There are two types of brake testing - complete and reduced. In addition, for freight trains, an inspection of auto brakes at stations and tracks has been established.

When fully testing the automatic brakes, they check the technical condition of the braking equipment, the density and integrity of the brake line, the action of the brakes on all cars, count the pressure brake pads on the train and the number of hand brakes.

With a short test, the condition of the brake line is checked by the action of the brake of two tail cars.

Full testing is carried out from a station compressor unit or a locomotive, an abbreviated one - only from a locomotive.

Complete testing of automatic brakes for freight and passenger-and-freight trains.

Before starting a full testing of automatic brakes, charge the TM, check the integrity of the train brake line and make sure that the compressed air passes through it freely. To do this, the inspector of the tail carriages of the train through park communication or radio communication is obliged through the inspector of the head of the train to notify the locomotive driver about the start of the check, and then, observing safety precautions, open the last end valve of the tail car and after 5-7 seconds close it.

After the locomotive automatic brakes are triggered, determined by the lighting of the TM lamp of the signaling device No. 418, the driver must stretch the speedometer tape to perform the braking stage by reducing the pressure in the equalizing tank by 0.5-0.6 kgf / cm 2, if the TM lamp lights up and goes out, then no additional pressure reduction is required. Then, after 5-7 seconds, leave and recharge the brake network of the train and report the results of the check to the inspector of the carriages of the head of the train.

After fully charging the brake network of the train to the set pressure, the driver and inspector are obliged to check the tightness of the brake line of the train. To do this, after turning off the compressors by the regulator when the maximum pressure in the main reservoirs of the locomotive is reached (on steam locomotives by closing the steam exhaust valve of the pump) and the subsequent decrease in this pressure by 0.4-0.5 kgf / cm 2, measure the time for its further decrease by 0.5 kgf / cm 2 with the train position of the operator's crane handle.

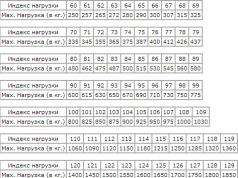

For trains with locomotives in the head, the shortest permissible pressure drop time when checking the density of the brake network, depending on the series of locomotives, the length of the train and the volume of the main tanks, is shown in Table 9.1. of this manual.

Table 9.1.

Time of pressure decrease by 0.5 kgf / cm 2 in the main tanks when checking the density of the train braking network

| Locomotive series | Time (in seconds), with the length of the train in the axles | ||||||||

| Up to 100 | 101-150 | 151-200 | 201-250 | 251-300 | 301-350 | 351-400 | 401-450 | 451-5000 | |

| TE10, TG-106, TGM3, TGM5, TEM1, TEM2, ChME2, ChME3, FD, LV, L, S, TE, E (all indices), E (all indices) | |||||||||

| VL60 (all indices), TE1, M62 | |||||||||

| VL8, T2, VL10 (from No. 19), VL11 | |||||||||

| VL80 (all indices), VL82 | |||||||||

| VL10 (No. 1 - 18), 2TE10, 2TE116, TE3, TG16, TG20, TG102, VL11m, VL85 | |||||||||

| VL15, 2TE10u |

Note to table 9.1:

1. The time of pressure reduction in the main tanks for locomotives of the series not indicated in the table, as well as in the tanks of the PTO consoles, should be taken according to the locomotive graph with the corresponding volume of the main tanks.

2. When working on a system of many units, when the main tanks are connected in one volume, the specified time increase in proportion to the change in the volumes of the main tanks.

3. When checking the density of the braking network of a freight train with an increased charging pressure of 6.0-6.2 kgf / cm 2, the time rate decreases by 20%, with a charging pressure of 4.8-5.2 kgf / cm 2 it increases by 10% ...

On freight trains equipped with a TM density device, check the density according to the indication of this device.

With a train length of more than 200 axles, the car inspector is obliged to measure the charging pressure in the tail car line using a pressure gauge installed on the head of the connecting sleeve of the last car and make sure that the charging pressure is not less than that set in clause 9.2.6. of this manual.

After the completion of the above operations and full charging of the TM, at the signal of the inspector of the tail section of the train, the inspector of the head of the train gives the driver a signal to check the operation of the automatic brakes. To do this, it is necessary to transfer the operator's crane handle from the train position to the V position and reduce the pressure in the surge tank by 0.6-0.7 kgf / cm 2, followed by transfer to the IV position (overlapping with the power supply), and then stretch the speed meter tape by 5- 10 mm.

Upon the expiration of 2 minutes after the braking has been performed, the car inspector is obliged to check the condition and operation of the brakes throughout the train for each car and make sure they are normal work for braking on the output of the brake cylinder rod and pressing the pads to the rolling surface of the wheels, and the driver must check the density of the TM, which should not differ from the density in the train position of the driver's crane handle by more than 10% downward. Otherwise, car inspectors need to eliminate air leakage through the BP, brake cylinders or auto modes.

During braking, the inspector of the tail section of the train measures the value of the output of the brake cylinder rod of the tail car, writes down the number of the tail car, and transfers this data to the inspector of the head of the train with his signature in the certificate f. VU-45.

On trains with a length of up to 350 axles, upon completion of the check of the braking action, at the signal of the inspector, release the automatic brakes by moving the operator's crane handle to the train position. In freight trains of increased length (more than 350 axles), the release of automatic brakes is carried out by setting the RKM in position I with holding in it until the pressure in the equalizing tank is 0.5-0.6 kgf / cm 2 higher than the charging one, followed by transfer to the train position.

Car inspectors are obliged to check the release of the brakes at each car of the train for the departure of the brake cylinder rod and the departure of the brake pads from the wheels. If BPs who have not worked on vacation are identified, it is not allowed to make their vacation manually until the reasons for not being released are clarified. All identified malfunctions braking equipment the wagons must be fitted and the brakes on these wagons retested with an abbreviated brake test.

