Purpose

2.4.1. Voltage indicators are designed to determine the presence or absence of voltage on live parts of electrical installations.

2.4.2. General technical requirements for voltage indicators are set out in the state standard.

Voltage indicators above 1000 V

Operating principle and design

2.4.3. Voltage indicators above 1000 V react to capacitive current flowing through the indicator when its working part is introduced into the electric field formed by live parts of electrical installations that are energized, and the “ground” and grounded structures of electrical installations.

2.4.4. The indicators must contain the main parts: working, indicator, insulating, and also a handle.

2.4.5. The working part contains elements that react to the presence of voltage on the controlled current-carrying parts.

The housings of the working parts of voltage indicators up to 20 kV inclusive must be made of electrical insulating materials with stable dielectric characteristics. The housings of the working parts of voltage indicators of 35 kV and above can be made of metal.

The working part may contain an electrode tip for direct contact with the controlled current-carrying parts and not contain an electrode tip (non-contact type indicators).

The indicator part, which can be combined with the working part, contains elements of light or combined (light and sound) indication. Gas-discharge lamps, LEDs or other indicators can be used as light indication elements. Light and sound signals must be reliably recognizable. The audio signal should have a frequency of 1 - 4 kHz and a chopping frequency of 2 - 4 Hz when indicating phase voltage. The sound signal level must be at least 70 dB at a distance of 1 m along the axis of the sound emitter.

The working part may also contain a body for its own serviceability monitoring. Control can be carried out by pressing a button or be automatic by periodically sending special control signals. In this case, it must be possible to fully check the serviceability of the electrical circuits of the working and indicator parts.

Working parts must not contain switching elements intended for turning on power or switching ranges.

2.4.6. The insulating part of the signs must be made of the materials specified in clause 2.1.2.

The insulating part can be composed of several links. To connect the links to each other, parts made of metal or insulating material can be used. It is permissible to use a telescopic design, but spontaneous folding must be prevented.

2.4.7. The handle can be one piece with the insulating part or be a separate link.

2.4.8. The design and weight of the signs must ensure that one person can operate them.

2.4.9. The electrical circuit and design of the indicator must ensure its operability without grounding the working part of the indicator, including when checking the absence of voltage, carried out from telescopic towers or from wooden and reinforced concrete supports of 6 - 10 kV overhead lines.

2.4.10. The minimum dimensions of the insulating parts and handles of voltage indicators above 1000 V are given in table. 2.4.

Table 2.4

MINIMUM DIMENSIONS OF INSULATING PARTS AND HANDLES FOR VOLTAGE INDICATORS ABOVE 1000 V

2.4.11. The voltage indicator indication voltage should be no more than 25% of the rated voltage of the electrical installation.

For indicators without a built-in power supply with a pulse signal, the indication voltage is the voltage at which the signal interruption frequency is at least 0.7 Hz.

For indicators with a built-in power supply with a pulse signal, the indication voltage is the voltage at which the signal interruption frequency is at least 1 Hz.

For other indicators, the indication voltage is the voltage at which there are distinct light (light and sound) signals.

2.4.12. The time for the first signal to appear after touching a live part under voltage equal to 90% of the rated phase voltage should not exceed 1.5 s.

2.4.13. The working part of the indicator for a certain voltage should not respond to the influence of neighboring circuits of the same voltage, spaced from the working part at the distances indicated in the table. 2.5.

Table 2.5

DISTANCE TO THE CLOSEST WIRE OF THE NEIGHBORING CIRCUIT

Performance tests

2.4.14. During operation, mechanical tests of voltage indicators are not carried out.

2.4.15. Electrical tests of voltage indicators consist of testing the insulating part with increased voltage and determining the indication voltage.

Testing of the working part of voltage indicators up to 35 kV is carried out for indicators of this design, during operations with which the working part can cause a phase-to-phase short circuit or a phase-to-ground fault. The need to test the insulation of the working part is determined by the operating manuals.

For voltage indicators with a built-in power source, its condition is monitored and, if necessary, the batteries are recharged or the batteries are replaced.

2.4.16. When testing the insulation of the working part, voltage is applied between the tip electrode and the screw connector. If the indicator does not have a screw connector electrically connected to the indication elements, then an auxiliary electrode for connecting the test installation wire is installed at the boundary of the working part.

2.4.17. When testing the insulating part, voltage is applied between the element of its articulation with the working part (threaded element, connector, etc.) and a temporary electrode placed at the restrictive ring on the side of the insulating part.

2.4.18. The indication voltage of indicators with a gas-discharge indicator lamp is determined according to the same scheme by which the insulation of the working part is tested (clause 2.4.16).

When determining the indication voltage of other indicators that have an electrode tip, it is connected to the high-voltage terminal of the testing installation. When determining the indication voltage of indicators without a tip electrode, it is necessary to touch the end side of the working part (head) of the indicator to the high-voltage terminal of the test installation.

In both of the latter cases, the auxiliary electrode is not installed on the pointer and the grounding terminal of the test setup is not connected.

The voltage of the test installation smoothly rises from zero to the value at which the light signals begin to meet the requirements of clause 2.4.11.

2.4.19. The standards and frequency of electrical tests of indicators are given in Appendix 7.

Terms of use

2.4.20. Before you start working with the pointer, you need to check its serviceability.

The serviceability of indicators that do not have a built-in monitoring device is checked using special devices, which are small-sized sources of increased voltage, or by briefly touching the electrode-tip of the indicator to live parts that are known to be energized.

The serviceability of indicators with a built-in control unit is checked in accordance with the operating manuals.

2.4.21. When checking the absence of voltage, the time of direct contact of the working part of the indicator with the controlled current-carrying part must be at least 5 s (in the absence of a signal).

It should be remembered that although some types of voltage indicators can signal the presence of voltage at a distance from live parts, direct contact with them by the working part of the indicator is mandatory.

2.4.22. In electrical installations with voltages above 1000 V, the voltage indicator should be used with dielectric gloves.

Voltage indicators up to 1000 V

Purpose, principle of operation and design

2.4.23. General technical requirements for voltage indicators up to 1000 V are set out in the state standard.

2.4.24. In electrical installations with voltages up to 1000 V, two types of indicators are used: double-pole and single-pole.

Bipolar indicators that operate when active current flows are designed for electrical installations of alternating and direct current.

Single-pole indicators operating when capacitive current flows are intended for electrical installations with alternating current only.

