- this is an unpleasant moment that negatively affects electrical equipment connected to the network at that moment. After all, it is the order of the phases and the voltage across them that makes electrical machines, such as motors and transformers, work. To avoid damage, use a relay that monitors the phases. So what is it and where is a similar design used? This device is necessary so that in a three-phase network each phase alternates correctly. If at least one fails, the device protects the equipment. Next we will look at the device, principle of operation and purpose of the phase control relay.

Design

Modern microprocessor mechanisms, which are used in the manufacture of the device, provide it with ease of setup, simplicity of design and high reliability of parameters. If the equipment is imported, then this is especially important, since they are particularly demanding on power supply and require a high-quality power supply network. After all, even a minor accident can cause large losses and failure of expensive equipment.

Below is a diagram of the device connection:

The design of the phase control relay is based on a microcircuit. It is she who directs his work. As soon as there is a decrease (or complete loss) of voltage on one of the phases, the microcircuit transmits a signal to an electromagnetic relay, which turns off the load.

Also, the RKF design may include indicators of phase voltage rotation and asymmetry, as well as a response time regulator.

Purpose

Since electrical equipment is used in almost all enterprises and it is constantly necessary to protect it from phase imbalance, relays are used in many areas of activity.

The mechanism is used to protect three-phase devices. The phase control relay protects against breaks, distortions or sticking, and also controls that each phase alternates correctly.

You can learn more about what relays of this type are used for from the video:

This device may also have a function - it monitors the voltage level and turns off the power at values below the set value.

Principle of operation

The operating principle of the device is self-resetting: the relay turns off when an alarm is triggered. When three-phase voltage is supplied to the mechanism, all operating and controlled parameters are checked.

If, during the check, all parameters are normal, then the built-in electromagnetic relay is turned on. If the control shows that at least one of the parameters does not correspond to the norm, then the mechanism is automatically turned off. Then, after all parameters return to acceptable levels, the device automatically turns on without delay. If not one phase is turned off, but two or three, then the device can turn off without delay.

When any emergency occurs, the load is switched off by the device. Emergency situations can be different, for example:

- any phase is missing;

- exit from the permitted voltage level limits (symmetrical or asymmetrical);

- erroneous connection of three-phase power, resulting in incorrect alternation.

Such control using a similar design allows you to quickly and efficiently protect equipment from dangerous and emergency power supply modes of the electrical network, as well as monitor the quality of consumed electricity.

Device types

There are a large number of phase control relays on the market today. Some of the popular types are the following:

- EL–13;

- EL–12;

- EL–11.

In addition, modifications of such models as EL-12 MT and EL-11 MT have become widespread and famous.

The EL-11 model and its modification EL-11 MT are used, as a rule, to protect generator sets, power supplies, as well as in automatic transfer switching (ATS) circuits.

The relay model EL-12 and its modification EL-12 MT are mainly used to protect electric motors of lifting equipment with a power of no more than 100 kW.

The EL-13 model and its modification EL-13 MT perform control in reversible electric drives with a power of no more than 75 kW.

The device is fixed in two ways. The first option is fastening using mounting screws, and the second option is fixing to.

So we looked at the purpose, principle of operation and design of the phase control relay. We hope you now understand what this device is and what it is needed for!

Operating principle of phase control relay

The main purpose of this device is to control and protect electrical equipment in the event of poor-quality three-phase voltage. This is especially important for imported equipment, therefore, to protect imported equipment, a phase control relay is always installed. This device monitors a three-phase network in the event of a break in one or more phases, incorrect phase rotation, voltage asymmetry or phase imbalance.

Phase control relay RNPP-301

If all phases correspond to the parameters of the control relay, then the contacts of this device are turned on, which give permission to turn on three-phase voltage through a magnetic starter, contactor. If one phase disappears, the relay will not start the magnetic starter, and voltage will not be supplied to the equipment. In emergency mode, an alarm can be activated via a relay.

When the missing phase is restored, then the device will turn on the load automatically after 5 seconds. Thus, control occurs automatically; in an emergency, the relay turns off the load, and when the network parameters are restored, it turns on the three-phase network voltage automatically. Some relay models have the ability to adjust the delay time for switching on their contacts.

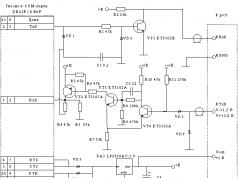

Phase control relay diagram

It is especially important to include a monitoring relay in circuits of mobile equipment with a three-phase electric motor. So, if the phase sequence is not correct, the pump will pump poorly, and the press may even break down. If one phase breaks, the electric motor will overheat and burn out.

