With the onset of the winter period, two-wheeled vehicles are losing their relevance. Using a car to overcome short distances with high snow cover is not particularly practical, and in most cases - impossible process. The snowmobile copes with this task much better.

A winter motor vehicle is in most cases equipped with a rear-wheel drive track and front steering skis. High cross-country ability, versatility and ease of use make the snowmobile by far the most popular means of transportation in the winter season.

Features of homemade snowmobiles

Nowadays, you can buy a snowmobile in any motorcycle dealership, both in a large metropolis and in a small city, but the prices of this equipment force many winter driving fans to make a homemade snowmobile on tracks with their own hands.

There are four important advantages of a self-made vehicle over a factory one:

- Price is the most important factor for most. The cost of some units of the leading manufacturers of motor vehicles can exceed the cost of those assembled from scrap materials by 5-10 times.

- Parameters - the ability to assemble a vehicle of the desired configuration. This applies to both the appearance and the power reserve, the type of chassis, etc.

- Reliability is the point that even well-known manufacturers do not always boast of. When self-manufacturing, a person uses the highest quality materials and pays special attention to the most important parts of the mechanism.

- Benefit - the ability to use materials, parts and accessories from other devices lying around in garages and backrooms.

At the same time, homemade snowmobiles are used both on the streets of settlements and on roadless areas of suburban expanses and ski resorts.

Homemade snowmobile on tracks with your own hands: where to start?

1 - rear light; 2 - hitch; 3 - body (plywood, s16); 4 - side reflectors; 5 - rear shock absorber (from the Dnepr motorcycle, 2 pcs.); 6 - gas tank (from the launcher of the T-150 tractor); 7 - seat; 8 - main frame; 9 - electronic ignition switch (from the Voskhod motorcycle); 10 - ignition coil (from the Voskhod motorcycle); 11 - power plant (from a motorized carriage, 14 hp); 12 - muffler (from motorized carriages); 13 - steering column; 14 - steering joint in a leather case filled with grease (joint from "UAZ"); 15 - limiter for vertical movement of the steering ski (chain); 16 - steering ski turn limiter; 17 - steering ski; 18 - side ski (2 pcs.); 19 - generator; 20 - clutch lever (from a motorized carriage); 21 - drive chain shield; 22 - footboard; 23 - drive shaft drive chain; 24 - the drive shaft of the caterpillar; 25 - lower track chain guide (polyethylene, s10, 2 pcs.); 26 - caterpillar chain (from the header of the forage harvester, 2 pcs.); 27, 31 - upper front and rear chain guides (polyethylene s10, 2 pcs.); 28 - shock absorber of the propeller hinge frame (shortened rear shock absorbers of the Dnepr motorcycle, 2 sets); 29 - support ski; 30 - rear spacer frame; 32 - rear axle.

A drawing of a homemade snowmobile is an essential step in the preparatory stage of manufacturing. Here to help engineering skills come in handy, and in the absence of such, surface sketches are made, creating a general image of the future mechanism.

Before creating a drawing, it is necessary to determine the list of required components. The basis of the standard configuration of the snowmobile is:

- Frame - depending on the complexity of the design, it can be borrowed from an ATV, motor scooter, scooter, motorcycle, etc. In their absence, the part is usually cooked from thin-walled metal pipes with a diameter of about 40 mm.

- Seat - given the difficult operating conditions of the equipment, the material of this element must have a high moisture-repellent ability.

- Engine - is selected with the calculation of the required speed and the total weight of the vehicle. The most commonly used motors are motoblocks, scooters, motorcycles, etc.

- Tank - 10-15 liter metal / plastic container will fully provide carefree trips over relatively long distances and will not take up much space on the unit.

- Skis - in the absence of ready-made options, it is recommended to use nine / ten-layer plywood sheets with a thickness of about 3 mm for self-production.

- Steering wheel - chosen with the calculation of convenience and practicality. Similar to the frame, engine and seat, it is removed from the specified two-wheeled units.

- Drive - a part that transfers rotary motion from the engine to the track. A motorcycle chain performs this function well.

- The caterpillar is the most complex and important element. Their types and methods of self-production will be discussed further.

How to make homemade caterpillars?

One of the most common materials for making a propulsion unit at home is car tire... A homemade snowmobile track from a car tire has one important advantage over other options - it is made in the form of a closed loop, which significantly reduces the likelihood of rupture.

