Measuring equipmentDEVICE FOR DETERMINING INTERTURN CLOSURES A simple attachment to an avometer, the diagram of which is shown in the figure, allows you to detect interturn short circuits of up to three or four turns in transformers, chokes and other parts with windings. The attachment is a low-frequency generator assembled according to a three-point circuit, with capacitive feedback through capacitors C1 and C2. The role of the inductance of the generator circuit is played by the coil being tested. Potentiometer R4 serves to maintain a constant amount of current flowing through transistor T1 when the internal resistance of the battery powering the generator changes. Avometer plugs are inserted into sockets Gn1 and Gn2. The tips are connected to the terminals of the part being tested. Socket Gn1 is also a power switch. To do this, it is cut lengthwise along its entire length. VHF circuit The halves of the socket are closed by the plug inserted into it, the power is turned on. Single-pole plugs, indicated by arrows below, are plugged into the sockets of the avometer to measure alternating voltage. The operation of the device is based on reducing the amplitude of the generated voltage when connecting a part with an interturn circuit, since in this case the quality factor of the circuit is significantly reduced. A decrease in voltage is noted by an avometer connected to the device. The assembled device is calibrated as follows. Prepare the device for measurements by connecting an avometer and probes to it as described above. Then a serviceable unified line regulator of the PRS-70 type with a core inserted inside the coil is attached to the probes. By adjusting potentiometer R4, the avometer shows the value of the alternating voltage...

For the circuit "Active probe for an oscilloscope"

Measuring equipment Active probe for an oscilloscope The input capacitance of modern oscilloscopes is about 30...50 pF. During measurements, the capacitance of the connecting cable is added to it, and the total input capacitance reaches 100...150 pF. This can lead to significant distortion of measurement results and incorrect settings, for example, of plug filters in the output stages of tape recorder recording amplifiers. That is why, when conducting research in circuits that are critical to the introduced capacitance of the measuring device, it is necessary to use special matching devices that have a high input resistance and a small capacitance. For most practical work, two main types of devices are needed: for harmonic signals of low amplitude (1...50 mV) with a transmission coefficient K>1 and for large amplitude signals (up to 10...20 V), allowing the transmission of the DC component of the signal and having a transmission coefficient K=0.2...0.5. The widespread use in recent years of high-speed analog and digital microcircuits operating at relatively high voltages (widespread op-amps, K561-series microcircuits up to 15 V) has revealed the need for a device operating in a wide voltage range with the ability to transmit a DC component of the signal. Puc.1 A diagram of such a device in the form of a probe is shown in Fig. 1. It is made according to the classic source follower circuit using a MOS transistor and contains a minimum number of parts. The operating frequency range is O...5 MHz. Power is supplied from any current source with a voltage of 7...15 V, for example, a 7D-0.115-U1.1 battery or galvanic batteries "Krona", "Korund". The input capacitance of the probe is no more than 4 pF, the input resistance is no less than 3 MOhm. The output voltage at Uin=0 is 2.5 V. The range of input voltages in the region of negative values (before cutoff) is 7 V, in the region of positive values (before the start...

