The interest of the modern motorist is not limited to attention to the car as a means of transportation. In many respects, the effect and impression that can be made on all participants in the movement is important. After a widespread ban on imitators of flashing lights of law enforcement officers and official cars, somehow unexpectedly, the fashion for a stroboscope on the grill and a double signal began to gain momentum.

Most of the above schemes are not designed to completely imitate the signals of official cars, it is rather a purely sporting interest. And to whom and for what to pay fines, everyone decides for himself, based on his capabilities.

There are several simple ways to organize a stroboscope on a car, it all depends on the amount of effort and money that can be spent to build a car stroboscope. Most often, they try to get the most realistic flickering of strobe lamps.

Several simple schemes of LED strobe lights for cars have been tested in practice:

- according to the simplest scheme using two relays 494.3787;

- based on the 555 timer and the k561ie8 circuit;

- on the PIC12F675 microcontroller;

- on the element base transistors 315 series.

For your information! The safest and most popular way is to use a flashing effect by installing LEDs in your car headlights. It's beautiful and stylish.

We assemble a car stroboscope with our own hands

The easiest way to build a reliable circuit on a car is to use a couple of relays from the gazelle turn signal system, a starter relay and a couple of trimming resistors. It is easy to assemble such a stroboscope circuit with your own hands, and even special knowledge or skills are not required.

The specified scheme provides for the connection to the daytime running lights of the car. If desired, you can switch the connected daytime running lights or strobe flashers. The advantage of this approach is the absence of overload-sensitive electronic components in the circuit. The relays, even in the event of an overload of the electrical circuit, in most cases will remain intact, although they can lead to blown fuses.

To build a strobe circuit, the following is required.

- First, we disassemble the case of the turn relay and carefully remove the white constant resistor with numerous transverse colored stripes.

- In a variable resistance of 20-25 kOhm, we solder the middle electrode to one of the side ones.

- We solder the variable resistance instead of the removed element in such a way that, after reassembly, the rotary stem of the variable resistor could be freely rotated.

- We assemble the circuit, we carry out a similar procedure with the second relay.

- We assemble the circuit shown in the figure, and after applying the supply voltage by turning the control rods, we select and synchronize the flashing frequency of the strobe lights on the car.

If you use a variable resistance of 450 kOhm, the blinking frequency will be much less, but for a more accurate selection of the blinking frequency, you can select several different resistances and achieve the required frequency.

Building a circuit based on a microprocessor

The most “advanced” motorists in the basics of microelectronics believe that the controller-based stroboscope circuit will be the most effective. On the PIC12F675 microcontroller, the circuit will be able to provide current pulses up to one ampere with adjustable duration.

The stroboscope circuit for a car is easy to assemble with your own hands. As a load, a package of light elements is most often used, with the ability to change the flicker frequency of the stroboscope on LEDs. The processor itself controls two powerful KT817 transistors and can produce seven different combinations of signals. The system itself is quite common in industrial circuits for service flashers, especially for simple strobe systems on a car radiator grille.

The most unpleasant thing in connecting such circuits is the high sensitivity of any microprocessors to overvoltage or the occurrence of a short circuit mode. Therefore, when assembling and soldering, it is imperative to use a good ground. In addition, the use of a stabilized power supply is mandatory; usually, a circuit on a paired low-voltage zener diode is used for these purposes.

When connecting the stroboscope circuit to the car's electrical wiring circuit, you must first completely disconnect the power from the battery, it is strictly forbidden to start and test the circuit in the absence of load.

Do-it-yourself police stroboscope on a logic counter

To obtain an effect similar to the flickering of LEDs in a strobe on law enforcement service motors, you can use an interesting option on the 561 series logic counter and 555 timer. The circuit turns out to be somewhat more complicated than previous developments, but if you have a couple of hours of free time and the ability to solder, you can assemble a small homemade product on a printed circuit board.

As a load, packages of LEDs with a total current consumption of not more than 3A are used; if desired, they can be replaced with low-power halogen lamps with a total power consumption of up to 30 W.

