The steering rack transfers rotation from the steering wheel to the wheels. It affects handling, and any malfunctions in this unit make the car less obedient. Steering rack elements are subject to natural wear and tear and are subject to shock loads from driving on uneven roads. This leads to the fact that the steering rack of almost every car needs to be replaced or repaired by a mileage of 200–250 thousand km.

8 signs of a faulty steering rack

When driving over bumps and when turning the steering wheel, a knock is heard in the area of the steering rack.

The handling has deteriorated, the car "throws", it is especially acutely felt at high speed.

Rudder free play (backlash) is increased.

The steering wheel turns harder than usual or jerks.

The steering wheel does not return to its original position after turning, you have to turn it with your hands.

The power steering pump makes noise, the sound increases when the steering wheel is turned.

The oil level in the power steering reservoir drops.

Oil leaks are visible on or near the rail.

Suspension elements can knock - ball bearings, steering tips, silent blocks, bushings and stabilizer struts. The wear of these parts leads to poor controllability, an increase in the steering wheel play. The suspension must be checked, defective elements must be replaced.

Heavy rotation of the steering wheel, non-return or slow return to the starting position may be the result of improper adjustment of the rack or violation of wheel alignment. If you have recently adjusted the rack, redo it, but already correctly, check the wheel alignment angles at the service station.

For vehicles with electric power steering, the cause of a "heavy" steering wheel may be a failure of the electric motor, open or short circuit, oxidation of contacts in the connectors, malfunction of the system control unit or blown fuses.

Leakage of fluid from the power steering system and the noise of the power steering pump are associated - oil flows out through worn out oil seals and seals. Through them, air enters the system, due to which the pump makes noise. Inspect the pump housing, hoses and connections; if you find a leak, fix it.

How to determine wear of parts inside the rail?

On a muffled car, shake the steering wheel left and right with a small amplitude. If you hear a knock, repair is needed. If there is an assistant, let him at this time take hold of the steering rod with his hand, so you can more accurately determine where the play is.

Repair or replace?

Replacing a faulty rail with a new one is easier than repairing it. But more expensive. Consider the cost of repairing the rail of a 2009 Ford Focus II. The new original rail costs 45,000 rubles. Substitutes offer to buy at a price of 20,000 rubles, but their resource, according to car owners, is unpredictable.

A repair kit for a Ford Focus II rail costs 2,500 rubles, anthers with clamps - 600 rubles. The savings are obvious, but it will take about 2 days to remove, repair and install the unit. For dismantling and installation, a regular set of wrenches is suitable, but in order to disassemble and assemble the rail, you need a special tool, which you will have to buy or make yourself.

Before starting the repair, try to soberly assess your strengths and capabilities, compare the benefits of self-repair and the upcoming labor costs.

Removing the steering rack

Dismantling the rail has its own characteristics for each car, but in general, the procedure is as follows:

Install the front of the car on the supports, remove the wheels.

Press out the steering tips from the steering knuckle pins (use a special puller).

Remove the heat shield of the rail.

For cars with power steering - unscrew the oil supply and return hoses (place a container under the hoses to drain the fluid), for cars with electric power steering - disconnect the connector or remove the steering shaft position sensor.

Remove the bolts securing the steering rack to the subframe or engine shield (depending on the make and model of the car).

Loosen the pinning bolt of the universal joint of the rack with the steering shaft.

Pull the rack in the direction of the steering shaft to release the spline connection (if the rack does not go, it is allowed to knock it down with light hammer blows).

Pull out the rack through the left or right wheel arch (depending on the layout of the engine compartment).

Pressing out the steering tip with a puller

Tip: not every car can get the rail just like that - the stretcher can interfere. Removing it completely is long and difficult, try to unscrew only the rear bolts and the engine support, then take the subframe down. This is often enough and the rake is released.

To remove the rack in the Peugeot 308, you need to unscrew the rear bolts of the subframe and take it down, this is easier than removing the entire subframe.

After dismantling, the rail must be cleaned of dirt and washed.

Disassembling the rail

It is better to disassemble and assemble the steering rack clean, without sand and dust. If abrasive particles get inside, the surfaces and seals will quickly wear out, the rack will flow. Fix the rail in a locksmith's vice, if not, put clean cardboard or other material in place of disassembly.