The beads are separated from the tire using a boot knife, leaving a flexible treadmill. The lugs are attached to the driving blade - plastic pipes sawn along with a diameter of about 40 mm and a thickness of about 5 mm. Cut to fit the width of the tire, half-pipes are attached to the canvas with bolts (M6, etc.) at intervals of 5-7 cm.

Homemade caterpillars are made in the same way. from conveyor belt... Their main advantage is the ability to choose the length of the propeller. After cutting to the required length, special attention should be paid to the hitch. The ends of the tape overlap each other by 3-5 cm, and are fixed across the entire width with the same bolts as the lugs.

Handmade tracks are often made with materials at hand, such as V-belts. Fastened in width by means of lugs, they make up a full-fledged caterpillar track with hollows for the gear already existing on the inside.

Note that the wider the track, the better the snowmobile's flotation, but the poorer handling. Factory options have three samples of canvas widths in inches: 15 - standard; 20 - wide; 24 - extra wide.

Let's go to practice

A frame made of pipes or corners is primarily equipped with a steering gear. Having chosen the height and angle of inclination, weld the element with spot welding. Install and secure the motor according to the drawing, taking care not to tilt too much. The snowmobile should not have a long fuel line, so try to position the tank closer to the carburetor.

The next step is to install the track. Attach the driven axle with the belt fitted to the rear of the frame (on a fork, suspension, shock absorber, etc., depending on the type of construction), the leading axle in the middle of the snowmobile (most often under the driver's seat), in the shortest possible hitch with the engine. The gears of both axles are pre-engaged.

Homemade snowmobile from a walk-behind tractor

This transformation is especially popular today. The walk-behind tractor can be used, either partially or completely. In the first case, a supporting frame with a rear axle is added to the unit (engine with steering fork and wheels). The most difficult stage in this case is the transformation of the working shaft of the walk-behind tractor into a drive gear.

A homemade snowmobile from a walk-behind tractor with partial use of parts is more versatile. In this case, only the engine and the steering fork are removed from the "donor", to the lower part of which skis are attached instead of wheels. The motor itself can be located at the rear of the structure.

It should be noted that the engines of the main part of the motoblocks are designed for the weight and pressure of the wheels, which is several times less than the tracked one. Therefore, in order to avoid increased wear of parts and fuel consumption, it is better to equip such a snowmobile with low pressure wheels.

Each driver decides for himself whether to buy tracks or do it himself. We will consider both aspects, but each of them is advisable only if the car drives not only on the highway. Tracks are a great way to improve off-road performance, and tuning is a must for many motorists. Is it worth buying tracks for Niva if you can make them yourself?

The challenges of transporting incredibly heavy camp gear and being tied to public transport on the hunting grounds are a must for every hunter. An off-road vehicle, even such as the Niva, solves these problems only partially, since there remain obstacles in the form of gullies, slopes and off-road terrain, which a car on standard wheels cannot cope with. There is an urgent need to switch your transport to caterpillar tracks. How to make tracks for Niva in three ways, in what cases is it better to buy ready-made ones?

In the production of tracks, special rubber is used with a special substance in the composition, thanks to which even aggressive weather conditions do not reduce their strength and elasticity. The weight of one track can vary between 75 - 110 kg, which is influenced by the design of the product and its type. Despite this weight, the transformation of the "Niva" into an all-terrain vehicle is not difficult, since the caterpillar easily rolls on the ground, there is no need to lift or drag it.

There is also nothing complicated in the design of the caterpillar propeller - a powerful metal frame in the shape of a triangle, one large roller at the top and five pairs or more of a smaller size at the bottom. The caterpillar is put on them.

The classic wheel hub is installed in the upper roller, then it is put on a rigid hitch, so that when the hub rotates, it transmits the rotational movements of the entire structure. The key advantage is the ability to turn the steering wheel just like with the wheels. If necessary, the tracks for the car are removed and replaced with ordinary tracks.

What are caterpillars for? Pros and cons of the design

The basis of the audience of drivers installing tracks on a car is made up of extreme people, hunters and fishermen, who, in pursuit of pristine beauty and maximum comfort, do not skimp on elements of car modernization. Given the purpose of using your own car and the size of your wallet, you will have to choose between buying tracks and making them yourself. If you rarely go off-road, and most often your Niva sees only the main road, there is no point in buying.