The specificity of constructing such a stroboscope circuit on LEDs is an interesting feature of the formation of a control signal. The microcircuit on the 555 assembly acts as a source of a control signal input to the counter. Without going into the specifics of the operation of the stroboscope, we can only note that the ignition and extinguishing circuit of the LEDs was copied from the stroboscope of a police car.

Rectangular pulses are fed to the counter and summed up. After a certain programmable time, the potential on the control contact changes from high to low.

The stroboscope works like this: each of the LED packages flashes, gives a certain programmed number of flashes and goes out, then the signal is transmitted to the next LED package and so on in a cyclic mode.

Important! Powerful KT819 or bipolar KT818 are used as control keys in the stroboscope circuit, which allows you to control high currents in the load.

To power the 555 microcircuit, the maximum supply voltage cannot be increased more than 18 volts, the stabilizer is not designed for a larger operating range, and the circuit remains operational even when the voltage drops to 5 V.

How to make a stroboscope with your own hands on simple spare parts

The most budgetary way to build a do-it-yourself LED stroboscope is not to buy a bunch of spare parts on the radio market for a couple of thousand, but to try to use old Soviet or Chinese spare parts.

We use mikruha 155 series as a signal source, AG1 can be used. After power is applied, the microcircuit sets a positive potential at the control pin, and as the capacitor charges, the potential drops and opens the control signal to the KT315. The capacitance of the capacitor determines the length of the flash, at 0.1 uF it will be approximately 0.01 sec, which is quite enough to obtain the desired optical effect.

On the 6th leg 155 of the microassembly, a series of pulses will be generated, coupled with the pulses of the ignition system. They fall on the control electrodes of two KT 829 transistors. Then the transistor opens, and a significant current will flow through the load from the LEDs.

If the stroboscope circuit consumes more than 60 watts, use standard aluminum radiators to cool the transistors.

The result, or the design of strobe LEDs for cars

For most fans of homemade strobe lights, it is sometimes more important to hide the fact of owning homemade light illumination similar to a police one. Therefore, often the package of light bulbs or LEDs is made removable so that it can be easily installed on the hood or roof of a car. Sometimes, for greater disguise, an easily removable plastic cover is put on top of such a block, in appearance it strongly resembles a taxi lantern.

The advantage of this design solution is that the stroboscope fixture is easy to remove and even throw away. A stroboscope with a plastic case on top will resemble a taxi driver's lantern and will not attract the attention of the police in the parking lot or when the car accidentally stops on the road.

The second installation option is to install a package of strobe LEDs in the area of \u200b\u200bthe radiator grille of a car or in the cavity of a headlight lamp. This is a more expensive and effective way, as it will require some alteration of the car's optics, and in the event of a conflict with law enforcement officers, it can become the basis for placing the car in a car impound.

Owners of carbureted cars are familiar with the difficulties of the ignition adjustment process. Usually this is done by ear, which is not very convenient. Using a stroboscope, this process can be facilitated. However, industrial devices are quite expensive, so many make a strobe for ignition with their own hands.

Disadvantages of industrial models

Industrial devices often have certain disadvantages, due to which the usefulness of the device is very doubtful.

For starters, they are quite pricey. For example, modern digital models will cost a motorist 1000 rubles. More functional models already cost from 1700. Advanced stroboscopes cost about 5500 rubles. Needless to say, a car stroboscope (made with your own hands) will cost a motorist 100-200 rubles.

Often in factory devices, the manufacturer uses a particularly expensive discharge lamp. The lamp has a certain resource, and after a while it will have to be replaced. And this in itself is tantamount to acquiring a new factory device.

Why is it worth making a stroboscope with your own hands?

The disadvantages of factory and technological devices are pushing the motorist to independently manufacture this device. In addition, it is much cheaper to equip this equipment with LEDs instead of an expensive lamp. An ordinary laser pointer or flashlight is suitable as a source of diodes or a donor.

The rest of the details will also cost a penny. It does not require any special tools. The budget for the manufacturing process of a stroboscope will be no more than 100 rubles.