Important: do not clamp the rail too tightly in a vice - its brittle aluminum alloy body may burst or deform.

Steering rack disassembly procedure

Remove the clamps and pull off the anthers of the steering rods.

Securely fix the rack housing and unscrew the steering rods (there are grooves for an open-end wrench on the threaded sleeve).

Unscrew the locknut and nut of the adjusting mechanism, remove the washers and the pressure sleeve from the seat.

Unscrew the drive shaft housing or nut (a special wrench may be needed), remove the shaft from the housing.

Pull out the rack rack.

Take out the sealing collars, bushings and PTFE rings from the rack housing.

The location of the drive shaft and toothed rod in the steering rack

Tip: Before disassembling the rack, mark the position of the toothed rod or measure how much it protrudes from the body on both sides so that you can reassemble it correctly. Mark the position of the adjusting nut and count the turns as you unscrew it in order to set the pressure sleeve in the correct position after assembly.

Troubleshooting details

The parts of the disassembled rail must be wiped off oil, cleaned of deposits and carefully inspected. Repair kits usually contain only rubber seals and PTFE bushings with rings. This may not be enough for every case.

Carefully inspect the surface of the toothed rod for damage and wear. Pay special attention to the working area - the teeth and the part of the stem that comes into contact with the rings, oil seals and bushings. Any damage, corrosion, risks and scuffing will lead to rapid wear of the seals and leakage of the rack.

Deep corrosion of the rod stem. Such a detail cannot be used.

There should be no cracks, notches, chips and deep wear on the bevel teeth of the drive shaft gear. It is dangerous to install a shaft with such damage - the rack can jam in motion.

A common cause of knocking on the rail is wear of the pressure sleeve. The working surface of the part must be smooth, without traces of punching and scoring. The clamping sleeve is usually not in the rack repair kit, but it can be bought separately for many cars.

Wear of the clamping sleeve - the PTFE insert is pressed through

Severely worn and damaged rail parts cannot be repaired in a garage. If problems are found during troubleshooting, contact specialized service stations for help. There they can restore the shaft and the rod of the rack using professional equipment.

Assembling the rail

Assemble the rail in the reverse order of disassembly. Lubricate the parts with power steering oil before installation so that no scoring occurs on the bushings.

Insert PTFE rings and bushings into the rack housing carefully - the material is fragile and can burst from impacts or great force. For accurate insertion, you can use an appropriately sized socket and extension from the wrench set.

After installing the toothed rod, center it according to the marks made before disassembling, then insert and screw the drive shaft.

Insert the clamping sleeve and washers into the socket, tighten the adjusting nut by the required number of turns and turn the mechanism by hand several times from stop to stop (you need to rotate by the drive shaft). If the rack is assembled correctly, the toothed rod should move easily without jamming. Tighten the adjuster locknut.

Tighten the tie rods and install the anthers, squeeze them with special clamps.

Important: do not put plastic ties instead of clamps, they do not provide reliable crimping of the boot, moisture will get into the rail, the stem will rust and damage the cuffs. The rail will flow.

Installing the steering rack

It is better to put the steering rack on the car with an assistant - one starts the rack from the side of the engine compartment, the other directs the cardan joint into the shaft splines from the passenger compartment. The cardan joint can only be put in one position - there is a special casting in the splined joint, which must be combined with the groove on the mating part. Do not immediately tighten the pinch bolt - the cardan joint will take the correct position on the splines after the rail and subframe are finally screwed on.

Install and tighten the steering rack and subframe mounting bolts, then finally tighten the steering shaft universal joint pinch bolt.

Insert the pins of the steering ends into the trunnions and tighten the nuts. Connect the tubes and hoses of the power steering (or wire connectors for the system with EUR). Fill the power steering fluid into the reservoir up to the “maximum” mark.

Install the wheels and, without removing the car from the stands, start bleeding the system (for cars with a power steering).

How to pump the power steering system

Scroll the steering wheel several times from lock to lock with a slight delay in the extreme positions.

Remove the car from the stands, add fluid to the power steering reservoir if the level drops.

Start the engine.

Scroll the steering wheel several times from lock to lock, also with a delay in the extreme positions.

Make sure that the power steering pump does not make noise, add fluid to the tank if the level has dropped and inspect the connections, hoses and power steering tubes for leaks.

Tip: do not rush to install the heat shield, it will be more difficult to inspect the rail during the test ride.

