots of the primary shaft of the gearbox | Inspect the slots, with a significant damage to the hub, replace the slave disk. In front of the assembly, apply on the slot shaft gearbox lubricant SHRUS-4 |

| The slave disk "glued" to the flywheel or the leading disk (after a long parking lot) | Set the stops under the wheels, turn on the first transmission and parking brake. Squeezing at the same time brake and clutch pedals, start the engine crankshaft starter |

The clutch pedal "fails" or is pressed very easily

Rods at Trogania

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Sweeping the working surfaces of the friction linings of the slave disk | Remove the slave and driven discs, rinse the White spirit or gasoline parts, wipe the working surfaces of the discs and flywheel. Eliminate the cause of the grinding (replace the gearbox or engine gland |

| Friction linings of the slave disk are very worn | Replace slave disk |

| Sediment or breakdown of springs of sprouts of steep oscillations, dismissed disk wear | Replace slave disk |

| Deformation of the slave disk | Replace slave disk |

| Loss of elasticity of the springs of the slave disk | Replace slave disk |

| Showing a slave disk on the shlits of the primary shaft of the gearbox, strong disk hub slots | With a strong wear of the hub slots, replace the slave disk. For the slots of the primary shaft of the gearbox, apply the lubricant Shrus-4 |

| Crapping Diaphragm Spring | Replace the drive disc assembly |

| Fortified Power Units Supports | Inspect the supports, replace faulty |

Noise when clutching or turning on the clutch

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Wear clutch pedals | Remove the pedal, replace its axis bushings |

| Strong sediment, breakdown springs of sprouts of vitrous oscillations | Replace slave disk |

| Weakening of fastening or breakdown of the closed disk friction linings | Replace slave disk |

| Strong wear or clutch shutdown bearing | Replace the bearing assembly with the working cylinder |

Noise in the gearbox (noise disappears when the clutch is turned off)

Noise in the gearbox (noise when moving on a certain transmission)

Transmissions are included with difficulty

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Faulty clutch | Do malfunction diagnostics withchains |

| Faulty (torn, grinded, stacked in the shell) the selection cable or gear shift cable | Replace faulty cable |

| Replace the mechanism | |

| Worn or damaged gear mechanism | |

| Synchronizers of gears are worn out | Repair or replace the gearbox |

Transmission spontaneously turn off

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Wanted gear shift mechanism | Repair or replace the gearbox |

| Worn or damaged gear control mechanism | To diagnose malfunction "Transmissions are included with difficulty" |

| Worn shorts gears gearbox gear synchronizers | Repair or replace the gearbox |

Oil leakage from box

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Worn primaries of the primary shaft, gear mechanism or wheel drive shafts | Replace defective gland |

| Oil leak through crankcase joints | Repair the gearbox |

| Oil leak through the reverse sensor and car speed sensor | Rear switch sensor Install on the sealant. Replace Rubber Speed \u200b\u200bSensor O-Rings |

Leakage of working fluid automatic gearbox

| Possible causes of malfunction | Troubleshooting |

|---|---|

| Liquid leak from the gearbox through the crankcase pallet seal | Liquid drums on the gearbox crankcase. Tighten the pallet mounting screws, replace the pallet laying |

| Leak fluid from under level pointer | Insert the pointer until you stop, if necessary, replace it |

| Leak fluids from fittings cooler tubes | Tighten the fittings |

The engine does not develop full power

The car does not have enough pickup. Rods and failures when driving

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Inspect the release system for the presence of rummed and damaged pipelines, check the condition of the catalytic neutralizer (backwards) (STO) | ||

| SUPPLICATION OF OUTHILITY IN THE INDUSTRATION | Inspect the joints, check the landing of the throttle node, the absolute pressure sensors and air temperature. For a short time, turn off the vacuum brake amplifier, shut down the fitting of the inlet pipeline | Replace strips, sealing rings, details with deformed flanges, faulty vacuum amplifier |

| Incomplete opening throttle | Determined visually on the engine stopped | Adjust the throttle drive |

| Low compression in engine cylinders (less than 11.0 bar): wear or damage to valves, their guide sleeves and saddles, occurring or breakdown of piston rings | Check compression | Replace faulty details |

| Gaps between candle electrodes do not correspond to the norm | Check the gaps | Pengetting the side electrode Install the desired clearance or replace the candles |

| Strong nagar on spark plug electrodes; Nagar particles enter the gap between the electrodes | Inspection | Check and, if necessary, replace the candles |

| Damage to the insulation of high-voltage devices and chains | Replace damaged ignition coil, high-voltage wires | |

| In the tank not enough fuel | On the level indicator and the fuel reserve alarm | Fuel frace |

| The fuel filter is clogged, the water has frozen in the system, fuel tubes are deformed | Check the pressure in the fuel system | Replace the fuel filter. In winter, place the car in a warm garage, blow fuel pipelines. Replace defective hoses and tubes |

