Yesterday, one of our regular customers came to us on the recently acquired Kalina of the second generation, replacing the timing belt, roller and pump plus all fluids, but more on that in another article. This engine was also installed on Grant, so this article will be relevant for her as well. On the speedometer 60,000 and I believe that for this engine this is the optimal replacement interval, even though all the reference books say about 75,000.

Let's make a reservation right away that when the timing belt breaks on this car, the valve bends. It is recommended to check the condition of the belt every 15,000 kilometers.

For work, we need a set of keys and heads, as well as a 5 hexagon and a key for the tension roller. The whole procedure takes about an hour and a half.

The engine is similar to the eighth.

First, remove the protection, drain the antifreeze, and you can remove the right front wheel for convenience. Next, we loosen the locknut of the alternator belt tensioner. Unscrew the tensioner pin with a 10 head and remove the belt.

We unscrew the four bolts with a 5 hexagon and remove the upper protective cover of the timing belt.

We set the top dead center (TDC). We twist the crankshaft by the pulley bolt clockwise until the mark coincides with the camshaft sprockets and the timing case.

Unscrew the crankshaft pulley bolt. We block the wheels with stops, tighten the hand brake, turn on the fifth gear and, with a slight movement of the key with a one and a half meter pipe extension, unscrew this bolt.

Remove the protective washer.

The marks on the crankshaft sprockets must be aligned with the oil pump drip.

Praise to the designers of AvtoVAZ, finally, rollers with a tension indicator appeared on the engines, now there is no need to pull it by eye and check the tension by twisting the belt, not even thirty years have passed since the invention of such a design. We unscrew the tension roller bolt and dismantle the latter as well as remove the old timing belt. The photo shows that the belt is stretched as the tension marks have dispersed, when monitoring the condition of the timing belt, if you see this, you just need to tighten it.

To replace the pump, we need to remove the camshaft sprocket, and also unscrew a few bolts of the inner casing and remove it.

Three bolts down and a replacement pump. The green arrow indicates the idler roller bolt hole.

Having changed the water pump, we proceed to install a new timing belt.

We put the camshaft cover and sprocket in place. We check the coincidence of all the labels, they were mentioned above. We put the tension roller, but do not tighten the bolt. We put on a new belt, observe the direction of rotation, first on the sprocket of the crankshaft, camshaft, tension roller and pump, the latter can be swapped. We tighten the timing belt. With a special key, turn the roller counterclockwise, as indicated on its body ...

... until the marks on it coincide and tighten the bolt.

We turn the crankshaft two turns and again check the coincidence of the marks and the belt tension.

We install all the parts in the reverse order of removal, fill in antifreeze and start. It couldn't be easier.

Good luck on the road. Not a nail, not a rod!

So, you have found a defect or the scheduled repairs are due. Replacement is carried out step by step only with a cooled motor:

So, you have found a defect or the scheduled repairs are due. Replacement is carried out step by step only with a cooled motor:

- Disconnect the battery of your Lada Granta.

- Remove the crankshaft position sensor. Place the sensor in a clean place such as a shelf free of steel filings or oil.

- Place the piston of the first cylinder at top dead center.

- Turn the crankshaft until the mark on its pulley aligns with the projection on the drive cover.

- Remove the plug from the sight glass (located on the clutch housing) and check the position of the shaft. If you did everything correctly, a mark will appear in the window and will be opposite the slot. Lock the flywheel with a screwdriver (it must be placed between its teeth).

- Unscrew the generator drive pulley, remove it from the axle and remove the washer.

- Remove the timing cover.

- Loosen the idler roller (it should turn).

- Remove the belt from all pulleys and pull out.

- If, in addition to installing the timing belt, you need to remove the tension roller and replace it with a new one, then unscrew the mounting bolt, and then remove the roller directly with it.

- Before installing a new roller, check if a replacement is really necessary. To do this, grasp the metal center of this mechanism and turn the plastic part. In a serviceable component, it moves smoothly, without jamming.

- Inspect the pump and begin reassembling the timing mechanism. Install the roller in the upper hole on the cylinder block, but do not fully tighten the bolt securing this part of the drive.

- Fit the belt so that it runs correctly on all pulleys and rollers. In order for the belt to lay down correctly, after laying it on the crankshaft pulley (it must first be installed in its place), tighten both parts of the part. Try to distribute the load evenly.

- The far part of the timing belt should lie on the pump pulley and go behind the tension roller (at this stage, check the diagram), and the near one should lie gently on the toothed part of the camshaft.

- Turn the camshaft pulley slightly (in the direction of less travel) so that the teeth of the belt line up with the notches on it. Use a wrench to turn the tension roller counterclockwise.