For the "Wideband aperiodic RF amplifier" circuit

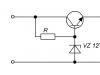

For the radio amateur designer Wideband aperiodic RF amplifier The high-frequency amplifier brought to the attention of readers can find the widest possible application. This is both an antenna amplifier for a radio receiver and an amplifier for oscilloscope with low sensitivity of the vertical deflection channel, and an aperiodic IF amplifier, and an instrumentation amplifier. The amplifier's input and output are designed to be connected to a line with a characteristic impedance of 75 Ohms. The operating frequency band of the amplifier is 35 kHz - 150 MHz with unevenness at the edges of the range of 3 dB. Maximum undistorted output voltage 1 V, gain (at 75 Ohm load) - 43 dB, noise figure at 100 MHz - 4.7 dB. The amplifier is powered from a 12.6 V source, current consumption is 40 mA. The schematic diagram of the amplifier is shown in the figure. It consists of two series-connected amplification cells, in each of which resistive amplifier stages on transistors N1, T3 are loaded onto emitter followers on transistors T2, T4. Triac TS112 and circuits on it To expand the dynamic range, the current through the last emitter follower is selected to be approximately 20 mA. The amplitude and frequency characteristics of the amplifier are formed by frequency-dependent feedback circuit elements R4C2, R10C5 and simple high-frequency correction chokes Dr1 and Dr2. Structurally, the amplifier is made on a printed circuit board made of foil fiberglass and placed in a silver-plated brass case. The connectors are high-frequency connectors SR-75-166 F. High-frequency chokes Dr1 and Dr2 are frameless. Their windings contain 10 turns of PEV-1 0.25 wire, the diameter of the windings is 5 mm. If 43 dB gain is excessive, only one amplification cell can be used, depending on the intended purpose, either on T1 transistors. T2 with a supply voltage of + 5 V, or on transistors T3, T4 with a supply voltage of +12.6...

For the circuit "Two circuits of simple sweeping frequency generators"

For the circuit "SIMPLE LF AND HF SIGNAL GENERATOR"

Measuring equipment SIMPLE LF AND HF SIGNAL GENERATOR A simple low and high frequency signal generator is designed for setting up and testing various instruments and devices manufactured by radio amateurs. The low frequency generator produces a sinusoidal signal in the range from 26 Hz to 400 kHz, which is divided into five subranges (26.. .240, 200...1500 Hz: 1.3...10, 9...60, 56...400 kHz). The maximum amplitude of the output signal is 2 V. The harmonic coefficient over the entire frequency range does not exceed 1.5%. Uneven frequency response - no more than 3 dB. Using the built-in attenuator, you can attenuate the output signal by 20 and 40 dB. There is also a smooth adjustment of the amplitude of the output signal with its control using a measuring device. The high-frequency generator produces a sinusoidal signal in the range from 140 kHz to 12 MHz (subranges 140...340, 330...1000 kHz, 1...2.8 ,2.7...12 MHz). The high-frequency signal can be modulated in amplitude by a signal from both the internal low-frequency generator. and from external sources. The maximum amplitude of the output voltage is 0.2 V. The power supply is based on thyristors. The generator provides a smooth adjustment of the output voltage with amplitude control using a measuring device. The supply voltage of both generators is 12 V. The schematic diagram of the device is shown in Fig. 1. The low frequency generator is built on the basis of a well-known circuit. The frequency of the generated signal is changed by a dual variable capacitor C2. The use of a block of variable capacitors to generate low (30...100 Hz) frequencies required a high input impedance of the generator amplifier. Therefore, the signal from the bridge goes to the flow follower on field-effect transistor V1, and then to the input of a two-stage amplifier with direct connections (chip A1). From the output of the microcircuit, the signal is supplied to the output emitter follower on transistor V3 and to the second diagonal of the bridge. From resistor R16, the signal is supplied to the output voltage divider (resistors R18-R22) and to the measuring device PU1. by which control...

For the "MODULATOR AND DEMODULATOR SSB" circuit

Units of amateur radio equipment MODULATOR AND DEMODULATOR SSB Similar ones are often found in the literature scheme on IC K174UR1, on K174URZ they are obtained simpler and with a smaller number of hanging elements (Fig. 1, 2). Scheme can also be performed with a separate local oscillator. In this case, the signal (Uget

For the scheme "ATTACHMENT-GKCH FOR RANGES 300...900 and 800...1950 MHz"

