Many owners of front-wheel drive VAZ cars, after a certain period of operation, managed to face the fact that the timing belt slips to the engine (which happens more often), or vice versa from the engine. In this case, the edge of the belt begins to rub against the engine part, the flange of the tension roller, and the cord threads break. And if this is not noticed in time, at the most inopportune moment the timing belt will break. If on an eight-valve VAZ engine, the consequences of a timing belt break threaten only to stop the engine, then on a 16-valve cylinder head repair results in a pretty round sum. Now let's look at the causes of the slipping of the toothed belt and how to fix this malfunction.

Why is the timing belt slipping.

The reason can be one or several in the aggregate. Let's consider them in order.

1. The belt itself may be to blame, or rather, the manufacturer who made the defect. The belt, which has different stiffness in width, begins to float towards lower stiffness almost immediately after installation. The diagnosis in this case is simple, we remove it, turn it over with the other side, install it, and if it starts to crawl in the other direction, then the culprit is found. Such a belt is definitely a junk. It is fair to say - now this is much less common. Tip: Always keep a supply of timing belts and alternators in your trunk.

2. Wear of the water pump (pump) bearings. With the belt removed, wiggle the toothed pulley. Bearing play is unacceptable, so we change it without hesitation, it will soon flow anyway. If the problems began after replacing the pump, then maybe, when installing a new part, the mating surface of the block was poorly cleaned from the old gasket and the pump body became skewed. It also happens that the pump itself is made "crooked", well, the turner was out of sorts.

3. The most common reason is the bending of the tension roller mounting stud, if not properly replaced. "According to the primer", the tightening torque of the roller eccentric nut is only 4.2 kgf / m, and if you tighten it "from the heart", then the M10 hairpin can bend slightly, and even 0.1 mm of displacement will be quite enough for the belt to slide to the side. Straightening the hairpin is almost impossible. Alternatively, you can try to turn it out of the block and screw it in with the other side. I had this option. But there is a better way. Described in the magazine "Behind the wheel". Pictures from the same place.

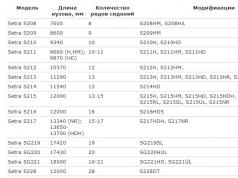

Adjusting washers are cut from a tin beer can, according to the size of the distance ring installed between the block and the eccentric of the tension roller. Cut in half in a crescent shape for a thinner one, or bend and fold for a thicker one.

Then they are installed according to the scheme. Closer to the center of the block (1) if the belt slides towards the engine, closer to the edge (2) if the belt slides outward. When installing, so that the washers do not fall, I recommend gluing them with a sealant.

The thickness of the set is selected experimentally. The method is simple and very effective.

4. By the way, the tension roller can often be the culprit. Now they are made on a single-row ball bearing, and the bearing surface for the belt is often far from ideal (taper, ovality and even steppedness). Therefore, the choice of a video should be approached as meticulously and carefully as possible. Bearing play should be minimal, the working surface, at least "by eye", should be smooth and even. Before installing, do not be lazy and check the presence of grease in the bearing. How neat. Very often this is a big "save".

5. I will repeat a little. There may be several implicit, almost imperceptible reasons, which are difficult to determine one by one, but in total they quite cope with the shift of the belt to the side. And this is where the shims will become just a panacea.

All car parts can “age” and wear out over time. Each of the car owners, sooner or later, is faced with a situation when it is necessary to change a spare part. The slip of the rubber ring is very common, especially among Vaz owners. We will find out what the reasons for this are.

Creep reasons

ATTENTION! Found a completely simple way to reduce fuel consumption! Don't believe me? An auto mechanic with 15 years of experience also did not believe until he tried it. And now he saves 35,000 rubles a year on gasoline!

As a rule, the complications of an eight-valve internal combustion engine of 1.5 liters after a scheduled duty change of a timing rubber product that has "plowed" the issued resource is familiar to many owners. It consists in the fact that the new part now jumps off, which inevitably leads to its breakage. If on such motors, with a rupture of the rubber ring, mutual collision of the valve-piston elements were observed, overhaul would not have been avoided in any way.