How to make a stroboscope with your own hands?

There are a huge number of schemes and options for manufacturing. However, for the most part, all projects to create this gadget are similar. Let's see what is needed for assembly.

We need a simple transistor KT315. It can be easily found in an old Soviet receiver. The designation may be slightly different, but it does not matter. The thyristor KU112A can be easily obtained from the power supply of an old TV. You can also find small resistors there. Since we make an LED strobe with our own hands, then, of course, we need an LED flashlight. To do this, it is better to purchase the cheapest one from China. In addition, you need to stock up on a capacitor up to 16 V with any low-frequency diode, a small 12 A relay, wires, crocodiles, a shielded wire 0.5 m long, and a small piece of copper wire.

We assemble the device

The scheme is small, and you can place it right in the same Chinese lantern. So, through the hole in the flashlight at the back, it is desirable to pass the wires to power the device. At the ends of the wires, it is better to solder crocodiles. A hole needs to be made in the side wall, if the Chinese have not already made it. A shielded wire will be routed through this hole. At the opposite end, it is necessary to insulate the braid and solder the same piece of copper wire to the main core of the wire. This will be the sensor.

Device diagram and principle of operation

After applying current through the power wires, the capacitor will charge very quickly through the resistor. When a certain charge threshold is reached, the voltage will flow through the resistor to the opening contact of the transistor. This is where the relay comes in. When the relay closes, it will create a circuit of thyristor, LED and capacitor. Then, through the divider, the pulse will go to the control output of the thyristor. Next, the thyristor will open, and the capacitor will be discharged to the LEDs. As a result, a do-it-yourself stroboscope will flash brightly.

Through a resistor and a thyristor, the base output of the transistor is connected to a common wire. Because of this, the transistor will close, and the relay will turn off. The time of the glow of the LEDs increases, since the contact is not broken immediately. But the contact will break, and the thyristor will be de-energized. The circuit will return to its base position until a new pulse arrives.

By changing the capacitance of the capacitor, you can change the glow time. If you choose a capacitor with a larger capacity, then the LED stroboscope, made by yourself, will glow brighter and last longer.

device on a microcircuit

The main part of this simple circuit is a DD1 chip. This is the so-called single vibrator 155AG1. In this circuit, it starts only from negative pulses. The control signal will go to the KT315 transistor, and it will generate these negative pulses. Resistors 150 K ohm, 1 k ohm, 10 k ohm, as well as the KS139 zener diode work as limiters for the amplitude of the incoming signal from the ignition of the car.

A 0.1 mF capacitor, together with a 20 kΩ resistance, will set the desired duration of the pulses that will be generated by the microcircuit. With such a capacitance of the capacitor, the duration of the pulses will be up to about 2 ms.

Then, from the 6th leg of the microcircuit, the pulses, which by this moment will be synchronized with the ignition of the car, will go to the base output of the KT 829 transistor. It is here as a key. The result is a pulsed current through the LEDs.

How is this auto strobe powered? With our own hands, we need to run a couple of wires to the terminals of the car battery. It is necessary to monitor the level of battery charge.

If you correctly assemble this simple circuit, you will immediately be able to see how the device works. If suddenly the brightness is not enough, then this is regulated by the selection of the appropriate resistance.

As a housing for the device, you can use an old or Chinese flashlight.

Another stroboscope circuit

This do-it-yourself LED stroboscope, made according to this principle, can also be powered from a car battery. Diodes will provide protection against reverse polarity. As a fastener, an ordinary crocodile is used here. It must be attached to the high voltage contact of the first spark plug on the motor. Next, the pulse will pass through the resistors and the capacitor and come to the input of the trigger. By that time, this input will already be turned on by the one-shot.

Before the pulse, the one-shot is in normal mode. The direct trigger output is low. Inverted input, respectively - high. A capacitor connected with a plus to the inverted output will be charged through a resistor.

A high-level pulse fires a one-shot, which switches the flip-flop and serves to charge the capacitor through the resistor. After 15 ms, the capacitor will be fully charged and the trigger will switch to normal mode.