Measuring equipment ATTACHMENT-GKCH FOR RANGES 300...900 and 800...1950 MHz Adjustment of radio-electronic equipment with visual display of amplitude-frequency characteristics is constantly of great interest among radio amateurs and specialists, as it allows you to quickly see on the screen of the measuring device the results of the influence when changing which -parameter or element of the customized product. The only drawback of this control method is the relatively high price(s) of industrial samples of frequency response meters. But radio amateurs have found a worthy solution here too - the creation of simple attachments for the already familiar oscilloscope. In this case, the frequency response of the oscilloscope itself does not play a special role. The magazine "Radio" 1994, No. 1, p. 26 provided a description of such a set-top box for adjusting television equipment, indicating the possibility of expanding its functionality. Today we provide recommendations for improving this set-top box with the task of using it to adjust devices operating in the UHF and microwave bands (UHF channel selectors, tuners for satellite television broadcasting systems, etc.). Amateur radio converter circuits The publication in the named magazine of a description of a set-top box for measuring frequency characteristics and subsequent responses from radio amateurs forced us to develop recommendations for the mass repetition of a device operating in higher frequency ranges. Below are descriptions of two options for modifications to the set-top box with generators at 300...900 and 800...1950 MHz. It turned out that modifying the set-top box does not require its complete rework; it is enough to just change the design of the high-frequency generator. Therefore, the numbering of elements on the schematic diagrams provided continues the numbering of the main scheme consoles. Fig. 1 shows the circuit diagram of the MCC, it is the same for both high-frequency...

For the "Eternal Power Supply" circuit

To operate a TV, computer, or radio, a stabilized power supply is required. Devices that are connected to the network around the clock, as well as circuits assembled by a novice radio amateur, require an absolutely reliable power supply unit (PSU) to prevent damage or fire to the power supply. And now a few “horror” stories: one of my friends, when a control transistor broke down, lost many microcircuits in a homemade computer; in another, after shorting the wires going to an imported radiotelephone with a chair leg, the power supply melted; the third has the same thing with the power supply of a “Soviet” industrial TA with caller ID; for a novice radio amateur, after a short circuit, the power supply began to deliver high voltage to the output; In production, a short circuit in a line of measuring instruments almost certainly leads to a stoppage of work and the need for urgent repairs. We will not touch upon the circuits of pulse blocks due to their complexity and low reliability, but will consider the circuit of a compensatory serial power regulator (Fig. 1). ...

Most oscilloscopes have an input impedance of 1 megohm and a capacitance of 20 pf. With the use of a 1X10 divider, the resistance increases to 10 MΩ and the capacitance drops to several picofarads. However, even such parameters can change the parameters of the measured circuit, producing unreliable readings. The task of this probe is to introduce a minimum error into the measured circuit. To do this, the probe resistance should tend to infinity and the capacitance to zero. To obtain such parameters, a precision operational amplifier and design tricks are required, in particular, the probe needle does not touch the board and, passing through the fluoroplastic boss, is soldered directly to the legs of the microcircuit. The widely used CA3140 was chosen as the operational amplifier. Here are the parameters we are interested in from the datasheet:

Since I don’t have the opportunity to control such high parameters, I’ll use slightly reduced datasheet data. Then the product parameters will be as follows:

- Input impedance - 1 Volume

- Input capacitance - 5 pF

- Gain - 1:10 and 1:1

- Maximum input voltage 12 volts

- Maximum output voltage - 8 volts

- Maximum operating frequency - 1 MHz

The circuit is as simple as a felt boot, so it does not indicate blocking capacitors for the power supply and a common-mode choke on the power wire. Trimmer resistors adjust DC offset and gain in 1:10 mode.

This is what the finished structure looks like, with the ground wire with the crocodile at the end not soldered on.

A good source of fluoroplastic bosses are SMA connectors; in this design, it is soldered in its entirety. An important step is to rinse the board with alcohol; without this, you can forget about ultra-high resistances, and sometimes even end up with an inoperable device.

The input capacitance of modern oscilloscopes is about 30...50 pF. During measurements, the capacitance of the connecting cable is added to it, and the total input capacitance reaches 100...150 pF. This can lead to significant distortion of measurement results and incorrect settings, for example, of plug filters in the output stages of tape recorder recording amplifiers. That is why, when conducting research in circuits that are critical to the introduced capacitance of the measuring device, it is necessary to use special matching devices that have a high input resistance and a small capacitance.

For most practical work, two main types of devices are needed: for harmonic signals of small amplitude (1...50 mV) with a transmission coefficient K>1 and for signals of large amplitude (up to 10...20 V), allowing the transmission of the DC component of the signal and having a transmission coefficient K=0.2...0.5.