9.2.5. Full testing of the automatic brakes of a freight train before long descents with a steepness of 0.018 and more is produced from the charging pressure in the TM according to Table 3.2. or paragraph 3.2.6. of this Instruction with holding in a braked state for 10 minutes and checking (before testing) the integrity of the TM of the entire train in accordance with clauses 9.2.3., 9.2.4. of this Instruction, as well as by measuring the charging pressure in the main line of the tail car of a freight train using a pressure gauge installed on the head of the connecting sleeve of the last car. Measure the pressure in the main line of the tail car of the train after fully charging the brake network of the entire train. By means of the specified measurement, the inspector of the tail group cars is obliged to make sure that the charging pressure is not less than that set in clause 9.2.6. of this manual. During a ten-minute hold in the braked position, no brake should spontaneously release. Otherwise, the malfunctions in the cars must be eliminated and the action of the automatic brakes on these cars again checked with an abbreviated brake test.

9.2.6. After the end of the full testing of automatic brakes on the train and the message of the inspector of the tail section (operator) via park communication or portable radio communication about the release of the brakes of all cars, the inspector of the head section is obliged to give the driver of the leading locomotive a certificate f. VU-45 on the provision of the train with brakes and their serviceable operation, and after testing with exposure for 10 minutes before long descents, make a note in the certificate about the brake testing performed.

In the issued certificate for all types of trains with locomotive traction, data on the required and actual calculated pressure of the pads, the number of hand brakes in the axles to hold freight, cargo-passenger and post-baggage trains in place and the presence of hand brake axles in these trains, the number of the tail car are indicated , the value of the exit of the brake cylinder rod of the tail car, the number (in percent) in the train of composite pads, the time of delivery of the certificate and the number of the car, which the inspectors met when testing the brakes, data on the density of the train brake network, the values of the charging pressure in the TM of the tail car in trains more than 200 axles in length, signatures of inspectors of the tail and head group of cars.

Help f. VU-45 for freight trains with a length of more than 200 axles, as well as after testing before long descents with a steepness of 0.018 and more, indicate the value of the charging pressure in the tail carriage line. With a charging pressure in TM on a freight train locomotive of 4.8-5.2 kgf / cm 2 or 5.3-5.5 kgf / cm 2, the pressure in the brake line of the tail car must be at least 4.0 kgf / cm 2, respectively and 4.5 kgf / cm 2, and at a charging pressure of 6.0-6.2 kgf / cm 2 - not less than 5.0 kgf / cm 2. With the charging pressure in the TM of a loaded cargo train of 5.0-5.2 kgf / cm 2, the pressure in the TM of the tail car should be at least 4.5 kgf / cm 2 with the number of axles up to 200 and at least 4.5 kgf / cm 2 if the number of axles is more than 200 4.0 kgf / cm 2.

The driver, having received the certificate, is obliged to make sure that the data on the train brakes indicated in it comply with the standards established by the UZ, the requirements of this Instruction; familiarize your assistant with the help. When traveling with a train with double or multiple traction, the drivers of all locomotives must personally familiarize themselves with the data specified in the VU-45 certificate before departure. Before the departure of a passenger train, the locomotive of which is equipped with a redundant power supply of wires No. 1 and No. 2 EPT, turn on this toggle switch.

Reduced brake testing

9.3.1. Abbreviated testing of brakes with checking the condition of the brake line by the action of the brake of two tail carriages in trains is carried out:

After the train locomotive was coupled to the train, if a complete testing of the automatic brakes from the compressor unit (station network) or the locomotive was carried out at the station beforehand;

After the change locomotive crews when the locomotive is not disconnected from the train;

After any disconnection of the sleeves in the train or between the train and the locomotive (except for disconnecting the pushing locomotive included in the brake line), connecting the sleeves due to the coupling of the rolling stock, and also after closing the end crane in the train:

V passenger trains: after a stop for more than 20 minutes, when the pressure in the main tanks drops below the charging pressure of the TM, when changing the control cabin or after transferring control to the driver of the second locomotive on the stretch after stopping the train due to the impossibility of further control of the train movement from the main cabin;

On freight trains, if the brakes were spontaneously activated or the density changed by more than 20% of the specified brake certificate f. VU-45;

On freight trains after a stop for more than 30 minutes.

When freight trains are parked for more than 30 minutes on the tracks, as well as at sidings, passing points and stations where there are no car inspectors or workers trained in performing operations for testing auto brakes (the list of positions is indicated by the head of the road), the auto brakes must be checked in accordance with cl. 9.4.1. of this manual.

If, when checking the density of TM, the driver discovers its change by more than 20% from the specified certificate f. VU-45, perform abbreviated brake testing:

If on a locomotive that has a signaling device No. 418, the signal lamp "TM" lights up in the parking lot, check the serviceability of the signaling device by the braking stage, at which the lamp "TM" should go out. After making sure of the normal operation of the signaling device, make a short test of the automatic brakes:

At stations where there are full-time car inspectors, reduced testing is carried out by these inspectors at the request of the driver, and in the absence of inspectors, by a locomotive crew or workers trained to perform an operation to test automatic brakes.

Abbreviated testing of electro-pneumatic brakes is carried out at the points of change of the locomotive and locomotive crews according to the action of the brake of two tail cars and when hitching cars with checking the action of the brakes in each coupled car:

9.3.2. On passenger trains, short testing is performed first with electro-pneumatic brakes and then with auto brakes. EPT testing is carried out in a manner similar to their complete testing from a locomotive in accordance with clause 9.2.3. without checking the voltage of the EPT in the tail car and without turning off the toggle switch of the EPT power circuit during the period of checking its release, taking into account clause 9.3.1. of this Instruction for the action of the brakes of the two tail carriages.

9.3.3. When performing an abbreviated test, at the signal of the employee who is responsible for testing the brakes, “Apply braking”, the driver must blow one short signal with a whistle and reduce the pressure in the surge tank by the value set for full testing.

After checking the actuation of the brakes of the two tail carriages, the signal "Release the brakes" is sent to braking. At this signal, the driver whistles two short signals and releases the brakes with the driver's crane handle in position I in passenger trains with an increase in pressure in the equalizing tank to 5.0-5.2 kgf / cm 2, and in a freight and passenger train until receiving the pressure in the equalizing tank is 0.5 kgf / cm 2 higher than the charging pressure with the handle moving to the train position. If an abbreviated testing of brakes on trains is carried out after full testing from a compressor installation (station network), car inspectors and the driver are obliged to check the density of the train's brake network and the integrity of the TM before testing in accordance with clauses 9.2.3., 9.2.4. of this Instruction, and if the length of the freight train is more than 200 axles, the wagon inspector is obliged to check the charging pressure in the main line of the last wagon in the manner prescribed by clause 9.2.4. After the end of such testing, the driver is handed a certificate f. VU-45, as in full testing.