As a result, the one-shot will respond to this with a synchronous sequence of rectangular pulses with a duration of approximately 15 ms. The duration can be adjusted by changing the resistor and capacitor.

The pulses of the second microcircuit are up to 1.5 ms. For this period, transistors open, which are an electronic switch. Then current flows through the LEDs. According to this principle, a strobe for a car works (it was made by hand or not, it does not matter - both devices shine the same way).

The current passing through the LEDs is much greater than the passport one. But, since the flashes are short, the LEDs will not fail. The brightness will be enough to use this useful device even in the daytime.

This do-it-yourself stroboscope can be assembled in a case from the same long-suffering pocket flashlight.

How to work with the device?

Having assembled the device according to one of the above schemes, you can simply and easily, and most importantly, accurately adjust the ignition on carburetor engines, check the correct operation of candles and coils, and control the operation of the advance angle regulators.

In order to set the ignition as correctly as possible, it is usually assumed that the mixture ignites a couple of degrees before the piston reaches its highest point. This angle is called the "advance angle". As the crankshaft rpm increases, the angle should also increase. So, this angle is set at idle, and then it is necessary to check the correctness of the settings in all operating modes of the unit.

We set the ignition

We start and warm up the engine. Now we power our LED stroboscope and connect the sensor. Now you need to point the device at the mark on the timing case and find the mark on the flywheel. If the moment is violated, then the marks will be far enough apart. By rotating the timing case, match the marks. When you have found this position, fix the distributor.

Then it's time to pick up the pace. The labels will diverge, but this is a completely normal situation. This is how the ignition is adjusted using a stroboscope.

So, we found out how a do-it-yourself LED stroboscope is made.

To accurately set the ignition on the engine, it is necessary to use special devices - stroboscopes. They can be purchased at car dealerships or made by hand. In the second case, you will save a decent amount and make the most suitable device for your car model.

Features of factory strobe lights and the principle of their operation

Precisely adjusting the ignition without using a strobe is quite difficult. Such a device significantly speeds up the tuning process, the lamp signals the appearance of a spark, which allows you to correctly set the ignition timing. Despite the fact that factory instruments work efficiently and accurately, many motorists are in no hurry to buy them. The main deterrent can be called the high price of strobe lights. Most models use an expensive gas discharge lamp, replacing it is equivalent to buying a new device.

The device itself can be made by hand, using simple and affordable materials. There are several good manufacturing schemes that will help you save on buying factory counterparts. For example, you can see the prices for the most popular strobe lights that are on sale:

- Multitronics C2 - 900-1000 rubles.

- AstroL5 - 1300 rubles.

- Focus F1 - 1700 rubles.

- Focus F10 - 5600 rub.

Homemade devices are made from flashlights, LEDs or a laser pointer. At a low cost (about 500 rubles), the device will work no less reliably and efficiently.

Instructions for the manufacture of the device for installing the ignition

The easy way

There are many different schemes on the network, almost all of them are easy to assemble and do not require large expenditures on materials. Consider one of the most popular schemes for creating a stroboscope at home. From the details we need:

- transistor KT315;

- thyristor KU112A, 0.125 W resistors;

- any flashlight on diodes (diodes should be 6 or more);

- capacitors C1;

- low frequency diode V2;

- relay with index RWH-SH-112D;

- 1 meter power cord;

- special clamps;

- copper wire about 10 cm.

All parts can be purchased at the radio market or in a specialized store. As a housing for the device, you can use an old flashlight or a flash from a camera.

Assembly diagram of a car strobe in a housing from an old flashlight

You can use such a device not only to install the ignition. They can check the candle, adjust the operation of the regulator.

Homemade stray using a timer

A stroboscope based on timer devices has a more complex circuit. Its main advantage is stable light pulses that do not depend on battery voltage. The device can also work in tachometer mode, for this you just need to change the position of the regulator.

Timed strobe lights can also be used as a tachometer

Tip: It is better to use diodes from the KD521 series in the circuit. If you have not found a domestic-made timer, you can take a foreign analogue NE555.