The widespread use in recent years of high-speed analog and digital microcircuits operating at relatively high voltages (widespread op-amps, K561-series microcircuits up to 15 V) has revealed the need for a device operating in a wide voltage range with the ability to transmit a DC component of the signal.

A diagram of such a device in the form of a probe is shown in Fig. 1. It is made according to the classic source follower circuit using a MOS transistor and contains a minimum number of parts. The operating frequency range is O...5 MHz. Power is supplied from any current source with a voltage of 7...15 V, for example, a 7D-0.115-U1.1 battery or galvanic batteries "Krona", "Korund". The input capacitance of the probe is no more than 4 pF, the input resistance is no less than 3 MOhm. The output voltage at Uin = 0 is 2.5 V. The range of input voltages in the region of negative values (before cutoff) is 7 V, in the region of positive values (before the start of limitation) is 13 V at Upit = 9V and 26 V at Upit = 15V.

The transmission coefficient in the specified frequency range is 0.4.

Resistors R1 and R2 form an input voltage divider, capacitor C1 serves for frequency compensation.

Due to the significant scatter in the parameters of specific transistor instances, the characteristics of the probe designs may also differ mainly in cutoff voltage and transmission coefficient. To obtain the maximum operating range in the region of negative input voltages, it is necessary to use transistors with a maximum (in absolute value) cutoff voltage. The author used a transistor with Uzi otc = 4.2 V. Most KP305I transistors have a lower value of Uzi otc, therefore, if necessary, the cutoff voltage of the probe can be increased by reducing the transmission coefficient of the input divider, for example, by increasing the resistance of resistor R1. However, for many measurements where adjustment to the maximum or minimum voltage is required, the value of the cutoff voltage of the probe is not significant, since adjustment can be made using the positive half-wave of the signal.

The probe is assembled in a felt-tip pen housing. The installation is three-dimensional, without the use of additional structural elements. The terminals of the radioelements are connected directly to each other. The probe is connected to the oscilloscope with a shielded cable no more than 30 cm long.

When installing the probe, measures should be taken to prevent breakdown of the field-effect transistor by static electricity and interference from the network.

Setting up the device consists of calibrating to obtain the required transmission coefficient and selecting the capacitance of capacitor C1. Calibration will require the use of a regulated DC power supply and a voltmeter. By selecting the resistance of resistor R1, the transfer coefficient K = 0.4 (or 0.5) is set, while taking into account the initial bias voltage at the output.

When selecting the capacitance of capacitor C1, a rectangular pulse generator with an output signal amplitude of 2...10 V and a repetition frequency of 1...10 kHz is required. To ensure steep edges, you can use a trigger frequency divider, for example, on microcircuits of the K155, K176, K561 series. By changing the capacitance of the frequency compensation capacitor C1, we achieve rectangular pulses on the oscilloscope screen without falling edges; the amplitude of surges at the edges should be no more than 10% of the pulse amplitude. Too much capacity causes significant surges along the fronts, while insufficient capacity causes them to be delayed.

On the body of the manufactured structure it is necessary to label the device parameters - input capacitance, resistance and transmission coefficient.

When carrying out measurements with a DC component reading, the oscilloscope must be adjusted to the reading level. To do this, short-circuit the probe input and set the oscilloscope beam to zero.

I present to you a review of an oscilloscope probe after 3+ months of use.

Upd. 02/22/2019: the review has been supplemented taking into account the experience gained from operating the probe. Addition at the end of the review.