The use of two-pole indicators is preferable.

The use of test lamps to check the absence of voltage is not allowed.

2.4.25. Bipolar indicators consist of two housings made of electrical insulating material, containing elements that react to the presence of voltage on the controlled live parts, and elements of light and (or) sound indication. The housings are connected to each other by a flexible wire at least 1 m long. At the points of entry into the housings, the connecting wire must have shock-absorbing bushings or thickened insulation.

Case sizes are not standardized and are determined by ease of use.

Each body of a two-pole indicator must have a rigidly fixed tip electrode, the length of the non-insulated part of which should not exceed 7 mm, except for indicators for overhead lines, in which the length of the non-insulated part of the tip electrodes is determined by technical conditions.

2.4.26. A single-pole indicator has one housing made of electrical insulating material, which houses all elements of the indicator. In addition to the electrode tip that meets the requirements of clause 2.4.25, there must be an electrode on the end or side of the housing for contact with the operator’s hand.

The dimensions of the case are not standardized; they are determined by ease of use.

Indication of the presence of voltage can be stepped, supplied in the form of a digital signal, etc.

Light and sound signals may be continuous or intermittent and must be reliably recognizable.

For indicators with a pulse signal, the indication voltage is the voltage at which the interval between pulses does not exceed 1.0 s.

2.4.28. Voltage indicators up to 1000 V can also perform additional functions: checking the integrity of electrical circuits, identifying phase wires, determining polarity in DC circuits, etc. In this case, the pointers should not contain switching elements intended for switching operating modes.

Expanding the functionality of the indicator should not reduce the safety of operations to determine the presence or absence of voltage.

Performance tests

2.4.29. Electrical tests of voltage indicators up to 1000 V consist of testing the insulation, determining the indication voltage, checking the operation of the indicator at an increased test voltage, checking the current flowing through the indicator at the highest operating voltage of the indicator.

If necessary, the indication voltage in DC circuits is also checked, as well as the correct polarity indication.

The voltage gradually increases from zero, while the values of the indication voltage and the current flowing through the indicator at the highest operating voltage of the indicator are recorded, after which the indicator is turned on for 1 minute. maintained at an increased test voltage, exceeding the highest operating voltage of the pointer by 10%.

2.4.30. When testing indicators (except for insulation tests), the voltage from the test installation is applied between the tip electrodes (for double-pole indicators) or between the tip electrode and the electrode on the end or side of the housing (for single-pole indicators).

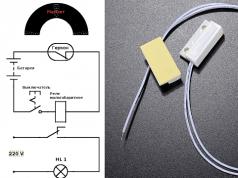

Rice. 2.1. Schematic diagram of testing the electrical strength of the insulation of handles and voltage indicator wires:

1—tested pointer; 2 - test transformer; 3 - bath with water; 4 - electrode

2.4.31. When testing the insulation of two-pole indicators, both housings are wrapped in foil, and the connecting wire is lowered into a vessel with water at a temperature of (25 +/- 15) °C so that the water covers the wire, not reaching the handles of the housings by 8 - 12 mm. One wire from the test installation is connected to the electrode tips, the second, grounded, is connected to the foil and lowered into water (scheme version - Fig. 2.1).

For single-pole indicators, the body is wrapped in foil along the entire length to the limiting stop. A gap of at least 10 mm is left between the foil and the contact on the end (side) part of the housing. One wire from the test setup is connected to the tip electrode, the other to the foil.

2 .1 .51 . When checking the presence or absence of voltage, the indicators should not be grounded. An exception is the use of UVN-10 type indicators on overhead line supports (except metal ones) or telescopic towers (hydraulic lifts), which is detailed in paragraph 2.1.46.

2 .1 .52 . When using the pointer, hold it by the handle within the limit ring.

2 .1 .53 . Before starting work, it is necessary to check the serviceability of the indicator using a special device (for example, type PPU-2) or by touching the contact electrode to live parts that are known to be energized.

The device is used in the absence of live parts in electrical installations that are known to be energized (at substations with one supply input, on cable routes when opening couplings, on single overhead lines, on electric motor cables, etc.)*, and is a small-sized device with a built-in power source , performance monitoring, equipped with a charger.

* It is prohibited to check the serviceability of voltage indicators on a car’s spark plug due to the possibility of false readings.

2 .1 .54 . It must be remembered that the glow of pulse type indicators is intermittent.

If there is no visual pulse signal, the pointer is removed from service.

2 .1 .55 . Voltage indicators can be used in outdoor installations only in dry weather. In wet weather, only specially designed signs can be used.

Voltage indicators above 1000 V non-contact type

Purpose and design

2 .1 .56 . The indicator is designed to check the presence or absence of phase voltage on the wires of 6 - 35 kV overhead lines and their current-carrying parts of indoor switchgear and outdoor switchgear 6 - 35 kV.

2.1.57. The operation of the pointer is based on the principle of electrostatic induction. The signal element can be incandescent lamps or LEDs.

2 .1 .58 . A voltage indicator usually consists of a working, insulating part* and a charger.

* Non-contact type indicators without an insulating part are allowed.

The indicator has a built-in power source, produces an intermittent light signal, which intensifies as it approaches live parts, provides serviceability monitoring, and turns on automatically when assembled.

The insulating part is a collapsible rod for a voltage of 35 kV.

Mechanical tests of the pointer in operation are not carried out.

Electrical tests

2.1.59. Testing the electrical strength of the insulating part of the indicator in operation is carried out according to the standards for insulating rods for a voltage of 35 kV (clause 2.1.20).

Rules for using the index

2 .1 .60 . The procedure for checking the presence or absence of voltage with a non-contact indicator is the same as for an indicator with a gas-discharge lamp. The pointer does not need to be grounded. It is prohibited to use the pointer if the sealing of the working part is broken.

Non-contact voltage detectors

2 .1 .61 . As auxiliary means of protection in electrical installations above 1000 V, non-contact voltage detectors with light and (or) sound alarms can be used to warn the worker about approaching live parts that are energized at a dangerous distance. Signaling devices can have different designs. It is recommended to use alarms designed to be placed on a helmet in a jacket pocket. The functionality of the alarms must be checked in accordance with the operating instructions. When using alarms, it should be remembered that the absence of a signal does not indicate a lack of voltage.

Voltage indicators up to 1000 V

Purpose and design

2.1.62. To check the presence or absence of voltage in electrical installations up to 1000 V, two types of indicators are used: two-pole, operating with active current flowing, and single-pole, operating with capacitive current.