Scheme for manufacturing a device on LEDs

Such a device is based on the 155AG1 chip; it is triggered by pulses with negative polarity. The circuit uses resistances R1, R2, R3, which limit the amplitude of the input signal. The required pulse duration is set by capacitance C4 and resistor R6. At default settings, this is 2 ms. The vehicle battery will be used as a power source.

LED strobe lights are highly reliable and can be used even in bright daylight

Video: how to make a stroboscope with your own hands

How to set up homemade

To test the device in practice and set the ignition timing, do the following:

- We warm up the engine and leave it to idle.

- We connect a homemade stroboscope to a power source.

- We wind the copper sensor on the core of the first cylinder.

- We direct the light source to a special mark, which is applied to the body.

- We find a fixed point on the flywheel pulley.

- In order for the two points to converge, it is necessary to rotate the ignition housing and then fix it in a certain position.

In practice, homemade strobe lights are in no way inferior to factory ones. The main thing is to correctly assemble the circuit and check the operation of the device. Homemade stroboscopes are quite inexpensive and can be easily repaired if necessary.

Many car owners would like to drive down the street at high speed with the specials turned on. signal to attract people's attention. But this pleasure is allowed only to a few, and the use of flashing lights and other special equipment in full view of mere mortals discredits a large fine. But these are just formalities, and having strobe lights and their competent use is not prohibited. In connection with this idea, the idea arose to design simple gates. The only difference between this type of strobe lights is their absolute simplicity in manufacturing and the availability of assembly elements.

Small assembly video:

For the device you will need:

- 2 turn relays - 494.3787 (used in GAZ-3110, GAZ-33021 Gazelle, GAZ-2752 Sobol)

- 2 variable resistors with a nominal value of 20 KΩ (flash rate will be high) or 470 KΩ (flashing will be a little slower).

- 1 five-pin automotive relay 983.3777-01 (98.3777, 903.3747-01, constant 984.377, 90.3747)

Assembly.

First you need to disassemble the turn relay and solder the resistor (it is shown in the photo) and instead solder a variable resistor. (Since the variable resistor has three legs, it is necessary to solder the central leg to one of the side ones)

For the second relay, you also need to do the same procedure.

- Advice! It is advised to bring out all variable resistors - since these elements regulate the speed of flashes of LEDs or bulbs and the speed of switching between themselves (strobe lights).

The best option is to connect the circuit to the DRL.

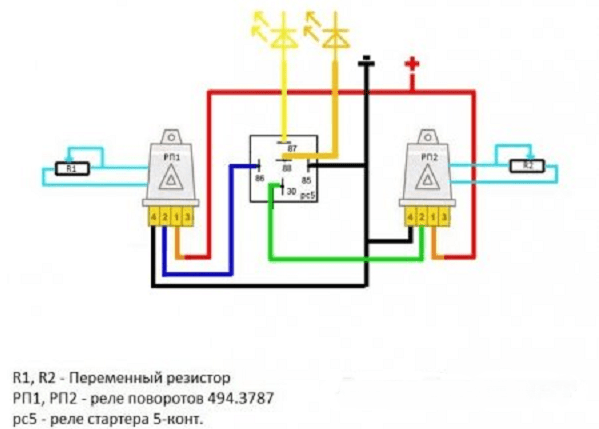

A simple circuit for stroboscopes.

- PC 5 is a simple five-pin relay.

But it is advised to assemble the circuit, which is presented below. To make, of course, it is a little more difficult, but here it will be easy to switch from using daytime running lights to strobe lights.

- R1, R2 - variable resistors;

- PC 5 - simple five-pin relay

- RP1, RP2 - turn relay 494.3787

Automotive chokeless PSU on IRS2153 for laptops and mobile phones Device for controlling the operation of the direction indicator Do-it-yourself steering wheel heating in a car Security sensor for gas tank

Automotive chokeless PSU on IRS2153 for laptops and mobile phones Device for controlling the operation of the direction indicator Do-it-yourself steering wheel heating in a car Security sensor for gas tank

The process of adjusting the initial ignition moment is greatly simplified when using special devices. Their work is based on the stroboscopic effect. The meaning of this physical phenomenon is as follows: if you illuminate a moving object with a short light flash, then there will be a visual illusion that it has remained in the same position in which this flash found it.