If you are fond of fishing and hunting, then increasing the cross-country ability of the vehicle due to such a modification is vital in order to master new cordons, as well as safely, quickly and comfortably get to the so-called fishing spots. After installation, you can see the following positive changes:

- The level of comfort when driving off-road is significantly increased, the difference between wheels and caterpillar tracks is immediately felt.

- The speed of the vehicle increases when traveling in snowy, swampy or sandy terrain. Indicators reach 80 km / h.

- The vehicle's cross-country ability also increases and this parameter can be compared with the cross-country ability of the Belarus tractor. The only limitation is the amount of ground clearance, which for the Niva is 30 cm.

The first tracks on cars appeared about 100 years ago, and during this time, motorists have fully appreciated their advantages, however disadvantages also exist:

- A set of tracks is expensive, and when making a homemade structure, you cannot do without basic skills and additional equipment.

- Slopes, hills and terrain with sudden elevation changes can be a problem for the suspension system and transmission, as a vehicle of this size requires more track area.

- Moving over a fallen tree trunk or similar obstacle is also not always possible.

Main manufacturers and prices

The first tracked mechanisms were developed in the USA, after which they were distributed throughout the world. Now, several dozen manufacturers are engaged in the production of such structures, including domestic ones. Of the imported brands, Mattracks is considered one of the most popular. Their prices correspond to the big name - one set corresponds to the cost of a Russian car.

Several companies are now engaged in the production of tracks for passenger cars, but such a purchase, again, will not be cheap. Pricing depends on the following factors:

- diameter of bearings and axles;

- metal thickness and quality;

- design features.

When choosing imported caterpillar mechanisms, focus on the price of 230 - 700 thousand rubles. By deciding to buy domestic tracks for Niva, you can cut costs in half.

Development of Chelyabinsk engineers

Engineers from Chelyabinsk offer an alternative design, thanks to which the vehicle will be able to conquer not only off-road conditions, but also water. Movement on water is provided by quick-detachable pontoons fixed on the chassis.

If not needed, they can be stored on a wheeled ski trailer or trunk. The installation of the tracks in this case is somewhat more laborious when compared with the classic tracked mechanisms, the installation of which does not take more than an hour. You will have to follow the step-by-step instructions:

- At the first stage, the car should be started on the tracked module, get rid of the wheels and lower the suspension onto the safety catches.

- Next, the car is attached to the frame, and the module bridge is connected to the cardan.

- At the final stage, the control unit is installed and the hydraulic system is pumped.

Such an all-terrain mechanism is installed for 2 hours, at least, after which control is available through the steering wheel. After another off-road raid, the car is brought back onto the platform, and the tracked modules replace the usual wheels. The price of the issue is 100 thousand rubles. and higher.

Can you make caterpillars with your own hands?

If the cost of a ready-made set of tracks discouraged you, you can consider the option with self-production, but you should know in advance about the laboriousness of such a process. You must have master level locksmith equipment and construction skills. Garage production may not even be considered, since you have to use special machines and tools for turning hubs, assembling and installing sprockets, shafts and bearings.

There are three ways in which the caterpillar made by you on the "Niva" will perform its functions - from a conveyor belt, from car tires or from belts. These will be the simplest designs, which, despite their functionality and maintainability, cannot be called full-fledged tracks.

Conveyor belt tracks

To assemble the tracked set, you can use a conveyor belt with a thickness of 8 - 10 mm and a sleeve-roller chain. Be sure to sew the edges of the tape with fishing line to reinforce it and avoid fraying. Use an overcast seam. The hinge can be used to connect the ends of the tape. The connection through flashing can also be applied, but the reliability will be questionable. In general, this design inspires confidence in terms of reliability and can be easily repaired.

Also, caterpillars can be made from the conveyor belt using a rectangular shaped pipe. To do this, you must first give the tracks the required shape using a pressing machine. You can use nuts and bolts to fix the tracks to the tape. We will consider this technology in more detail. You will need the following tools and materials:

- pressing machine;

- hammer and a set of keys;

- hole puncher;

- drill, angle grinder and welding machine;

- fittings and shaped pipes;

- Grover, washers, nuts and bolts;

- conveyer belt.

The phased technology is as follows:

- Taking into account the width of the caterpillar being manufactured, cut the blanks of the tracks with the help of a grinder.

- Press the workpieces on the machine to give them the desired shape, use waste oil to lubricate the ends.

- Weld on each track the fangs-restraints and additionally at the top of the V-shaped reinforcement.

- Check the correct dimensions at the track installation site.