After the replacement has been made, check the timing belt tension. Excessive stress in it on the Lada Grant is fraught with failure of the pump of the cooling system. Also, if too tight, the belt can fail very quickly.

A loose belt can lead to a valve timing failure. Turn the crankshaft to the right so that the timing marks are aligned. Then reassemble the alternator pulley. Remember that it is strictly forbidden to turn the shafts with the belt removed on the Lada Grant model car. The setting is only done when the replacement has already been carried out.

All the latest models of front-wheel drive cars, which are produced by the automobile plant located in Togliatti, have a timing belt in the timing mechanism. Lada Granta fully refers to these models.

The car is equipped with several engine modifications, which can have 8 or 16 valves in the cylinder head. Many owners service and repair this model on their own, so it will be useful for them to learn about how to change the timing belt on a Lada Granta with 8 valves.

Lada Granta motors with 8 valves in the cylinder head have an index of 11183 and 11186. The first of them began to be produced in 2004, the second later, namely in 2011. The power of the "83" unit is 82 horses, at 87 hp for the "86" modification. The 11186 engine is an improved model “83” engine. It uses a lightweight connecting rod and piston group. It was possible to achieve a reduction in the mass of the piston group by almost 30%. The cylinder head is subjected to a specific heat treatment, which increases its strength and wear resistance.

And also the cooling system of the power unit received some changes. The skirts of lightweight pistons are coated with graphite grease, this avoids the appearance of scoring on the cylinders of an unheated engine. The compression ratio "86" of the engine was 10.5 against 9.6 for the "83" modification. The cylinder head gasket of the new engine is now thinner, it is equal to 0.43 mm versus 1.2 on the old model. The diameter of the intake valves was increased, which improved the filling of the cylinders with the air-fuel mixture.

Does the valve fold

This problem, unfortunately, is present for Lada Granta. It appeared from the moment the production of the first cars with front-wheel drive VAZ 2108 began. Later, the working volume of the power unit of this model was increased, it became equal to 1.5 liters. The engine index became 21083, in which the pistons have a recess in the head. This made it possible to exclude the meeting of the pistons with the valves when the toothed belt in the timing belt breaks or if it is incorrectly installed. It was this power unit that was taken as the basis for the engine for Grants, so the valves did not bend.

The upgrade of this motor to model 11186 provides for the installation of lightweight parts of the connecting rod and piston group. The piston has become shorter in height, which does not allow making recesses in the head to avoid meeting with the valve. Therefore, a break of the toothed belt is always accompanied by damage to the valves on the 8 valve Grant, sometimes connecting rods, pistons. This problem accompanies all subsequent modifications of engines for Lada Grant.

Replacement procedure

Many owners of this car prefer to carry out this operation in specialized workshops, but some do it themselves. There is nothing super complicated in this procedure, there is no need to purchase special equipment or devices. You can replace the toothed belt in the garage yourself. You will need to prepare a set of wrenches, a mounting spade, a jack, a support for the body, wheel chocks, gloves, and rags. Use round nose pliers as a key for adjusting the tensioner roller.

Replacing the timing belt on the Lada Grant is performed in approximately the following sequence:

- The car is installed above the inspection pit or on a flat surface, the handbrake cable is tightened, and chocks are installed under the rear wheels.

- Open the hood of the engine compartment, disconnect the terminals from the battery.

- The drive belt of the generator set will interfere with work, so it is removed.

- Now "5" with the hex number unscrew the four screws that secure the front protective casing of the timing drive.

- To avoid accidentally damaging the crankshaft position sensor, it should be removed from the cylinder head and set aside. Do not allow metal filings to come into contact with the sensor, they may distort its readings in the future.

- Next, you need to set the piston of the first cylinder to the top dead center position.

- Removal of the toothed belt is interfered with by the alternator drive pulley on the crankshaft, which must be removed. To do this, rip off the wheel bolts of the right front wheel, raise the body with a car jack.

- A stand is installed under the body, the wheel is removed, the protective shield is on the mudguard.

- An assistant is needed to remove the crankshaft pulley. Ask him to put in fifth gear and push the brake pedal hard. Some specialists insert a powerful screwdriver into the hatch on the gearbox cover between the flywheel teeth.

- Applying some effort to the head "17", unscrew the bolt, remove the pulley from the crankshaft.

- Again, you need the fifth hex number, which you need to unscrew the three screws of the lower timing case, then you can remove the protection.

- Now it is necessary to loosen the tension roller fixing bolt, the “15” spanner wrench is best suited for this. After that, the roller will turn, release the tension on the drive belt, which can be easily removed from the toothed gears and removed from the engine compartment.