To protect the electric motor from phase failure, a thermal relay is also installed on the magnetic starter. Its shutdown time is quite long. For each electric motor, the thermal relay must be selected not according to its operating current, but the rated current of each thermal relay must be adjusted with special screws. For this purpose, a stand is assembled.

As a rule, there is neither a stand nor the desire to accurately select the current of a thermal relay. Therefore, a phase control relay is simply necessary in this case. The operation of the relay is based on the detection of negative sequence harmonics that occur at the moment of phase failure or imbalance.

Connection diagram of the phase control relay to the network and magnetic starter

These harmonics pass through passive analog filters where they are separated from the fundamental harmonics. The signal from the selected harmonics is sent to the control board, which includes contacts. The phase control relay circuit is assembled using transistors or a microcontroller. The connection diagram for the phase control relay is simple.

Three phases L1, L2, L3, and neutral N are connected to the corresponding terminals of the device, and the relay contacts are connected to the starter coil. In normal mode, the control relay contacts are closed, the magnetic starter is turned on, and power is supplied to the equipment.

In emergency mode, the device turns on its contacts, they open, and the load supply voltage is turned off until the power supply parameters are restored. The use of a phase control relay in the electrical circuit protects electric motors from overheating and failure. In domestic conditions, this device protects a three-phase compressor, refrigerators, and washing machines.

To safely use your home electrical network, you need to ensure its reliable protection. The vast majority of users understand this, which is why automatic circuit breakers are installed in all power lines, and often RCDs are installed along with them. However, these devices are not enough to protect the network from all negative factors. The machine will save the line from overload and short circuit, the RCD will protect people and pets from injury from leakage current. But if a problem occurs in a three-phase network (this could be a break in one of the three phase cables, a neutral conductor, or a pulsed voltage surge caused by a thunderstorm), these devices are useless. You can prevent negative consequences by connecting a 3-phase voltage control relay.

Three-phase voltage relay: purpose and principle of operation

This device, as the name implies, is designed to control the potential difference in a three-phase network. Its indicator is 380V. Of course, there are small limits within which the voltage can fluctuate without harming the wiring and connected equipment. But if it becomes too high or, conversely, low, serious problems arise.

Too much voltage causes the cable insulation to overheat and melt. In addition, under its influence, household appliances connected to the circuit burn out. If the potential difference is too small, then due to a decrease in power, malfunctions begin in the operation of the equipment, and some devices turn off. For electric motors, the consequences of a voltage drop are even more serious - the units simply burn out. By installing relays to monitor the phases, these problems can be prevented.

Many owners of private houses are deterred from purchasing a phase control relay by the fairly high price of the product. But installing this device in a three-phase network is completely justified, because eliminating the consequences of a line failure along with the connected devices will cost tens or even hundreds of times more. Not to mention that a voltage failure in the 380V network can cause a fire.

Nowadays there are various types of ILVs on sale, differing from each other in design features and functionality. But they all work on the same principle.

The mains voltage monitoring relay (3-phase) has a microcontroller in its circuit, through which the device monitors the potential difference across the phases.

When the voltage on one conductor changes under the influence of the controller, an electromagnetic relay is switched on. This happens automatically. The contacts of the device open and the power supply to the line is stopped. After the voltage parameters return to normal, the current will be released into the circuit again. No outside intervention is required for this.

To check the RKN, you can use a tester. If the device is working properly, then when the multimeter probes touch contacts numbered 1 and 3, the number “1” should appear on the display of the measuring device. When the probes close contacts 2 and 3, the tester should show “0”.

Installation procedure

Control relays are usually installed on a DIN rail. Devices may differ from each other in connection diagram, but since it is printed on the body of the device, there are usually no problems with connecting the RKN. The connection of the input contacts to the line should be made through the starter.

The relay connection diagram is shown in the figure below.

It is important to ensure good contact on all connections. Twisting, especially when connecting cables to the contactor, should not be done. It is best to purchase special tips for this purpose - they are quite inexpensive.

The RKN is connected to a three-phase electrical network via wires. Copper cables with a diameter of 1.5-2.5 square meters. mm are quite suitable for this purpose.

Video about the connection:

How to set up a voltage relay?

Let's look at the procedure for setting up the device using the VP-380V device as an example. When the device is already connected to the circuit, you need to apply power. Then look at the display readings:

- Until voltage is applied to the device, the numbers displayed on it blink.

- The appearance of dashes on the display may indicate a changed phase sequence, or the absence of one of them.