- Use an industrial hole punch to create holes in the conveyor belt. You can make such a hole punch yourself - it will be a tube sharpened from the end part with a side hole for removing rubber waste.

- Drill two holes in the tracks at each end.

- At the final stage, the assembly of the caterpillar is waiting for you.

Tracks from car tires

Having decided to use car tires for the manufacture of tracks, it is worth choosing them with the appropriate tread pattern, which will replace the lugs. Tires from tractors or trucks will do. Carefully remove the tire beads using a well-sharpened boot knife. Moisten the blade periodically in soapy water to make cutting easier.

If you are skilled at using an electric jigsaw, you can also use this tool in tandem with a fine-toothed saw.

To achieve the required level of elasticity, several layers of the inner ring can be removed. Compared with the first option (conveyor belt + sleeve-roller chain), car tires are more reliable, since the ring contour in this case is closed and the ends do not need to be connected.

Belt tracks

Crawler belt kits also fall under the category of easy-to-manufacture structures. Grousers are used to assemble the track from V-shaped rubber belts. The connection is made by means of small bolts and rivets. The spacing between the belts must match the dimensions of the drive sprocket. Use rivets to secure the ends of the resulting blade.

conclusions

Summing up, it is worth mentioning the ease of installation of the tracks, which takes less than an hour, unless of course we are talking about a Chelyabinsk invention.

Before installation, weld special triangle-shaped kerchiefs to the Niva bridges to strengthen them. As for self-made designs, they are unlikely to compete with the factory options in terms of reliability, but they will be an excellent solution for single raids for game or fish.

For the movement of most motoblocks, ordinary wheels are used. The throughput of the apparatus in such cases is extremely small. Fortunately, there are several good ways to turn a walk-behind tractor into an all-terrain vehicle or snowmobile. To do this, it is enough to make homemade caterpillars.

Manufacturing methods and materials

When choosing a material for a future caterpillar with your own hands, you should take into account the type of work for which they are intended. The product should not only be extremely durable, but also lightweight for easy handling of the unit.

The first step is to install additional wheels on the walk-behind tractor so that there are a pair on each side. The future units will be mounted on them, the length of which will be the circumference of each wheel plus the distance between their axles, multiplied by two. All wheels must be of the same diameter.

The most popular raw materials for making do-it-yourself caterpillars include:

- Conveyor belts and roller chain.

- Waste car tires.

- Chains and belts.

Each method implies its own course of action.

Conveyor belt and chain

The method of manufacturing the unit from these materials, according to the majority, is the simplest. It does not require a large number of tools and materials. It is recommended to consider the following tips:

Tire construction

In addition to the product from the transport tape, you can make a caterpillar from the tire with your own hands. There is no need to sew and hook anything with each other, since the tire already has a closed structure with a special grip protector.

Ordinary passenger car tires will not work. You need to find products for trucks or tractors that have a pronounced tread pattern.

The manufacturing procedure for such a unit can be divided into three main stages:

It is worth carefully examining the tread pattern. It should be clearly defined to maximize the throughput of the walk-behind tractor by increasing the traction of the track to the surface.

Belts and chains

This method uses standard V-shaped belts. They are attached to each other using rivets that are placed on them. This track is made from two pieces of the same chain and belts. The algorithm of actions is as follows:

Thus, you can get a durable and high-quality do-it-yourself track from belts and chains. This method is the most time consuming of all presented.

Track tracks

Tracks are the main part of any track. Fortunately, you don't have to buy them from specialty stores. It is quite easy to make them yourself from various materials. The main thing to consider is the level of load that is planned to be applied to the walk-behind tractor. You can make tracks from:

- plastic pipes;

- wooden bars;

- metal tracks.

To make tracks from plastic pipes, you will need a water pipe no. 40. It is cut into segments, the length of which is equal to the width of the caterpillar. After that, each such segment is cut lengthwise into two halves. A circular saw with a saw blade will help to cope with this.

To make tracks from plastic pipes, you will need a water pipe no. 40. It is cut into segments, the length of which is equal to the width of the caterpillar. After that, each such segment is cut lengthwise into two halves. A circular saw with a saw blade will help to cope with this.

When all the tracks are ready, they can be hooked onto the main structure. For this, furniture bolts No. 6 and large hemispherical caps are used. With these bolts, each segment is attached to the structure itself.

Thus, an excellent embossed track for a walk-behind tractor is obtained, which allows you to pass in difficult places even in winter.