9.3.4. When attaching a car or a group of cars to a train that has arrived, an abbreviated test of the brakes is carried out with a mandatory check of their operation for each car to be coupled and the density of the brake line of the train, and in a freight train, in addition, check the integrity of the TM of the train. At each reduced testing of auto brakes, the inspector of carriages, and where this position is not provided, the station attendant, chief conductor, train builder or employees who are entrusted with the responsibility to test the brakes, make a note about the reduced testing of auto brakes (with a note about the change in the composition of the train, indicating the number of the tail car) in the certificate f. VU-45, which the driver has. In the event of a change in the density of TM due to the hitching (uncoupling) of cars, the driver enters new data on the density of the braking network in the certificate f. VU-45.

If the abbreviated testing of the brakes of a passenger train was carried out with the involvement of the chief (mechanic-foreman) of the train and the conductors of the carriages, then the chief (mechanic-foreman) must make a note on the performance of abbreviated testing of the brakes in the certificate f. VU-45, which the driver has.

9.3.5. At stations where the position of a car inspector is not provided, the operation of the tail car brakes in passenger trains is checked by the conductors of the carriages, in freight trains - by workers trained in performing operations for testing auto brakes (the list of positions is established by the head of the road).

9.3.6. It is prohibited to send a train to the haul without performing an abbreviated test or with inoperative brakes for two tail cars.

If during testing, air diffusers that did not operate on release are identified, it is not allowed to release them manually until the reasons for the non-release are clarified. In these cases, it is necessary to check whether there are any closed end cranes on the train, especially in those places where cars were coupled or uncoupled, to re-test the brakes again. Replace defective air distributors, and at intermediate stations, turn them off and release air through Exhaust valve, make a note about this in the VU-45 help.

Checking auto brakes on freight trains

9.4.1. On freight trains, the brakes are checked:

After transferring control to the driver of the second locomotive;

When changing the cab on the stretch after stopping the train due to the impossibility of further control from the head cabin of the locomotive;

When the pressure in the main tank drops below the charging TM;

When attaching an additional locomotive to the head of a freight train to follow one or more hauls and after uncoupling this locomotive;

After parking for more than 30 minutes (in the cases provided for in paragraph 9.3.1.), Carry out the next check of the automatic brakes.

The driver, after restoring the charging pressure, check the density of the brake network at the II position of the RKM, which should not differ from the density indicated in the certificate f. VU-45 by more than 20% in the direction of decreasing or increasing (when the volume of the main tanks changes due to the transfer of control to the driver of the second locomotive, change this rate in proportion to the volume of the main tanks). After making sure that the density of the brake network has not changed more than the specified value, the driver must perform a braking stage by reducing the pressure in the SD by 0.6-0.7 kgf / cm 2 and release the brakes. The driver's assistant must check the effect of the brakes on the braking and release of cars at the head of the train, the number of which is indicated in local instructions depending on the weight of the train and the profile of the section.

If, when checking the density of the brake line, the driver detects a change of more than 20% from the value indicated in the certificate f. VU-45, then perform an abbreviated brake test. If on a locomotive equipped with signaling device No. 418, the signal lamp "TM" lights up in the parking lot, then it is necessary to check the serviceability of the signaling device by the braking stage, at which the lamp "TM" should go out. After making sure that the indicator is in good working order, carry out a short test of the brakes.

At a station where there are full-time car inspectors, reduced testing of brakes is carried out by inspectors at the request of the driver, and where this position is not provided by a locomotive crew or conductors who are trained to perform operations for testing auto brakes (the list of positions is established by the head of the road).

9.4.2. If there is a pushing locomotive in the tail of the freight train, which is included in the common brake line of the train, and the radio communication is working properly, the density check in this case is not checked, and the braking and release of the brakes are not performed. The driver of the pushing locomotive monitors the condition of the train's brake line and the free passage of compressed air along it according to the brake line pressure gauge and triggering of the signaling device No. 418. The density of the TM is not checked, as well as braking and release of automatic brakes are not performed.

To check the action of the brakes, and also to make sure that the brake lines of all cars are included in the brake network of the train, perform a brake test.

There are two types of testing of automatic brakes: complete andabbreviated ... In addition, for freight trains, an inspection of auto brakes at stations and tracks has been established.

When the brakes are fully tested check the technical condition of the braking equipment, the density and integrity of the braking network, the action of the brakes on all cars, - the pressure of the brake pads in the train and the number of hand brakes are counted.

With reduced sampling the condition of the brake line is checked by the action of the brakes of the two tail carriages, which confirms the passage of compressed air along the entire brake line, and in multi-unit trains by the action of the tail car brake.

Complete brake testing produced from stationary devices or a train locomotive, abbreviated - only from the locomotive.

When testing automatic brakes on a train, the locomotive brakes are controlled by the driver, and from the stationary compressor unit - by the employee who is entrusted with testing the automatic brakes (car inspector, central console operator, passenger carriage conductor),

The operation of the brakes on the train and the correctness of their activation are checked by an automatic inspector or a car inspector. After that, they draw up and issue to the driver a certificate of the VU-45 form about the provision of the train with brakes and their serviceable operation. The certificate of the VU-45 form is drawn up as a carbon copy in two copies. The original of the certificate is handed over to the locomotive driver, and a copy is kept in the book of these certificates for seven days by the official who tested the brakes.

The driver must keep the certificate of the VU-45 form until the end of the trip and, upon arrival at the depot, hand it in along with the speed meter tape. If a change of locomotive crews is made without uncoupling the locomotive, then the changing driver is obliged to hand over his certificate of brakes to the driver who received the locomotive. The last on the speed meter tape, which is removed by the changing driver, makes a note: “I received a certificate of the VU-45 form for train No. depot ".

The tightness of the braking network from the locomotive should be checked by the driver and the inspector of the cars during full testing of automatic brakes and an abbreviated test if it is performed after full testing from a stationary compressor unit. In case of reduced testing of automatic brakes in other cases, the presence of a car inspector when checking the density is not required.