Instead of a preface

At the time of ordering (10/26/2014), the probe cost $6.89, but I also had BiK coins, taking into account which the price turned out to be 6.55 and I did not find any cheaper offers. The dipstick was ordered on 10/26 and shipped on 10/28—quite standard two days for BiK. The parcel was without a track number. I do not provide photos of the parcel and packaging. BIK has never been known for its good packaging quality (although I haven’t ordered anything more expensive than $20 from them, I think they pack expensive orders much better). Currently the price tag for the dipstick is set at $4.17, but it is out of stock. BiK also changed the photo of the probe on the description page, which shows that the colors of some components have changed (the switch slider is black, the rings are yellow, the caps are gray to match the probe) and the equipment (there are 2 times more caps, and a couple fewer rings) ). By the way, the last review about the probe on the store page is mine. :)

Characteristics of the probe from the store page:

The dipstick was packed in a plastic bag with instructions and insert, here is its contents:

A few words about the purpose of all these additional “things”.

The rings are attached to the bayonet connector connected to the oscilloscope and the probe handle and are used to conveniently determine by the color of the rings which probe handle is connected to which channel of the oscilloscope (but since there is only one probe included in the kit, these rings will be useful for owners of the same complete probes). Here I changed the rings on my dipstick to light green ones:

The attachment in the form of a cap is intended for isolation from the general one; it is useful when you need to “get through” wires/boards with a probe.

Almost the same nozzle, differing only in protrusions on both sides of the signal needle, can be used like the first, but is just as convenient for “poking” into boards with SMD components. These caps are quite difficult to put on and even more difficult to remove. :)

And finally, the most useful thing, in my opinion, is the grip. Used to hold the probe by the wire/output of the measured signal. Allows you to cling to thicknesses from fractions of a mm to 2.5mm. Works as it should. I use it, unlike all those described above, regularly.

The kit also includes a screwdriver with a plastic handle for calibrating the probe.

The appearance of the probe itself is quite clear from the above photos, but for completeness I will add a photo from this angle:

It should be noted that the instructions included in the kit are not just for show; they contain almost all the necessary information. See for yourself:

But I’ll tell you what the instructions are silent about. The length of the probe cable with a bayonet mount is 104cm, the length of the probe handle from the cable to the needle is 14cm (i.e. the total length of the probe is 104+14=118cm, 2cm was not enough to reach the stated 120cm), the length of the common wire with the crocodile is 14.5cm . The probe did not produce any odors; I liked the softness/flexibility of the cable. During use, the x1/x10 switch slider (divider switch) has become less clear in its extreme positions. The design of the switch itself does not inspire confidence, I try to use it as little as possible (as a rule, the probe is always operated in x10 mode), which I recommend to all users of similar probes. The common wire with the crocodile is removable. The alarm needle is not so sharp that you could accidentally prick yourself with it, but it is not dull either. During use, if it became dull, I didn’t notice it. The metal from which it is made is not magnetic.

Even before ordering this probe, as befits a person buying an item for personal use, I found out the questions that interested me regarding such probes. And therefore I knew that the imported connector called “BNC” on the probe does not fit perfectly with our “CP-50-73” mount on the oscilloscope - the BNC connector does not screw in completely. And I knew that this could easily be corrected with a suitable file.

Actually, this is what happened - the probe was inserted tightly into the input connector of the oscilloscope, but it was not possible to fix it - the angle of the machined grooves on the BNC connector was a little too large. Well, I take it off and carefully sharpen it with a file. This is what a BNC connector adapted for the domestic bayonet looks like:

It is worth noting that the weight of the BNC connector of this probe is much less than the weight of the CP-50-74 connector of the supplied probe. This is not surprising because BNC uses much less metal.

I bought a probe for my S1-65 oscilloscope. This oscilloscope has a declared channel Y bandwidth of 0-35 MHz (with frequency response roll-off not exceeding 3 dB, for 5 mV/div), input capacitance no more than 30 pF with a resistance of 1.0 MΩ ± 5%. We compare it with the characteristics of the probe - the input resistance is suitable, the capacitance compensation range is also suitable. Those. no contraindications :)

The C1-65 has a built-in calibrator that produces a 1 kHz square wave with an amplitude from 0.02 to 50 V or a constant voltage with the same range. The calibrator is designed specifically for checking and adjusting the Y channel of the oscilloscope and the complete divider with a division coefficient Kd=10. Unfortunately, I came into possession of an oscilloscope with only one such probe (from now on in the text I will call it a complete probe, although in fact the history of its origin is unknown to me):

Oscilloscope calibrator S1-65:

This is what the schematic diagram of the complete remote divider for the S1-65 oscilloscope looks like (which I don’t have):

But the actual schematic diagram of the device under review is unknown to me, because its design is not collapsible, but knowing that the probe is a frequency-compensated voltage divider and knowing its parameters, I believe that it (the circuit) looks like this:

Where Rк is the resistance of the central core of the probe cable, and Ck is the capacitance formed by the nearby central core and braid of the probe cable and its installation.