A track made of wooden blocks is suitable for light loads, since the structural strength is not so great. To make a caterpillar from this material, you will need birch blocks of the same size and length, equal to the width of the tracks.

The main advantage of a track with wooden bars as tracks is the availability of materials, the lightness of the entire structure, and the ability to quickly make repairs.

It is not surprising that the most common and reliable are metal track links, because the level of their strength is quite high. Most often, metal pipes or a profile are used, which is cut into pieces of suitable length and attached to the track in the same way as in the previous methods.

The main disadvantage of this design is the large mass and complexity of repair. If one of the tracks bends during operation, it will take a lot of effort to replace it.

It is not so difficult to make a caterpillar for a walk-behind tractor with your own hands, although it takes a fair amount of time. It is important to treat the process with the utmost care and carry out all calculations correctly. Also, it is necessary to assess the degree of load with which the walk-behind tractor works, and select the most suitable materials for the product.

A do-it-yourself caterpillar can be made by any craftsman. If you have been thinking about how to make a caterpillar for a long time, then you should read the presented recommendations. For work, you can use a variety of tools and materials. It is permissible, of course, to use, if necessary, a caterpillar that was produced in the conditions of the plant. But this will cost much more than if you do the manufacturing yourself. The article will present several options for manufacturing tracks, one of which you can choose for yourself.

A simple option for making a caterpillar

A do-it-yourself caterpillar can be made using the simplest technology. It will take you a minimum amount of time. The caterpillar propeller can be made on the basis of a sleeve-roller chain, as well as a conveyor belt. To carry out the work, you need to prepare a certain set of special tools or equipment. In order to extend the life of the tape, it is recommended to stitch its edges with a fishing line, reinforcing it at a distance of 1 cm. It is necessary to use the principle that seamstresses use to overcast the edges of the fabric, which will protect the tape from damage.

A do-it-yourself caterpillar can be made by pairing elements into a single ring, this can be done in several ways. So, it is permissible to use a hinge like a piano hinge; you can also use a less reliable method, which involves patching the ends of the tape. It is important to take into account that the thickness of the tape must be chosen, which corresponds to the power of the motor. If you intend to use an engine from a motorcycle of domestic production, then you can use a belt, the thickness of which is 10 mm, of the type that is used on agricultural conveyors.

If the caterpillar is made with your own hands using this technology, then you will not have to spend a lot of effort. Despite the fact that such a model of a caterpillar is made quite simply, it has a long service life and a large resource.

Making tracks from car tires

You can make a caterpillar yourself using car tires. To carry out the work, it is necessary to select tires borrowed from trucks, it is recommended to use a suitable tread pattern, while you will spend less effort when working with the tire. The manufacture of such a caterpillar must be done by cutting out the sides from the tire, while leaving space for the treadmill. It should be borne in mind that this work is quite laborious and involves the application of a lot of patience and strength, in this case it is necessary to use an exceptionally well-sharpened boot knife.

In order to make less effort when making a caterpillar for a car with your own hands, you can wet the blade from time to time using a soap solution. As an alternative solution, you can use a device designed for cutting, it is permissible to use an electric jigsaw. On the latter, you first need to fix a file with small teeth, the file must also be pre-moistened with water, during operation such manipulations must be performed periodically.

Work technology

Do-it-yourself tracks for a car should be made using a technology that involves the initial removal of the beads from the tires, then, if necessary, you need to remove excess layers that are located on the seamy side of the formed ring, this is necessary if the track has increased hardness. If the tread pattern does not fit, then a new structure must be cut, which will be necessary so that the structure can cling to the soil.

A self-made caterpillar for a snowmobile, made according to the above scheme, will have many advantages, even if compared with the above option. This is due to the fact that it has a closed loop, which indicates reliability. But there are also disadvantages, one of which is expressed in the limited width of the caterpillar, but if there is a need, then you can apply a double width.

Making a caterpillar from belts

The next version of the caterpillar is especially attractive in that you do not have to spend extra energy in the process of carrying out the work. Before starting, it is necessary to prepare belts that have a V-shaped profile. They will have to be joined together using soil hooks, which are fixed with screws; rivets can be used as an alternative solution. As a result, you will get a snowmobile track, created by your own hands, which has holes for the drive sprocket. In order to form the holes, it will be necessary to leave some space between the belts.