Full testing of automatic brakes on trains is carried out(p.52. Appendix 6 PTE):

- at the stations of formation before the departure of the train;

- after changing the locomotive;

- at stations dividing adjacent guaranteed sections of freight trains, during maintenance of the train without changing the locomotive;

- before the release of the multi-unit train from the depot or after it has been left without a brigade at the station;

- at stations preceding the runs with long descents, where the train stops are provided for by the schedule (before long descents, 0.018 and steeper, full testing is carried out with a ten-minute holding in a braked state);

- on the tracks n / a in the points of technical maintenance of specialized trains (at least 1 time per day) with a ten-minute holding in a braked state and when changing locomotive crews at opencast mining enterprises

Abbreviated testing of automatic brakes on trains is carried out(p.52. Appendix 6 PTE):

- after the train locomotive has been coupled to the train, if a complete testing of the automatic brakes from a stationary device or a locomotive has been carried out at the station beforehand;

- when changing the direction of movement from head to tail, if not changing the locomotive;

- after changing the control cabin of the motor-carriage train and after changing the locomotive crews, when the locomotive is not disconnected from the train;

- after any disconnection of the sleeves in the train, closing the end valve in the train, after connecting the sleeves due to the coupling of the rolling stock (with checking the action of the brake on each connected car);

- in passenger trains after the train has stopped for more than 20 minutes, when the pressure in the main tanks drops below 5.5 kgf / cm 2, when changing the control cabin or after transferring control to the driver of the second locomotive on the stretch after stopping the train due to the impossibility of further controlling the movement of the train from the head cockpit;

- on freight trains, if during the train stop there was a spontaneous actuation of automatic brakes or a change in density by more than 20% of the VU-45 form indicated in the certificate;

- in freight trains after a train stop for more than 30 minutes, where there are car inspectors or workers trained in performing operations for testing automatic brakes and who are assigned this responsibility.

In the event that the brakes of the two tail carriages do not work during the reduced testing of auto brakes, the employee who is entrusted with testing the auto brakes is obliged to take measures to prevent the train from leaving.

It is forbidden to install wagons in the train, in which the braking equipment has at least one of the following faults: faulty air distributor, electric air distributor (in a passenger train), brake cylinder, reservoir; damage to air ducts - cracks, abrasions and delamination of connecting hoses, cracks, breaks and dents on air ducts, looseness of their connections, weakening of the pipeline at the attachment points; malfunction of the mechanical part - traverse, levers, rods, suspensions, auto-adjuster linkage, shoes; cracks or fractures in parts; improper fastening of the pads in the shoe; faulty hand brake; loosening of fastening of parts; unadjusted linkage and many others.

When the brakes are fully tested, the technical condition of the braking equipment of all cars is checked.

Full testing of automatic brakes is carried out from a stationary compressor unit or a locomotive. When testing automatic brakes on a train, the brakes are controlled from the locomotive by the driver, and from the stationary compressor unit - by the car inspector or operator. The operation of the brakes in the train and the correctness of their activation are checked by the inspectors of the carriages. At intermediate stations or sidings where there are no regular car inspectors, full testing of auto brakes on trains is carried out by inspectors sent from the nearest service stations, or workers specially assigned for these purposes by order of the head of the road.

Complete testing of automatic brakes on trains is carried out by:

- at formation stations before train departure;

- after changing the locomotive;

- at stations dividing adjacent guaranteed sections of freight trains during maintenance of the train without changing the locomotive;

- before the release of the multi-unit train from the depot or after it has been left without a brigade at the station;

- at stations preceding the runs with long descents, where the train stops are stipulated by the schedule (before long descents, 0.018 and steeper, full testing is carried out with a ten-minute holding in a braked state).

Complete testing of passenger train automatic brakes.

Before carrying out a full brake test, check the integrity of the train brake line and make sure that compressed air passes through it. For this, the inspector of the tail group cars is obliged to notify the driver about the start of the inspection and open the tail end carriage end valve. After triggering accelerators emergency braking close the end valve of the carriages. When the locomotive's automatic brakes are triggered, the driver must stretch the speedometer tape and perform a braking stage of 0.5 - 0.6 kgf / cm2. At the end of the release of air from the brake line through the driver's crane, release the auto brakes and charge the brake network of the train. The driver must report the result of the check to the inspector of the carriages of the head group.

Check the density of the brake network after charging it to the set pressure. To check, it is necessary to turn off the combined valve and, after 20 seconds, measure the rate of pressure drop in the brake line, which should be no more than 0.2 kgf / cm2 per minute.

Check the operation of the electro-pneumatic brakes, Switch on the power supply - the signal lamp "O" should light up. At the signal of the car inspector, perform the braking stage by setting the driver's crane handle to the VA position until the pressure in the brake cylinders of the locomotive is 1.0-1.5 kgf / cm2, and then move the crane handle to position IV. In braking mode, the power supply voltage must be at least 40 V, and the "T" lamp must light up on the warning light. When the crane handle is moved to the overlap position, this lamp should go out, and the "P" lamp should light up. Inspectors are required to check the operation of the electro-pneumatic brakes throughout the train.

At the signal of the inspector to release the brakes, the driver must turn off the power to the electro-pneumatic brakes, leaving the driver's crane handle in the overlapped position. After 15 seconds, turn on the toggle switch of the EPT electric power supply.

Car inspectors must check the release of brakes on all cars and inform the driver about the end of the check. The driver is obliged to move the driver's crane handle to the train position, charge the train's brake network and turn off the EPT power supply.

After full testing of the EPT and full charging of the brake network, the operation of the automatic brakes is checked. To check the automatic brakes for sensitivity to braking, perform a braking step of 0.5 - 0.6 kgf / cm2, followed by the transfer of the driver's crane handle to the position of overlapping with power supply. Not earlier than 2 minutes after braking, the inspectors are obliged to check the action of the brakes on each car by the exit of the brake cylinder rod and the pressing of the pads to the wheels.

At the end of the braking action check, release the brakes by moving the operator's crane handle to the train position. Car inspectors must check the release of the brakes at each car for the brake cylinder rod leaving and the shoes moving away from the wheels.

Complete testing of automatic brakes for freight and freight-passenger trains.