Double-pole indicators are intended for electrical installations of alternating current and direct current, and single-pole indicators are intended for electrical installations of alternating current.

The use of test lamps to check the absence of voltage is PROHIBITED due to the risk of their explosion when a 220 V lamp is switched on to a line voltage of 380 V.

2 .1 .63 . Bipolar indicators consist of two housings containing elements of the electrical circuit. The elements of the electrical circuit are connected to each other by a flexible wire that does not lose elasticity at low temperatures, with a length of at least 1 m. At the points of entry into the housings, the connecting wire has shock-absorbing bushings or thickened insulation.

A single-pole indicator is housed in one housing.

2 .1 .64 . The electrical circuit of a two-pole voltage indicator must contain contacts - tips and elements that provide visual, acoustic or visual-acoustic indication of voltage. Visual and acoustic signals must be continuous or intermittent.

The electrical circuit of a two-pole indicator with visual indication may contain a pointer-type device or a digital sign-synthesizing system (with a small-sized power supply for the indicating scale). Indicators of this type can be used for voltages from 0 to 1000 V.

The electrical circuit of a single-pole voltage indicator must contain an indication element with an additional resistor, a contact tip and a contact on the end (side) part of the housing, with which the operator’s hand comes into contact.

2 .1 .65 . The length of the uninsulated part of the contacts and lugs should not exceed 5 mm. The tip contacts must be rigidly fixed and must not move along the axis.

Voltage indicator tests

In operation, mechanical tests of indicators are not carried out.

Electrical tests

2.1.66. Operational tests of voltage indicators up to 1000 V consist of determining the indication voltage, checking the circuit with increased voltage, measuring the current flowing through the indicator at the highest operating voltage, and testing insulation with increased voltage.

2.1.67. To check the indication voltage for a two-pole indicator, the voltage from the test installation is applied to the tip contacts, for a single-pole indicator - to the tip contact and the contact on the end (side) part of the housing.

The indication voltage of voltage indicators up to 1000 V should be no higher than 90 V.

2 .1 .68 . To check the circuit for a two-pole indicator, the voltage from the test installation is applied to the tip contacts, for a single-pole indicator - to the tip contact and the contact on the end (side) part.

The test voltage when checking the circuit must exceed the highest operating voltage by at least 10%. Test duration - 1 min.

The value of the current flowing through the indicator at the highest operating voltage should not exceed:

0.6 mA for single-pole voltage indicator;

10 mA for a two-pole voltage indicator with elements providing visual or visual-acoustic indication of the signal;

for voltage indicators with an incandescent lamp up to 10 W with a voltage of 220 V, the current value is determined by the power of the lamp.

The current value is measured using an ammeter connected in series with the pointer.

2.1.69. To test the insulation of voltage indicators with increased voltage for bipolar indicators, both insulating bodies are wrapped in foil, and the connecting wire is lowered into a grounded vessel so that the water covers the wire, not reaching the handle by 9 - 10 mm. One wire from the test installation is connected to the tip contacts, the second, grounded, is connected to the foil and lowered into water (Fig. 2.1).

Rice . 2 .1 . Schematic diagram of testing the electrical strength of the insulation of handles and voltage indicator wires

1 - tested pointer; 2 - and testing transformer; 3 - bath with water; 4 - electrode

For single-pole voltage indicators, the insulating body is wrapped in foil along its entire length up to the limiting stop. A gap of at least 10 mm is left between the foil and the contact at the end of the housing. One wire from the test setup is connected to the tip contact, the second, grounded, to the foil.

The insulation of voltage indicators up to 500 V must withstand a voltage of 1 kV, and voltage indicators above 500 V - 2 kV. Test duration - 1 min.

To begin installation or repair work on electrical stations and wires, it is necessary to check the network indicators, the absence of current or its parameters. For this, a voltage indicator is used, which can determine the presence of voltage and its coincidence up to 1000V.

Description and principle of operation

The high and low voltage indicator is a universal portable device designed to determine the voltage on live wires or terminals of individual electrical devices (UVN 10, UNK, UVNK-10, BN-020022 Profipol Benning and others).

This device is necessary when working at various enterprises or when electricians travel to the site. The main difference between this indicator and standard meters is that it will help determine only the presence of a load, but not its indicators, unlike models that are mounted on a DIN rail.

Photo - indicator with digital displayBasically, only voltage devices up to 1000 Volts are now used; such an indicator can be bipolar or single-pole; they have a similar circuit, but different areas of application. During operation, devices with two poles must be connected to two current-carrying conductors or contacts, while single-pole devices must be connected to only one. You should know that two-pole indicators are more accurate, which is why they are called high-voltage and are used during complex work.

Photo - UN PIN-90

Photo - UN PIN-90 In addition to this, there is also a contactless pointer. Testing with its help is carried out without connecting to live terminals. This significantly increases safety during voltage determination. The device is equipped with a digital display, and it indicates not only the presence of voltage, but also the approximate size due to the magnetic field.

Photo - single-pole model

Photo - single-pole model There are portable battery-powered models and options that require connection to the network (for example, a pointer or voltage indicator of the Kontakt 55EM type, UVNU-10 kV SZIP, ELIN-1-SZ VL). In the first case, power is provided using two or more batteries, less often from a battery (these are UVNK, UNNO, UNK, EI-9000/1, Duspol digital LC, Raton). This allows you to use the device on site, when traveling or for repair work far from the working power supply network.

Photo - imported UN DT-9902

Photo - imported UN DT-9902 The operating principle of the device is quite simple. During connection to the network (by connecting to live parts), a comparison of potentials is made. This increases or decreases the resistance in the pointer resistors. This causes the indicator, which draws the smallest fraction of the amps flowing in the wires or terminals, to light up or beep. If the indicator is silent during operation, then there is no load. In some cases, a systematic attenuation of the signal is observed - this means that there was residual energy in the wires.

Requirements for voltage indicators GOST 20493-2001:

- For devices up to 1000 Volts, the indicator load must be no higher than 90 V;

- A single-pole device is located in one housing, while a two-pole device is located in two, connected by a cord;

- Any indicator of the presence of a load (on-board, combi and others) must have three surfaces: working, insulated, defining and holder;

- In some models, the working part is connected to the indicator;

- The indicators are checked each time before use using a voltage of 2 kV, and it lasts no more than a minute.