Another option for making a caterpillar

Before making a caterpillar with your own hands, you need to choose the technology for carrying out the work. It is also acceptable to use the technique presented below. The frame of the propellers can be welded using pipes that have a rectangular cross section. It is recommended to connect them using a frame, this will make the structure collapsible. The spline part can be borrowed from "Buran", this will allow the drive shafts to be made, to them you need to weld the spline part of the shafts, which are borrowed from the "Oka". It will be necessary to use brake discs as well. When working on the front shafts, you need to install brakes on them. Some part of the gearbox housing must be cut off. Making a caterpillar with your own hands will not only save money, but also move around the snow-covered area without any problems. This design can be used for a long time without the need for repairs.

When operating in off-road conditions, tracked vehicles have undeniable advantages over wheeled transport due to its all-terrain qualities, allowing to overcome deep loose snow, soggy arable land or stony ford.

The popularity of tracked vehicles among household users is so great that many home craftsmen independently "change" their wheeled vehicles into homemade products - tracks made from scrap materials.

One of the options for re-equipment is the use of old tires from MTZ tractors, which allows significantly increase cross-country ability personal auto and motor vehicles with minimal financial costs.

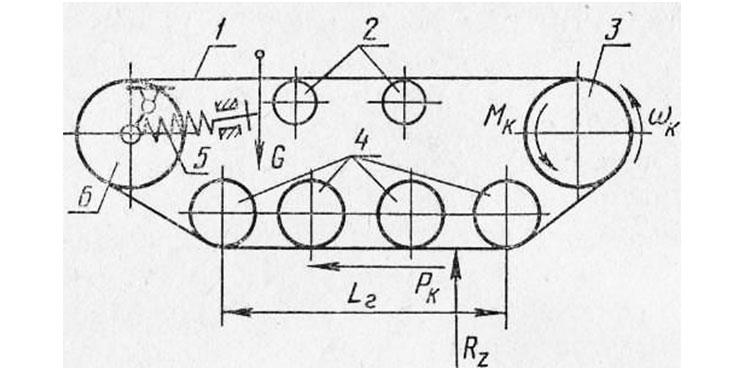

For a tracked vehicle of any purpose, be it a tank or a snowmobile, the forward motion is provided by a tracked propulsion unit (DM).

It uses two motivating factors:

- torque M k, transmitted from the engine / power drive to the drive wheels;

- traction of tracks with the ground.

The caterpillar or caterpillar chain of the main engine is called a link structure, which is a solid continuous belt or chain.

For full traction on the ground, the track equipped with embossed protrusions serving as active lugs.

The principle of the caterpillar track is illustrated by the kinematic diagram of the operation of the main engine, located below. The following positions are indicated on the diagram:

- pos. 1 - caterpillar;

- pos. 2 - supporting rollers to prevent sagging of the track belt;

- pos. 3 - a driving sprocket (driving wheel), which converts the torque from the engine into the traction force required for the forward movement of the machine;

- pos. 4 - support rollers, providing full contact of the track bed with the surface of the ground support;

- pos. 5 - shock absorbers;

- pos. 6 - a guide wheel, which serves to direct the forward motion of the machine, and transfers part of its weight to the ground.

Crawler driving is carried out as follows:

- The driving sprocket (pos. 3) is supplied with torque M to.

- The spinning sprocket rewinds the continuous belt / track chain (key 2).

- The caterpillar (pos. 2) is in close adhesion to the support surface (ground, loose soil, etc.). It is affected by:

- force R z - reaction of the support surface, which the caterpillar transmits to the vehicle frame;

- tangential reaction of the soil support Р к.

The rewound belt / track chain is continuously laid in the direction of the forward movement of the vehicle on the surface of the ground support under the track rollers, creating for the wheels of the machine path with lower resistance to movement than on soft ground.

In the process of movement, the track rises from the supporting surface and transmits the pushing force to the vehicle frame.

The specific pressure on the support (soil) along the length of the track is uneven - increased in the area of the driving sprockets, decreased in the front part in the area of the guide wheel (pos. 6). The maximum ground pressure from the main engine is in the area of the track rollers (pos. 4).

Advantages of homemade gas engines from MTZ tires

Due to the continuous insertion of the track under the rollers of the machine, a large contact area of the tape with the ground, significantly reducing the average machine pressure on the ground.

The range of the average ground pressure of the equipment with the main engine is from 11.8 to 118 kN / m2 (from 0.12 to 1.2 kgf / cm2), which is significantly lower than the pressure of a human leg.