Before starting a full testing of automatic brakes, check the integrity of the train brake line. For this, at the command of the head group car inspector, the second inspector opens the last end valve of the tail car and closes it after 8-10 seconds. After the locomotive's automatic brakes are triggered, the driver is obliged to stretch the speedometer tape, and then, after at least 2 minutes, perform a braking stage of 0.5 - 0.6 kgf / cm2, followed by moving the driver's crane handle to position IV and report the result of the check to the inspector of the carriages of the head group ... At the end of the check in trains with up to 100 axles, release the brakes by overestimating the pressure in the equalizing tank by 0.5 kgf / cm2 higher than the charging pressure by setting the valve handle to position I, followed by moving the handle to the train position. In trains with a length of more than 100 axles, the brakes are released in the same manner, but at the signal of the car inspector, who is obliged to measure the brake release time of the last two cars in the train.

After charging the brake network of the train to the set pressure, the driver and inspector of the carriages must check the tightness of the brake network. To do this, after turning off the compressors and reducing the pressure in the main tanks of the locomotive by 0.5 kgf / cm2, measure the time for a further decrease in pressure in the main tanks by 0.5 kgf / cm2. This time should not be less than that indicated in the table at a charging pressure in the brake line of 5.0 - 5.2 kgf / cm2. If the charging pressure in the brake line is 5.3 - 5.5 kgf / cm2, then the indicated time rates should be reduced by 10%, and at a charging pressure of 5.6 - 5.8 kgf / cm2 - reduced by 20%.

Time of pressure reduction by 0.5 kgf / cm2 in the main tanks

when checking the density of the brake network of the train

On all freight trains, the wagon inspector is obliged to measure the charging pressure in the tail wagon line and make sure that the charging pressure is not less than that specified in the following table.

Minimum pressure in the main line of the tail car of a freight train

Then, the sensitivity of the air distributors to braking is checked: at the signal of the car inspector, the driver sets the driver's crane handle to the fifth position and reduces the pressure in the equalizing tank by 0.6 - 0.7 kgf / cm2 with its subsequent transfer to the IV position. After 2 min. after braking, the inspectors check the actuation of the brakes for each car by the exit of the brake cylinder rod and the pressing of the pads to the wheels. The locomotive driver at this time once again (with the IV position of the driver's crane handle) checks the density of the brake network, which should not differ from the density with the train position of the driver's crane handle by more than 10% downward.

At the signal of the car inspector, release the automatic brakes: in trains with up to 350 axles, the driver moves the crane handle to the train position; in trains with a length of more than 350 axles, the driver's crane handle is set to the first position and the pressure in the equalizing tank is overestimated by 0.5-0.6 kgf / cm2 more than the charging one, and then transferred to the train position. Car inspectors should check the release of the brakes for each car in the train for the brake cylinder rod leaving and the departure of the shoes from the wheels. If wagons with a brake that have not been released are identified, it is not allowed to release them manually until the reasons for the non-release are clarified. Identified faulty air distributors must be replaced with serviceable ones. After that, the action of the brakes on cars with replaced air distributors is again checked.

At the end of the testing, the driver is given a certificate of the VU-45 form about the provision of the train with brakes.

Full testing of automatic brakes before long descents with a steepness of 0.018 and more is carried out with holding in the braked state for 10 minutes. During this time, no air distributor should release spontaneously.

The procedure for full testing of auto brakes in a freight train by one inspector.

After attaching the locomotive to the train and charging the brake line, the inspector of the cars, together with the driver, check the tightness of the brake line of the train. Then, at the command of the car inspector, the driver performs the braking stage set for complete testing of the brakes, and the inspector walks along the train from head to tail to check the operation of the automatic brakes. The driver at this time is obliged to check the tightness of the brake line at the IV position of the driver's crane handle.Having reached the tail of the train, the car inspector gives the signal to release the brakes. After releasing the brakes and recharging the brake network of the train, the car inspector measures the pressure in the brake line of the tail car. Observing precautions, the inspector opens the end valve of the tail car for 8-10 seconds in a freight or cargo-passenger train, and in a passenger train until the emergency braking accelerators of the air distributors are triggered.

The car inspector must measure and record in the certificate of the VU-45 form the brake cylinder rod outlet, the number of the tail car and the charging pressure in the brake line of the last car (in freight trains).

When the locomotive brakes are triggered, which is determined by the lighting of the "TM" lamp of the brake line break alarm with sensor No. 418, the pressure drop in the brake line or the specific noise of the driver's crane supplying the brake line leak, the driver must stretch the speed meter tape, after which, after at least 2 minutes. (in freight and freight-passenger trains) perform the braking stage by reducing the pressure in the equalizing tank by 0.5 - 0.6 kgf / cm2 and after the end of the air release from the brake line through the driver's crane, release and charge the train brake network. On a train with a length of more than 100 axles, a car inspector must measure the maximum brake release time for the last two cars in the train. In the absence of radio communication, the car inspector measures the time from the moment the tail car end valve is opened to the start of the brake cylinder rods leaving and the brake pads leaving the rolling surface of the wheels. The locomotive driver measures the time from the moment the locomotive's automatic brakes are triggered, determined by the lighting of the TM lamp of the signaling device No. 418, until the moment the driver's crane handle is put in the first position. The driver informs the car inspector of this time, who subtracts it from the time measured at the tail of the train, and the result is entered into the certificate of the VU-45 form (such a procedure for measuring the release time of the tail car brakes in the absence of radio communication is established on the Oktyabrskaya road). In a train with up to 100 axles (inclusive), after releasing the brakes of the last car, the car inspector does not measure the release time of the tail cars, but immediately goes to the head of the train, identifying unreleased brakes.

After completing the full testing of the brakes, the car inspector hands the locomotive driver a certificate of VU-45 brakes.

Complete testing of the brakes on an electric train

performed by the locomotive crew, and when leaving the planned types of repairs (except for TO-2) together with the foreman or foreman of the automatic department of the depot.

Full brake testing is carried out:

- after renovation or Maintenance;

- after sitting without a crew at a station or depot for more than 12 hours;

- after connecting the carriages to the train.

After each complete brake test in the log technical condition form TU-152, a record is made indicating:

- numbers and series of MVS;

- the date and time of the complete brake test;

- pressure limits in the main tanks maintained by the pressure regulator;

- pressure in the brake line with the train position of the driver's crane handle;

- the amount of air leakage from the brake network of the train;

- surname and signature of the driver and driver's assistant, and after repair or maintenance (except TO-1), the foreman and driver.