| The fuel pump does not create the required pressure in the system | Check the pressure in the fuel system, make sure that the fuel module's mesh filter is clean | Clean the fuel module mesh filter. Faulty fuel pump, pressure regulator Replace |

| Bad contact in the supply chain of the fuel pump (including the masses "masses") | Checked Ommeter | Clean contacts, exhaust wire tips, replace faulty wires |

| Fortless nozzles or their chains | Check the nozzle winding module and their chains (no cloth and short circuit) | Replace faulty nozzles, secure contact in electrical circuits. |

| Fortified air temperature sensor or its chain | Check the sensor and its chain | Restore contact in electrical circuits, replace the faulty sensor |

| The absolute air pressure sensor or its chain is faulty | Assess the performance of the absolute air pressure sensor using diagnostic equipment for a hundred | Restore contact in electrical circuits, replace the faulty sensor |

| Restore damaged electrocups. Faulty sensor Replace | ||

| Faulty ECU or his chain | To check the ECU, replace it with knowingly serviceable | Replace defective EBU |

| Not adjusted gaps in the valve drive | ||

| Strong camshaft camshaft wear | Inspection when disassembling the engine for a hundred | Replace the worn camshaft per hundred |

| Sediment or damage valve springs | Inspection when disassembling the engine | |

| Fortified throttle position sensor or its chain | Check the throttle position sensor | Restore contact in electrical circuits, replace the faulty sensor |

| Faulty coolant temperature sensor | Check the sensor resistance tester at different temperatures | Restore contact in electrical circuits, replace the faulty sensor |

Cotton in the inlet pipeline

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Not adjusted gaps in the valve drive | Check the gaps in the valve drive | Adjust the gaps in the valve drive |

| Intake valves are seated in guide sleeves: resinous sediments on the surface of the valve rod or sleeves, precipitate or damage valve springs | Inspection when disassembling the engine (service station) | Repair the engine (service station) |

| Violated phases of gas distribution | Check the gas distribution phases | Set the correct interconnection of the crankshaft and distribution shafts. Check compression |

Shots in the muffler

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Not adjusted gaps in the valve drive | Check the gaps in the valve drive | Adjust the gaps in the valve drive |

| Exhaust valves are covered in sleeves: elevated wear of the valve rod or sleeves, precipitate or damage valve springs | Inspection when disassembling the engine | Repair the engine at a hundred |

| Violated phases of gas distribution | Check the gas distribution phases | Set the correct set of shafts. Check compression |

| Candles are checked at a special stand (ST). The absence of external damage and sparking between the electrodes on the twisted candle does not allow to conclude its performance | Replace the candles | |

| Damage to the isolation of high-voltage devices and chains - interruptions in sparking | Ommeter Check for a breakdown or "breakdown" (closure on "mass") winding of the ignition coil, high-voltage wires | Replace the faulty ignition coil, damaged high-voltage wires (disconnecting the wire, pull for its tip). In severe operating conditions, it is desirable to replace the wires every 3-5 years. |

| Faulty nozzle | Check the operation of the nozzles |

Elevated oil consumption (more than 500 g per 1000 km run)

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Leak oils through: seals of the crankshaft and distribution shafts; Carter pallet gaskets, cylinder head; oil pressure sensor; O-ring oil filter | Wash the engine, then after a short run, inspect the place of possible leakage | Tighten the cylinder head fastening elements, cylinder head cover, crankcase pallet, replace worn glands and gaskets |

| Wear, loss of elasticity of oil recovery caps (valve oil seals). Wire of valve rods, guide bushings | Inspection of parts when disassembling the engine | Replace worn items |

| Wear, breakage or clogging (loss of mobility) piston rings. Wear pistons, cylinders | Inspection and promoter details after engine disassembly | Replace worn pistons and rings. Spread and chonint cylinders |

| The use of oil inappropriate viscosity | - | Replace oil |

| Carter ventilation system clogged | Inspection | Clean the ventilation system |

Increased fuel consumption

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Blank air filter element | Check the condition of the replaceable element of the air filter | Flow or replace the replaceable air filter element |

| Unegredity of the system | Smell of gasoline, fuel flow | Check the tightness of the compounds of the fuel system elements; When a malfunction is detected, replace the corresponding nodes |

| Faulty spark plugs: current leakage on cracks in an insulator or by car on a thermal cone, poor contact of the central electrode | Candles are checked on a special stand on a hundred. The absence of external damage and sparking between the electrodes on the twisted candle does not allow to conclude its performance | Replace the candles |

| Throttle Drive Malfunction | Check the stroke of the "gas" pedal, the gap in the drive (free pedal stroke), make sure that the cable and pedal are missing | Replace faulty parts, lubricate with engine oil |

| Fortified idling regulator or its chain | Replace the controller knowingly | Replace faulty regulator |

| The throttle is not completely closed | The slope is visible to the gap between the throttle valve and the walls of the case | Replace throttle knot |

| Increased pressure in the fuel line due to the malfunction of the pressure regulator | Check the pressure gauge in the fuel system (no more than 3.5 bar) | Replace faulty regulator |