Such low pressure indicators provide protection of equipment from immersion in the ground, swampy soil or snow. By varying the size of the surface area in the contact zone of the caterpillar with the support, the optimal ratio of the vehicle's cross-country ability with its tractive effort for towing loads is achieved.

When equipping vehicles with caterpillar tracks, homemade Samodelkins use a transport belt or tires from automobile and tractor wheels.

The photo below shows homemade all-terrain vehicle on caterpillars made of reinforced conveyor belt 250 mm wide. The lugs are 25 mm high.

All-terrain vehicle on a caterpillar track from a conveyor belt:

For most craftsmen, old tires from MTZ tractors of various models are more preferable raw materials for the manufacture of main engines.

Among the main advantages of MTZ tires, as a source material, and the tracks themselves made from these tires, include the following factors:

- Availability old tires MTZ. Quite often, after dismantling, they are stored in the depths of enterprises' utility yards, cluttering up the territory.

- The tire is a closed continuous structure, does not require stitching of the ends ribbons.

- On a tracked platform made of a tractor tire no need to build lugs because the tires have a pronounced factory-made tread pattern.

- MTZ wheel tires have high strength and wear resistance, ensuring reliable, trouble-free operation of the track on soils containing sharp stones.

- Versatility applications - you can choose tires for all types of tracked vehicles, including measures to modernize equipment or increase the width of the tracks.

- Recycling of used tractor tires solves the most important task of recycling dismantled wheels - the possibility of their reuse.

From disadvantages working with tractor tires note two circumstances:

- limited fixed track length due to the dimensions of the blank tire;

- the need to double two tires when mounting a caterpillar with a width exceeding the width of one blank tire.

Requirements for converting equipment to caterpillar tracks

The figure shows simplest in design homemade - a cart with caterpillars made of tires.

Retrofitting of equipment at the main engine house is carried out exclusively for utilitarian reasons of pragmatic owners of wheeled vehicles or motor vehicles who wish improve off-road performance their "assistants".

For all models of equipment designed for driving in the field, the market offers serial versions of industrial-made main engines.

However, all this costs a lot of money, and tires free or very cheap.

Many equipment users manage to independently, in a home workshop, make tracks from tractor tires, install them on their cars and successfully operate in off-road conditions.

Regardless of the type of car or motor vehicle, the craftsmen take into account the following factors:

- To install the mechanisms of the main engine, it is necessary to equip special frame structures increased strength and rigidity, capable of withstanding increased weight and dynamic loads.

- When using improvised means, many craftsmen use pneumatic wheels as tensioners as well as a pair of driven and driven wheels. The tape is put on flat wheels, which are then inflated, creating the required track tension.

- The owner of the equipment must clearly determine the purpose of the machine in order to select the optimal dimensions of the width and length of the track.

- Taking into account the increase in the weight and traction loads on the engine after the installation of the main engine, it is necessary to optimize the correspondence between the maximum engine power and the track width. Otherwise the engine breaks down quickly.

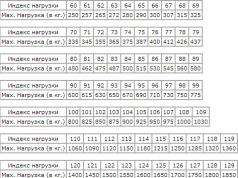

When choosing the ratio of engine power and belt width of a homemade tracked installation you can be guided by the data of the price lists on all-terrain vehicles equipped with serial tracks.

Below we will consider the categories of machines that are most popular among craftsmen when converting to a caterpillar track.

The main categories of popular vehicles equipped with main engines

The list of models of household vehicles and motor vehicles operating on loose snow and swampy soils is unusually wide.

The names of the machines themselves, adopted in everyday life, indicate their field of application.

Snowmobiles

This is a vehicle designed to travel on loose snow cover.

In contrast to Englishism "snowmobile", which denotes any vehicle adapted to driving on snow (snowmobiles, all-terrain vehicles on tracks and pneumatic wheels, etc.), in Russia only a snowmobile is called a snowmobile. ski-caterpillar means of movement(rear main engine, in front - skis instead of the front wheel) with control bodies similar to motorcycle ones.

For utility snowmobiles, the engine power is 30-40 hp, the track width ranges from 38 cm to 50 cm and even 60 cm.

Accordingly, if the master sets as his task the creation of a machine for movement on virgin snow with a load, then he should be guided by these indicators.

Similar parameters must be maintained when creating the so-called snow and swamp-going vehicles.