But on a 16-valve unit, the results of a timing ring rupture are much more sad. In this case, one stop of the motor will not end.

On the other hand, why does the belt slide off after all? And this happens both in the direction of the power plant and vice versa. Well, how much can you change the belt, it's time to find the cause and eradicate it.

Reason 1: the culprit strap

The fact that these days the quality of new parts does not stand up to criticism does not surprise anyone. And it would be correct to say that the main factor of jumping off is just the unoriginal and poor quality of the timing belt. It is no secret that a rubber element with an uneven structure, which tends to stretch in certain places in different ways, is no longer an option. Such a belt will always be skewed, albeit imperceptible to the eye, but extremely negatively affecting the work of the part.

Note. You can check the curvature of the belt as follows. It is necessary to turn it over on the drive, and then diagnose the operation in this position. If the belt starts to slide in the other direction, the problem is in the belt itself.

The manufacturer's mistake, who made the product defect, gives us a belt with different stiffness in width for use. As a result, the rubber part, under the influence of the force, "floats" in the direction of less elasticity. And this happens almost immediately after installation.

Reason 2: pump

The second common cause is related to the coolant pump shaft play. In the people, this problem is usually called "pump kick". It is quite easy to determine the presence of a backlash: you need to remove the belt and check the pump gear for rolling. If there is a backlash, then the pump will have to be replaced, since sooner or later it will completely fail, if this has not already happened.

Often the pump is made simply "crooked". Maybe the turner was under this case, or something else, but this really happens. In addition, problems often begin after replacing the pump with a new one. In this case, it is recommended to check how the block mating surface is cleaned. It is possible that when installing a new pump, the mating zone was poorly cleaned of pieces of the old gasket. As a result, the pump misplaced, skewed.

Finally, pump bearings can wear out over time, leading to operational problems.

Reason 3: NTZH roller

The third common reason is the tension roller or NTZh. Being a high-precision device, it does not accept any deviations, even the smallest ones. The correct operation of the NTZH roller depends on the accuracy of the characteristics of its components. In the case of belt slipping, everything is simple: if the NTZh roller is initially curved, it will move the timing rubber ring sideways, thereby, the edge of the rubber part will wear out.

In addition, the most common cause of belt slippage problems associated with the NTR roller is bending of the retention pin. This happens, again, during the "amateurish" replacement of the roller, when the tightening is not carried out at the proper level. Any specialist will confirm that it is impossible to tighten the eccentric nut "from the heart", since the hairpin can easily bend, and any discrepancy, as mentioned above, negatively affects the sensitive roller.

It is almost impossible to straighten this hairpin. On the other hand, there is an option to turn it out of the block and then put it back on.

But there is another effective way. It is necessary to cut out washers from a tin can the size of a distance ring, and then put them between the block and the eccentric of the NTZH roller.

This method will also help to resolve complications with the dismount of the rubber timing ring:

- If the belt slips towards the motor, it is recommended to place homemade washers closer to the block.

- If the belt slips away from the motor, it is advisable to place the washers closer to the edge.

The thickness of the washers is selected depending on the situation. If it is necessary to reduce the washer, it is simply cut into two halves with a crescent moon. If you increase it, they fold it in half.

It will be useful to know that some car owners recommend putting an old-style roller on the Vases NTZh. It has a different design compared to the latest NTZH samples.

Of course, the problem with belt slipping cannot be solved by replacing the NTZH roller, but it will be easier to determine belt wear. Let us remind you that the old-style roller has a metal side, while the modern one has a plastic one. It turns out that the old-style NTZh roller will eat up the belt more noticeably than a part with a plastic rim.

In some cases, a snag with a rubber timing ring can be resolved by pulling the NTJ towards the camshaft. In this case, a large break point will form on the upper part of the ring, but this can adversely affect the correct operating conditions for the entire GDS mechanism.