It must be remembered that the safety instructions require full preparation before using the device. In particular, it is necessary to wear an energy kit, including dielectric gloves and boots. These requirements are specified for an electrical device, and they differ from the indicator models in UAZ, VAZ and other cars, ships, etc.

Video: UT 15V voltage indicator

Specifications

Voltage indicators for phasing must have certified quality parameters. They depend on the specific model of the device; let’s consider the data using the example of UNNU-40-1000:

The two-pole operating voltage indicator of the UNN Combi type has parameters similar to UNNDP 12 660 (except for a maximum voltage of 660 V and operating temperatures up to +35):

Photo - UNN Combi

Photo - UNN Combi The bipolar voltage indicator UNN 1, PIN 90, UNK 04, Lotsman-2 and UVNI 150 A have similar technical characteristics. Their quality certificate differs only in terms of load data and service life.

Photo - UN Pilot-2

Photo - UN Pilot-2 Parameters of single-pole UVN 80:

Technical data of single-pole UVNBU 6–35:

A very interesting model, UNVL-0.4, is used mainly on overhead power lines. It has the following parameters:

In addition, all models have a one-year warranty, but only subject to regular inspection before starting work. When purchasing, always pay attention to the availability of GOST data, certificates and quality compliance and the ability to check before purchasing. Every six months you need to calibrate the sensor using special equipment.

Its peculiarity is that the working contact is made in the form of a hook, which clings to the wire regardless of height. Now on sale there is a newer model for determining voltage - this is the UVNU-10FB Poisk 1 indicator, where a rod is responsible for attaching contacts to live parts of wires or machines. Using a device of this type is very simple - the height is adjusted using manual manipulations, in addition, you can fix the length of the retractable part.

Photo - UVNU-10FB Search 1

Photo - UVNU-10FB Search 1 You can buy a voltage indicator in any city in specialized electrical stores, but the price will depend on the manufacturer and the type of device. Bipolar devices are more expensive than single-pole devices. The cost also varies depending on the city of purchase. For example, in Moscow a certain UN may cost higher than in Yekaterinburg or Novosibirsk.

Dear readers, I welcome you to my resource “Notes of an Electrician”.

Today we will talk to you about the high voltage indicator, or it is called UVN for short.

I am writing this article, so to speak, in hot pursuit.

A few days ago, electrical equipment with a voltage class from 0.4 (kV) to 10 (kV) was phased.

Application of UVN

High voltage indicators (HVD) are used to check the presence or absence of high voltage in the switchgear on those. Also, UVN is used to check phase coincidence, i.e. high voltage phasing.

What does the high voltage indicator consist of?

To learn how to properly use a high voltage indicator, you need to know its design.

This is what we will talk about now.

In my work and practice, I most often have to use a high voltage indicator such as UVN-10 and UVNU-10. Therefore, in this article I will focus on the design, testing and use of voltage indicators UVN-10 and UVNU-10.

The UVN-10 and UVNU-10 high voltage indicator consists of the following main parts:

- working part

- indicator part (gas-discharge or LED lamp, window slot for a lamp or shade)

- insulating part

- handle with limit ring

The working and indicator parts are attached to the insulating part using threads. The photo above shows the UVNU-10 transport type.

To bring it into working condition, you need to unscrew the thread, turn the working and indicator parts over and screw them in the opposite direction. What will come of this - see the picture below.

The working part consists of elements that react to the presence of voltage in the controlled circuit. The body of the working part is made of electrical insulating material with improved dielectric properties.

Pointers can be:

- contact type (UVN-10)

- contactless type

- combined type (UVNU-10)

In the first case, the working part of the UVN has an electrode tip (probe) for direct contact with the current-carrying part. In the second case, there is no electrode tip.

The indicator part of high voltage indicators consists of elements with light or light-sound indication.

Light indication is performed using:

- gas discharge lamps

- LED lamps (newer designs UVNU-10)

The insulating part of voltage indicators above 1000 (V) is made of electrical insulating material that repels moisture, with improved dielectric and mechanical properties. Its surface should be smooth.

The insulating part of high voltage indicators must be free of various cracks, scratches, delaminations and other defects.

It is prohibited to use paper-bakelite tubes as an insulating part.

The UVN handle can be part of the insulating part, or it can be a separate link. It all depends on the type and design of the voltage indicator used.

There are standards for the minimum length of handles and insulating parts of high voltage indicators, depending on the voltage class. All data is shown in the table below.

And I also forgot to mention that the UVN indication voltage should be no more than 25% of the rated network voltage.

All UVNs must be periodically tested during operation. The insulating part is subject to high voltage tests, and the indication voltage is also checked.

The working part of the UVN is tested only at the request of the operating manual.

If, due to the nature of work with the UVN, the working part can cause a short circuit of a phase to ground or two phases to each other, then in this case it is necessary to carry out electrical tests of the working part of the UVN.

Voltage indicators (VVN) react to capacitive current. When a high voltage indicator is introduced into the electric field, which is created from live parts that are under voltage, capacitive current passes through the UVN along the circuit: current-carrying part - probe - gas-discharge lamp (LED lamp) - capacitor built into the tube - conductivity of the insulating part - conductivity man - the earth.

P.S. This concludes the article on the topic of high voltage indicator. I think that this material will be useful to you, because... I repeat again and again that this is above all, and even more so in high voltage electrical installations.

Purpose and design

2.2.1. Insulating rods are designed for operational work (operations with disconnectors, changing fuses, installing parts of arresters, etc.), measurements (checking insulation on power lines and substations), for applying portable grounding, as well as for releasing the victim from electric current.

2.2.2. General technical requirements for operational insulating rods and portable grounding rods are given in the state standard.

2.2.3. The rods should consist of three main parts: working, insulating and handle.

2.2.4. Rods can be composed of several links. To connect the links to each other, parts made of metal or insulating material can be used. It is permissible to use a telescopic structure, but reliable fixation of the links at their joints must be ensured.

2.2.5. The rod handle can be one piece with the insulating part or be a separate link.

2.2.6. The insulating part of the rods must be made of the materials specified in clause 2.1.2.

2.2.7. Operating rods can have replaceable heads (working parts) to perform various operations. At the same time, their reliable fastening must be ensured.

2.2.8. The design of portable grounding rods must ensure their reliable detachable or permanent connection with grounding clamps, installation of these clamps on live parts of electrical installations and their subsequent fastening, as well as removal from live parts.