After bleeding, check again the tightness of all threaded connections and make a test drive. Repair of the steering rack can be considered successful if:

The steering wheel has become lighter and "sharper".

The knocking and noises stopped.

The fluid level in the power steering reservoir does not drop.

The rail does not flow.

The car handles well, holds the road confidently.

If everything is in order, reinstall the heat shield.

After repairing the steering rack, be sure to check the alignment at a car service or yourself.

Steering rack repair: do it yourself or at a service station?

Repairing the steering rack yourself in the garage is profitable, but not easy. It will take a tool, time and patience.

Specialized car services offer an alternative to repairing in the garage or buying a new part - a complete restoration of the rail.

The specialists themselves will remove the rail, select the necessary repair kit, and restore problematic elements that are not on sale. If the work described in the article seems difficult, entrust the repair of the rail to professionals.

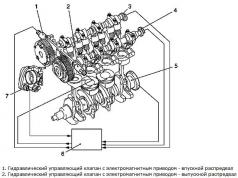

I have already talked about the Fiat electric power steering systems. The Fiat uses electric power steering located directly on the steering rack. There is an advantage here: the system is under the "protection" of the passenger compartment, that is, all the electrics, electronics, gearbox, and drive are located in the passenger compartment. Among the disadvantages: it requires a lot of free space in the area of the steering rack; increased load on the steering gear. Recently, electric power steering has become widespread, on which the drive with a gearbox is located directly on the steering rack.

Disadvantages and advantages of electric rails

Main disadvantages:

- actuators are located in the engine compartment, where there is a high probability of ingress of foreign liquids and dirt;

- complication of the already capricious design of the rails;

- the electrical wiring of the electric amplifier is in extremely unpleasant climatic conditions.

The advantages of this design:

- freeing up free space in the area of the steering column, which increases the driver's safety in the event of an accident;

- all kinematics of the power steering is concentrated in one place - on the rail;

- reduction in the total weight of the steering;

- the possibility of prompt repair by means of aggregate replacement.

Principle of operation

In the middle position of the steering wheel, the steering position sensors generate a zero signal to the electronic power steering control unit. No voltage is applied to the drives, the rail remains in the neutral (zero) position. When the steering wheel is turned in one of the directions, the angular displacement sensors generate a control signal to the control unit, which generates control currents to the electric drive, which facilitates the movement of the wheels in the required direction. At the end of the maneuver, the control unit returns the mechanism to its original position.

Structurally, electric rails are currently made in the following versions:

- rails with parallel drive;

- direct drive rails;

- electric racks with an additional gear.

According to the design, the drive motor can be mounted directly on the rail:

or mounted on a rail as an additional mechanism.

The power steering electronics are quite complex. It uses signals from multiple sensors, which are not necessarily electric power steering sensors, to process information about the required steering effort, for example:

- vehicle speed sensor;

- crankshaft speed sensor;

- wheel rotation sensors.

This is necessary to make the steering wheel more informative. It is one thing when the wheels turn at a speed of 5 km / h, another - at a speed of 100 km / h. At high speed, in the absence of "feedback" of the steering, even minor angular displacements of the wheels can lead to an emergency. Therefore, a malfunction of the electric power steering system, especially its electronic part, is fraught with serious consequences.

Communication with sensors of other vehicle systems, control units is organized via the CAN bus. Malfunctioning CAN bus is a common cause of failure of the electric power steering system.

Manufacturers geographically install control units in different places. For example, Asians prefer to install control units (electronics) away from the rack drive. In this case, they are guided by the fact that electronics in this case are more protected from pollution, dust, water, oils. But there are also disadvantages:

- sufficiently powerful electrical wiring goes directly to the electric drive;

- the signal wires of the sensors can be damaged, resulting in a definite loss of functionality.

Quite the opposite is done by European manufacturers who install control units directly on the drive, that is, on the structure of the electric rail. I think they rely on the quality of their roads. From this point of view, I would choose the Asian option. But from the point of view of repair, a European rail is better, on which everything is concentrated in a single place: removed the rail - and fiddle with it.