It would be more correct to pay attention to the quality of the product when replacing the NTZh roller with a new one. As mentioned above, modern products not only fall behind the old samples with the material of the side, but are also made on a 1-row ball bearing. In addition, the surface of NTZH rollers can be far from ideal: a cone, oval, and even steppedness are not uncommon.

And of course, it is necessary to carefully check the NTZH roller for play (must be scanty) and on the surface without protrusions or irregularities.

Finally, during installation, it is necessary to check if there is any grease in the roller bearings. Do not be surprised, in our time they can save even on this.

Original solution

In most cases, adjusting the timing belt involves adjusting the spacer washer installed under the NTZh roller. Experienced craftsmen and motorists are advised to inspect this very washer, to check whether it is installed with the reverse side.

Indeed, the dilettantism of service station workers in some cases simply enrages. Practicing mechanics even for several years may simply not notice the gluing on the spacer washer pointing to the correct side. Yes, it is applied with acrylic varnish and may not be noticeable, but if you look closely, you can see it.

What is the function of the spacer washer? The main reason for the slipping of the belt, as described above, is not at all the misalignment of the crankshaft, but the initial unevenness of the working surface. Knowing this, the designers and mechanics at AvtoVAZ initially came up with the idea of aligning the seat with a remote washer. And they put it on acrylic glue.

All this is understandable, but that's why AvtoVAZ couldn't solve the problem with the internal combustion engine in some other way? It turns out that there is also our inherent laziness and unwillingness to work to the end.

According to the standard, all engines assembled at AvtoVAZ must be checked on a conveyor belt. If a problem with belt slippage is found, the power plants are sent for revision to special workshops, where Uncle Vasya and Uncle Kolya simply, in order to save time, put remote washers. Simple and ingenious, but what will happen to the engine after a long run, when the belt is replaced, the manufacturer no longer cares. The main thing is to provide a factory warranty, and an obviously defective engine can be imagined as fully working. These are the pies.

Therefore, if auto mechanics are struggling and racking their brains over the problem of belt slippage, and cannot come up with anything, it is quite possible that the engine is simply from the category of defective and modified by Uncle Vasya.

The problem is also solved simply: the washer, firstly, is placed on the correct side, and, secondly, it is sharpened on the grindstone or grows on one side. If you do everything correctly, the belt will run clearly and exactly in the middle of the flywheels the first time, and will not jump anywhere.

Choosing a quality timing belt

Often, the problem of belt slipping is associated with the poor quality of the product itself. For this reason, knowing how to choose the right belt will be of great benefit.

First of all, it should be noted that today there are several popular manufacturers of belts. Their products are worth buying, but again not thoughtlessly, but carefully checking, since no one ruled out fakes and marriages.

Note. If for other hinged systems of the car you can choose a belt and a simpler one, then for the GRS mechanism only high-quality, good, albeit for a lot of money. This is an axiom that every vehicle driver should know. It is probably not worth writing about what troubles can begin due to a broken belt at the engine.

So, let's go directly to choosing a good timing belt.

Contetag

Belts of the "Kontiteg" company are supplied to almost all countries of the world, and the main consumers of the products of this company are such giants of the automotive industry as Volkswagen, Fiat, Opel and others.

As you know, recently, Contitech purchased several subsidiaries in the Middle Kingdom, which speaks of the expansion of the sphere of influence in Asia and throughout the world. Today, it is in China that practically everything is done, you just need to be able to distinguish the official Chinese factories from the "left".

So, in the near future it is expected that Kontiteg products will appear on the market with a Chinese logo, but this is unlikely to affect the quality.

Today timing belts from Kontiteg are considered the best for installation not only in foreign cars, but also on domestic cars. They are reliable, rarely torn, and serve for a long time.

This does not mean at all that by putting a belt from Koniteteg, you can forget about the service life and proper care. Despite the high reliability of products of this brand, if the operating rules are not followed, problems cannot be avoided.