Composite portable grounding rods for electrical installations with voltages of 110 kV and higher, as well as for applying portable grounding to overhead line wires without lifting them to supports, may contain metal current-carrying links if there is an insulating part with a handle.

2.2.9. For intermediate supports of overhead power lines with a voltage of 500-1150 kV, the grounding structure may contain, instead of a rod, an insulating flexible element, which should be made, as a rule, of synthetic materials (polypropylene, nylon, etc.).

2.2.10. The design and weight of operational, measuring and relief rods for releasing a victim from electric current at voltages up to 330 kV must ensure that one person can work with them, and the same rods for voltages of 500 kV and higher can be designed for two people using a support device. In this case, the maximum force on one hand (supporting it at the restrictive ring) should not exceed 160 N.

The design of portable grounding rods for applying to overhead lines with a person lifting to a support or from telescopic towers and in switchgear with voltages up to 330 kV should ensure that one person can work with them, and portable grounding rods for electrical installations with voltages of 500 kV and higher, as well as for applying grounding to overhead line wires without lifting a person to a support (from the ground) can be designed for work by two people using a supporting device. The greatest force on one hand in these cases is regulated by technical conditions.

2.2.11. The main dimensions of the rods must be no less than those indicated in the table. 2.1 and 2.2.

Table 2.1

Minimum dimensions of insulating rods

Table 2.2

Minimum dimensions of portable grounding rods

| Purpose of the rods | Length, mm | |

| insulating part | handles | |

| For installation of grounding in electrical installations with voltage up to 1 kV | ||

| For installation of grounding in switchgear above 1 kV to 500 kV, on overhead line wires above 1 kV to 220 kV, made entirely of electrical insulating materials | According to the table 2.1 | According to the table 2.1 |

| Composite, with metal links, for installing grounding on overhead line wires from 110 to 220 kV | According to the table 2.1 | |

| Composite, with metal links, for installing grounding on overhead line wires from 330 to 1150 kV | According to the table 2.1 | |

| For installation of grounding on lightning protection cables isolated from supports of overhead lines from 110 to 500 kV | ||

| For installation of grounding on lightning protection cables isolated from supports of overhead lines from 750 to 1150 kV | ||

| For grounding installations in laboratory and test installations | ||

| To transfer the wire potential | Not standardized, determined by ease of use |

Note to table 2.2:

The length of the insulating flexible grounding element of a rodless design for overhead line wires from 35 to 1150 kV must be no less than the length of the grounding wire.

Performance tests

2.2.12. During operation, mechanical tests of rods are not carried out.

2.2.13. Electrical tests with increased voltage of the insulating parts of operational and measuring rods, as well as rods used in testing laboratories for supplying high voltage, are carried out in accordance with the requirements of section 1.5. In this case, voltage is applied between the working part and a temporary electrode placed at the restrictive ring on the side of the insulating part.

The heads of measuring rods for monitoring insulators in electrical installations with voltages of 35-500 kV are also tested.

2.2.14. Portable grounding rods with metal links for overhead lines are tested according to the method of clause 2.2.13.

Testing of other portable grounding rods is not carried out.

2.2.15. An insulating flexible grounding element of a rodless design is tested in parts. For each 1 m section, a portion of the total test voltage is applied, proportional to the length and increased by 20%. It is allowed to simultaneously test all sections of an insulating flexible element wound into a coil so that the length of the semicircle is 1 m.

2.2.16. The standards and frequency of electrical testing of rods and insulating flexible grounding elements of a rodless design are given in Appendix 7.

Terms of use

2.2.17. Before starting to work with rods that have a removable working part, it is necessary to ensure that the threaded connection of the working and insulating parts does not “jam” by screwing and unscrewing them once.

2.2.18. Measuring rods are not grounded during operation, except in cases where the principle of the rod design requires its grounding.

2.2.19. When working with an insulating rod, you should climb onto a structure or telescopic tower, as well as descend from it, without a rod.

2.2.20. In electrical installations with voltages above 1000 V, insulating rods should be used with dielectric gloves.

2.3. INSULATING PLIERS

Purpose and design

2.3.1. Insulating pliers are intended for replacing fuses in electrical installations up to and above 1000 V, as well as for removing linings, fences and other similar work 1 in electrical installations up to 35 kV inclusive.

1 Instead of pliers, if necessary, it is possible to use insulating rods with a universal head.

2.3.2. The pliers consist of a working part (plier jaws), an insulating part and a handle (handles).

2.3.3. The insulating part of the pliers must be made of the materials specified in clause 2.1.2.

2.3.4. The working part can be made of either electrical insulating material or metal. Oil and petrol resistant tubes must be placed on the metal jaws to prevent damage to the fuse holder.

2.3.5. The insulating part of the pliers must be separated from the handles by limit stops (rings).

2.3.6. The main dimensions of the pliers must be no less than those indicated in the table. 2.3.

Table 2.3

Minimum sizes of insulating pliers

2.3.7. The design and weight of the pliers must ensure that one person can operate them.

Performance tests

2.3.8. During operation, mechanical tests of the pliers are not carried out.

2.3.9. Electrical tests of clamps are carried out in accordance with the requirements of section 1.5. In this case, increased voltage is applied between the working part (jaws) and temporary electrodes (clamps) applied at the restrictive rings (stops) on the side of the insulating part.

2.3.10. The standards and frequency of electrical tests of clamps are given in Appendix 7.

Terms of use

2.3.11. When working with pliers to replace fuses in electrical installations with voltages above 1000 V, it is necessary to use dielectric gloves and eye and face protection.

2.3.12. When working with pliers to replace fuses in electrical installations with voltages up to 1000 V, it is necessary to use eye and face protection, and the pliers must be held at arm's length.

2.4. VOLTAGE INDICATORS

Purpose

2.4.1. Voltage indicators are designed to determine the presence or absence of voltage on live parts of electrical installations.

2.4.2. General technical requirements for voltage indicators are set out in the state standard.

Performance tests

2.4.14. During operation, mechanical tests of voltage indicators are not carried out.

2.4.15. Electrical tests of voltage indicators consist of testing the insulating part with increased voltage and determining the indication voltage.

Testing of the working part of voltage indicators up to 35 kV is carried out for indicators of this design, during operations with which the working part can cause a phase-to-phase short circuit or a phase-to-ground fault. The need to test the insulation of the working part is determined by the operating manuals.