The main symptoms and causes of malfunction

The main signs of malfunctioning electrical rails are:

1. Jamming or sticking of the rail... Such a malfunction is usually associated with damage to the boot. In this case, dust gets into the area of the teeth, which, when mixed with moisture, turns into an excellent abrasive, which with every minute of movement (especially in the urban cycle) slowly "eats" the teeth. After several thousand kilometers of run, the teeth are erased so much that the result is visible without a microscope. There is only one way out of the situation: replacement.

Repairing the control unit for the electric booster belt is troublesome. If the firmware has flown, then it is almost impossible to find it, except perhaps from professionals in their field.

Adaptation of the electric rail

After repair or maintenance of the electrical rail, it must be adapted again, otherwise the steering wheel and rail will work with angular displacement, and the error signal on the dashboard will not be deleted. This can be done only with the help of diagnostic equipment, by manipulating the steering wheel to the extreme positions in accordance with the instructions given by the diagnostic scanner.

- Check the condition of the rail anthers regularly.

- If an error message of the electric amplifier appears, immediately proceed with the elimination of the malfunction.

- If possible, turn the steering wheel to extreme positions less often.

- Do not leave a car with inverted wheels on a long parking lot.

Nowadays, it is difficult to imagine a car that is not equipped with power steering. The amplifier can be electric (), hydraulic (power steering) or electro-hydraulic (). However, power steering remains the most common type at the moment. It is designed in such a way that even if it fails, the ability to drive a car will remain. In this article, we will analyze its main functions and find out in detail what it consists of.

Functions and purpose of power steering

Power steering rackHydraulic Power Steering (Power Steering) is a steering element in which additional steering force is generated by hydraulic pressure.

For cars, the main purpose of power steering is to provide comfort. Driving a vehicle equipped with hydraulic power steering is easy and convenient. In addition, the driver does not need to make a full five or six turns in the direction of the turn to make a maneuver. This is especially true when parking and maneuvering in tight spaces.

Maintaining control of the vehicle and mitigating the shock transmitted to the steering wheel as a result of a collision of the steered wheels on bumps in the road is also an important function of the power steering.

Requirements for the hydraulic booster

For the efficient operation of the power steering, the following requirements are imposed on it:

- system reliability and quiet operation;

- ease of maintenance and minimal device size;

- manufacturability and environmental safety;

- small turning moment on the wheel with automatic return to neutral position;

- ease and smoothness of steering;

- ensuring kinematic tracking action - correspondence between the angles of rotation of the steered wheels and the steering wheel;

- ensuring a power tracking action - proportionality between the forces of resistance to turning the steered wheels and the effort on the steering wheel;

- the ability to drive a car when the system fails.

Power steering device

The main components of the power steering

The main components of the power steering Power steering is installed on any type. For passenger cars, the rack and pinion mechanism is most widespread. In this case, the power steering scheme is as follows:

- reservoir for working fluid;

- oil pump;

- spool valve;

- hydraulic cylinder;

- connecting hoses.

Power steering reservoir

Power steering reservoir

Power steering reservoir A filter element and a dipstick for monitoring the oil level are installed in the reservoir or reservoir for the working fluid. With the help of oil, rubbing pairs of mechanisms are lubricated and force is transferred from the pump to the hydraulic cylinder. A mesh in the tank serves as a filter from dirt and metal chips that arise during operation.

The liquid level inside the tank can be checked visually when the tank is made of translucent plastic. If the plastic is opaque or a metal tank is used, check the fluid level with a dipstick.

In some vehicles, the fluid level can only be checked after a short period of time with the engine or by rotating the steering wheel several times in different directions while the vehicle is idling.

Special notches are made on the probes or reservoirs, both for a "cold" engine, and for a "hot" one that has been running for some time. Also, the required liquid level can be determined using the "Max" and "Min" marks.

Power steering pump

Power Steering Vane Pump

Power Steering Vane Pump It is necessary so that the required pressure is maintained in the system, and oil is circulated. The pump is mounted on the engine block and is driven from the crankshaft pulley using a drive belt.

Structurally, the pump can be of different types. The most common are vane pumps, which are characterized by high efficiency and wear resistance. The device is made in a metal case with a rotor with blades rotating inside it.

In the process of rotation, the blades capture the working fluid and supply it under pressure to the distributor and then to the hydraulic cylinder.

The pump is driven by the crankshaft pulley, so its performance and pressure depend on the number of engine revolutions. To maintain the required pressure in the power steering, a special valve is used. The pressure that the pump creates in the system can reach up to 100-150 bar.