If the master needs make a faster snowmobile(sports type), the width of the tire tracks can be reduced.

If the master needs make a faster snowmobile(sports type), the width of the tire tracks can be reduced.

The weight loads of the speeder are much lower than that of the utility utility vehicle.

The illustration shows a motorcycle-based snowmobile equipped with a 23cm homemade track cut from an excavator tire.

The rest of the homemade snowmobile track is made by hand according to the basic principle.

ATVs

In everyday life they are considered to be any vehicle capable of off-road driving and even overcome water obstacles.

There are plenty of varieties of all-terrain industrial machinery:

- off-road vehicles;

- swamp walkers;

- amphibians;

- tracked tractors and conveyors;

- ATVs;

- ATV category cars, etc.

Their cost not everyone can afford, therefore, in home workshops they prefer to create their own exclusive products, “changing shoes” on their cars to tracks made of tires made by their own hands for an all-terrain vehicle.

Depending on the power of the vehicle engine, wider webs can be allowed.

For homemade all-terrain vehicles with a 40-70 hp engine. and with a small weight load, a tape width is sufficient 30-40 cm.

For UAZ vehicles with 110-150 hp engine caterpillar width required 40 cm with track rollers (6 pcs.) and support rollers (3 pcs.).

For UAZ vehicles with 110-150 hp engine caterpillar width required 40 cm with track rollers (6 pcs.) and support rollers (3 pcs.).

Naturally, the height of the tractor tire profile will not be enough to overcome the water obstacle, it is necessary to install high lugs.

The figure shows an all-terrain vehicle based on the Oka vehicle with a tracked belt made of tires.

Motoblocks

Represented by numerous mobile devices on the basis of a single-axle chassis... Self-made versions of walk-behind tractors converted for the State Duma are widely in demand among rural residents and owners of country houses or summer cottages.

The motivation for self-re-equipping the units, bypassing the purchase of serial tracks, is obvious.

The cost of the NEVA wheeled walk-behind tractor does not exceed 1000 USD... USA, while the simplest machines, adapted for driving on snow, are estimated at 5-10 thousand dollars... and higher.

The drive power of the walk-behind tractor (5-8 hp) is quite enough to be successfully operated as an all-season vehicle

Motorized dogs

Motorized towing vehicles, nicknamed in everyday speech motor dogs, are a mechanical coupling of a sleigh with a towing vehicle on the main engine. The driver and the load are placed in the sleigh.

Serial models are produced in a wide range of drive power (from 6 to 30 hp) and are equipped with a main engine made of a rubber-metal band with a width of up to 60 cm.

Home craftsmen usually make tugs based on a 15 hp engine from improvised means, installing tracks from tires width 500 mm.

Home craftsmen usually make tugs based on a 15 hp engine from improvised means, installing tracks from tires width 500 mm.

Such self-made motorized dogs are capable of transporting sleds with a load of up to 700 kg, developing speeds of up to 40-50 km / h.

Most often, a home-made caterpillar for a motor dog is made from a tire to save money.

The photo shows a homemade towing vehicle based on a walk-behind tractor.

DIY caterpillar manufacturing algorithm

A caterpillar track for any model from the above categories of equipment is made from tires of various sizes corresponding to the selected design. We will analyze step by step how to make a caterpillar from a tire.

The work on the production of the tape is of a unified nature and is subject to a general algorithm.

No special knowledge is required when making a track from a tractor or car tire, however you can't do without certain locksmith skills.

The process of forming a caterpillar track from an MTZ tire consists of several stages:

- A tire with a slightly worn tread pattern is selected.

- The track is cut for a caterpillar using a sharpened boot knife. Working with a sharp knife is traumatic and requires increased care and attention.

- To cut the rubber better, it is recommended to use a knife periodically moisten with soapy water.

- Cutting with a knife can be successfully replaced jigsaw, secured against possible injury.

- Both sides are cut off tires.

- Excess material is removed from the inside of the tire.

The criterion for a well-performed work is smooth cut without tousled edges of the resulting tape.

Thus, the track element is ready for use:

Related Videos

You can see a homemade snowmobile track in action in this video:

Conclusion

Making homemade tracks for converting equipment to caterpillar tracks is a very popular way to expand the functionality of machines at minimal cost.

The use of dismantled old tractor tires for the main engine contributes to the solution of the issues of disposal of old tires without the use of traditional waste recycling methods - incineration, grinding, chemical treatment, etc.

In contact with