A full brake test begins with checking that the valve handles on the supply and brake lines are in the correct position. Then check the operation of the pressure regulator. The pressure in the main tanks should be maintained within 8.0 - 6.5 kgf / cm2 with a deviation of no more than 0.2 kgf / cm2.

After charging the brake and supply lines, check their tightness. To do this, on an electric train with a driver's crane, service no. 395, shut off the release valves on the brake and supply lines, and with a crane service number 334E, shut off the isolation valve on the supply line. The decrease in pressure observed on the pressure gauge should be:

- in the brake line from normal charging pressure by no more than 0.2 kgf / cm2 for one minute;

- in the supply network from 7.0 to 6.8 kgf / cm2 in 3 minutes or from 7.0 to 6.5 kgf / cm2 in 7.5 minutes.

Before the checks, the electric train must be secured against leaving. On next step check the tightness of the surge tank of the driver's crane.

First, the operation of the EPT is checked. After charging the brake line, turn off the control generator (phase splitter) and turn on the searchlight, signals and other consumers of electricity. When the brake switch handle is pressed down in the working and non-working control cabins and in the whole negative wire, it should light up control lamp"TO". The voltage in the circuit according to the voltmeter should be within 45 - 50 V.

Then move the handle of the driver's crane service. No. 334E to IV position, No. 395E to position VА. The braking signal lamp "T" should light up and when tap No. 334E the shut-off valve is triggered, and with tap No. 395 the "SK" on the EPK service No. 150I will turn off for a short time without triggering the auto-stop. In this case, it is allowed to release compressed air from the brake line through valve No. 395 and reduce the pressure in it by no more than 0.5 kgf / cm2.

When the brake cylinder is filled to the full pressure, the operator's valve handle should be moved to the overlap position without supplying the brake line leaks. The driver's assistant walks along the train and checks the actuation of the brakes on each car by the exit of the brake cylinder rod and pressing the pads against the wheels.

On a signal from the assistant, the driver turns off the brake switch on trains up to No. 1028, and on the other trains, the EPT is turned off with the power switch. The driver's assistant controls the release of the brakes by the release indicator lamp and the departure of the brake pads from the wheels of each car.

At the second stage, the operation of the automatic brake is checked. Switch off the EPT before checking. From the set charging pressure, the sensitivity of the automatic brakes to braking is checked. To do this, it is necessary to perform the first stage of braking with a decrease in pressure in the surge tank by 0.5 - 0.6 kgf / cm2. After reducing the pressure in the equalizing tank by the required value, move the handle of the valve No. 334E to the III position, and the valve No. 395E to the IV position. After 5 min. the driver's assistant checks the actuation of the brakes on each carriage by the exit of the brake cylinder rod and the pressing of the pads to the wheels.

At the command of the assistant driver "Release the brakes", the driver moves the handle of crane No. 334E to position IIA, and crane No. 395 to position II. After releasing the brake of the last car, the driver's assistant checks the departure of the shoes from the wheels and the departure of the brake cylinder rod for each car in the train.

From the opposite control cab, the locomotive crew should check the operation of the automatic and electro-pneumatic brakes as in the abbreviated brake test.

Reduced brake testing

Abbreviated testing of automatic brakes is carried out in order to check the air permeability along the brake line from the locomotive to the tail car.

Abbreviated testing is performed by:

- after hitching a train locomotive to the train, if a full testing of auto brakes was previously performed from a compressor unit or another locomotive;

- after a change of locomotive crews, when the locomotive is not disconnected from the train;

- after any disconnection of the hoses in the train or between the train and the locomotive (except for uncoupling the pushing locomotive included in the brake line), connecting the hoses due to the coupling of the rolling stock, as well as after closing the end crane in the train;

- in passenger trains after a train has stopped for more than 20 minutes, when the pressure in the main tanks drops below 5.5 kgf / cm2, when changing the control cabin or after transferring control to the driver of the second locomotive on the stretch after stopping the train;

- in freight trains, if the automatic brakes were triggered when the train was parked, the density of the brake line changed by more than 20% from the VU-45 form indicated in the certificate, after the train stopped for more than 30 minutes.

When performing an abbreviated test of the brakes, at the signal of the car inspector, the driver discharges the brake line by the amount of the braking step, as in full testing, and sets the driver's crane handle to position IV. The inspector checks the actuation of the brakes of the two tail carriages by the exit of the brake cylinder rod and the pressing of the brake pads to the wheels. At the signal of the inspector “Release the brakes”, the driver releases the brakes by setting the driver's crane handle to the first position. In passenger trains, the operator's crane handle is kept in this position until the pressure in the equalizing tank is 5.0 - 5.2 kgf / cm2, and in freight and passenger trains up to the pressure in the equalizing tank is 0.5 kgf / cm2 higher than the charging one. After that, the operator's crane handle is moved to the train position. A car inspector checks the release of the brakes of the two tail carriages for the departure of the brake cylinder rod and the departure of the brake pads from the wheels. If a group of carriages is attached to the tail of a train, the inspector checks the operation of the brakes on each coupled car.

At stations where the positions of car inspectors are not provided for, workers trained to perform operations on testing auto brakes are involved in the abbreviated testing (the list of positions is established by the head of the road).

After performing an abbreviated test of the brakes, the car inspector is obliged to make a note in the certificate of the VU-45 form about its implementation, and the driver enters the data on the density of the brake network in the certificate.

If the reduced testing of the brakes on the train is carried out after complete testing from the compressor installation, then the inspectors of the cars are obliged to check the density of the brake network of the train at the second and fourth positions of the driver's crane handle, the integrity of the brake line, measure the charging pressure in the tail car, and with the length of the freight trains with more than 100 axles determine the longest release time for the automatic brakes of the two tail carriages. At the end of testing, the driver is handed a certificate of the VU-45 form, as in full testing.

Reduced testing of electro pneumatic brakes

are performed at the points of changing locomotives and locomotive crews according to the action of the brakes of two tail cars and when hitching cars with checking the action of the brakes on each coupled car. On passenger trains, an abbreviated test of the electro-pneumatic brakes is performed first, followed by the automatic brakes. Abbreviated testing of EPTs is carried out in a manner similar to their complete testing from a locomotive. The brakes are released by short-term, for 1 - 2 seconds, by moving the operator's crane handle to the first position, followed by moving its train position. The actuation of the brakes and their release are monitored by the indicator lamps in the locomotive cabin, as well as the pressing and retracting of the brake shoes from the wheels of the two tail carriages.