Depending on the type of control, oil pumps are divided into variable and fixed:

- variable pumps maintain constant pressure by changing the productive part of the pump;

- constant pressure in unregulated pumps is maintained by a pressure reducing valve.

The pressure reducing valve is a pneumatic or hydraulic choke that acts automatically and controls the oil pressure level.

Power steering distributor

Schematic device of the distributor

Schematic device of the distributor The power steering valve is mounted on the steering shaft or on the elements. Its purpose is to direct the flow of the working fluid into the corresponding cavity of the hydraulic cylinder or back to the tank.

The main elements of the distributor are the torsion bar, the rotary valve and the distributor shaft. The torsion bar is a thin, springy metal bar that twists under the action of a torque. The spool and the distributor shaft are two cylindrical parts with fluid channels inserted into each other. The spool is connected to the steering gear, and the distributor shaft to the cardan shaft, that is, to the steering wheel. The torsion bar is fixed at one end on the distributor shaft, its other end is installed in the rotary valve.

The valve can be axial, in which the spool moves translationally, and rotary - here the spool rotates.

Hydraulic cylinder and connecting hoses

The hydraulic cylinder is built into the rack and consists of a piston and a rod that moves the rack under the action of fluid pressure.

The scheme of fluid circulation in the hydraulic booster

The scheme of fluid circulation in the hydraulic booster The high pressure connecting hoses circulate the oil between the distributor, hydraulic cylinder and pump. Oil from the reservoir to the pump and from the distributor back to the reservoir flows through low pressure hoses.

The principle of operation of the power steering

Consider several modes of operation of the hydraulic booster when turning the wheels in any direction:

- The vehicle is stationary and the wheels are straight. At the moment, the hydraulic booster does not work and the liquid is simply pumped through the system (from the tank to the distributor and vice versa).

- The driver starts to turn the steering wheel. The torque from the steering wheel is transmitted to the distributor shaft and then to the torsion bar, which begins to twist. The rotary valve does not rotate at this moment, since it is prevented from doing so by the friction force that prevents the wheels from turning. Moving relative to the spool, the distributor shaft opens a channel for fluid to enter one of the cavities of the hydraulic cylinder (depending on where the steering wheel is turned). Thus, all pressurized fluid is directed to the hydraulic cylinder. The liquid from the second cavity of the hydraulic cylinder enters the drain line and then into the tank. The liquid presses on the piston with the rod, due to which the wheels move and turn.

- The driver has stopped turning the steering wheel, but continues to hold it in the turned position. The steering rack, moving, rotates the rotary valve and aligns it with the distributor shaft. At this moment, the distributor is set to the neutral position and the liquid again simply circulates through the system, without doing any work, just like when the wheels are in a straight line.

- The driver "unscrewed" the steering wheel to the extreme position and continues to hold it. This mode is the most difficult for the hydraulic booster, since the valve cannot return to the neutral position, and all fluid circulation occurs inside the pump, which is accompanied by an increased noise of its operation. But once you let go of the steering wheel, the system will return to normal.

The scheme of the hydraulic booster

The scheme of the hydraulic booster The power steering is designed in such a way that if it fails, the steering will continue to work and the ability to drive the car will remain.

Frequency of fluid replacement in power steering

In theory, the working fluid can be used for the entire life of the vehicle, but it is recommended to change the oil periodically.

The replacement time depends on the intensity of vehicle operation. With an average annual mileage of 10-20 thousand km, it is enough to change the oil every two to three years. If the machine is used more often, then the fluid must be changed more often.

As a result of the operation of the hydraulic booster, the temperature of its elements rises. Due to this, the oil is also heated, which leads to a deterioration in its physical properties. If, when checking the condition of the liquid, foreign particles or the smell of burning oil are noticed, then it is time for a replacement.

The steering rack is the centerpiece of the steering system in virtually any modern vehicle.

In essence, this is a mechanism that converts the rotation of the steering wheel by the driver into turning the wheels of a car in one direction or another.

Of course, modern steering models are equipped with hydraulic or electric boosters, include hydraulic cylinders and other technical refinements, but initially everything was very, very laconic - the steering column had a gear at its end, coupled to the steering rack and steering rods, respectively. That's all.

Types and versions

Now let's figure out what a rack is in the framework of the steering of a modern passenger car, what it consists of, how the steering rack works, what types there are, what is the structure of the steering rack and the principle of operation of the steering rack.