- If the connection is made correctly and the network parameters are normal, after 15 seconds the relay contact 1-3 closes and power begins to flow to the contactor coil, and then to the line.

- If the device screen flashes for a long time, the contactor will not turn on. Check the connection - most likely there was an error somewhere.

After making sure the connection is correct, you can proceed to the settings. Next to the relay screen there are 2 setting buttons with triangular symbols.

On one button the apex of the triangle points up, on the other - down. To set the maximum shutdown limit, press the top button. You need to hold it in this position for 2-3 seconds. A number corresponding to the factory level will be displayed in the central part of the monitor. After this, by pressing the buttons, you should set the desired upper limit for turning off the control device.

The lower limit is set in a similar way. The device will be programmed automatically 10 seconds after the setup is completed. In this case, all set parameters will be saved in the relay memory.

How to set the restart time?

On the body of the device, next to the display, there is a button for setting the restart time. It is located between the ▲ and ▼ buttons, indicated by a clock icon. After pressing and holding it, the setting number set at the factory will appear on the display. Most often it is 15 seconds.

What does this feature do? If, for example, a potential difference occurs on one phase that exceeds the limit values, the relay will turn off the power to the network.

After the voltage is normalized, the control device will turn on the electricity supply after the period set at the factory (15 seconds). To change the value, hold the setting button until this number appears on the screen. After this, set the desired number by manipulating the upper or lower button. The change step provided by the device is 5 seconds.

How to adjust phase imbalance?

To set the interval between voltage readings on different phase conductors, press the upper and lower buttons simultaneously. The factory setting value will appear on the screen; as a rule, it is 50V. This means that the relay will stop supplying power if the voltage difference between the phases is 50V.

You can change this value by pressing both buttons at the same time, and then setting the upper or lower number to the desired number.

More details about the settings using the example of one of the models in the video:

Conclusion

In this article, we have discussed in detail why a three-phase voltage relay is needed and how to configure it.

Connecting and setting up the device is not difficult at all; this procedure will take no more than 30 minutes. If the installation is completed without errors, the relay will provide reliable protection of the home line from voltage surges in the supply network.

The phase voltage control relay allows you to instantly turn off the electricity after the meter in the event of an emergency - a power surge in the network. This device is used in both single-phase and three-phase electrical networks to protect electricity consumers from failure. Next, we will look at typical wiring diagrams for voltage relays in an apartment panel.

So, the simplest wiring diagram from the input circuit breaker in the apartment to the voltage control relay looks like this:

In this case, the network is single-phase (220 Volts) and the load is no more than 7 kW, so there is no additional need to connect it to a DIN rail. If the load is more than 7 kW, it is recommended to connect via a starter, as shown in the second diagram for connecting the RN-113 relay:

We immediately draw your attention to the fact that in addition to the distribution panel there must be an RCD or a circuit breaker in order to protect the residents of the house from leakage currents that can cause. The schematic diagram for connecting a voltage relay and an RCD (or a difavtomat) looks something like this:

If you have a three-phase 380-volt network in your private home, the protective device can be connected according to one of two schemes:

The first is recommended to be used if there are no three-phase consumers in the house - a powerful electric stove or 380 V boiler. If you use 3-phase electric motors, you need to protect them with an appropriate voltage relay, for example, RNPP-311 or RKN 3-14 -08, the diagrams of which we provide you with:

Correctly connecting the device to the network

Using a cross module

As you can see, both options additionally have a magnetic starter, which allows you to switch high loads (over 7 kW). In addition, the starter allows you to remotely control the protection, which makes this voltage relay connection diagram very convenient!

In a three-phase electrical circuit, when the voltage is uneven across different phases, a very unpleasant phenomenon occurs - phase imbalance. Its result, as a rule, is a significant decrease in the power of the device. This will lead to breakdown of both industrial equipment and ordinary household appliances.

We will not delve into the causes of this imbalance, but will consider ways to eliminate it. To prevent the occurrence of phase imbalance, which mainly manifests itself in three-phase networks, phase monitoring relays are used.

Purpose

The main purpose of the phase control relay is, of course, the protection of all electrical industrial and household devices connected to a three-phase network. The relay provides control over the presence of mains voltage, its symmetry in all phases and correct alternation. In addition to these direct responsibilities, this relay can have the function of monitoring a given voltage level, and when a certain threshold decreases or increases, turn off the power.

It is advisable to place the relay where multiple reconnections of devices occur, for example, for equipment that is often moved from one place to another and where incorrect phase rotation will be quite critical. Or when using a significant number of high-power devices at the same time (in apartments or private houses).