Without performing an abbreviated brake test or with inoperative brakes for two tail cars, it is prohibited to send a train to the haul.

Abbreviated testing of the brakes of the motor of wagon trains

Abbreviated testing of automatic brakes with checking the condition of the brake line by the action of the tail car brake is performed:

- after any disconnection of the sleeves or closing of the end cranes in the train;

- after a train stop for more than 20 minutes or a pressure drop in the main tanks below 4.5 kgf / cm2.

Abbreviated testing of electro pneumatic brakes is performed:

- after changing the control cabin;

- after changing locomotive crews;

- after any disconnection of the electric circuit of the EPT.

Abbreviated testing of automatic and electro-pneumatic brakes is also performed after the train has stood without a locomotive crew for a time less than that established by the order of the head of the road (on the Oktyabrskaya railway, this time is 12 hours).

When starting a short brake test, the locomotive crew must charge the brake line to the charging pressure and check the operation of the EPT first, and then the automatic brakes on the action of the tail car brake.

To do this, turn on the EPT in the working cabin and, at the signal of the driver's assistant, perform a braking stage until the pressure in the brake cylinder of the head carriage increases by 1.0 - 1.5 kgf / cm2. The driver's assistant is obliged to check the action of the tail car brake by the brake cylinder pressure gauge and by the brake cylinder rod output and the pressing of the brake pads to the wheels, and then give a signal to release the brakes. On this signal, the driver moves the operator's crane handle to the I position, then the crane handle No. 334 E - to the IIА position, the crane No. 395 to the II position. The driver's assistant should check the tail car brake release on the gauge in the non-working cab. If the test is positive, the driver turns off the EPT and checks the operation of the automatic brakes by reducing the pressure in the surge tank by 0.5 - 0.6 kgf / cm2. The driver's assistant signals the release of the brakes after checking the operation of the tail car brake. On this signal, the driver moves the operator's crane handle to position I, then crane handle # 334E to position IIA, crane # 395 to position II.

The driver controls the operation of the brakes using the brake cylinder pressure gauge and warning lights in the working cab.

If, during a short test, the brakes of the tail carriage do not work, then the employee who checks the brakes of this carriage must prevent the train from leaving. The driver and the driver's assistant are responsible for the correct execution of the abbreviated brake test on multi-unit trains.

Checking auto brakes on freight trains

Testing of automatic brakes of freight trains by the action of the brakes of the head group of cars is carried out:

- after a freight train has stopped for more than 30 minutes;

- transferring control to the driver of the second locomotive or changing the cab on the stretch after stopping;

- when the pressure in the main tanks drops below 5.5 kgf / cm2;

- when attaching an additional locomotive to the head of a freight train to follow one or more hauls and after uncoupling this locomotive.

Such testing of auto brakes in freight trains is carried out on hauls, as well as at stations and sidings, where there are no car inspectors or workers trained in performing operations for testing auto brakes. Before testing the automatic brakes, the driver must make sure that the density of the train's braking network at the second position of the driver's crane handle does not differ from the density indicated in the certificate of the VU-45 form by more than 20%. Then, at the command of the assistant, the driver must discharge the brake line by the amount of the braking step, as in full testing, and set the driver's crane handle to position IV. The driver's assistant checks the actuation of the brakes on each car of the head group (the number of cars in the head of the train is set by the head of the road) and gives the command “Release the brakes”. After releasing the brakes by the first position of the operator's crane handle, the assistant returns to the cab and reports to the driver about the results of the check.

If there is a pushing locomotive in the tail of a freight train, the brake line of which is included in the general line of the train, and the radio communication is working properly, then the density of the brake network is not checked and the brakes are not tested. Before the train departs, the driver of the pushing locomotive must communicate the pressure in the brake line to the driver of the head locomotive by radio communication.

Abbreviated testing of automatic brakes with checking the condition of the brake line by the action of the brakes of two tail carriages in trains:

· After the locomotive has been coupled to the train, if a complete testing of the automatic brakes from the compressor unit or the locomotive has been carried out at the station beforehand;

· After a change of locomotive crews, when the locomotive is not disconnected from the train;

After any disconnection of the sleeves in the train or between the train and the locomotive, as well as after closing the end sleeve of the crane in the train;

In passenger trains after a train has stopped for more than 20 minutes, when the pressure in the GR is below 5.5 atm, when changing control cabins or after transferring control to the driver of the second locomotive on the stretch after stopping the train due to the impossibility of further control from the head cabin;

· On freight trains, if during the train stop there was a spontaneous actuation of automatic brakes or changes in density by more than 20% of the VU-45 norm specified in the certificate;

In freight trains after a stop for more than 30 minutes,

In passenger trains, an abbreviated test is carried out first of the EPT, and then of the automatic brakes. EPT testing is carried out in a manner similar to their complete testing by the action of the brakes of two tail carriages.

When performing an abbreviated test on the signal "Perform braking", the driver must give a signal and reduce the pressure in the surge tank by the value set for a full test. After checking the actuation of the brakes of the two tail carriages, the signal "Release the brakes" is sent to braking. On this signal, the driver whistles two short beeps and releases the brakes I position of the crane handle. Maintain the valve handle in position I in passenger trains until the pressure in the equalizing tank rises to 5.0 - 5.2 atm, in a freight train until the equalizing pressure is 0.5 higher than the charging pressure, followed by moving the handle to the train position.

If an abbreviated testing of brakes on trains is carried out after full testing from a compressor installation, car inspectors and the driver are obliged to check the density of the train's brake network, the integrity of the TM by opening the tail car crane (as in full testing) before testing. In freight trains, the driver is obliged to check the density of the train's braking network after the braking stage at the IV position of the driver's crane handle, the car inspector must check the charging pressure in the tail car line, with a freight train length of more than 100 axles, measure the release time of the automatic brakes of the two tail carriages. At the end of this testing, the driver is given a VU-45 certificate, as in the case of full testing.