The DC divider parameters are calculated as follows:

Probe resistance Rп=Rх+R2;

Division coefficient Kd=R2/(Rx+R2).

where Rx is the total resistance, consisting of the series-connected resistances of resistor R1 and the central core (signal wire) of the probe cable Rk equal to 100 Ohms (measured by a Chinese multimeter ADM-02), and R2 is the input resistance of the oscilloscope (datasheet).

Those. in our case, at direct current, a tenfold voltage division is provided by a divider consisting of a series-connected 8.9999 MOhm resistor (+100 Ohm cable) and 1.0 MOhm (±5%) input resistance of the oscilloscope.

On alternating current, the parameters of the divider are more difficult to calculate, because already involved are capacitances C1, the capacitance of the probe cable and its installation - Sk, the tuning capacitor C2 and the input capacitance of the oscilloscope, conventionally designated as capacitor C3.

If the ratio of capacitances in the capacitive divider formed by C1 and Ck+C2+C3 (hereinafter referred to as Cx) is equal to the ratio of resistances in the resistive one, then the amplitude-frequency characteristic of the probe will be smooth over the entire range, starting from direct current and up to frequencies limited by the general (active + reactance) resistance of the probe (after all, 22.5 pf indicated in the characteristics of the probe at a frequency of 35 MHz is a reactance of 202 Ohm). Therefore, the value of capacitance C1 is chosen, as a rule, equal to 1/9 of the value of capacitance Cx. In our case, we will take the total capacitance of the input of the oscilloscope and the probe to be 30 + 120 = 150 pF (in reality it could be more, but it is not possible to accurately measure the capacitance of the probe, so I took the maximum value stated in the characteristics), therefore, the capacitance of capacitor C1 should be no more than 16.7 pF. By changing the capacitance of the tuning capacitor C2, the compensation condition is achieved - Zc1*(R1+Rк)=Zcх*R2 (where Z=1/2πFC).

Setting the stylus compensation.

As shown in the instructions for the probe under review, when the probe divider is not configured, the meander can take one of two forms:

This is what rectangular pulses look like when the probe capacity is greater than necessary.

And so - when the probe capacity is less than necessary. Oscillograms from my oscilloscope with a signal from the calibrator at the extreme positions of the trimming capacitor (C2). By the way, C2 is located, as you already understood, on the bayonet mount:

And so, too much capacity causes significant surges along the fronts, while insufficient capacity causes them to be delayed. It is clear that with the divider adjusted, the shape of the top of the rectangular pulse should tend to a flat straight line (the shape of a real rectangular pulse is different from a rectangle - in any case, there is a spike in the form of a needle along the front of the pulse, and rounding is present along the fall). By changing the capacitance of capacitor C2, we achieve rectangular pulses on the oscilloscope screen without falling edges; the amplitude of surges at the edges should be no more than 5-10% of the pulse amplitude. For greater clarity/accuracy, I decided to carry out the adjustment by comparing the signal shape when measured with the supplied probe and the monitored one (taking into account the above thoughts). Having started to calibrate the probe divider from the calibrator built into the oscilloscope, I discovered how “sluggishly” the shape of the pulse front changes with a significant amount of rotation of the trimmer capacitor (C2), which clearly indicates that for a more accurate calibration of the probe divider in my case, it is necessary to use a signal more high frequency. This means that a rectangular pulse generator with a higher frequency was needed. Since there was no such ready-made generator on the farm, an HF pulse generator was “assembled” for these purposes. Well, “assembled” is not quite the appropriate term in this case, because... the whole structure is an Arduino board (by the way, at that time the Arduino board was homemade) with a power supply filled in and connected to it (the sketch was written not by me, but by a friend maxim from the resource arduino.ru). With a good power source, the shape of the rectangular pulses produced by the atmega328 microcontroller (my Arduino board is based on it) at a master oscillator frequency of 16 MHz has little distortion at frequencies up to 2 MHz. It was decided to carry out further calibration of the built-in divider of the probe under review at a frequency of 1 MHz. This is what the assembled test generator looks like:

And here is a comparison photo when setting up the probe divider:

1 MHz on the included probe.

1 MHz on the monitored probe in x1 mode.

Also in x10 mode.

And this is what the top of a pulse with a signal frequency of 4 MHz looks like on my oscilloscope:

The complete probe is on the left, viewed in x1 mode on the right.

The photo clearly shows that the monitored probe in this measurement mode is inferior to the complete probe and that both probes are not suitable for such accurate observation of the RF signal shape (4 MHz). The loss of the reviewed probe in such a test is quite natural, because C2 is connected to the probe and the length of its cable is significantly (33 cm) greater, and, therefore, its capacity is greater. However, in the instructions for the probe, the monitored probe in mode x1 suggests using up to frequencies of 6 MHz. Of course, it is possible, but if the input sensitivity of your oscilloscope allows you to observe a signal with a divider (in x10 mode), then I recommend using it at frequencies up to 6 MHz, because this reduces the input capacitance of the oscilloscope, and, therefore, introduces less distortion into the signal being studied (a clear example is in the photo above). It is worth noting that I was never able to perfectly calibrate the probe.

Conclusion - I personally am completely satisfied with the probe. Paired with a Soviet oscilloscope with a bandwidth of up to 100 MHz and a high-impedance input, it looks more attractive than the kit one. It makes sense to buy it if you don’t have a complete remote oscilloscope divider.

Upd. 02/22/2019

Another preface

Some time ago I needed nichrome/tungsten, and by searching on the Internet I found what I was looking for. So I found out the price of these metals and after that the thought did not leave me that this probe was somehow being sold cheaply - such a complex/technological device that also contained expensive materials (nichrome/tungsten). But while the probe was working, I didn’t want to open it (I assumed that it was not collapsible). However, not so long ago the contact in the probe mount began to disappear and, accordingly, there was a need to open it. I remembered that someone had already asked about opening this probe and the ratings of the parts in the mount. After digging through the site's personal messages, I found this correspondence with comrade -. He also showed me how the bayonet mount of such probes is disassembled.

It turns out that the bayonet is quite easy to disassemble - you just need to pull the rubberized “tail” of the probe off the metal shank of the bayonet (see photo). After this, part of the inner world of the probe will be revealed to us, and at the same time disappointment may come, because... The central core of the probe is made of ordinary stranded copper wire (no nichrome/tungsten), and the resistance of the central core of 100 Ohms is achieved by using an SMD resistor soldered on the board inside the bayonet. Also on the board, in addition to the tuning capacitor and a resistor with a nominal value of 100 Ohms, there is another resistor with a nominal value of 33 Ohms. The value of the second resistor may differ from mine depending on the capacitance of the tuning capacitor and the maximum declared frequency of the probe.

As you can see from the photo, the flux has not been washed off.

The board is screwed to the metal frame of the bayonet with an M1.7 screw. The screw also acts as a conductor - it connects the board track to the common one (frame).

The probe cable is crimped with a bayonet shank.

The reason for the loss of contact turned out to be a broken central metal core on the bayonet side. After cleaning the remaining part of the central contact with a scalpel, it was perfectly coated with inactive flux.

As a result, the probe circuit actually most likely looks like this:

What conclusions can be drawn? - The Chinese are such Chinese :) But seriously, since the central core is made of copper, there can be no talk of any distributed resistance. Accordingly, the accuracy at high frequencies will be lower... however, there are no alternatives available for such a price on the open market.