Design features

In the manufacturing process of such relays, reliable microprocessors are used, which explains the ease of setup, as well as the high reliability of these devices. The design of the control relay necessarily includes a circuit that calculates the order of phase rotation, and in accordance with the algorithm embedded in the circuit, the contacts at the relay output are activated.

In the simplest devices, 3-phase and zero are supplied to the input, and at the output we have a relay with a switching contact. The internal circuit is powered by phase L1. There are also usually 2 or more indicators, depending on the model and manufacturer.

More advanced devices contain a response time (delay) regulator and a circuit that responds to both a decrease and an increase in voltage.

Magnetic starters and contacts for starting electric motors or any signal circuit that warns of deviations in the network from the norm can be connected to the outputs of the monitoring relay.

Types

The most common types of phase control relays, which are mainly used in production and in domestic conditions, are EL11, EL12, EL13 and EL11MT, EL-12MT.

To protect power supplies, automatic transfer switches, generators and power converters, EL11 and EL11MT are used.

To ensure the safety of crane electric motors with a power of up to 100 kW, EL-12 and EL12MT are used.

EL13 is mainly used when connecting reversible electric motors up to 75 kW.

These relays can be mounted using either a DIN rail or mounting screws.

Characteristics

Below are the main characteristics of the relay.

1) Operating voltages:

- EL11 – 100 V, 110 V, 220 V, 380 V, 400 V, 415 V

- EL12 -100 V, 200V, 280 V

- EL13 – 220 V, 380 V

2) Relay operation limit.

a) With symmetrical phase voltage reduction:

- EL11 – 0.7 * Ufn

- EL12 – 0.5 * Ufn

- EL13 – 0.5 * Ufn

b) If 1 or more phases break:

- All types of relays are activated.

c) If the phase sequence is incorrect

- EL11, EL12 – triggered

- EL13 – does not work

3) Delay time (action) in seconds

- EL11, EL12 – 0.1 to 10

- EL13 – no more than 0.15

4) Operating temperatures:

- EL11, EL12 – -40 to +40 C

- EL13 – – 10 to +45 C

5) Storage temperature from -60 to +50

6) Device weight

- EL11,EL13 – 0.3 kg

- EL12 -0.25 kg

How to connect a relay

If frequency converters are used when connecting industrial or household equipment, then the use of a phase control relay is not at all necessary.

The frequency converter is not location sensitive and it always converts AC to DC voltage.

Direct connection is carried out according to the instructions on how to connect a relay of this particular type. Quite often, the connection diagram is shown on the device body. To do this, you should pay attention to various photos of phase control relays.

Connection to external and internal sources is carried out using wires with clamps. Either one wire with a cross-section of 2.5 mm or two wires with a cross-section of up to 1.5 mm are supplied under it. To connect, it is necessary to observe strict alternation of phases A, B and C.

Usually the relay checks the plus break, their alternation, and the network voltage level. When a fault is detected in the network, the relay comes into action. The connection diagram can be either three-wire without zero, or four-wire with zero. In apartments, this connection scheme is often used. The connected load is formed evenly on each of the 3 phases.

If the input voltage does not coincide with the norm, the relay is triggered, but in order to ensure that the current does not disappear in the entire apartment, instead of one general apartment, three different relays are made, one for each phase.

When any of the phases goes beyond the specified values, the relay responsible for this circuit is activated, and the rest of the load (provided it is within the required range) continues to operate.

Let's consider a connection diagram with zero. This circuit provides complete control over the voltage on each phase, skew and correct alternation, and it is also worth noting the fact that they are used as an industrial option. At the output of the device, using a power contact, we connect a contactor, which with one end of its winding is connected to the neutral wire, and the other end to the output of one of the phases.

Contacts 1, 2 and 3 connect the voltage removed from the voltage control relay to any three-phase load such as an electric motor, or high-power flow heaters, etc. The internal circuit of the relay measures the voltage value on each of the phases and when U is within normal values, it supplies energy to the connected contactor. This, in turn, keeps the contacts in a closed state, and the voltage reaches the external connected load.

If the voltage on any of the phases goes beyond the range we set, the relay stops powering the winding of our contactor and it, in turn, opens its contacts, de-energizing the entire connected external load.

If the external voltage source returns to the specified operating range, the relay, after some time, again supplies voltage to the contactor terminals, then it closes our circuit again. Various phase control relay circuits are given below.

Relay selection

The choice of the type of relay we need depends directly on the technical characteristics of the connected device and the relay itself. Let's consider which relay is better for us to choose using the example of connecting an ATS (automatic backup power input). First, we determine the connection option we need with or without a neutral wire.