5.28. The actions of the locomotive crew before the departure of the freight train after parking at the intermediate station for more than 30 minutes (clause 9.4.1. Instrument No. 277, Order No. 66 / N dated June 30, 1999)

After parking at an intermediate station for more than 30 minutes before departure at presence of full-time inspectors the locomotive crew is obliged to carry out a shortened testing in accordance with the established procedure 5 wagons each triggered from the tail and the head.

If there are no regular inspectors, make the following check:

· Check the density of the brake network when the crane handle is in train position, which does not differ from the density indicated in the VU-45 certificate by more than 20% in the direction of decreasing or increasing;

Perform a braking stage by reducing the pressure in the surge tank by 0.6 - 0.7 atm and release the brakes ... The assistant must check the action of the brakes on braking and release by 10 brake cars at the head of the train.

If, when checking the density of the brake network, the driver detects a pressure change of more than 20% from the VU-45 specified in the certificate, reduced testing of the automatic brakes by the action of the brakes of the last 2 cars.

9.3.1. Abbreviated testing of brakes with checking the condition of the brake line by the action of the brake of two tail carriages in trains is carried out:

after hitching a train locomotive to the train, if a complete testing of automatic brakes from a compressor unit (station network) or a locomotive was carried out at the station beforehand; after a change of locomotive crews, when the locomotive is not disconnected from the train;

after any disconnection of the sleeves in the train or between the train and the locomotive (except for disconnecting the pushing locomotive included in the brake line), connecting the sleeves due to the coupling of the rolling stock, and also after closing the end crane in the train:

in passenger trains: after a stop for more than 20 minutes, when the pressure in the main tanks drops below the charging pressure of the TM, when changing the control cabin or after transferring control to the driver of the second locomotive on the stretch after stopping the train due to the impossibility of further controlling the movement of the train from the main cabin;

in freight trains, if the brakes were spontaneously activated or the density changed by more than 20% of the specified certificate of brakes f. VU-45; in freight trains after a stop for more than 30 minutes.

When freight trains are parked for more than 30 minutes on the tracks, as well as at sidings, passing points and stations where there are no car inspectors or workers trained in performing operations for testing auto brakes (the list of positions is indicated by the head of the road), the auto brakes must be checked in accordance with cl. 9.4.1 of this Manual.

if, when checking the density of TM, the driver discovers its change by more than 20% from the specified certificate f. VU-45, perform abbreviated brake testing:

if on a locomotive that has signaling device No. 418, the signal lamp “TM” lights up in the parking lot, check the serviceability of the signaling device by the braking stage, at which the lamp “TM” should go out. After making sure of the normal operation of the signaling device, make a short test of the automatic brakes:

At stations where there are full-time car inspectors, reduced testing is carried out by these inspectors at the request of the driver, and in the absence of inspectors, by a locomotive crew or workers trained to perform an operation to test automatic brakes.

Abbreviated testing of electro-pneumatic brakes is carried out at the points of change of the locomotive and locomotive crews according to the action of the brake of two tail cars and when hitching cars with checking the action of the brakes in each coupled car:

9.3.2. On passenger trains, short testing is performed first with electro-pneumatic brakes and then with auto brakes. EPT testing is carried out in a manner similar to their complete testing from a locomotive in accordance with clause 9.2.3. without checking the voltage of the EPT in the tail car and without turning off the toggle switch of the EPT power circuit during the period of checking its release, taking into account and. 9.3.1. of this Instruction for the action of the brakes of the two tail carriages.

9.3.3. When performing an abbreviated test, at the signal of the employee who is responsible for testing the brakes, “Apply braking”, the driver must blow one short signal with a whistle and reduce the pressure in the surge tank by the value set for full testing.

After checking the actuation of the brakes of the two tail carriages, the signal "Release the brakes" is sent to braking. At this signal, the driver whistles two short signals and releases the brakes with the driver's crane handle in position I in passenger trains with an increase in pressure in the equalizing tank to 5.0-5.2 kgf / cm 2, and in a freight and passenger train until receiving the pressure in the equalizing tank is 0.5 kgf / cm 2 higher than the charging pressure with the handle moving to the train position. If an abbreviated testing of brakes on trains is carried out after full testing from a compressor installation (station network), car inspectors and the driver are obliged to check the density of the train's brake network and the integrity of the TM in accordance with

Sec. 9.2.3., 9.2.4. of this Instruction, and if the length of the freight train is more than 200 axles, the wagon inspector is obliged to check the charging pressure in the main line of the last wagon in the manner prescribed by clause 9.2.4. After the end of such testing, the driver is handed a certificate f. VU-45, as in full testing.

9.3.4. When attaching a car or a group of cars to a train that has arrived, an abbreviated test of the brakes is carried out with a mandatory check of their operation for each car to be coupled and the density of the brake line of the train, and in a freight train, in addition, check the integrity of the TM of the train. At each reduced testing of auto brakes, the inspector of carriages, and where this position is not provided, the station attendant, chief conductor, train builder or employees who are entrusted with the responsibility to test the brakes, make a note about the reduced testing of auto brakes (with a note about the change in the composition of the train, indicating the number of the tail car) in the certificate f. VU-45, which the driver has. In the event of a change in the density of TM due to the hitching (uncoupling) of cars, the driver enters new data on the density of the braking network in the certificate f. VU-45.

If the abbreviated testing of the brakes of a passenger train was carried out with the involvement of the chief (mechanic-foreman) of the train and the conductors of the carriages, then the chief (mechanic-foreman) must make a note on the performance of abbreviated testing of the brakes in the certificate f. VU-45, which the driver has.

9.3.5. At stations where the position of a car inspector is not provided, the operation of the tail car brakes in passenger trains is checked by the conductors of the carriages, in freight trains - by workers trained in performing operations for testing auto brakes (the list of positions is established by the head of the road).

9.3.6. It is prohibited to send a train to the haul without performing an abbreviated test or with inoperative brakes for two tail cars.

If during testing, air diffusers that did not operate on release are identified, it is not allowed to release them manually until the reasons for the non-release are clarified. In these cases, it is necessary to check whether there are any closed end cranes on the train, especially in those places where cars were coupled or uncoupled, to re-test the brakes again. Replace defective air distributors, and at intermediate stations turn them off and release air through the exhaust valve, make a note about this in the VU-45 help.