| Leakage of nozzles | Check the nozzle | Replace faulty nozzles |

| Faulty coolant temperature sensor or its chain | Check the sensor resistance to the ommeter at different temperatures. | Restore contact in electrical circuits, replace the faulty sensor |

| Faulty oxygen concentration sensor | Evaluate the performance of the oxygen concentration sensor and the reliability of the connections of its electrical caps using diagnostic equipment to a hundred | Restore damaged electrocups, replace faulty sensor |

| Faulty ECU or his chain | To check, replace the ECU obviously good | Replace faulty ECU, restore damaged electrocups |

| Low compression in the engine cylinders (less than 11.0 bar): the gaps in the drive, wear or damage to the valves, their guide sleeves and saddles, lounge or breakdown of piston rings | Check compression | Adjust the gaps in the valve drive. Replace faulty details |

| Fortified throttle position sensor, absolute pressure and air temperature sensors in the inlet pipe or their chain | Check sensors and their chains | Restore contact in electrical circuits, replace the faulty sensor (sensors) |

| Increased resistance to the movement of gases in the exhaust gas production system | Inspect the exhaust gas output system for rummed and damaged pipes, check the condition of the catalytic neutralizer | Replace damaged elements of the exhaust gas release system |

| Faults of the chassis and brake system | Check the chassis and brake system | Adjust wheel installation angles, replace faulty chassis parts, troubleshoot the brake system |

The detonation of the engine (high-tone metal stuffs, arising, as a rule, when the engine is loaded under load, especially on low revs, for example, the dispersal of "sweat" and T. P., and disappearing when the load is reduced)

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| - | ||

| Engine overheating | By coolant temperature pointer | Eliminate the cause of overheating ( "The engine gets very hot") |

| Inspection after removing the head of the cylinder block | Eliminate the cause of the nagar formation ( To diagnose malfunction "Increased fuel consumption" ,"Elevated oil consumption"). Apply recommended viscosity oils and, if possible with low ash | |

| Ignition candles are used with inappropriate caliling | - | Use the candles recommended by the manufacturer |

Insufficient oil pressure (insufficient oil pressure warning

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Little oil in the engine | On the oil level pointer | Freight oil |

| Oil filter faulty | Replace the filter is obviously good | Replace faulty oil filter |

| Weakened tightening bolt mounting pulley drive auxiliary aggregates | Check the tightening of the bolt | Town Bolt Prescribed Moment |

| Clogging of the grid of the oil worker | Inspection | Clean the grid |

| Skot, clogging of the oil pump reduction valve or attenuation of the valve spring | Inspection when disassembling the oil pump | Clean or replace the faulty reducing valve. Replace the pump |

| Wear of the gear oil pump | Replace the oil pump | |

| Excessive gap between bearing liners and crankshaft necks | Determined by the measurement of parts after disassembling the oil pump (per service station) | Replace worn liners. If necessary, replace or repair the crankshaft |

| Faulty oil pressure sensor faulty | Turn the sensor of insufficient oil pressure from the hole of the cylinder head and install a well-serviceable sensor instead. If at the same time the alarm will go out during engine operation, the sensor turned out is faulty | Replace faulty oil pressure sensor |

The engine overheats (engine overheating alarm

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Faulty thermostat | Check the thermostat service | Replace faulty thermostat |

| Insufficient amount of coolant | The fluid level is below the MIN mark on the expansion tank | Eliminate leaks. Follow the coolant |

| Many scale in the cooling system | - | Rinse the cooling system to remove scale. Do not use rigid water in the cooling system. Concentrated antifreeze Divide only distilled water |

| Cells of radiator are contaminated | Inspection | Rinse the radiator of water under pressure |

| Faulty coolant pump | Remove the pump and inspect the node | Replace the pump assembly |

| The cooling system fan does not turn on | Check the fan power circuits | Restore contact in electrical circuits. Faulty fuse, relay, cooling system fan, temperature sensor, ECU - replace |

| Unacceptable low octane number of gasoline | - | Place the car with fuel recommended by the manufacturer |

| Many Nagar in combustion chambers, on the bottoms of the pistons, valve plates | Inspection after removing the head of the engine cylinders | Eliminate the cause of the nagar formation (see "Increased fuel consumption" ,"Elevated oil consumption"). Use the oil of the recommended viscosity and, if possible with low ash |

| Breakthrough of exhaust gases into the cooling system through a damaged cylinder head gasket | In the expansion tank there is a smell of exhaust gases and bubbles pop up | Replace the cylinder head laying. Check the non-blocks of the head of the cylinder block |

Constantly running engine cooling system fan (Even on a cold engine)

| List of possible faults | Diagnostics | Elimination methods |

|---|---|---|

| Open in the coolant temperature sensor or its chain | Sensor and chains are checked by an ohmmeter | Restore contact in electrical circuits. Replace faulty sensor |

| Do not open the contacts of the fan switching relay | Check tester | Replace faulty relay |

| Faulty ECU or his chain | Check the computer or replace knowingly | Replace defective EBU |