Important! After that, the engine crankshaft must not be turned so that the pistons do not meet the valves.

Usually, the belt is replaced in conjunction with the idler roller and the coolant pump, so they must be removed from the cylinder block. There is an adjusting washer under the roller, which is installed back during assembly. When removing the pump, a certain amount of antifreeze is poured into a previously prepared container. The installation of a new timing belt is carried out in the reverse order. Please note that you need to check the position of all alignment marks on the crankshaft and camshaft, the cylinder block and the timing case.

Setting labels

This is an important procedure when replacing a timing belt and must be taken seriously. This motor has four timing marks. Two on the crankshaft and camshaft gears, one on the cylinder block in the area of the crankshaft, the last on a metal protective casing. Two more marks are located on the flywheel and gearbox housing. They will be clearly visible when the rubber plug is removed. It is the marks of the flywheel and the box casing that will indicate the position of the piston of the first cylinder at top dead center.

The crankshaft is turned clockwise with a “19” wrench until all marks of the mechanism match. The tapered groove or tide mark on the camshaft pulley will be horizontal and aligned with the lip on the guard. The mark on the crankshaft pulley will look strictly vertical and coincide with the mark on the cylinder block.

Tension

The installed new toothed belt must be tensioned to the required parameters. Before that, be sure to check the position of the alignment marks again, if everything is in order with them, you can tension the drive. To do this, turn the tension roller counterclockwise until the marks on it coincide. One mark in the form of a cutout is on the outer cage, the second on the inner one in the form of a ledge. You can turn the tension roller with a special wrench, round-nose pliers.

Some craftsmen insert drills suitable in diameter into the holes on the moving part of the roller. Between them, a screwdriver as a lever and turn the clip until the marks coincide. Then you can tighten the tension roller fixing screw. After all the work has been done, it is necessary to manually turn the crankshaft a few turns, making sure that the marks have not moved. Then you can install the protective cover.

How long does it take to replace

The factory operating manual for the car recommends replacing the toothed belt with a mileage of 75 thousand km. This norm is not always fulfilled by the owners; there are good reasons for this. How long the drive takes before replacement depends on many factors. This is the quality of the parts used, the operating conditions of the vehicle, the technical condition of the engine. At each maintenance, the tension and condition of the timing drive should be checked. When cracks, delamination, or other damage appear, the belt is changed.

With a high mileage of the machine, natural wear of the crankshaft and camshaft pulleys occurs, this significantly reduces the service life of the entire timing drive. And also the drive is afraid of engine oil getting into the belt operation zone. It softens its structure, the teeth are easily cut off. If the car has been standing still for a long time, it is also better to replace the drive due to its aging. Most owners, experts recommend changing the belt after a run of 50 thousand km.

Which kit to buy

In addition to the toothed belt, a tension roller and a coolant pump are purchased. The main supplier of rubber products is the RTI plant in Balakovo. Products from the companies GATES, BOSCH, DAYCO, CONTITECH have proven themselves well. If the pump in the engine cooling system is replaced, you will need antifreeze to top up.

It serves to timely open and close valves in the block head. Such a mechanism is also available on the Lada Grant. However, there are two types of drive - chain and belt. If we talk about "Grant", then it is the second type that is applied here. It must be said that such a drive is quieter, but less reliable. The chain is always more difficult to break than the belt. However, if you observe the replacement interval, you may not encounter a break. And in today's article we will pay attention to replacing the timing belt "Lada Grants".

How it works?

The principle of operation of this element is quite simple. First, let's tell you about the location. And this element is located on the side of the crankshaft pulley. Since the "Grant" has a transverse engine, the belt is located on the side of the right front wheel. Unlike a chain, it does not require lubrication and therefore can be installed openly. The belt has special teeth on the inside. Thanks to them, the element engages with several parts at once:

Thus, when the first shaft rotates in a chain reaction, the rest of the elements also rotate. And since the belt is flexible, it is pulled with a special roller for high-quality engagement. Thus, the two shafts rotate synchronously. It is unacceptable for the belt to jump one or more teeth. Otherwise, the intake and exhaust settings are instantly lost. This will immediately be felt on the nature of the car's behavior. The car will triple, consume more fuel and not pull.

How often to change?

According to the regulations, it is required to replace the timing belt on a Lada Grant with an 8-valve engine every 75 thousand kilometers. However, the manufacturer recommends checking its condition every 15 thousand kilometers. It often happens that the belt has lost its tension or has acquired signs of wear ahead of schedule.