It is usually customary to distinguish 3 main types of steering racks:

Fully mechanical option

This is the simplest and most primitive version of the existing ones, although we must pay tribute to innovative technologies - cars with such mechanisms are becoming less and less every year. Buying a car without electric or hydraulic power steering is already considered almost "mauvais ton", especially among the representatives of the "office class". Of course, grandfather, who needs his swallow to regularly transport potatoes from the market to the house, or, depending on the situation, grandfather's entrepreneurial spirit and weather conditions in the opposite direction, do not need such bells and whistles. But the number of "swallows" dying in an unequal battle with road troubles is growing from year to year, and grandfathers are already, willy-nilly, forced to retrain as "loganovodov".

So the essence of the mechanical steering rack is the complete absence of auxiliary mechanisms and devices and is reduced to the rotation of the steering wheel solely with the help of the driver's physical strength.

Of course, here the designers also managed to introduce several technical tricks, such as a changing gear ratio, that is, changing the pitch between the teeth on the rail closer to the edges, optimizing vehicle control, both for driving at high speeds on the highway, and for maneuvering when parking a car. but, nevertheless, this technology is no longer just the past, but deeply past century.

Hydraulic power steering (GUR)

As the name of this type of steering implies, the driver's effort used to turn the steering wheel, and therefore the wheels themselves, in this version of the version replaces the hydraulic booster, in abbreviated form - power steering. This system is very widespread today, and there is no reason to believe that it will be replaced by something else in the foreseeable future. For the system, although it was once a rarity and an expensive curiosity, but today it is already well known in almost all services, it is great - they know how to fix it quickly and efficiently, and most importantly, it does not break down very often. So there is almost a golden mean. The steering when using the power steering is quite informative and sharp, so - we put a big fat plus!

In addition, power steering makes driving much safer, thanks to less strong feedback between the steering wheel and road surface defects. If on the "mechanics" the steering wheel, when it gets into a particularly deep hole, could break out of the driver's hands, then the hydraulics will calmly "swallow" all the irregularities and flaws, with its twitching and vibration, however, informing the driver that "we drove something like that there." ...

Electric steering (EUR)

Here, in principle, everything is completely similar to the power steering, with the only difference that the power to the steering rack from the steering wheel is transmitted not by the power steering, but by the electric one, which on modern cars, starting with the golf class and above, has adaptive mechanisms and with the help of the onboard the computer focuses on the speed of movement, increasing or decreasing its effort, making the steering wheel, thus, extremely sensitive and responsive to any ride. At high speed, the steering wheel "becomes heavier", allowing you to avoid unnecessary "bumpiness" on the road, and at low speed, on the contrary, it becomes "lighter", making it easier to maneuver in traffic jams and when parking.

There is, of course, a serious disadvantage in such adaptive systems, if such a mechanism fails, driving will be almost impossible, since the steering wheel will stop turning, but these problems were left behind already 10 years ago, so now we can actually talk about solid advantages:

1. A more economical option compared to hydraulics - the electric motor only turns on when you are turning.

2. Higher degree of sensitivity than power steering - you will feel the steering wheel equally well at any speed mode.

3. Complete absence of dependence on air temperature - there is no fluid in the system that could freeze, as in hydraulic variations

4. Again, due to the lack of process fluids, there is no need to carry out regular service work

5. And of course a higher level of reliability and safety compared to power steering - again because there are no hoses and joints that can leak or break.

Steering rack malfunctions and repair

Despite the high level of reliability of modern steering systems in general and steering racks in particular, they periodically fail. The cost of repairing the steering rack is a very expensive thing, so it makes sense to immediately contact the service in order to limit yourself to preventive measures if necessary, and not bring the situation to the replacement of the assembly.

What is the main reason for the failure of steering racks in Russia, and what are the first signs of a malfunction of the steering rack? And also, why is the steering rack knocking?

You will not be surprised - these are roads, or rather, their extremely low quality. Dust falling on the steering joints under the boot of the steering rack, wheels turned out in severe frost (only for the power steering), driving through severe damage to the road surface at high speed - all this will definitely lead to the fact that the steering rack will be broken.

Any extraneous knocking coming from under the steering wheel, closer to the engine compartment, is most likely emitted by your steering rack. And a knock on the steering rack is the first sign that it's time to contact the service.