Making your own LED stroboscope is very simple. There are schemes of simple devices that even an inexperienced radio amateur can repeat.

LED stroboscope on NE555 timer

The main component in this strobe circuit is the NE 555 integrated timer. This is a common microcircuit often used in electronic homemade products.

A ready-made assembly of six LEDs from a Chinese lantern was used as a light emitter.

Strobe circuit on the NE555 timer

Potentiometer P1 sets the pause time between pulses that are applied to VT1. Opening at the moment the signal is given, the field-effect transistor "ignites" the stroboscope.

It should be borne in mind that at the time of the flash, the current passing through the emitter exceeds two amperes. This circumstance forces the use of a limiting resistor with a power dissipation of at least 2W. There is no reason to worry about the failure of the LEDs. Ultra-short operating time in such modes will not cause damage to semiconductors.

Instead of the transistor indicated in the diagram, you can use its closest analogues: IRFZ44, IRF3205, KP812B1 and others.

Requirements for the diode VD1 - high speed. 1N4148 is successfully replaced by the domestic version of KD522. Any Schottke diodes will also work well.

The capacitance of capacitors can be increased by one order of magnitude. This will not affect the performance of the circuit in any way.

This is what the assembled device looks like, with three heavy-duty LEDs.

Stroboscope assembly

Stroboscope assembly A small number of parts allows you to make a stroboscope from LEDs using a hinged method or using special mounting panels. If no mistakes are made during the soldering process, the circuit will work immediately, without additional adjustment.

Another variation of assembling a do-it-yourself automotive LED strobe is based on the TL494 PWM driver. The cost of a microcircuit lies in the range of 10 - 20 rubles apiece, so you cannot call it scarce. In addition, you can remove the required component from an old ATX power supply from a personal computer.

LED stroboscope circuit on a TL494 PWM controller

LED stroboscope circuit on a TL494 PWM controller As in the previous case, the emitter is controlled by a MOSFET transistor. Here it can be of any type that meets two requirements:

- Rated current - from 2A;

- internal structure - N-type.

Examples of suitable field workers: AP15N03GH or IRLZ44NS.

The trimming resistor VR1 sets the duty cycle (flash duration), and VR2 sets their frequency. It is more convenient to use potentiometers with a linear relationship, so the tuning process is much easier to perform.

The light source in this strobe circuit is one powerful LED. To connect a 12 volt LED strip, resistor R6 must be removed by installing a jumper instead.

The remaining elements of the LED stroboscope circuit can be any with the indicated ratings.

Device circuit board

You can minimize the size of the structure using SMD components. Some novice radio amateurs try to avoid their use, believing that the installation of small parts is too laborious. And in vain! A little practice will help you easily cope with this task. But the result will be an excellent reward for your patience.

A sample implementation of the printed circuit board of the LED stroboscope is shown in the figure.

Strobe Light PCB Sample

Strobe Light PCB Sample

Here, a two-way wiring method is used. Large radio elements are installed on top: a microcircuit, terminal blocks and electrolytic capacitors, below are resistors and capacitors of size 1206, LEDs of size 0805, a MOSFET transistor in a DPAK package. Regulating resistors are replaced by trimmers. This was done to reduce the design.

The appearance of the board of the finished device from both angles is shown below. To transfer a pattern with tracks to a foil textolite, the LUT method was used. Etching was carried out in an aqueous solution of ferric chloride.

If you want to repeat the LED stroboscope circuit with your own hands, you can use the project for the Sprint Layot tracer, changing it if necessary according to your own needs. .

Consideration in the article of the strobe circuit is distinguished by the simplicity and low cost of electronic components. The total cost of materials will cost ten times less if you purchase a ready-made LED stroboscope. In addition, using a home-made device is much more pleasant, and the experience gained in the process of work is irreplaceable and priceless.