For voltage indicators with a built-in power source, its condition is monitored and, if necessary, the batteries are recharged or the batteries are replaced.

2.4.16. When testing the insulation of the working part, voltage is applied between the tip electrode and the screw connector. If the indicator does not have a screw connector electrically connected to the indication elements, then an auxiliary electrode for connecting the test installation wire is installed at the boundary of the working part.

2.4.17. When testing the insulating part, voltage is applied between the element of its articulation with the working part (threaded element, connector, etc.) and a temporary electrode placed at the restrictive ring on the side of the insulating part.

2.4.18. The indication voltage of indicators with a gas-discharge indicator lamp is determined according to the same scheme by which the insulation of the working part is tested (clause 2.4.16).

When determining the indication voltage of other indicators that have an electrode tip, it is connected to the high-voltage terminal of the testing installation. When determining the indication voltage of indicators without a tip electrode, it is necessary to touch the end side of the working part (head) of the indicator to the high-voltage terminal of the test installation.

In both of the latter cases, the auxiliary electrode is not installed on the pointer and the grounding terminal of the test setup is not connected.

The voltage of the test installation smoothly rises from zero to the value at which the light signals begin to meet the requirements of clause 2.4.11.

2.4.19. The standards and frequency of electrical tests of indicators are given in Appendix 7.

Terms of use

2.4.20. Before you start working with the pointer, you need to check its serviceability.

The serviceability of indicators that do not have a built-in monitoring device is checked using special devices, which are small-sized sources of increased voltage, or by briefly touching the electrode-tip of the indicator to live parts that are known to be energized.

The serviceability of indicators with a built-in control unit is checked in accordance with the operating manuals.

2.4.21. When checking the absence of voltage, the time of direct contact of the working part of the indicator with the controlled current-carrying part must be at least 5 s (in the absence of a signal).

It should be remembered that although some types of voltage indicators can signal the presence of voltage at a distance from live parts, direct contact with them by the working part of the indicator is mandatory.

2.4.22. In electrical installations with voltages above 1000 V, the voltage indicator should be used with dielectric gloves.

Performance tests

2.4.29. Electrical tests of voltage indicators up to 1000 V consist of testing the insulation, determining the indication voltage, checking the operation of the indicator at an increased test voltage, checking the current flowing through the indicator at the highest operating voltage of the indicator.

If necessary, the indication voltage in DC circuits is also checked, as well as the correct polarity indication.

The voltage gradually increases from zero, while the values of the indication voltage and the current flowing through the indicator at the highest operating voltage of the indicator are recorded, after which the indicator is turned on for 1 minute. maintained at an increased test voltage, exceeding the highest operating voltage of the pointer by 10%.

2.4.30. When testing indicators (except for insulation tests), the voltage from the test installation is applied between the tip electrodes (for double-pole indicators) or between the tip electrode and the electrode on the end or side of the housing (for single-pole indicators).

Rice. 2.1. Schematic diagram of electrical insulation strength test

handles and voltage indicator wires:

1 - the tested pointer; 2

3 - bath with water, 4 - electrode

2.4.31. When testing the insulation of bipolar indicators, both housings are wrapped in foil, and the connecting wire is lowered into a vessel with water at a temperature of (25 ± 15) ° C so that the water covers the wire, not reaching the handles of the housings by 8-12 mm. One wire from the testing installation is connected to the electrode tips, the second, grounded, is connected to the foil and lowered into water (scheme version - Fig. 2.1).

For single-pole indicators, the body is wrapped in foil along the entire length to the limiting stop. A gap of at least 10 mm is left between the foil and the contact on the end (side) part of the housing. One wire from the test setup is connected to the tip electrode, the other to the foil.

2.4.32. The standards and frequency of operational tests of indicators are given in Appendix 7.

Terms of use

2.4.33. Before starting to work with the pointer, it is necessary to check its serviceability by briefly touching live parts that are known to be energized.

2.4.34. When checking the absence of voltage, the time of direct contact of the pointer with the controlled live parts must be at least 5 s.

2.4.35. When using single-pole indicators, contact must be ensured between the electrode on the end (side) part of the housing and the operator’s hand. The use of dielectric gloves is not allowed.

2.5. INDIVIDUAL VOLTAGE DETECTORS

Performance tests

2.5.6. The norms, methods and frequency of testing alarm devices are given in the operating manuals.

Terms of use

2.5.7. Before using the alarm, you should ensure that it is in working order. The procedure for checking the serviceability is given in the operating manuals.

2.5.8. When using alarms, it is necessary to remember that just as the absence of a signal is not a mandatory sign of a lack of voltage, the presence of a signal is not a mandatory sign of the presence of voltage on the overhead line. However, the voltage signal should in all cases be perceived as a danger signal, although it can be caused by the electric field of the wires of unswitched overhead lines of higher voltage classes located in the operator’s work area. Therefore, the use of alarms does not negate the mandatory use of voltage indicators.

2.5.9. If a danger signal suddenly appears, the operator must immediately stop work, leave the danger zone (for example, get down from an overhead line support) and not resume work until the reasons for the signal appear.

2.6. STATIONARY VOLTAGE DETECTORS

Performance tests

2.6.4. The norms, methods and frequency of testing alarm devices are given in the operating manuals.

The frequency of monitoring the serviceability of alarms may be regulated by local regulations.

Terms of use

2.6.5. Rules for using alarms are set out in the operating manuals.

2.6.6. If there are signaling devices in electrical installations, it must be remembered that the absence of a signal is not a mandatory sign of a lack of voltage. Therefore, the use of alarms does not negate the mandatory use of voltage indicators. At the same time, the signal about the presence of voltage should in all cases be perceived as a signal that work is prohibited in a given electrical installation.

2.7. VOLTAGE INDICATORS FOR CHECKING PHASE COINCIDENCE

Performance tests

2.7.5. During operation, mechanical tests of indicators are not carried out.

2.7.6. During electrical tests of indicators, the electrical strength of the insulation of working, insulating parts and connecting wires is checked, as well as their verification according to consonant and counter-connection schemes.

2.7.7. When testing the insulation of the working part, voltage is applied between the tip electrode and the threaded connector element. If the pointer does not have a threaded connector, then an auxiliary electrode for connecting the test installation wire is installed at the boundary of the working part.

2.7.8. When testing the insulating part, voltage is applied between the element of its articulation with the working part (threaded element, connector, etc.) and a temporary electrode placed at the restrictive ring on the side of the insulating part.