Daiko

The oldest manufacturer of motor belts. In addition to timing belts, Dayco Aftermarket also produces good quality NTZh rollers, various attachments and pumps.

All products fully comply with the standards of the giant automakers.

Interestingly, Daiko supplies its products not only to primary sales markets, but also provides secondary sites. This is done for the sake of the repair needs of car owners of different social status.

The manufacturer's “secondary market” is so developed that it is divided into two geographic zones. Separately, the products go to North America, and separately to other countries.

Many car owners give preference to belts of other companies, bypassing Daiko products, for only one reason - they are bribed by advertising. The same "Kontiteg" occupies a higher position in comparison with "Daiko" on the competitive ladder not because of the quality of its products (it is good, there are no words), but thanks to a powerful advertising campaign.

But "Daiko" takes others. His products, he believes, do not need PR. Indeed, among the elite, this particular manufacturer is considered better, despite the second place in the world ranking.

Note that Daiko periodically updates technologies, moving to more advanced techniques. As a result, the belts of this company are always distinguished by the highest parameters of wear resistance.

For some reason, Daiko products are not very popular in Russia. Most likely, this is from ignorance. Or maybe this was affected by the negative quality of the products, which are also available.

| The positive qualities of Dayco timing belts | Negative qualities of Dayco timing belts |

| Relatively low cost. | Belt tears after a slight run. |

| High wear resistance and low noise due to a special Teflon coating of the timing belt teeth profiles. This technology is patented by the manufacturer Daiko and is used in the most modern cars with high requirements for durability and increased durability. | There are times when the belt is stretched without departing from the prescribed service life. |

| Vibration noise of work and belt after replacing the timing kit. |

In addition, Daiko belts are often counterfeited, which also negatively affects the consumer / producer relationship.

Distinguishing a quality Daiko belt from a fake is, in principle, not so difficult. Usually, they look at the packaging: if it is light blue or dark blue, it must be belts of American or Italian production.

It is also characteristic that the original Daiko belts are covered with a special white film on the seamy side (as a rule, they do not have fakes of this film).

And some general tips:

- The belts should not be too stiff.

- An unpleasant odor should not be emitted from the products.

- The marking must be clear and not blurry.

Video about why the belt comes off

We hope this article was helpful to the reader. In any case, you have learned the main reasons why the timing belt comes off, and what can be done to fix this problem. Of particular interest is the adjustment of the belt using the spacer washer. We also recommend that you pay attention to a video review presenting the theory of internal combustion engines: why the belt jumps off or tears.

In this article, we will consider options for solving the problem with the slipping of the VAZ 2109 timing belt. As you know, all car parts tend to wear out over time, and sooner or later it becomes necessary to replace one or another worn out part with a new one. Owners of the VAZ 2109, as well as other front-wheel drive VAZ vehicles equipped with an 8-valve 1.5-liter engine, after the next replacement of the timing belt (timing belt) is often faced with one problem. The new timing belt, installed to replace the used one, begins to pull an unknown force from the place of its normal location in the middle of the camshaft drive gear to its edge, which leads to the edge of the belt being eaten by the drive parts. This leads to rapid wear and thinning of the timing belt, and as a result, its quick break and the need to replace the belt again. It is good that on these engines, if the timing belt breaks, the desynchronization of the movement of the valves and pistons does not lead to their mutual collision, and the engine overhaul will most likely not threaten you. The belt can be pulled both from the engine and in the opposite direction.

In the process of solving this problem (yes, it did not pass me by), the author changed 3 belts before he solved it, having tried many ways. These are the ways I will share with you in this article.

Recently, the quality of spare parts leaves much to be desired, so I think that the main reason for the slipping of the belt is low-quality spare parts, in this case the timing belt itself. It can have an uneven structure, stretch in different places in different ways, be skewed in the case of even an imperceptible difference in the diameters of its two edges. To determine if a newly installed belt is crooked, you can turn it over on the drive and check the operation in this position. If it pulls in the other direction, the belt itself is to blame.