I liked the review

+39

+57

Active oscilloscope probe - a simple amateur radio design that can work with any oscilloscope

Good afternoon, dear radio amateurs!

Welcome to the website ““

In this article we will look at a design that is very necessary in the practice of radio amateurs - active probe for oscilloscope.

Many people are familiar with the situation when the connection oscilloscope to the configured device leads to a violation of its modes. The reason for this is primarily the capacitance and resistance of the oscilloscope input introduced into the circuit under study. Most oscilloscopes used by radio amateurs have a high input impedance of 1 MΩ and an input capacitance of 15-20 pF. In combination with a connecting shielded cable about a meter long, the total capacitance increases to 100 pF or more. For devices operating at frequencies above 100 kHz, this capacitance can have a significant impact on the measurement results. To eliminate this drawback, radio amateurs use either unshielded wire or active probes, proposed in this article, can work with various oscilloscopes, the input impedance of which can be low - 50 ohms or high - 1 megohms. Its transmission coefficient is 1 or 10. That is, it not only does not weaken, but also enhances the signal. The advantages include small dimensions. Such parameters were achieved through the use of a high-speed operational amplifier.

Upper operating frequency of at least 100 MHz, input resistance 15 MOhm, input capacitance 1.7 pF, input voltage up to ± 13.5 volts, current consumption in the absence of a signal 6 mA. It should be especially noted that the presence of an amplification mode allows you to observe input signals with an amplitude of 200...300 μV on the oscilloscope screen with a sensitivity of 10 mV per division.

Most of the probe parts are placed on a printed circuit board made of double-sided fiberglass foil. Connections between the mounting sides are made with conductors through holes in the board. The switches are installed on the probe body, and the capacitor directly on SA1.

The probe body consists of a plastic case 1 (from a felt-tip pen with a diameter of about 18 mm) which is inserted into a metal casing 2. Inside the case there is a board 3, switches SA1, SA2 (4 and 5) are mounted on it, connecting and power wires 6 are routed through the bottom. The common wire of the board is connected to the casing, and a wire for the metal pin X1 - 7 is brought out through a hole in it. All internal connections must be made with a minimum length wire, and external connections - the power and signal circuits - must be made with a shielded and RF cable, respectively. Since one of the two amplifiers in the microcircuit is not used, its inputs (pins 5 and 6) are connected to a common wire.

The probe body consists of a plastic case 1 (from a felt-tip pen with a diameter of about 18 mm) which is inserted into a metal casing 2. Inside the case there is a board 3, switches SA1, SA2 (4 and 5) are mounted on it, connecting and power wires 6 are routed through the bottom. The common wire of the board is connected to the casing, and a wire for the metal pin X1 - 7 is brought out through a hole in it. All internal connections must be made with a minimum length wire, and external connections - the power and signal circuits - must be made with a shielded and RF cable, respectively. Since one of the two amplifiers in the microcircuit is not used, its inputs (pins 5 and 6) are connected to a common wire.

Setting up the device comes down to setting the required gain, which, when operating the probe with an oscilloscope with a high input impedance, is set to 10 at a frequency of 10 MHz by selecting resistor R1 (with SA1 closed). If the probe is used with an oscilloscope with a low-impedance input, part of the output signal is suppressed at the termination resistor R5. Therefore, resistor R6 is introduced into the circuit and its resistance is selected (with SA1 open), the transmission coefficient is set to 1. With SA1 closed (high sensitivity mode), the gain is set to 10 by selecting resistor R1.

The device uses resistors MLT, C2-10, C2-33, R1-12, capacitors – C1-C3 of the KM series or other small-sized ones (K10-17, K10-47), C4 and C5 of the K52 group or similar. You can use broadband op-amps AD812AR, AD817AN, AD818AN from the same company, which are cheaper due to their smaller frequency band, but their use will also lead to a reduction in operating frequencies. To power the probe, a bipolar stabilized power source with an output voltage of ± 12…15 volts is required. The current consumption of the probe during operation can reach 100 mA.