2.7.9. When testing a flexible wire of indicators for voltages up to 20 kV, it is immersed in a bath of water at a temperature of (25 ± 15) ° C so that the distance between the place where the wire is terminated and the water level is within 60-70 mm. Voltage is applied between one of the electrode tips and the bath body.

The flexible wire of voltage indicators 35-110 kV is tested using a similar method separately from the indicator. In this case, the distance between the edge of the wire tip and the water level should be 160-180 mm. Voltage is applied between the metal ends of the wire and the bath body.

2.7.10. When checking the pointer according to the consonant connection circuit, both tip electrodes are connected to the high-voltage terminal of the test setup (Fig. 2.2a).

When checking the pointer using a counter-connection circuit, one of the electrode tips is connected to the high-voltage terminal of the test installation, and the other to its grounded terminal (Fig. 2.2b).

Rice. 2.2. Schematic diagrams for testing a voltage indicator to check the phase coincidence according to the consonant (a) and opposite (b) connection circuit:

1 - test transformer; 2 - voltage indicator

Table 2.6

Indication voltages of voltage indicators for checking phase coincidence

During testing, the voltage gradually rises from zero until clear signals appear. The normalized indication voltage values for both test schemes depending on the rated voltage of the electrical installations are given in Table. 2.6.

2.7.11. The standards and frequency of electrical tests of indicators are given in Appendix 7.

Terms of use

2.7.12. When working with signs, the use of dielectric gloves is mandatory.

2.7.13. Before use, the serviceability of the indicator is checked at the workplace by a two-pole connection to a phase and a grounded structure. In this case, there must be clear light (and sound) signals.

2.7.14. If the voltage phases on the controlled current-carrying parts coincide, the indicator does not produce signals.

2.8. ELECTRICAL PLIERS

Purpose and design

2.8.1. The clamps are designed to measure current in electrical circuits with voltages up to 10 kV, as well as current voltage and power in electrical installations up to 1 kV without violating the integrity of the circuits.

2.8.2. The clamps are a current transformer with a detachable magnetic core, the primary winding of which is a conductor with the measured current, and the secondary winding is closed to a measuring device, pointer or digital.

2.8.3. Pliers for electrical installations above 1000 V consist of a working part, an insulating part and a handle.

The working part consists of a magnetic circuit, a winding and a removable or built-in measuring device, made in an electrically insulating housing.

The minimum length of the insulating part is 380 mm, and the handle is 130 mm.

2.8.4. Clamps for electrical installations up to 1000 V consist of a working part (magnetic core, winding, built-in measuring device) and a body, which is also an insulating part with a stop and a handle.

Performance tests

2.8.5. When testing the insulation of clamps, voltage is applied between the magnetic core and temporary electrodes placed at the restrictive rings on the side of the insulating part (for clamps above 1000 V) or at the base of the handle (for clamps up to 1000 V).

2.8.6. The standards and frequency of electrical tests of clamps are given in Appendix 7.

Terms of use

2.8.7. Working with clamps above 1000 V requires dielectric gloves.

2.8.8. When taking measurements, the pliers should be kept suspended; it is not allowed to lean towards the device to take readings.

2.8.9. When working with clamps in electrical installations above 1000 V, it is not allowed to use remote devices, or switch measurement limits without removing the clamps from live parts.

2.8.10. It is not allowed to work with clamps up to 1000 V while on an overhead line support, unless the clamps are specifically designed for this purpose.

2.9. DEVICES FOR REMOTE CABLE PINCING

Purpose and design

2.9.1. Cable piercing devices are designed to indicate the absence of voltage on the cable being repaired before cutting it by piercing the cable along its diameter and ensuring a reliable electrical connection of its cores to the ground. Three-phase cable puncture devices also provide electrical connection of all conductors of different phases to each other.

2.9.2. The devices include a working element (cutting or stabbing element), a grounding device, an insulating part, an alarm unit, as well as components that activate the working element.

The devices can be pyrotechnic, hydraulic, electric or manual.

The grounding device consists of a grounding rod with a grounding conductor and clamps (clamps).

2.9.3. The design of the device must ensure its reliable fastening to the cable being pierced and automatically orient the axis of the cutting (piercing) element along the diameter of the cable.

2.9.4. Pyrotechnic devices must have a locking mechanism that prevents firing if the bolt is not fully closed.

2.9.5. Specific parameters of devices, methods, terms and standards of their testing are regulated by technical specifications and are given in the operating manuals for these devices.

Terms of use

2.9.6. The cable is punctured by two workers who have undergone special training, with one worker being the supervisor.

2.9.7. When puncturing a cable, it is necessary to use dielectric gloves and eye and face protection. In this case, the personnel performing the puncture must stand on an insulating base at the maximum possible distance from the cable being pierced (on top of the trench).

2.9.8. Specific safety measures when working with devices of various types, features of working with them, as well as maintenance rules are given in the operating manuals.

When working with a pyrotechnic device, the requirements of the current instructions for the safe use of powder tools during installation and special construction work must be met.

2.10. DIELECTRIC GLOVES

2.10.1. Gloves are designed to protect hands from electric shock. They are used in electrical installations up to 1000 V as the main insulating electrical protective agent, and in electrical installations above 1000 V as an additional one.

2.10.2. In electrical installations, gloves made of dielectric rubber, seamless or with a seam, five-fingered or two-fingered, can be used.

In electrical installations, it is allowed to use only gloves marked for the protective properties of Ev and En.

2.10.3. The length of gloves must be at least 350 mm.

The size of dielectric gloves should allow knitted gloves to be worn underneath them to protect hands from low temperatures when working in cold weather.

The width along the bottom edge of the gloves should allow them to be pulled over the sleeves of outerwear.

Performance tests

2.10.4. During operation, electrical tests of gloves are carried out. Gloves are immersed in a bath of water at a temperature of (25±15) °C. Water is also poured into the gloves. The water level both outside and inside the gloves should be 45-55 mm below their top edges, which should be dry.

The test voltage is applied between the bath body and the electrode, which is lowered into the water inside the glove. It is possible to test several gloves simultaneously, but it must be possible to control the current flowing through each glove under test.