Also, slipping of the belt can be caused by the backlash of the coolant pump shaft, in the common people called the pump. It is not difficult to determine the presence of backlash: with the timing belt removed, shake the pump gear with your hand. If there is even the slightest backlash - a node for replacement, she will not live long.

The next part of the VAZ 2109 gas distribution mechanism is the belt tensioner. It is a high-precision device, and even small deviations of the characteristics of its parts from the specified ones lead to deviations from its correct operation. Simply put, if the roller is curved, it will direct the belt away from the straight motion, and thereby wear out the edge of the belt with its bead.

Some car owners note the elimination of belt slippage when replacing the camshaft and crankshaft drive gears with new ones. But these gears can reach a similar degree of wear with runs of 100,000 km or more, so if you have less mileage, this replacement is unlikely to lead to a positive result.

Also, some motorists point to a solution to this problem with the timing belt by installing an old-style tension roller, which has a slightly different design compared to the new-style roller.

1- old-style video

2 - new sample video

I suspect that such a replacement does not solve the problem of slipping, just the old-style roller has a side of a different shape and is made of metal (the new side has a plastic one), which causes less friction at the point of contact of the side with the belt and the belt eating up does not manifest itself as noticeably as in the case with a roller of a new sample.

You can try to pull the roller in the other direction, closer to the camshaft gear. True, in this case, the belt will receive a greater bend in its upper part when switching from the camshaft gear to the roller. With the standard method of tensioning it, the roller is located approximately in the middle between the camshaft gears and the pump, which, in my opinion, is more correct in terms of the operating conditions of the belt.

There is a great way to eliminate timing belt slippage by adjusting the position of the idler roller by placing a piece of aluminum beer can in the shape of a half washer between the cylinder block and the roller spacer ring. A similar need arises if the distance ring has different thicknesses, it can be measured with a caliper. By selecting the position of this half washer, you can completely eliminate the timing belt slipping.

If the timing belt slides towards the engine, then this is one of the reasons for the wear of the timing belt. The belt is, as it were, "devoured". The sliding effect occurs as a result of misalignment between the pulleys of the parts that make up the timing belt. In the vast majority of cases, the tension roller is to blame. The technical documentation, which is attached by the manufacturer to each car brand, has its own tightening torques for threaded connections. For the tension roller mounting bolt, this value is 4.2 N * m. But such is the Russian mentality, few people look at the technical documentation. Most don't even know what it is. Even the repair of the engine for our craftsmen gradually turned into a tightening "at random" with the help of a bunch of pipes-levers of different lengths.

Let us explain what the "fault" of the tension roller manifests itself in. As you know, it is mounted on a threaded rod. When the owner of the car changes the timing belt, he does not even think about the moment with which it is necessary to tighten the bolt of its fastening after tensioning the belt. We are always tightening up with all our might. It is not right. If too much force is applied, the pin is bent slightly towards the cylinder block. But this is enough for the timing belt to start sliding towards the engine. Of course, you can do with replacing the hairpin and everything will fall into place. By the way, this method is the only one for fixing the stud, which is bent so that the belt eats up almost completely. The option that we describe below will no longer work to troubleshoot a severely curved stud.

Digging through the old garbage, or go to the store and buy a can of Coca Cola. The one that is made of aluminum. Its thickness is approximately 0.1 mm. We cut out 2 - 3 washers under the diameter of the hairpin, or rather their half. We put them under the right side of the tension roller. Attention! Place washers only on the spacer ring, otherwise all work will be in vain. Usually, installing two half washers is enough to stop the timing belt from sliding towards the engine.

Set the valve timing, tighten the belt and start the engine. Visually check the belt for slippage. We recommend doing this every 1000 km after the procedure. If the belt continues to slip, place another half washer. If nothing could be fixed with the washer lining, then the reason is no longer in the tension roller. Or simply the tensioner stud is so crooked that the problem can only be fixed by replacing it.