Signs of wear

How to understand that a given element is out of order? The first sign indicating the need to replace the timing belt on the "Grant" is a significant wear of the material. This usually occurs due to poor performance of the idler roller bearing or a deviation in its position. So, at high humidity, the belt can jump by one or several teeth.

It is important to carefully check the external condition. So, the belt must be replaced if there are tissue remnants, cracks or delamination on it. The more of these defects, the higher the likelihood that the element will suddenly break. Do not use too hard belt. This will be indicated by the characteristic brilliance of the element. Because of this, high-quality contact with the engine crankshaft pulley is not ensured. What brand should I choose a new belt? It is not necessary to purchase the original. There are several good analogs:

But do not buy too cheap analogs. Otherwise, no one can guarantee that such a belt will serve 75 thousand kilometers specified by the manufacturer.

Preparation

For work we need a standard set of tools, a new belt with a roller, as well as a roller wrench. It will not be superfluous to buy a new alternator belt, since we will also be removing it.

It is not necessary to carry out work in the pit. It is enough to unscrew the right front wheel for convenience. So, you need an additional wheel wrench and a jack. Place anti-roll bars under the machine before lifting.

Getting Started

So, first we need to remove the plastic protective cover. This can be done using a 5 Allen key. The cover is secured with four screws. If the motor 11183 is installed on the "Grant", here you need a key for 10 for this. It is enough for them to unscrew the three fastening bolts. Next, the crankshaft position sensor is removed. The fastening screw is unscrewed with a 10 spanner. The DPKV is also dismantled.

Setting labels

Now it is important to install the crankshaft and camshaft according to the marks. To do this, turn on neutral. Remove the rubber cover on the crankcase (closer to the clutch). We need to align the marks in the scale slot and on the flywheel. Then the latter is fixed with a minus screwdriver. The crankshaft itself can be rotated with a 17 or 19 key (depending on the specific type of motor). Better to perform this operation together. While one rotates the shaft, the second fixes the position of the marks. The main thing is that they match exactly.

What's next?

Then you need to remove the alternator belt. This is the only way to get to the timing belt "Lada Grants". We loosen the tensioner and remove the generator drive. With a 13 key, loosen the lower fastening bolt and unscrew the upper fastening nut. The bolt can also be removed. The generator casing is pressed against the engine by means of a wire and fixed.

Change the belt

When the flywheel is fixed, using a 19 or 17 key, unscrew the bolt that holds the generator drive pulley. The pulley is dismantled together with the washer.

- If it is an 11183 series engine, use a 17 key to loosen the retaining nut. The roller itself rotates clockwise.

- On other engines, a head 15 is used. It is used to unscrew the bolt by about three turns. Then the roller will release the belt on its own.

Now we just have to remove the old belt and install a new one. Timing on "Lada Grant" with an 8-valve engine is performed in reverse order. To tighten the outer part of the roller, rotate counterclockwise. In this case, the two marks (rectangular) must coincide with each other. After installing the element, it is worth checking the labels again.

As for the alternator belt, it is installed in the following sequence:

- First, the generator itself is mounted.

- Next, the belt is put on the pulleys.

- Having turned on the fifth gear, they roll the car back.

That's all. Belt replacement completed successfully. You can start full-fledged operation of the car.

About tightening torques

When changing the timing belt on a Lada Granta car, it is important to use a torque wrench. So we will know for sure that the bolts and all connections are properly tightened and, most importantly, not overtightened. Depending on the type of part, the following values are set on the key:

Please note: when changing the timing belt on a "Lada Grant" with an 8-valve engine, first adjust the tension on the roller. And after that, the fastening bolt is tightened.

Conclusion

So, we found out how the timing belt is replaced on the Lada Grant. As you can see, this operation can be performed independently. In total, the replacement will take about two hours. But if the work is not done for the first time, then the time can be cut in half.

Timing replacement Lada Granta 8 valves required once every 75 thousand kilometers. If you ignore the planned replacement of the belt, tension roller and sometimes the pump (coolant pump), then you can run into a serious repair of the Lada Granta engine. After all, a break in the timing belt almost always leads to damage to valves, valve seats and even pistons. Therefore, the timing drive must be treated very carefully. Once 15 thousand, it is imperative to inspect the belt for breaks, cracks, delamination or oiling.

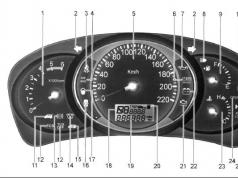

A detailed diagram of the timing drive Lada Granta more.