Rice. 2.3. Schematic diagram of testing dielectric gloves, boots and galoshes:

1 - test transformer; 2 - switching contacts; 3 - shunt resistance (15 - 20 kOhm); 4 - gas discharge lamp; 5 - throttle; 6 - milliammeter; 7 - arrester; 8 - bath with water

Gloves are rejected if they are punctured or if the current flowing through them exceeds the normalized value.

A variant of the test setup diagram is shown in Fig. 2.3.

2.10.5. The standards and frequency of electrical testing of gloves are given in Appendix 7.

2.10.6. At the end of the test, the gloves are dried.

Terms of use

2.10.7. Before use, gloves should be inspected, paying attention to the absence of mechanical damage, contamination and moisture, and also check for punctures by twisting the gloves towards the fingers.

2.10.8. When working with gloves, their edges are not allowed to be turned up. To protect against mechanical damage, it is allowed to wear leather or canvas gloves and mittens over gloves.

2.10.9. Gloves in use should be washed periodically, as necessary, with soda or soap solution, followed by drying.

2.11. SPECIAL DIELECTRIC FOOTWEAR

Purpose and general requirements

2.11.1. Special dielectric footwear (galoshes, boots, including tropical boots) is an additional electrical protective equipment when working in closed or, in the absence of precipitation, in open electrical installations.

In addition, dielectric shoes protect workers from step stress.

2.11.2. In electrical installations, dielectric boots and galoshes are used, manufactured in accordance with the requirements of state standards.

2.11.3. Galoshes are used in electrical installations with voltages up to 1000 V, boots - for all voltages.

2.11.4. Based on their protective properties, shoes are designated: En - galoshes, Ev - boots.

2.11.5. Dielectric shoes should be different in color from other rubber shoes.

2.11.6. Galoshes and boots must consist of a rubber top, rubber grooved sole, textile lining and internal reinforcing parts. Uniform boots can be produced without lining.

Boots must have lapels.

The height of the boat must be at least 160 mm.

Performance tests

2.11.7. In operation, galoshes and boots are tested according to the method described in clause 2.10.4. During testing, the water level both outside and inside horizontally installed products should be 15-25 mm below the sides of the galoshes and 45-55 mm below the edge of the lowered lapels of the boots.

2.11.8. The standards and frequency of electrical tests of dielectric galoshes and boots are given in Appendix 7.

Terms of use

2.11.9. Electrical installations should be equipped with dielectric shoes of several sizes.

2.11.10. Before use, overshoes and boots must be inspected in order to detect possible defects (delamination of facing parts or lining, the presence of foreign hard inclusions, etc.).

2.12. DIELECTRIC RUBBER CARPETS AND INSULATING STANDS

Purpose and general requirements

2.12.1. Dielectric rubber carpets and insulating supports are used as additional electrical protective equipment in electrical installations up to and above 1000 V.

Carpets are used in closed electrical installations, except in damp rooms, as well as in open electrical installations in dry weather.

The stands are used in damp and dirty areas.

2.12.2. Carpets are manufactured in accordance with the requirements of the state standard, depending on the purpose and operating conditions of the following two groups: 1st group - conventional design and 2nd group - oil and petrol resistant.

2.12.3. Carpets are manufactured with a thickness of 6±1 mm, a length from 500 to 8000 mm and a width from 500 to 1200 mm.

2.12.4. Carpets must have a corrugated front surface.

2.12.5. Carpets must be one color.

2.12.6. The insulating stand is a flooring supported on supporting insulators with a height of at least 70 mm.

2.12.7. Flooring with a size of at least 500 x 500 mm should be made from well-dried planed wooden planks without knots or cross-layers. The gaps between the slats should be 10-30 mm. The planks must be connected without the use of metal fasteners. The flooring must be painted on all sides. It is allowed to make flooring from synthetic materials.

2.12.8. Stands must be strong and stable. If removable insulators are used, their connection to the flooring must prevent the possibility of the flooring slipping. To eliminate the possibility of the stand overturning, the edges of the deck should not protrude beyond the supporting surface of the insulators.

Operating rules

2.12.9. Carpets and coasters are not tested for use. They are examined at least once every 6 months. (clause 1.4.3), as well as immediately before use. If mechanical defects are detected, the carpets are removed from service and replaced with new ones, and the stands are sent for repair.

After repair, the stands must be tested according to acceptance testing standards.

2.12.10. After storage in a warehouse at sub-zero temperatures, carpets must be kept in packaged form at a temperature of (20±5) °C for at least 24 hours before use.

2.13. SHIELDS (SCREENS)

Purpose and design

2.13.1. Shields (screens) are used for temporary fencing of live parts that are energized.

2.13.2. Shields should be made of dry wood, impregnated with drying oil and painted with clear varnish, or other durable electrical insulating materials without the use of metal fasteners.

2.13.3. The surface of the shields can be solid or lattice.

2.13.4. The design of the shield must be strong and stable, preventing it from deforming and tipping over.

2.13.5. The weight of the shield should allow it to be carried by one person.

2.13.6. The height of the shield must be at least 1.7 m, and the distance from the bottom edge to the floor must not be more than 100 mm.

2.13.7. The warning posters “STOP! VOLTAGE" or corresponding inscriptions are applied.

Operating rules

2.13.8. The shields are not tested in operation. They are examined at least once every 6 months. (clause 1.4.3), as well as immediately before use.

During inspections, you should check the strength of the connection of parts, their stability and the strength of parts intended for installation or fastening of panels, the presence of posters and safety signs.

2.13.9. When installing shields enclosing the workplace, distances to live parts that are energized must be maintained in accordance with the “Inter-industry labor protection rules (safety rules) for the operation of electrical installations.” In electrical installations of 6-10 kV, this distance can be reduced to 0.35 m if necessary.

2.13.10. Shields must be installed securely, but they must not prevent personnel from leaving the premises if danger arises.

2.13.11. It is not allowed to remove or rearrange the fences installed during the preparation of workplaces until the work is completed.

2.14. INSULATING COVERS

Purpose and design

2.14.1. Covers are used in electrical installations up to 20 kV to prevent accidental contact with live parts in cases where it is not possible to protect the workplace with shields. In electrical installations up to 1000 V, linings are also used to prevent switches from being switched on incorrectly.

2.14.2. Overlays must be made of durable electrical insulating material.

2.14.3. The design and dimensions of the linings must allow complete coverage of live parts.

2.14.4. In electrical installations above 1000 V, only rigid linings are used.

In electrical installations up to 1000 V, flexible dielectric rubber pads can be used to cover live parts during work without removing voltage.