It may be that a knock appears when the steering wheel is turned only in one direction or both at once, sometimes it can be a creak, but if there is already something crunching, then the matter is definitely a disaster.

In no case should it be brought to this, because if it crunches, it means that soon the wheels and the steering wheel will cease to obey each other.

In addition, it obviously indicates that you have something wrong with the rail, a suddenly "heavy" steering wheel, especially with regard to electric boosters.

If you have fluid flowing from the power steering, it means that the hose or the steering rack oil seal is leaking, it is very easy to notice, since spots of black oil will remain at the parking place of your car. A leaking steering rack will quickly cause the hydraulic mechanism to stop working and the steering wheel can only be turned with great effort. Therefore, as soon as you notice the spots - immediately go to the service!

The knock of the steering rack can turn into steering vibration, and in general can be heard even with sharp jerks of the steering wheel to the side on a completely muffled car (by the way, this is the answer to the question - how to check the steering rack as part of the initial diagnosis, which you can perform yourself).

Incorrect centering of the steering wheel, most likely, indicates that your tooth has come off and you need to adjust the steering rack - this can happen if you fly a hole at high speed, hitting it with one or two front wheels at once.

And, of course, the complete lack of effort when turning the steering wheel will also indicate that the amplifier is not in order.

If any of the above signs are found, you should urgently contact a car service for an early resolution of the problem, where professionals know how to tighten the steering rack, adjust the EUR or replace the steering rack bushing.

Delay is fraught not only with expensive repairs, but also with the fact that you will just stand firmly somewhere on the road and it’s also good if in the city, where you can call a tow truck. Remember, we said that if the EUR fails, the steering wheel cannot be turned. Do-it-yourself steering rack repair on the track is unlikely to be possible. Do not take risks, do not lead to serious damage!

09.03.2017

Experienced motorists know what a steering rack is and how important it is to keep it in working order. The correct name for this unit is the rack and pinion steering gear, but it did not take root among the people. The essence of the mechanism is quite simple - to convert the steering wheel turn into a left-right movement of the rods (for the front wheels this is a horizontal deflection), which redirect the force to the front wheels through the steering knuckles.

In simple terms, the steering rack is an intermediate link between the person sitting at the steering wheel and the wheels being steered. It is not surprising that the performance of such a mechanism must be flawless. How does the steering rack work?

Principle of operation

The specified mechanism from the structural point of view is a rod with a piston. Its base acts as a power steering cylinder. There are two cavities in the cylinder, which are filled with liquid by means of its distribution by a spool located in the body. Taking into account the steering side (left or right), the side where the fluid is under pressure also changes.

Today, there are 3 types of rack and pinion mechanisms in cars, which differ in the principle of operation:

- mechanical;

- hydraulic;

- electric.

Mechanical rail device

This type is characterized by its structural simplicity and efficiency. The principle of operation of the steering rack is as described above, and the rotation of the wheels is ensured by the applied force from the driver. To reduce the load on the hands, manufacturers are completing new vehicle models with a variable ratio rack.

Simply put, the pitch between adjacent teeth of the rack is adjusted from the edges to the middle. As a result, with an increase in driving speed, maneuverability decreases, and it becomes more difficult to control the steering wheel. Even a child can turn the steering wheel at minimum speeds, due to the minimum gear ratio. Such a simple design has proven itself perfectly in the domestic VAZ-2110 car.

Hydraulic steering gear

The main difference between the power steering rack and the one discussed above is that the driver's physical efforts are increased due to the built-in hydraulic amplifier. With such a device, ease of control of the vehicle and its high maneuverability are provided, regardless of the driving speed. Almost all modern cars are equipped with such mechanisms.

High traffic safety is ensured by the power steering: it extinguishes small potholes and irregularities on the roadway due to the hydraulic booster. The driver's hands remain on the steering wheel without any jerking. Many owners of such vehicles complain that they do not "feel" their iron horse.

This disadvantage is partially offset by modern suspensions in combination with an electric hydraulic booster.

Electric mechanism

The principle of operation of the electrical mechanism is almost completely identical to the hydraulic one. In this case, the power unit is an electric motor integrated into the steering shaft, steering column or rack (considered the safest option). The option with an electric motor in the steering column did not find popularity due to its low structural reliability.