- 1 - crankshaft toothed pulley

- 2 - toothed pulley of the coolant pump

- 3 - tension roller

- 4 - back protective cover

- 5 - toothed pulley of a camshaft

- 6 - timing belt

- A - lug on the rear protective cover

- B - mark on the camshaft pulley

- C - mark on the cover of the oil pump

- D - mark on the crankshaft pulley.

To replace the timing belt, we should remove the alternator belt or accessory belt for Grant with air conditioning. With a "5" hexagon, unscrew the four screws securing the front top cover of the timing drive and remove the plastic casing.

To avoid damage to the crankshaft position sensor, remove it as well. With the ignition off, squeeze the lock of the wiring harness block and disconnect the block from the sensor connector. Using the "10" head, unscrew the sensor mounting bolt.

We take out the sensor from the tide hole of the oil pump cover and put it aside in a place where there are no steel filings that could subsequently disrupt the operation of the sensor.

Before dismantling the belt, it is necessary to check the valve timing of the engine - set the piston of the 1st cylinder to the TDC (top dead center) position of the compression stroke. Using the “17” head, turn the crankshaft clockwise by the bolt securing the alternator drive pulley until the mark 1 on the camshaft toothed pulley aligns with the tide 2 on the rear cover of the timing drive.

To make sure that the crankshaft is in the correct position, remove the rubber plug of the sight glass at the top of the clutch housing. Risk 2 on the flywheel should be located opposite the slot 1 of the scale that is visible in the window of the clutch housing cover.

Before unscrewing the bolt securing the alternator drive pulley, we ask the assistant to secure the crankshaft from turning by inserting a screwdriver through the window in the clutch housing between the flywheel teeth.

Using the "17" head, unscrew the bolt securing the alternator drive pulley, remove the pulley and washer.

With a "5" hexagon, unscrew the three screws securing the front lower timing cover. Remove the cover.

Using a 15 spanner wrench, weaken the tightening of the tension roller bolt.

This will rotate the tension roller and release the belt tension. Remove the timing belt from the crankshaft and camshaft pulleys. We take out the belt from the engine compartment Grants.

Attention! After removing the timing belt, do not turn the crankshaft and camshafts to avoid the pistons sticking into the valves. The dimensions of the timing belt of the Lada Granta timing belt with an 8-valve engine are 17 mm wide, the number of teeth is 113.

To remove the timing belt tensioner, unscrew the bolt and remove the tensioner along with the bolt.

We rotate the plastic clip of the roller, holding it by the eccentric. The roller should rotate quietly, evenly and without jamming. Otherwise, the roller must be replaced.

At the same time, you can check the serviceability of the coolant pump by twisting and shaking it by the pulley. We install the tension roller in place, completely without tightening the bolt of its fastening. For various engine modifications, two threaded holes are made in the cylinder head for the tension roller bolt. Screw the roller mounting bolt into the upper hole of the cylinder head. In the photo below, the hole is indicated by a red arrow.

Install the Grant timing belt in reverse order. Before installing the belt, make sure that the timing marks of the crankshaft and camshaft are aligned. We put the belt on the crankshaft toothed pulley, then pulling both branches of the belt, put the rear branch on the coolant pump pulley and put it behind the tension roller, and put the front branch on the camshaft pulley.

If necessary, turn the camshaft pulley in the direction of the smallest stroke until the belt teeth coincide with the pulley grooves. To tension the belt, turn the tension roller counterclockwise. To do this, insert the rods (diameter 4 mm, distance between the rods 18 mm) into the grooves of the outer disk of the roller with a special key (for clarity, it is shown on the removed roller).

Such a key was used to adjust the belt tension in all front-wheel drive VAZs; you can buy it at any auto parts store.

Also, to adjust the tension of the Lada Granta timing belt, you can use pliers to remove the retaining rings. We tighten the belt by turning the belt tension roller counterclockwise until the cutout of the outer disk of the roller coincides with the rectangular protrusion of its inner sleeve, and tighten the roller mounting bolt to a torque of 34–41 Nm.

Excessive belt tension will reduce belt life as well as the life of the coolant pump and idler roller bearings. Insufficient belt tension also leads to its premature failure and can cause a violation of the valve timing. We turn the crankshaft two turns clockwise. We check the belt tension and the coincidence of the crankshaft and camshaft timing marks. With the generator drive pulley removed, it is convenient to check the correct position of the crankshaft by aligning mark 1 on the crankshaft toothed pulley with rib 2 of the oil pump cover. Photo for clarity below.

If you are not confident in your abilities, then you can entrust the work of replacing the belt on the Lada Granta to a car service. For an engine with an 8-valve timing mechanism, this is cheaper than for a version with a 16-valve engine.